Replacing the engine oil pump with your own hands Instructions + Video

The oil pump is the main part of the engine system, affecting the circulation of lubricant throughout all mechanisms. It is he who creates the necessary pressure, working from the crankshaft. Over time, the device wears out, forcing the owner to replace it. Find out how to do it yourself.

Repair or replacement of the VAZ 2106 oil pump

VAZ 2106 cars, like any other cars, have many units that create a sufficient level of pressure for various fluids that the vehicle requires for normal functioning. One of the most important such units is the oil pump, which sooner or later fails.

You can tell that it is faulty by the low pressure light, which is located on the dashboard. In this case, the vehicle engine should be warmed up to 80 degrees Celsius, and its speed should be at least 800 per minute.

There are many reasons why an oil unit can fail. But with each of them there is only one way out - dismantling, diagnostics, repair or replacement. Video. How to remove and disassemble the oil pump

Let us recall that in the previous article we looked at why the VAZ 21099 starter does not turn and how to repair it with your own hands.

Replacing the oil pump VAZ 2106

Changing the oil unit is the easiest and fastest way to troubleshoot problems with oil pressure levels. To carry out this manipulation you will need two socket heads for ten and thirteen, an extension cord equipped with a cardan and a car pit (a car lift or car overpass is also suitable).

You need to start by unscrewing the four mounting bolts that secure the engine crankcase protection. Next, drain all the lubricant present in the car engine and remove the crankcase, which is responsible for the movement of oil in the system, along with its gasket. All that remains is to unscrew the two bolts securing the oil pump to the engine and completely dismantle it.

A very important point is to mark the oil pump bolts, as they have different lengths. Also, carefully inspect the oil unit gasket; if it is leaky, replace it. Installation of the new oil unit is carried out in the reverse order.

Repair of oil pump VAZ 2106

If you like to tinker with your car and want to save a little money, then instead of changing the oil unit, you can carry out restoration work on it. This is not a very complicated procedure, which will require a very primitive set of tools: all options for ten keys, a vice, a ruler, several flat probes.

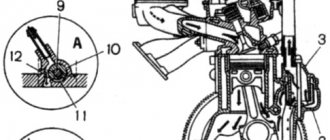

When you have prepared everything you need, you can begin to carry out the work. First, remove the inlet pipe from the unit body. To do this, you should clamp this element in a vice and unscrew the three bolts. Mark all bolts, as they have different lengths. Now do the following sequentially: remove the pipe, remove the reduction valve washer, remove the valve itself.

Next, you can move directly to the oil pump. Start by removing its cover and dismantling the drive and driven gears, then rinse them in kerosene and dry them thoroughly. After this, inspect the gears for mechanical damage and measure the distance between the driven gear and the axle; it should not be more than 0.1 millimeters. Also, you should measure the gap between the gear teeth and the distance from the housing to the outer diameter of both elements. These distances should not exceed a quarter of a millimeter. If everything is in order with the gaps, you can continue the repair work, but if not, then there is nothing left but to replace the oil pump.

Then make sure that none of the oil pump system components are mechanically damaged. After this, check that the degree of compression of the spring is correct; under normal load, its height should be 2 centimeters, and in a free position - 3.8 centimeters.

Now you should replace all damaged elements with new ones, and rinse those that remain in kerosene and dry them. After this, all you have to do is assemble the oil unit and install it on the vehicle engine.

Automatic transmission diagnostics

Repairing automatic transmissions just like that, at random, is impossible. For its high-quality organization, it will be necessary to diagnose the unit. Even if the automatic transmission fails again after repair, it would be irrational to blame the previously broken unit again, because there are more than a hundred elements in the design of the automatic transmission. Each of them may well break down at the most inopportune moment.

Determining what exactly has gone wrong in the box takes place in several inseparable stages:

The first stage is an analysis of the operation of the unit both “cold” and “hot”

If, when starting the car, the automatic transmission does not change gears or works incorrectly in some other way, and when warming up all the problems disappear, you should pay attention to the valve body and the level and quality of the oil poured into the box. This type of work often indicates problems in the lubrication system of the machine.

