In order for the brake system to always be normal, it is necessary to constantly monitor its components. Since brake pads work exclusively on friction, they wear out faster than other parts. It is impossible to say exactly when wear will occur; their conventional operational life is from 8 to 15 thousand kilometers during normal driving without “recklessness”. Checking the brake pads gives you an idea of when to replace them.

Brake system

Each vehicle is equipped with:

- braking mechanism;

- parking brake;

- spare brake . Used in emergency cases, when the main brakes fail. In passenger cars, this is usually achieved by dividing the brake system into several circuits diagonally or front/rear.

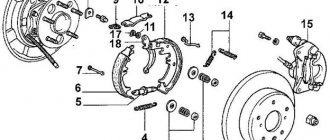

The brake system consists of a drive and a braking mechanism with a drum or disc, as well as brake pads. Drum brakes are now used less frequently, although they last longer. Today, almost all cars have a disc brake; such a system is considered fixed and has a caliper and two pads that are stable in one position. When the brake pedal is pressed, they compress the disc. There are also systems with a floating block; they are more complex. During braking, the caliper piston touches one of them, it moves away, leans against the disc and moves it towards the other, after which clamping occurs.

The main reasons affecting the wear rate

A brake pad has two components: a frame and a friction lining. In short, it is the pad that performs the main task of braking, stopping the brake disc with its friction. Front brake pads wear out two to three times faster than the rear ones. This is because a large load during braking falls on the front wheel mechanism, and the weight of the car is redistributed to the front axle. The wear rate is directly affected by:

- the material from which the parts are made. Each manufacturer sets its own thickness for the product, so you don’t need to look at the price and purchase original linings;

- weight vehicle;

Pads - sudden changes in air temperature;

- driving conditions . Sharp accelerations and emergency braking certainly shorten the life of products;

- brake assembly design . If there is a failure in the cylinders, this will also affect the pads.

It is noteworthy that in the winter season, replacement is performed less frequently, which suggests that in winter there are few maneuvers while driving.

Diagnosis of the cause by wear

Most often, the pads wear out differently on all wheels in a car. Moreover, the front axle is loaded more heavily during braking, since the body tilts forward due to inertia, and the rear axle is unloaded. If the driver uses hard braking, the linings will wear out much faster.

Many modern models are equipped with an ESP system (how the exchange rate stabilization system works is described separately ). The peculiarity of this device is that it automatically brakes when there is a risk of the car skidding. Although such a system provides safety and control of the vehicle, its frequent operation causes wear on individual pads, and this process cannot be controlled. Otherwise, you have to turn off the device (how this is done is described here ).

Here is a short list of the reasons why frequent or unnatural pad wear occurs.

Wedge wear

The reasons for this effect may be:

- Errors when installing pads;

- The material of the block linings is of poor quality;

- A feature of the design of some brake systems, for example, those that are equipped with additional calipers to improve performance;

- The caliper bracket must effectively guide the part so that all parts of it are simultaneously adjacent to the disc. This may not occur due to poor tightening of the mounting bolt;

- Violation of the rules for tightening the fastening bolt of the bracket can lead to its deformation;

- Malfunctions in the chassis of the car, for example, wear in the wheel bearing, which causes play (this happens extremely rarely);

- Souring of guides;

- The bearing on the struts (or strut) has a bent axle.

Rapid pad wear

Accelerated production of material may be due to the following reasons:

- The pad has the wrong material for the specific vehicle, such as being too soft;

- Aggressive driving;

- The car is equipped with an ESP system;

- Development on the brake disc or drum;

- Incorrect caliper adjustment - the pad is pressed against the surface of the disc or drum;

- The car sits idle for a long time.

Wear of the inner and outer pads

The internal element wears out due to:

- Soured piston;

- Dry or damaged guide supports;

- Caliper failures.

The external element can wear out for the following reasons:

- The caliper guides have become sour;

- The guides have lost lubrication or their surface has worn out;

- The caliper structure is deformed.

Different pad wear

Pads on individual wheels may wear differently due to:

- Incorrect operation of the GTZ;

- The driver often uses the handbrake;

- The material of the pads may differ in composition or hardness;

- Brake disc deformation.

It happens that the pads wear unevenly on one wheel. This can happen for the following reasons:

- The kit may contain pads of different quality;

- The caliper piston is soured.

