The brake system is the most important component of a car and is responsible for safety. Even minor brake malfunctions can lead to serious consequences for both the driver and other road users. To prevent malfunctions of the braking system, you need to regularly check the condition of all its elements (pads, discs, lines and, importantly, brake fluid). An important part of maintenance is bleeding the brake system. More details about the features of pumping brakes on VAZ cars will be discussed in this article.

Tools

Before bleeding the brakes on a VAZ-2110, you need to prepare a small set of tools. For this we need:

- Empty container for old brake fluid. A plastic bottle is often used as it. It is desirable that its walls are transparent. A regular 1.5-liter mineral water container will do.

- Rubber hose. It should also be transparent.

- Jack and wheel wrench.

- New brake fluid.

- Special gas stop. The presence of this tool is not necessary if you can call an assistant. We will tell you how to bleed the brakes on a VAZ-2110 alone in one of the sections.

Functions and purpose of the brake force regulator

“Sorcerer” is used to automatically change the brake fluid pressure in the rear brake cylinders of a car depending on the load acting on the car at the moment of braking. The rear brake pressure regulator is used in both hydraulic and pneumatic brake actuators. The main purpose of changing the pressure is to prevent wheel locking and, as a result, skidding and skidding of the rear axle.

In some cars, in order to maintain their controllability and stability, in addition to the rear wheel drive, a regulator is also installed in the front wheel drive.

The regulator is also used to increase the braking efficiency of an empty vehicle. The adhesion force to the road surface of a car with and without a load will be different, so it is necessary to adjust the braking forces of the wheels of different axles. In the case of a loaded and unladen passenger car, static regulators are used. And in trucks, an automatic brake force regulator is used.

In sports cars, another type of “sorcerer” is used - a screw regulator. It is installed inside the car and adjusts the brake balance directly during the race itself. The setting depends on weather conditions, road surface conditions, tire conditions, etc.

How to do it?

To make the procedure easier, it is recommended to drive the car onto a lift. But since in most cases this is not possible, we unscrew the wheels in order. This will give us convenient access to the fittings. The latter must be cleaned of adhering dirt. Its presence in the system is extremely undesirable. Before bleeding the brakes on a VAZ-2110, you need to top up the fluid level in the plastic tank. It is located near the brake cylinder.

Diagnostics of the pressure regulator

How to check if the VAZ brake pressure regulator is working? This procedure is quite simple:

Place the car above the inspection hole (lift it on a special lift).

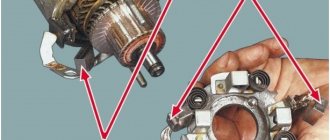

Thoroughly clean the regulator body and protective cover, as well as the junction of the torsion arm and the piston, from dirt and old grease.

After pressing the brake pedal, the movement of the piston (with simultaneous tightening of the torsion lever) of a working regulator should be 0.5-0.9 millimeters.

Repeat the described procedure several times. This will allow you to verify the stable functioning of the pressure regulator.

The immobility of the piston after pressing the brake pedal suggests the presence of corrosion processes in the area of contact between the housing and the piston, which indicates the need to replace the regulator with a new one. Upon completion of the performance check, a layer of lubricant (“DT-1”) is applied to the working elements of the regulator and a protective cover is installed.

How to bleed brakes on a VAZ-2110 without an assistant

There are situations when it is not possible to call a second person. How to bleed the brakes on a VAZ-2110 in this case? For this we need a gas stop. It is this part that will press on the brake, creating pressure in the system. After pressing the pedal several times, place the tool under it and unscrew the fitting to bleed the fluid. The emphasis will press on the trigger, thereby creating the necessary pressure.

see also

- How to correctly install the rocker on a VAZ 2109

- VAZ 2107 correct lowering

- Repair of VAZ 2101 distributor

- VAZ 2107 silent block

- How to install trunk lock from viburnum to vaz 2109

- How to raise the rear suspension of a VAZ 2107

- VAZ 2107 adsorber purge valve

- VAZ 2107 how to make the headlights shine brightly

- How to make the trunk on a VAZ 2107 open with a button

- Expansion tank plug VAZ 2109

- Why does the clutch on a VAZ 2107 move?

How to bleed the brakes on a VAZ-2110 if the fitting is broken?

This element often breaks down on cars of the “tenth” family. In itself it is reliable, but marriage should not be ruled out. The solution to the problem is to replace the fitting with a new one. Some people buy a complete caliper for this. But this is very expensive. A cheaper solution is to replace a separate fitting on the caliper. The problem is how to unscrew it. This is done using a minus screwdriver. It is driven into the fitting with a hammer and unscrewed.