In a situation where noise in the automatic transmission or its jerking, kicking is repeated in all modes of engine operation and throughout the entire operating time of the unit, with a high degree of probability we can say that not only problems in the oil supply may be to blame; The second stage is checking the box through the control panel and on-board computer. Here, perhaps, everything is extremely simple. It's no secret that most modern cars are fully electronic, so breakdowns of certain components are diagnosed independently using special sensors. Automatic transmission maintenance is no exception, so the occurrence of transmission breakdowns is also displayed in electronic devices. Often information from this is very useful when organizing machine repairs; The third stage is complete or partial disassembly of the box. Unfortunately, this cannot be avoided, especially if the signs of an automatic transmission malfunction are quite severe and cannot be eliminated by simply changing the oil or flushing the transmission. If your particular machine has a removable tray, then first you should remove it and evaluate the visible components. Are there any problems? Then you will have to remove the box completely, disassemble it and, analyzing the signs of a malfunction of the automatic transmission, look for the broken element.

In general, there are no particular difficulties in answering the question of how to check an automatic transmission. Diagnostics of the box is carried out by organizing the steps noted above. Of course, some steps are not so easy to implement, but you cannot do without them, so you should be prepared for difficulties. If you are not ready to check the machine yourself, then it is better not to experiment and entrust this work to professionals. This approach will not only simplify the repair of the unit, but will also speed up its progress several times.

How to Change the Oil Pump on a VAZ 2106

Replacing the oil pump on a VAZ 2101-VAZ 2107

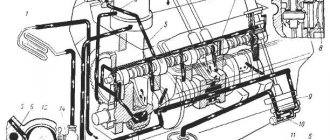

Welcome! Oil pump. Usually called the "oil pump", it performs a very important function when the engine is running, namely, it supplies oil located in the oil pan, the crankshaft bearings and then through the air duct, distribution oil and the camshaft bearings, in most cases lubricating them.

Therefore, the oil pump plays a very large and important role in a car engine, and if it is damaged, then the lubrication system should not have the pressure it should have. (For more information about what will happen if the pressure in the lubrication system disappears, see the article “Useful information about oil pressure on a VAZ”).

The note! To replace the oil pump with a new one, you will need to stock up on: a basic set of wrenches, which will include a "10" and "13" wrench, and you will need to take the end sockets and extension cord to match the same heads, if possible, and pack your pockets with you!

Where is the oil pump located? It is located inside the engine so just by looking at the engine you won't see it, but to look at it you will first need to remove the crankcase, then you will need to remove the pan and only then will you see the oil pump with your own eyes.

READ How to Check Hall Sensor Audi 100 C4

When should I replace my oil pump? It can be replaced with:

1. Pressure drop in the vehicle's lubrication system at engine idle temperature, as shown by the oil pressure indicator.

2. As well as failure of the pump itself or its transmission, which, by the way, can be replaced individually without completely replacing the oil pump, see Article: “Oil pump repair.”

The note!

Sorry for the quality of lighting, this video shows the method of replacing the oil pump of you 2106

No.

Diagnostics and replacement of VAZ classic oil pump (LADA 2101-07)

Oil pump

the main part of any engine. And how much the engine depends on its condition. If you notice a drop in oil pressure after a hard blow to a bump that causes the crankcase to deform, it is likely that the oil pump, namely its intake pipe, is to blame for the drop in oil pressure! 3. And if your car's oil pressure is too high and outside the normal range, then most likely the culprit is a clogged relief valve, which can also be removed and replaced with a new one. (See How to remove this in the same pump repair article)

READ Knocking In Steering Rack Mazda 6

The note! What pressure in the lubrication system can you determine using a special indicator that shows the oil pressure in the system!

