The transmission is what the operation of the car directly depends on. Many drivers prefer to drive cars with a manual transmission. They think that they can avoid spending a lot on automatic transmission repairs. However, this is a bit of wrong thinking. The operating principle of an automatic transmission in a car makes transport easy to drive, especially in a big city. Just two pedals allow beginners to feel more confident on the road, and professionals to move quickly and without delay.

History of invention

It occurred to inventors at the beginning of the twentieth century to improve gear shifting, thereby relieving drivers of manual work with a lever. Now it is impossible to name this person, since the creation of the automatic transmission went along three lines, which ultimately merged into one.

The main gearbox mechanism is the planetary gearset. In 1908, the first such car was produced and it was called “Ford T”. In those years, it could not yet be called full-fledged, since the driver had to press two foot pedals. Despite this, the development was able to make driving easier.

In the 1930s there was another breakthrough. Clutch control was transferred from the driver to the servo. Then these boxes were called semi-automatic. But later a fully automatic gearbox was released. This happened in the same decade. The boxes were installed on French cars.

At that time, something similar was being developed in Europe. British and German cars were equipped with automatic transmissions. American engineers have moved further and equipped the box structures with hydraulic elements. They also developed a torque converter, which became a world first.

At the beginning of the twentieth century, automatic transmissions were technically complex parts, and they were not particularly durable. They were no easier to operate than mechanical gearboxes with synchronizers.

Towards the end of the 80s, manufacturers began to computerize motor control systems. A little later they were introduced into gear shift systems. This helped make shifting smooth and comfortable. In addition, different operating modes were “introduced” into the machines to help control the gearbox manually.

Thus, the development of technological progress led to the creation of Buick cars. They had a 2-speed automatic transmission. Over time, the number of steps increased. For example, a 9-band device was installed on the Range Rover Evoque crossover.

What is automatic transmission

A classic automatic transmission is a combination of two devices. You can understand what it is and what the operating principle of a car’s automatic transmission is if you first understand its design.

The device is based on 3 parts:

torque converter;

planetary gear;

control systems.

The torque converter is an important element that serves to receive torque from the power unit and transmit it to the next mechanism. This element also reduces vibration that occurs when starting to move and changing speed.

The torque converter (GTF) has blades in its design, between which there are channels for the movement of ATF fluid. The lock-up clutch blocks the GTF, and the freewheel, in turn, rotates the reactor wheel. The torque converter operates in a closed circle. First, transmission oil enters the turbine wheel, and then it moves to the reactor wheel. The flow rate increases, the liquid is transferred to the pump wheel. The revolutions increase, and as they increase, the speed of rotation of the wheels evens out. The clutch (locking) comes into operation. As the wheel speed equalizes, blocking occurs in every gear. Some automatic transmissions have a slipper clutch that prevents complete locking. The mode is needed for acceleration, to withstand heavy loads, and also to reduce fuel consumption along with smooth gear shifting.

The planetary gearset is a mechanical gearbox that allows you to change the gear ratio. This helps to change the speed of the machine and the amount of torque. The element includes planetary gearboxes arranged in series. Planetary gears consist of several parts. Blocking one or two entails the transfer of torque. For example, if the sun gear becomes stationary, this will result in a reduction in the gear ratio. It may increase if the ring gear becomes locked.

Control systems include a hydraulic unit and an electronic control unit. They create a load on the friction clutches. The design also includes an oil sump and a gear pump. The valve body, in turn, includes channels with plungers and solenoids. Sensors that collect various indicators help the ECU carry out control.

Advantages and disadvantages

Before you learn how a car’s automatic transmission works, you need to understand its advantages and disadvantages. This transmission has become so popular for a reason.

Firstly, many people like the ease of operating the box. The driver, especially a novice, does not need to worry about the clutch and think about speeds. While driving, a person can concentrate on the road. A car with automatic transmission is suitable for driving in big cities, where traffic jams are common. A person does not get so tired while driving because he does not have to constantly pull the lever.

Secondly, the automatic transmission provides a smooth ride. The car starts moving quite smoothly, without jerking, as happens “with mechanics”. For the convenience of drivers, auxiliary modes are provided (sports, winter, for driving on mud).

Thirdly, due to the operation of electronics, the units have a long service life. As for the “mechanics”, its elements often burn out due to the mistakes of beginners. They shift gears incorrectly or hold up the clutch. Not only the engine suffers from this, but also the car as a whole.

Automatic cars also have a few disadvantages. Expensive services probably do not apply to all categories of people. However, this problem does exist. For example, the cost of ATF fluid starts from 1000 rubles per liter. At the same time, the design of an automatic transmission is much more complex than a manual transmission, so if it breaks down, the driver will have to spend a lot of money on repairs.