Signs of wear

Sometimes, just to assess the condition of the linings, it is not at all necessary to get into the brake system. Many people are interested in how to check brake pads without removing the wheel? Wear can be determined by the following signs:

- When emergency braking occurs, a specific sound occurs in the wheel. This indicates that uneven wear of parts has occurred. Their plates are worn out and touch the brake discs, creating a squeak. A similar noise is accompanied by disk wear.

- Pad wear sensor. Almost all modern cars have indicators showing the condition of the mechanism. The sensor looks like a lamp; when it lights up, it means it’s time to change the pads. Sometimes oxidation of the contacts occurs, and the indicator may simply not work, then wear will have to be determined visually.

- The system began to behave strangely when the speed decreased. The brake fluid level decreases, and the pedal is pressed softly, slightly pressing down, or, conversely, when pressed, a lock is activated.

Brake pad replacement process - If you find metal shavings on the discs, you need to go to a service station, since not only the pads have worn out, but also the disc has worn out.

- Long braking distance.

Useful tips

- To avoid premature pad wear, try not to use the brake pedal unless absolutely necessary. Do not accelerate in short sections and when you know for sure that after a few tens of meters you will have to slow down. This increases pad wear and shortens their service life, as well as the service life of the brake discs.

- Buy only high-quality spare parts, preferably original ones. Make sure that the parts are compatible; it is not recommended to buy brake discs from one manufacturer and pads from another. Each manufacturer has its own composition of pads and discs, so different materials may conflict. As a result, incorrect operation of the vehicle, the appearance of different sounds, as well as increased wear of discs and pads are possible.

- Regularly monitor the condition of the pads, discs, brake fluid and the entire brake system as a whole. This can be done independently or using the services of a service station.

- Buy pads with a wear indicator. Thanks to a special wear indicator, which is a regular metal pin, you can monitor the condition of the pads. As soon as the pad wears down to a critical level, the metal pin will begin to touch the brake disc. As a result, during braking, due to the friction of metal on metal, a metallic whistle will appear, which will be a sign that it is time for you to replace the pads.

I’ll probably end here, watch your brakes and replace brake elements on time, your safety, as well as the safety of other road users, depends on this. Write in the comments how you monitor the degree of wear of the pads, and also what signs you use to assess the need to replace them. Thank you for your attention, see you again on Question Auto. Bye.

Checking the pads without removing the wheel

Checking brake pad wear is not difficult, especially when the vehicle has alloy wheels with large holes through which the brake assembly is visible. As a rule, only the outer block is visible. If you determine its thickness visually, then 1.5–2 millimeters is considered critical. When, even without removing the wheels, you notice that the thickness of the lining is less than 5 millimeters, this is a reason for replacement. If the holes on the wheel are too small and the brake mechanism is hard to see, you need to start dismantling the wheel. When nothing interferes with the view, it is easy to assess the condition of the second lining and, at the same time, the brake disc.

When to change pads

If a motorist’s knowledge of the operation of the brake system is complete darkness, then it is better to trust a professional to replace consumables in it. Typically, pads are changed when the material has already worn down to a critical value (at the same time, characteristic sounds of alarms are heard or the wear sensor on the instrument panel is triggered). The second case is scheduled vehicle maintenance.

Most motorists perform this procedure in the first case. If the car travels a short distance throughout the year, it would be better to carry out diagnostics of the entire vehicle at least once a year, which will involve various manipulations, including checking the condition of the pads.

In the case of high mileage with measured “retirement” driving, the pads may still look good even after 50 thousand. It is still recommended to replace such elements, since over time, due to their strong heating and cooling, the material becomes coarser. Because of this, during the braking process, it is not the friction lining that can wear out, but the disc or drum itself.

Permissible pad wear

Typically, the standard by which the permissible wear of friction material is determined is universal for all cars. The minimum thickness of the lining should be between three and two millimeters. At this stage they need to be changed. Moreover, when diagnosing, you should pay attention to the thinnest part of the block if uneven wear is observed on it. Of course, in this case it is necessary to eliminate the reason why the pad does not completely adhere to the surface of the disc.

It is worth noting that as the tonnage of the vehicle increases, the minimum thickness of the pads should be greater. As for SUVs or crossovers, this parameter should be 3.5-3.0 millimeters. For small cars and passenger cars, the acceptable thickness is considered to be up to two mm.