How to replace the oil pump with the same oil pump on a VAZ 2101-VAZ 2107?

The note! This job is time consuming, but it is still possible if you have the special tools, and this work should be done in a ditch or on elevators, otherwise the oil pump will need to be replaced!

Conclusion: 1) First remove any parts that prevent access to the pump, so first remove the crankcase from the car and then slide it to remove the pan. (For information on how to remove the deflector and oil pan, see the article “Replacing the oil tank on a VAZ”)

2) Next, remove the two screws that secure the oil pump to the car engine.

The note! Be sure to check which bolt you are going to remove as the two bolts are different lengths (one is shorter and the other is longer) so follow and then after installing the new pump, turn the same bolts in the correct places they were previously installed!

READ Replacing Oil Filter Nissan X Trail

3) Once the bolts are turned upside down, remove the pump and pay attention to it, as there should be a gasket on it, which also needs to be removed, and if it becomes deformed, replace it with a new one. The note! If you are going to install a new pump on a car, this gasket is replaced with a new one, because over time the old gasket shrinks and takes shape, and when you buy a new pump, it usually has a slightly different shape and can therefore oil leak through this place, the gasket does not fits its shape!

The note! If you are going to install a new pump on a car, this gasket is replaced with a new one, because over time the old gasket shrinks and takes shape, and when you buy a new pump, it usually has a slightly different shape and can therefore oil leak through this place, the gasket does not fits its shape!

Assembly: The new oil pump is installed on the vehicle in the reverse order before removal.

Required tools + consumables

Here are the tools and equipment you will need:

- containers for draining used car fluid and antifreeze;

- set of wrenches and sockets;

- jack, winch;

- cardan, ratchet, extension;

- compressor or can of compressed air;

- wooden hammer;

- fine abrasive paper;

- special lapping paste and lubricant for bolts;

- fresh oil, antifreeze;

- new oil pump, filter, gaskets.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

What engines was equipped with the VAZ 2103

The VAZ 2103 power plant is a classic model, part of the engine line. This is a modernized version of the FIAT-124 unit, developed by domestic engineers back in the second half of the last century. The changes affected the camshaft and the inter-cylinder distance.

The tuning of the FIAT-124 engine was carried out with high quality, because in the future its mass production did not stop for decades. Of course, restylings were carried out, but the main root of the engine remained the same. The peculiarity of the VAZ 2103 engine is that its timing shaft is driven by a chain rather than a belt.

I would like to draw your attention to the fact that the VAZ-2103 engine is a truly high-quality product, made of very durable materials, however, due to age, some components of old engines can fail, they need to be replaced, and not driven into a frenzy. All the FIAT-124 engines that became the basis of the VAZ have long since rotted, while the VAZ-2103 still carries its owners. FIAT 124

Yes, it reminds me of something

FIAT 124. Yes, it reminds me of something

The 1.5-liter power unit represents the third of four generations of the classic. This is the heir to the 1.2 liter VAZ 2101 and 1.3 liter VAZ 21011 engines. It preceded the creation of the powerful 1.6 liter VAZ 2106 unit and more modern injection engines for front-wheel drive cars. All modifications of the VAZ 2103 engine were distinguished by improved technical capabilities. The VAZ 2103 became virtually the golden mean of all engines, the ideal creation of a classic of the genre.

This is interesting! Very often, while admiring the engines of the VAZ series, you can hear (especially from young and inexperienced mechanics) that the Zhiguli is not a classic, and if it is a classic, it is not at all legendary. They are starting to cite the example of the great Ford Mustang, Chevrolet Camara, etc. However, gentlemen, let’s find at least one part for these cars in the original. They cost a lot of money and are very difficult to get. At the same time, VAZ has everything. Modern factories and shops will allow you to assemble a completely new VAZ in your garage for little money.