When to bleed the brakes

With working brakes, all channels for brake fluid are completely sealed, and possible leakage occurs only if they are damaged. If a brake fluid leak occurs, it will need to be drained, the overpasses repaired, and then filled with air removed from the system by bleeding. There should be no air in the brake system a priori, since its presence there can lead to a tragic outcome when an emergency occurs on the road and the brake pedal sinks instead of activating the brake pads.

Drivers usually feel the occurrence of play in the corresponding pedal, when pressed, the brakes do not immediately respond properly. This behavior of this vehicle control is simply called “cotton brakes” in garage parlance. And the reason for this condition can be various situations:

- interference with equipment operation;

- low quality brake fluid;

- damage to system hoses;

- replacing disks without proper bleeding;

- water content in brake fluid.

When bleeding the brakes, you need to add the same brake fluid that was used previously. If this is not possible, then all the liquid is drained and a new one of a different brand is poured into the system.

In this case, it is necessary to anticipate the occurrence of such problems and stock up on a certain amount of the exact product that was used previously.

This can't be done

There is one very important point regarding brake fluid. You should pay special attention to it, since it will be difficult to predict the result if the recommendations are violated.

Do not mix different types of brake fluid. If you simply need to add it to an existing one, choose only the one that was filled in earlier. Mixing fuel fluids from different manufacturers can lead to unpredictable consequences.

If you need to top up, but you don’t know what kind of fuel fluid is currently there, there is only one way out - a complete replacement of the brake fluid.

Bleeding the brake system with an assistant

Before starting work, you need to make sure that all pipelines and connections are tight. It is better to carry out the work with an assistant, since not all actions can be done efficiently on your own.

The brake system is bled in the following order:

- right rear (wheel);

- left front;

- left rear;

- right front.

The sequence of work is as follows:

- before starting work, you need to make sure that the brake fluid level in the system is maximum;

- cleaning the brake system air outlet valve;

- removing the protective cap from the valve, for which a hose is put on the latter, the other part of which is lowered into a clean and transparent container. Some part of this vessel is filled with brake fluid, where the end of the hose is placed;

- then the assistant presses the brake several times (for example, five) with sharp movements with a pause of a couple of seconds and then fixes the mechanism in the recessed position;

- When you press the brake pedal, you need to unscrew the valve responsible for the air escaping part of a turn (half or three-quarters). When performing this operation, air bubbles will come out of the tube, which is located in a vessel with liquid;

- when the solution stops flowing out of the tube, the valve closes and the assistant releases the pedal;

- Such actions are continued until the air disappears in the drained substance. In this case, you need to add fluid to the brake system, making sure that its level does not drop below the regulated minimum;

- Once pumping is complete, the hose is removed, and the air release valve fitting is wiped dry, after which a cap is put on it.

When carrying out this work, there is no need for special tools, since the appropriate spanner and containers for draining will be quite sufficient. All these manipulations can be carried out in the same sequence not only for this model, but also for other cars and the VAZ family, as well as for cars with an automatic wheel locking system. Experts also advise carrying out all pumping operations in a “pit” or a lift, with proper comfort and lighting.

"CHEVROLE-NIVA"

By the way, before testing tires on cars without ABS, each time we slightly adjust the regulator taking into account the road condition (snow, ice, asphalt), ensuring that the rear wheels lock a little later than the front ones. Let's not break tradition. Our Shniva found the gap between the cheeks of the regulator to be 16 mm, which was adjusted using a stop screw.

Several brakings, and the braking distance from 80 km/h for a car with a partial load is determined: 34.4 m. With a full load... 33.6! Almost a meter shorter! At the same time, the driver noted a heavier pedal and rapid heating of the brakes, which required cooling before each measurement. Let’s remember these parameters and make adjustments to the “sorcerer” adjustment. First, let's reduce the gap to 8 mm. Now the regulator significantly limits the pressure in the rear brakes, transferring almost all the hard work to the front ones.

We work independently

It is possible to carry out all the steps to rid the VAZ-2110 brake system of air yourself. This fairly simple method also allows you to complete all the assigned tasks alone:

- the brake fluid reservoir cap is replaced with an old clutch reservoir cap with a hole pre-drilled in it into which a car nipple is inserted;

- the compressor sets the pressure to 1.5-2 atmospheres and supplies it to the installed nipple on the tank lid;

- the second hose is put on the fitting through which the brakes are pumped, and its other end is lowered into a container (for example, a bottle);

- When air stops coming out of the hose, the fitting can be closed.

This operation is repeated on all wheels of the car. It is worth noting that in camping conditions the compressor can be replaced even with a regular bicycle pump, which will be somewhat more difficult than working with a compressor, but with due diligence it is also effective.