Regardless of whether the pads have become unusable or not, for the sake of safety on the road, we still recommend double-checking to what extent they have worn out. The seasonal tire change procedure is ideal for this.

Proper Pad and Disc Inspection Process

Before checking, review the table of permissible dimensions of brake parts. When the data matches, start making replacements. The process is divided into the following stages:

- We place the vehicle on a jack and remove the front wheel.

- We clean the disk from settled dust.

- Using a caliper we determine the thickness of the disc. The permissible wear parameter is 10.8 mm.

- In the inspection window we determine the thickness of both pads; you can take a caliper.

- Use a screwdriver to see how the pads move. When they move tightly, it means they have compressed the disc. If the wear is uneven, a new cylinder and caliper must be installed.

- To get to the rear ones, remove the wheel and drum.

- We measure their thickness and the size of the drum surface. The diameter should not exceed 201.5 mm.

Brake pads

Parts need to be replaced if:

- linings in oil;

- products thinner than 1.5 mm;

- the linings are not tightly connected to the base;

- Discs need to be replaced if there are scratches or deformation.

How to check brake pads and for what reasons?

1. Checking the brake pads while driving. To understand whether the brake elements are working effectively or not, perform a test while driving.

Important! The brake check should be carried out on a section of the road empty of cars, people and buildings. If the brakes are ineffective during the test, you may hit someone or an obstacle.

It is necessary to check the pads while driving; to do this, pick up a speed of 50-60 km/h and press the brake pedal.

Replacing front brake pads

- We secure the car with the handbrake and place barriers under the wheels. All you need are keys No. 13 and 17, as well as a screwdriver.

- We dismantle the wheel and check the brake fluid level at the same time. It should be between the MIN and MAX marks on the tank body.

- We press on the piston and pull the caliper until it stops.

- Use a wrench No. 13 to remove the lower bolt, and use a wrench No. 17 to hold the guide pin at this moment. We lift the body and take out the pads. We remove dirt, if any.

- We install new products, the springs are installed parallel to the top of the pads. We move the bracket body down and fasten the bolt in place, after which we bend the tendril of the lock washer.

- Install the wheel. Next, you need to press the brake several times to check the piston.

Worn brake pad

What happens if you don't change the brake pads for a long time?

What happens if you don't replace the brake pads on time? Severely worn pads can cause the pistons in the brake cylinders to become distorted and jam.

Interesting materials:

How to work with Voskoplav? How to work with the Burner? How to work with XML files? How to work with a tongue twister? How to work with layers in After Effects? How can a student work in Google Classroom? How to work in Bitly? How to work in the office and not get tired? How to work in telegram? How to calculate the percentage of work completed?

Verification algorithm

The car owner should take care of diagnosing the condition of the linings. This is easy to do: you should choose a wheel position in which the block will be visible. Using a ruler, a special probe, or a caliper, the thickness of the working surface is measured. If the measurement result is less than 4-5mm, then the pads need to be replaced.

Brake pads are a material that is responsible for safety and ensures trouble-free driving. Therefore, you should carefully and promptly inspect the braking system and assess its condition. This is possible without removing the wheels, without contacting a service center. By replacing consumable parts if necessary, you can operate the car without fear for your life.

Advantages and disadvantages of drum brakes

Drum brakes are indispensable on trucks and buses, as they allow you to achieve the necessary braking force for heavy vehicles. The reasons for using them on the rear axle of passenger cars are somewhat different.

- Drum brakes simplify the design of the parking brake mechanism.

- They are less susceptible to wear due to the larger contact area between the friction linings and drums.

- Finally, they are less critical to road conditions, as they are reliably protected from dust and moisture getting inside.

Disadvantages of drum brakes include their slower response and less stability, which is a result of uneven contact between the friction lining and the drum. Another disadvantage of drum brakes is their more complex design. So how to check the condition of the rear brake pads?

How to check the condition of the brake pads without removing the wheel - KnowKak.ru

Safe driving is the most important factor for every car owner. And therefore, monitoring the condition of car brake pads is very important. You can do this without even removing the wheels from the car.

Brake pads are the main element of the braking system. With constant use of the car, the surface of the parts wears off, creating the need for urgent replacement. Grinding their working area creates minimal adhesion to the brake disc, thereby increasing the braking distance. This creates a greater likelihood of failure in a traffic accident. Therefore, the car owner must track and replace the spare part in a timely manner.