VAZ 2103 appeared in 1972 and became the first four-eyed Zhiguli model. Maybe this was the reason for equipping the car with a new and powerful unit that develops 71 hp. With. It was rightly called the most “survivable” engine of its time - even a mileage of 250 thousand km did not have a detrimental effect on it if the driver adhered to the factory rules of operation and maintenance. The usual service life of this engine was 125 thousand kilometers. Again, the main reason for such low mileage was the quality of gasoline. Gasoline of that time was not so pure, contained a lot of oil and had a detrimental effect on pistons and rings.

The improved performance of the VAZ 2103 power unit is immediately noticeable in the design features. The engine is equipped with a different cylinder block - as much as 215.9 mm instead of 207.1 mm. This made it possible to increase the working volume to 1.5 liters and install a crankshaft with an increased piston stroke.

The camshaft is driven by a chain without a tensioner. It is not provided, and therefore the tension has to be checked and adjusted regularly.

Let's take a look at the features of this machine.

- Valve clearances are subject to periodic adjustment, since the timing belt is not equipped with hydraulic compensators.

- The cylinder block is cast iron, the head is cast from an aluminum alloy.

- The camshaft is made of steel and has the peculiarity of 1 untreated journal with six edges.

- It is paired with either a carburetor with a VROZ (vacuum ignition regulator) or an injection system, but with a corresponding timing belt - the design of the cylinder head has been changed.

- The lubrication pump is located in the engine crankcase.

The technical capabilities of the engine are as follows:

- the cylinder diameter was returned to 76 mm;

- The piston stroke was increased by 14 mm;

- Engine volume in cubic centimeters became equal to 1452 cubic meters. cm;

- two valves work with each cylinder;

- the engine is powered by gasoline with an octane rating of AI-92 and higher;

- The oil used is within the range of 5W-30/15W-40, its consumption is 700g/1000 km.

It is interesting that the subsequent VAZ 2106 engine received cylinders with a diameter increased to 79 mm.

Instructions for replacing the oil pump VAZ 2107

The VAZ 2107 oil pump is designed to create pressure in the lubrication channels of an internal combustion engine. Thanks to it, oil flows to all moving parts of the engine: crankshaft, camshaft and other parts.

If the pump malfunctions, the lubrication of the sliding bearings and internal combustion engine parts will stop and they will quickly fail. Therefore, if there are any signs of malfunction, the oil pump should be replaced or repaired immediately.

Where is the oil pump VAZ 2107

The “seven” oil pump is located inside the engine and it is impossible to check it without removing the oil pan. To get to the pump, it is necessary to remove the crankcase protection and pan. To do this, you will have to put the car on a pit or lift it with a car lift.

How does an oil pump work?

The sevens are equipped with a gear oil pump with external gearing. The VAZ 2107 oil pump is driven by a chain drive from the crankshaft. The same chain rotates the camshaft while the engine is running. The pump housing contains two gears, to which oil flows from the crankcase through the oil intake channel.

As the gears rotate, they capture oil and pump it into the lubrication system. Pump performance depends on temperature (oil viscosity) and engine speed.

To prevent excessive pressure in the system, a pressure relief valve is installed, which opens when the pressure rises and releases some of the oil back into the crankcase.

Causes and symptoms of oil pump malfunction

If any problems arise in the operation of the oil pump, the pressure in the lubrication system drops. At the same time, the warning light on the dashboard starts to light up. This usually starts with the light coming on at idle.

Gradually, the malfunction worsens and the pressure does not exceed the minimum even when the speed increases. Accordingly, the warning lamp may light up while driving. In this case, you must immediately stop using the vehicle until the problem is resolved.

The VAZ 2107 oil pump (injector and carburetor) may not work well for the following reasons:

- clogged pressure relief valve or oil receiver;

- wear or damage to pump gears;

- drive failure.

These reasons can cause either a decrease in oil pressure or a complete lack of engine lubrication. Therefore, it is necessary to find out the cause of the malfunction and eliminate it.