Another drawback is the presence of restrictions during operation. What does it mean? The driver cannot quickly accelerate the car, nor can it be started “from a pusher”. Also, the car enthusiast will not be able to tow with or without a cable. This will lead to breakdown in any case, so you will have to call a tow truck. Thus, if a person accidentally gets stuck in the mud, he will not be able to get out using the “swinging” method.

In practice, the design of an automatic car transmission has a completely different form than a manual one. But with proper maintenance, it can work without repair for as long as a manual transmission.

Comparison of manual and automatic transmission

If the future driver does not know which car with which gearbox to buy, he needs to study the principle of operation of an automatic transmission and a manual one. In addition, it is worth deciding for what purpose the car is being purchased, and whether the person has any driving experience at all.

Cars with automatic transmission cost at least 50,000 rubles more than manual transmissions. This is due to the fact that you always have to pay for comfort. Each gearbox requires maintenance and oil changes. An automatic transmission will require 6-10 liters of fluid, while a manual transmission will require only 3 liters. Accordingly, automatic transmission maintenance will be more expensive.

As for acceleration and efficiency, the mechanical ones have higher parameters. With manual control you can accelerate to full speed almost immediately, which cannot be said about the automatic. If we take into account the reliability parameter, then it becomes difficult to compare both boxes. The mechanical design looks more reliable, since it lacks electronics. But the machine, in turn, completely controls the operation of the system, excluding the “human factor”.

Operating a car in winter will become more comfortable with the mechanics. The fact is that the car is ready to drive almost immediately after starting. Also, the mechanics are not afraid of ice and slipping. A large volume of fluid does not allow the automatic transmission to warm up faster than a manual transmission. When towing on ice, the engine will begin to overload, increasing wear on parts.

In terms of driving comfort, the automatic transmission wins. A beginner will be able to calmly move away, drive up a mountain and not stall on the road. Driving a manual requires care and control.

Automatic and manual interact with the engine differently. A manual transmission can spin the engine to the limit, thereby reducing its service life. The automatic machine does not allow you to do this because it controls the engine speed.

Automatic transmission in operation

Any modern automatic transmission has the following mandatory provisions on the cab selector lever:

- P – parking, or parking lock: locking the drive wheels (does not interact with the parking brake). In the same way as with a “mechanics” the car is left “at speed” when parked;

- R – reverse, reverse gear (it was always forbidden to activate it while the car was moving, and then the design included a corresponding lock);

- N – neutral, neutral transmission mode (activated during short parking or when towing);

- D – drive, forward movement (in this mode the entire gear row of the box will be used, sometimes the two highest gears will be cut off).

It may also have some additional, auxiliary or advanced modes. In particular:

- L – “lower”, activation of the low gear mode (low speed) for the purpose of moving in difficult road or off-road conditions;

- O/D – overdrive. Economy and measured movement mode (whenever possible, the automatic transmission switches upward);

- D3 (O/D OFF) - deactivation of the highest stage for active driving. It is activated by the braking of the power unit;

- S – gears spin up to maximum speed. There may be the possibility of manual control of the box.

- The automatic transmission may also have a special button that prohibits changing to a higher gear when overtaking.

Panel symbols

An automatic transmission whose operating principle is very simple, has a panel with alphabetic symbols and numbers. To control the automatic transmission, it is worth understanding them. Designations may vary depending on the make of the machine.

R - parking. Turns on when the car is parked. This is a kind of parking brake in which there is a shaft lock.

R - reverse speed. It turns on when the car starts moving backwards.

N - popularly called “neutral”. If the car is at neutral speed, then its wheels are not locked. If something happens, the car may “roll”.

D - stands for forward movement.

A - automatic mode.

M - imitation of a manual transmission in a simplified mode.

L and B - low gear.

S - sport mode.

W - “winter” mode, allowing you to start from 2nd gear.

OD - accelerated mode.

E - economical mode.

Before you learn how an automatic transmission works, as well as what certain symbols on the panel mean, you need to read the instruction manual. For different car models, the meaning of the letters may differ. For example, sometimes B means lock, and L is translated as “Lock,” which means “lock.”

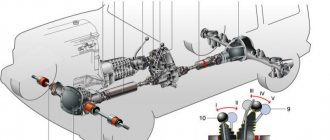

The difference between the automatic transmission of rear-wheel drive and front-wheel drive vehicles

There are a number of differences between the automatic transmission layout of front- and rear-wheel drive vehicles. The automatic transmission of front-wheel drive cars is more compact and has a separate compartment called the differential.

In all other aspects, both transmissions are identical, both structurally and functionally.

To effectively perform all functions, the automatic transmission has the following elements: a torque converter, a control unit and a mechanism for selecting the driving mode.