Service life of brake pads

Each batch of mechanisms has its own expiration date, which is indicated by the manufacturer on the spare parts. In fact, everything depends on the performance properties of the car. Their service life can be affected by driving style and skill, the conditions in which vehicles move and many other factors. There are cases when, with a mileage of 20,000 km, the pads remained in perfect condition and were ready to last the same amount, or vice versa, with a mileage of 10,000 km, the pads remained too worn and required urgent replacement. It is already established that the service life of pads from Chinese manufacturers is a maximum of 10-12 thousand km. When purchasing Chinese products, you should already save money for new ones. You should give preference to original spare parts or companies that have reliably proven themselves in the market.

During operation, low-quality products may produce an unpleasant squeaking sound. Often car owners can confuse it with worn out pads and rush to change them. But there is no need to rush, since these are only manufacturing defects and they have not yet become unusable. The owner should rely on his own sensations when braking and constantly inspect the condition of the wheels.

If you notice:

• decrease in brake fluid level;

• soft pressing of the brake pedal or, on the contrary, blocking;

• long braking distance;

• specific sounds when braking means it’s time to urgently pay attention to the condition of the brake pads.

Routine inspection is a fairly effective method in determining system wear in the presence of alloy wheels with large holes. Through them you can see the entire brake assembly. The examiner will see only the outer block. If the holes are small, then you need to dismantle the wheel, and then you can evaluate the condition of the second lining along with the brake disc. In order to see the condition of the pads without removing the wheels, you need to put the car in the correct position so that the mechanism is visible between the wheel spokes. This method will allow you to determine the residual wear of the pad. You can use a ruler to determine the working thickness.

According to the recommendations of car manufacturers, the pads should be replaced if the thickness of their working surface is 2 mm or less. But most experts advise changing when the mark reaches less than 5 mm. This reinsurance will allow you to feel more confident on the road and allow you to effectively slow down on the roadway in emergency situations.

Summing up

The conclusion suggests itself - there should be no savings on the quality of car service. First of all, you need to pay attention to the health of the brake system. Their replacement must be carried out strictly in accordance with the regulations, upon reaching 4-5 mm of the working area. At the same time, the use of high-quality and original pads will eliminate unpleasant squeaking. The use of recommended products will sufficiently increase the service life of the mechanism, which will simplify vehicle maintenance.

The easiest way for car owners to assess wear is on alloy wheels. Using available means, you can measure the residual usefulness of the pad and decide whether to replace or extend its service. The situation is different with disks that have metal stamping. To evaluate the brake system, you need to use a jack, remove the wheels and then inspect the pads. This process is more labor-intensive, but by carrying it out, the owner of the car will probably already know how things are going with the pads. We will carry out high-quality vehicle maintenance with complete replacement of necessary parts.

Wear limit

Each brake disc has its own limited resource. It is set by the manufacturer from the factory, and resource wear is affected by mileage, braking intensity, the condition of the entire braking system, the characteristic features of the vehicle itself, etc.

When buying a new set of brake discs for his car, the driver must always follow the recommendations of the car manufacturer. Therefore, first we look at the instruction manual, or according to convenient catalogues, based on the characteristics of our particular machine, we select a part via the Internet. If you take a high-quality kit from a trusted manufacturer, you can be sure that wear will not occur very quickly, and when braking hard, the car will definitely stop, as you expected. The same applies to buying new pads.

There are international norms and standards for the production of such components for passenger cars. They oblige all manufacturers to make appropriate engravings or markings on products.

The essence of the engraving is to indicate information that relates to the maximum permissible degree of wear.

There is such a thing as the thickness of the brake disc. And it has a certain maximum wear limit.

To obtain the relevant information, you should look at the end part of the product. It is there that, according to international standards, all manufacturers of certified parts are required to display data regarding the wear of the brake part. Information about the initial thickness, as well as what thickness is considered minimal, should be located here. As soon as the disk reaches this value, it must be replaced. In fact, the manufacturer thereby relieves itself of responsibility. If a driver wears a disc below normal and causes an accident, he will not be able to blame the brake manufacturer or auto company for this.

There is an interesting feature here. When the question arises about when to change brake discs, many people look at the end side of the old product, but find nothing there.

This happens, but only on products that have not been certified or are counterfeit. It is strictly not recommended to buy such parts without information about wear.