Important: the warning lamp may also light up if the pressure sensor is faulty. Therefore, before disassembling the engine and checking the condition of the oil pump, it is necessary to measure the pressure in the lubrication system using a pressure gauge

What is needed to replace the oil pump of a VAZ 2107

To replace the oil pump you will need:

- set of socket wrenches;

- knife;

- jack;

- winch or strong wooden block;

- wooden spacer;

- container for draining oil;

- new oil pump gasket;

- new pan gasket;

- new oil pump.

How to change the oil pump of a VAZ 2107

If the problem is not a clogged pressure relief valve or oil intake screen, the pump must be repaired or replaced with a new one. Replacing the VAZ 2107 oil pump is performed as follows:

- install the machine on the inspection hole;

- clean the lower part of the engine, sump and crankcase protection from dirt;

- unscrew the bolts securing the crankcase protection (mud guard) and dismantle the part;

- place an oil container under the oil drain plug;

- unscrew the plug and drain the oil;

- unscrew the nuts holding the lower fastenings of the front engine mounts;

- placing the spacer, lift the engine using a jack;

- remove the studs from the crossmember supports;

- hang the engine on a winch or on a wooden block placed on the front wings of the “seven”;

- Using a 10mm socket wrench, unscrew the pallet mounting bolts (19 pieces);

- remove the pan and gasket;

- Use a knife to clean the pan and the adjacent surface of the engine from any gasket or sealant residues;

- Using a 13mm wrench, unscrew a pair of bolts securing the oil pump;

- remove the oil pump along with the gasket;

- install a new oil pump along with a new sealing gasket;

- tighten the oil pump mounting bolts;

- install the pan cover along with a new gasket;

- evenly tighten the 19 bolts holding the pan cover;

- lower the engine and install the engine mounts in place;

- tighten the support nuts;

- install the crankcase protection and tighten the fastening bolts;

- add new oil.

This completes the replacement of the VAZ 2107 oil pump. All that remains is to start the engine and check the operating oil pressure in the system.

Rotary type device

- suction cavity

- oil

- outer rotor

- discharge cavity

- drive shaft

- internal rotor

The design of a rotary type oil pump consists of a driving (internal) and driven (external) rotors placed in a housing.

In a non-variable rotary pump, the oil drawn in by the pump is forced into the system by being carried through the rotor blades. If the pressure is exceeded, the pressure relief valve is also automatically activated.

Unlike an unregulated pump, an adjustable rotor type pump has a movable stator equipped with an adjusting spring to ensure constant pressure, regardless of the crankshaft speed. This movable stator controls the constant pressure by changing the volume of the cavity between the inner and outer rotors, turning the stator in the desired direction.

The advantages of an adjustable oil pump over a non-adjustable type are:

Oil pump on VAZ cars, operating principle and main malfunctions

The device that supplies oil to all components and assemblies of the engine is called an oil pump.

The life of the internal combustion engine as a whole depends on the correct operation of the oil pump, so it is very important to ensure that the operation of this unit is at the proper level. At the slightest sign of a malfunction in the oil pump, it is necessary to repair it, since if you do not pay attention to this problem, there is a high risk of engine seizure. The VAZ oil pump has two types of device: one type is typical for all front-wheel drive cars (the VAZ 2109, 2110, 2112 oil pump has an almost identical design), and the other type is typical for both classics and the Niva model

If we talk about the principle of operation of the oil pump, then on front-wheel drive cars it is driven directly from the crankshaft, but on classics the system is more complicated. For example, the VAZ 2106 oil pump is driven using a chain drive

The VAZ oil pump has two types of device: one type is typical for all front-wheel drive cars (the oil pump VAZ 2109, 2110, 2112 have an almost identical design), and the other type, typical for both classics and the Niva model. If we talk about the principle of operation of the oil pump, then on front-wheel drive cars it is driven directly from the crankshaft, but on classics the system is more complicated. For example, the VAZ 2106 oil pump is driven using a chain drive.