We hope that our article was as useful as possible for you and helped you understand the principles of automatic transmission operation.

Principle of operation

Learning how an automatic transmission works is not that difficult. The main thing is to understand the functioning of the planetary gears.

First, the driver starts the engine, and then the GTF pump wheel starts to rotate. The liquid spins the turbine wheel. Between them is a reactor wheel, which redirects the flow to speed up the rotation of the pump so that it increases torque. If the pump and turbine move in the same way, a transition to fluid coupling mode occurs.

Planetary gears are connected from the input shaft. The ring gear and sun gear take over the rotation. Their speed is adjusted along with the rotation adjustment from the carrier. When the car goes uphill, the wheel stops, which transfers more torque to the pump. As soon as the required speed is reached, a gear change occurs in the row.

When the ECU gives the command, the brake band and clutches slow down the downshift. An increase in oil flow begins through the valve. The overdrive accelerates and shifts without losing power.

When the car brakes or slows down, the fluid pressure also decreases, shifting the gear down. The GTF loses pressure after the engine is turned off. That is why it will not be possible to start a vehicle by pushing it.

Torque converter

By analogy with a manual transmission, the torque converter performs clutch functions and also regulates the gearbox, taking into account the engine speed and power output.

The design of the torque converter consists of three parts:

- Centripetal turbine;

- Centrifugal pump;

- Guide apparatus-reactor;

Due to the fact that the turbine and pump are as close to each other as possible, the working fluids are in constant motion. Thanks to this, it is possible to achieve minimal energy losses. In addition, the torque converter boasts very compact dimensions.

It is worth noting that the crankshaft is directly connected to the pump wheel, and the box shaft is directly connected to the turbine. It is due to this that the torque converter does not have a rigid connection between the driving and driven elements. Working fluids transfer energy from the engine to the transmission, which, in turn, transfers it through the pump blades to the turbine blades.

How to start it correctly

Drivers must not only know the principle of an automatic transmission, but also be able to operate it correctly. Unlike manual transmission, there are no difficulties here. The driver does not need to constantly monitor the speed limit and try to determine the moment to change speed by sound.

When you turn on the engine, the selector lever should be in “N” or “P”. The protection system signals the start in this way. If the lever is positioned differently, the ignition will not turn on. Before you start moving, you need to make sure of this. If the car is in the “P” value, then its drive wheels are blocked. This will prevent rolling. In the “N” position, emergency towing is possible. Automatic vehicles may start when the brake is applied. In this case, accidental rollback will not occur.

How to drive a car with automatic transmission

The gearbox will last a long time if the driver selects the correct modes, focusing on driving conditions. A correct start involves the beginning of movement after a push, signaling that the gear has engaged. When slipping, it is best to start in a lower gear. In this case, it is worth adjusting the rotation of the wheels using the brake pedal. In order to improve your driving skills in a car with an automatic transmission, we recommend using the services of an automatic transmission driving instructor.

When using different modes, the driver will be able to brake the engine and limit acceleration. It is not worth towing other vehicles, as this will negatively affect the operation of the engine. But if there is no other option, then the towed car should be lighter than the towed one.

There are several recommendations showing what not to do when driving a car with an automatic transmission.

The most common mistake made by drivers is turning on the “D” mode when there is no complete stop when moving backwards.

A big misconception for beginners is also the use of neutral mode. It is designed for emergency situations when you need to unlock the wheels to move the car.

Neutral mode is also prohibited from being turned on while in traffic jams. Short-term movements provoke water hammer. In traffic jams, you need to turn on the “drive” mode in combination with the brake.

Another mistake is switching from “drive” mode to “neutral” while driving. This is especially done when driving at high speed. Doing things like this is dangerous. This results in the power steering and brake booster being turned off.

Often, inexperienced drivers try to start a car “from a pusher”. It is possible to do this, but it is not necessary. The engine though. If you do this “trick” often, the machine will become unusable without even using up half of its service life.

As for operation in winter conditions, you should be more careful. For the machine to function well, it needs to warm up the box for a few minutes after starting. As soon as the driver starts driving, he should avoid acceleration and sudden movements for the first 10 km.

If the car gets stuck in the snow, you must first engage a lower gear, and then, switching the gas and brake, slowly drive out. Under no circumstances should you rock the car, as this will damage the torque converter. Low gear should also be used on wet roads, and in combination with the brake pedal on slippery downhill grades.

Types of automatic transmission

According to technicians, the hydromechanical automatic transmission is represented only by the planetary part of the unit. After all, it is responsible for changing gears and, together with the torque converter, is a single automatic device. The automatic transmission includes a classic hydraulic transformer, a robot and a variator.

Classic automatic transmission

The advantage of a classic automatic transmission is that the transmission of torque to the chassis is provided by the oil fluid in the torque converter.

This allows you to avoid clutch problems that are often detected when operating machines that have other types of gearboxes installed. If you maintain the box in a timely manner, you can use it almost forever.

Robotic gearbox

View of a robotic gearbox.

It is a kind of alternative to mechanics, only the design has a double clutch controlled electronically. The main advantage of the robot is considered to be fuel efficiency. The design has software installed, the work of which is to rationally determine the torque.

The box is called adaptive, because it is able to adapt to your driving style. Most often, the clutch breaks in a robot, because... it cannot bear heavy loads, such as when driving in difficult terrain.

Variable speed drive

The device provides smooth, stepless transmission of torque to the vehicle chassis. The CVT reduces gasoline consumption and improves dynamics, providing the engine with a gentle operating mode. Such an automated box is not durable and does not tolerate heavy loads. Inside the unit, parts constantly rub against each other, which limits the life of the variator.

Features of operation

The car will begin to move smoothly after the driver inserts the key, turns it, presses the brake, puts the selector handle in the correct position and releases the pedal.

There is no need to switch mode “D” at a traffic light. The brake pedal is being used. When parking, turn on the “P” mode.

It is possible to avoid premature breakdowns if you do not drive off-road or on uneven surfaces. It is also worth doing your best to avoid slipping. Before starting to drive a car with an automatic transmission, the driver needs to further study the documentation. Perhaps for this type of box slipping is not allowed at all. You need to know them to prevent breakdowns.

The automatic transmission structure and operating principle are folded in such a way that it is not recommended to allow severe overload. “Automatic” has sensitive mechanics, which are not designed for heavy loads. You should not put large loads in the cabin or even pull a trailer behind you.

Thus, it becomes clear that cars with automatic transmission are conquering the market. More than 80% of the European population already drive an automatic car.

What is better - manual or automatic?

As many may have already noticed, most Russian motorists prefer manual transmission. Some experts believe that this is due to the mentality of the nation, others – with established negative stereotypes.

It's a different matter for Americans, 95% of whom cannot imagine driving a car without an automatic transmission. But this is not at all surprising, because the automatic transmission was invented by American engineers who wanted to simplify the lives of drivers.

The situation is the same in Europe. If 15-20 years ago everyone used mechanics, now it has almost been squeezed out of the market.

In Russia, there is also an increase in the popularity of automatic transmissions, but, according to experts and analysts, Russians do not know how to use an automatic transmission correctly. Every day, a lot of car enthusiasts come to auto repair shops with malfunctions, the main cause of which is precisely improper operation.

Maintenance and repair

Having figured out how an automatic transmission works, you need to study the maintenance features of the machine itself. No matter how reliable and new the car may seem, you should not neglect maintenance. This will help get rid of most problems.

Checking the oil in a timely manner, as well as replacing the oil filter, is what you need to do first when visiting a service station.

The oil and filter require replacement every 50-60 thousand kilometers. Vehicles operated in difficult conditions must be “checked” every 30-40 thousand km. Do not allow the oil level to be low. The coordinated work of the CP depends on him. An insufficient amount of oil leads to slipping, which consequently provokes overheating.

When the oil level is low, a characteristic hum appears coming from the torque converter. An excessive oil level is also unacceptable. Overfilling makes the lubricant poor quality. Thus, the entire mechanism fails completely. You can check the level using a dipstick.

When pouring liquid, you need to be extremely careful. After the procedure, you should drive no more than 10 km and then check the level again. When checking, the machine must be placed on a level surface. Having measured the level, the driver will have to either drain the excess or add fluid. It is not recommended to mix oils from different manufacturers. This is guaranteed to lead to automatic transmission failure.

Do not forget that when draining the oil, the driver must change the filter. It is advisable to remove the pan and gasket along with it. The maintenance will determine if anything else needs to be changed. If the box was operated in accordance with the recommendations, then no additional “intervention” will be required.

It happens that the oil begins to darken and smell like burning. The clutches may have worn out. In this situation, additional maintenance of the box with disassembly is required.

Additional automatic transmission maintenance includes flushing and diagnostics. Washing is carried out rarely, only after the box is heavily soiled. Flushing is especially necessary when the mechanisms are completely destroyed, or at a time when the unit is already very old and functions poorly.

Among other things, automatic transmissions often experience leaks, electric motor malfunctions, and lack of sealing.

Diagnostics, in turn, is carried out using self-diagnosis or a computer. Regular procedures allow you to identify problems at an early stage. If you miss this moment, there will be a need for expensive repairs. Proper maintenance will increase the life of the gearbox.