Having understood the differences, let's talk about the technical part.

The device of the oil pump on VAZ cars

So, the oil pump consists of a housing, an oil receiver, a drive and driven gear, an oil pump pressure reducing valve and other small elements, such as an oil pump gasket, oil seal, etc.

Consequently, given the design of the oil pump on domestic cars, the weak points are the oil seal and the oil receiver. As a result of using low-quality oil, the receiver grid quickly becomes clogged and the oil pressure in the engine system drops. The oil pump itself has a service life of 120–150 thousand km, but sometimes certain problems occur that may require repair or replacement of the oil pump. Of course, replacing the oil pump on a VAZ 2109, or on any other model, is a complex and costly procedure, so it is better to carefully monitor its correct operation and, if necessary, arrange for preventive maintenance in the form of more frequent oil changes.

In addition, periodic checks of the oil pump will not be superfluous.

How to check the oil pump?

The first and main sign of a malfunction in the oil pump will be a warning light that comes on, but it already indicates the presence of a serious malfunction. In order to check the correct operation of the oil pump, it is not at all necessary to remove it, as some experts advise. It is enough just to measure the engine oil pressure and compare it with the indicators that are considered normal for your car. Having received the number, you can already know what to do next - use the car with peace of mind, or prepare for repairs.

When replacing or repairing the oil pump of a VAZ 2109, 2110, and even 2106, be sure to use only original spare parts. The problem is that for domestic cars there is a large selection of parts from various manufacturers, and, as a rule, the bulk of these parts are of very low quality.

- Repairing a muffler with your own hands If the “X” day has come in your life, when the car stopped purring like a kitten and roared like a hungry bear, do not rush to look for options for an old, burnt-out muffler, because it is quite possible that you can improve the situation with the help of repairs that , besides, you can also make your own...

- Adjusting headlights with your own hands It is believed that adjusting car headlights can only be done at a specialized service center that has the necessary equipment, stands, etc. Of course, this is preferable, but no one ruled out the possibility of adjusting the headlights with their own hands, because most of us do just that...

- Flushing diesel injectors One of the most common problems with a diesel engine is a malfunction of the fuel injectors. The design features of a diesel engine, low-quality fuel - all this eventually leads to problems associated with injectors. The engine begins to operate unstably, fuel consumption increases, the engine starts reluctantly, and puffs of black smoke come out of the exhaust pipe. All …

A few words about the service life of the automatic machine of modern passenger cars

Automatic transmissions released in recent years have become noticeably more reliable than their predecessors. Despite this, the complexity of the design of such a transmission requires its owners to properly operate and maintain it. Often, violations in the organization of these particular events provoke typical unit breakdowns, in which the automatic transmission hums or begins to “kick” or “push.”

To prevent a kicking transmission from causing inconvenience to the owner, first of all, he must study in detail the rules of operation and maintenance of the machine. With the proper approach in these procedures, automatic transmission malfunctions will bypass any motorist, and its unit will cover its entire operational mileage without any problems. By the way, the service life of many automatic transmissions of modern cars is designed for the service life of the engines with which they are equipped. That is, the service life of an average automatic machine is 300,000-600,000 kilometers. Quite a lot, right?

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

Causes of oil pump failure

The reason why the oil pump has failed can be determined by diagnostics. There are at least 8 main oil pump faults. These include:

- Clogged oil pickup strainer. It is located at the inlet of the pump, and its function is to coarsely filter the engine oil. Like the system’s oil filter, it gradually becomes clogged with small debris and slag (often such slag is formed as a result of flushing the engine with various means).

- Malfunction of the oil pump pressure reducing valve. Usually the piston and spring included in its design fail.

- Wear of the inner surface of the pump housing, the so-called “mirror”. Occurs for natural reasons during engine operation.

- Wear of the working surfaces (blades, splines, axles) of the oil pump gears. It happens both over time of long operation and due to rare changes of (very thick) oil.

- Using dirty or unsuitable engine oil. The presence of debris in the oil can be for various reasons - careless installation of a pump or filter, use of low-quality lubricating fluid.

- Careless pump assembly. In particular, various debris was allowed to get into the oil or the pump was not assembled correctly.

- Drop in oil level in the engine crankcase. Under such conditions, the pump operates at excessive capacity, which causes it to overheat and may fail prematurely.

- Dirty oil filter. When the filter is very clogged, the pump has to make significant efforts to pump the oil. This leads to its wear and partial or complete failure.

Regardless of the reason that caused the partial failure of the oil pump, it is necessary to carry out a detailed check of it and, if necessary, make repairs or complete replacement.

Why us?

Tiptronic car service is an experienced team of craftsmen with all the necessary equipment and tools. Reviews from satisfied customers and an impeccable reputation in the automotive service market speak for us. We will repair the automatic transmission pump or install a new one. Our specialists will cope with tasks of any level of complexity. Our advantages include free diagnostics when ordering repair work, the best price in the capital, a large selection of consumables and spare parts, and an individual approach to customer needs.

Contact us to agree on all the details of cooperation.

Oil pump drive

The oil pump drive is a part that needs to be discussed separately. The fact is that the duration of operation of the entire motor depends on it. The drive part of the oil pump itself consists of several parts:

- parasitic shaft;

- intermediate gear;

- small shaft;

- big shaft

The drive is considered a simple part of the pump, but the gear splines quickly wear out during operation.

Most cases of oil pump failure are associated with a breakdown of the drive, or more precisely, with wear of the gear splines. Most often, the splines “lick off” when starting the car in winter; in this case, the engine cannot be started again.

Gear wear is an irreversible process during long-term operation of the machine. If the gear teeth begin to slip, the pressure in the oil system will be below operating pressure. Accordingly, the engine will not receive the amount of lubricant that it needs for normal operation.

How to replace the pump drive

Replacing the drive gear is not an easy procedure, but after careful preparation, you can remove the drive and repair it:

- Remove the car's ignition distributor.

- To remove the intermediate gear, you will need a special puller. However, you can get by with a simple wooden stick with a diameter of about 9–10 mm. The stick needs to be hammered into the gear and then rotated clockwise. The gear will then easily come out.

- Install a new one in place of the worn gear using a regular stick.

- Replace the ignition distributor.

Video: replacing the oil pump drive mechanism

What is a “hog” and where is it located?

The VAZ 2106 mechanisms include a shaft, which is called the “hog” (or “pig”). The shaft itself drives the car's oil pump, as well as the gasoline pump and sensors. Therefore, if the “hog” suddenly fails, then the machine ceases to function normally.

The intermediate shaft is located in the engine compartment of the VAZ 2106 on the front side of the cylinder block. On the “six” the “hog” is started using a chain drive. This shaft has an extremely simple structure - only two necks. However, if the bushings on the journals are heavily worn, the operation of the oil pump and other mechanisms will be difficult. Therefore, when checking the pump, they usually look at the operation of the “hog”.

The shaft, called the “hog”, is mounted in front of the cylinder head

You can work with the oil pump on the VAZ 2106 yourself in the garage. The main feature of domestic “sixes” is precisely their unpretentious maintenance and simplicity of design. You can repair the oil pump and adjust the pressure in the system yourself, since there are no special requirements for this procedure.

Location

The oil pump in an automatic transmission is located inside the gearbox, so if problems arise with this element, it is necessary to dismantle the protective metal casing from the automatic transmission. In most cases, repair work does not require removing the transmission from the vehicle. However, in this case, you must take into account the design features of each specific vehicle and specific modifications of the automatic transmission. Only an experienced technician will be able to quickly determine the location of the oil pump and carry out all the necessary repair work as quickly as possible.

In order to understand the location of the oil pump, familiarize yourself with the automatic transmission structure as a whole.

The design and principle of operation of the oil pump - Video