For tuning purposes, you can make a hydraulic handbrake yourself. VAZ of any model is equipped with a hydraulic brake system, but the parking brake is of a cable design. This impairs performance, since the cable tends to stretch, so the effectiveness of the handbrake is reduced. And drum brakes themselves have low reliability.

Braking efficiency is extremely low. But for the hydraulic handbrake to fully function, it is imperative that the rear wheels have disc brakes. The second, negative side is that according to traffic regulations it is forbidden to make changes to the brake system. Therefore, when carrying out such an upgrade, you act at your own peril and risk.

The main purpose

You can install and configure a hydraulic handbrake on a VAZ-2109 yourself if you have certain skills and tools. Despite the prohibitions, such designs can be found on sale and can be installed on any make and model of car. It is advisable to carry out all work on an inspection pit or a lift. With the help of a hydraulic handbrake you can greatly increase the efficiency of the braking system. The design provides for a regulator that allows you to distribute the force between the front and rear circuits. The regulator allows you to prevent complete blocking of the rear wheels.

Now about the unpleasant, about the shortcomings, that is, the disadvantages of this scheme:

1. If the “right front - left front” circuit fails, braking efficiency will be significantly reduced;

Agree, there are not so many shortcomings, and besides, they exist always and everywhere, but if you clearly measure the force using the handbrake handle of the car, braking is carried out very effectively and this fact has been personally verified in practice. However, a true lover of do-it-yourself tuning will never miss the chance to retrofit your car with a hydraulic handbrake , making it more advanced, as well as an excellent opportunity to gain invaluable experience and a lot of pleasure from the result.

What can a hydraulic handbrake do?

Using this design of the handbrake, you can completely block the rear wheels in order to warm up the tires on the front axle. This will prove useful for racing enthusiasts. Ordinary drivers will find the lock useful in reducing the chance of skidding when turning on wet roads. The device is installed near the handbrake lever so that it can be easily accessed. If the regulator is installed correctly, the force on the rear brake will be distributed smoothly, and the efficiency of the front will increase.

Advantages and disadvantages of GR

We have already noted that usually a hydraulic handbrake is installed when the drum brakes on the rear axle are replaced with disc-type devices. Before we talk about the pros and cons of hydraulic CT, let's talk about what the use of disc brakes gives:

- Drum brakes are subject to high heat, which leads to a decrease in stability over time. Disc mechanisms are cooled much more efficiently, so their characteristics are practically not subject to age-related changes - and this is considered one of the main advantages of brakes of this type;

- the second advantage emerges from the first - this is a reduction in the braking distance due to the higher efficiency of disc mechanisms. And increasing traffic safety is a very powerful argument given the ever-increasing density of traffic flow and speed on suburban highways;

- Structurally, disc brakes are more compact and noticeably lighter than their drum counterparts.

But the slightest distortion during installation of the system - and the uniform distribution of the braking force applied to the rear/front axles or rear wheels will be disrupted. This is the main disadvantage that accompanies the installation of disc brakes. The solution to this problem is to install a dual-circuit system, with each circuit involving the connection of the right and left wheels of both axles. The main thing is that the regulator is located in front of the hydraulic handbrake drive, but after the main TC. Only in this case can the advanced braking system operate optimally.

Now let's look at how important the role of the hydraulic hand brake is in this. In fact, if we limit ourselves to only replacing drum brakes with disc brakes, without installing a hydraulic handbrake and a dual-circuit system, in order for the braking efficiency to be at least as good, additional circuits will need to be connected to the rear suspension. In addition, additional calipers will need to be mounted on both sides of the rear suspension. It is clear that such tuning is very burdensome in terms of money, time and effort spent. However, everything is much simpler if you install a hydraulic handbrake instead. This will allow:

- ideally distribute braking force on the rear axle;

- noticeable effort of rear brake power;

- the same thing will happen with the front brakes, since the lines will be schematically shifted to the vacuum booster.

However, there are also disadvantages. The main one is a noticeable reduction in braking intensity if for some reason the front circuit fails. Most importantly, there will be no complete failure of the brake system.

This is definitely very important

Hydraulic hand brake kit

In automobile stores you can purchase a hydraulic handbrake kit. You can install it yourself, but you will need a few additional elements:

- Copper washers for brake mechanisms, 10 pcs.

- Metal tubes in the amount of 5 pcs. To save a little, you can purchase a complete set for Gazelle cars.

- Plugs.

- Twists.

- Brake hoses for VAZ-2101-2107.

- Tee for the brake system.

- Plastic clamps, 50 pcs.

- Brake regulator for VAZ cars of any model.

- GTZ for VAZ-2101. If this is not the case, then you can use any other cylinder.

In addition to all this, you will need brake fluid for subsequent refilling of the system. After all, the modification includes inserting an additional circuit into the brake lines.

We lay the brake line into the interior.

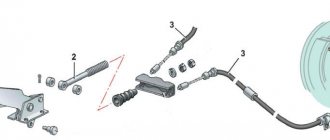

Using the technical hole in the speedometer drive cable, it is necessary to extend the brake pipe into the interior. It must be bent in such a way that it does not touch anything in the engine compartment, then connect it to the GTZ. Using the previously prepared “twist”, you need to lengthen the line using an additional metal brake pipe; a regulator will be installed at the place of twist a little later.

Preparatory work

Before starting tuning, you need to get rid of the old, imperfect system. To do this, the mechanical drive is completely dismantled. Please note that after installing the hydraulic handbrake, the operation pattern of the caliper drive will completely change. If by default the mechanisms worked in pairs, which are located on wheels located diagonally, then after the modification the circuit will turn out to be axial (rear and front). But before installing the hydraulic handbrake, you need to remove the old one.

Tags: hydrohandler, hydrostick, ate, hash tags no one reads

Comments 104

Order? not an option?

The job was done super! If it’s not too difficult, send me the drawings.

Nice! Only more holes had to be made to make it more like the original!

The work was done great, super...

Huge request - send me the drawing in a personal message! I beg you)) Well done, it turned out great!

Did you sharpen the adapters or buy them somewhere?

I bought) from the Volga, if I'm not mistaken, an adapter from 12 to 10)

If it's not too much trouble, then post the drawings in the PM.

How to remove the handbrake cable

To dismantle the old handbrake you will need to perform several steps:

- Place the car on an overpass, inspection hole or lift. It all depends on what amenities you have. If there are no such amenities, then it is better not to even start doing the work.

- Raise the rear of the car with a jack, having previously installed stops under the front wheels.

- Install supports under the rear beam.

- Since the hydraulic handbrake can also be installed with drum brakes, the design does not need to be changed much. Remove the wheels and drums from the rear axle.

- To avoid interference, remove the resonator and muffler.

- Remove the equalizer from the rod.

- Dismantle the cable by removing it from the blocks on both wheels.

- Now you need to perform several manipulations inside the car. Open access to the handbrake lever and unscrew the fasteners. Then remove it completely from its seat.

Now you can begin installing the new system; to do this, you can use one of two popular methods.

Feel.

At first, everything was somehow unusual - pedal travel, force, braking, force calculation, and so on. I was very pleased that now the VAZ parking brake was not “dead”, as it was before, now by pulling it, it was possible to adjust the force, thus stopping the “eight” in various ways, as they say in their own way. The hydraulic handbrake perfectly fulfills its direct duty - it holds the car in place on an incline. Since that day, I “forgot” what overbraking is, braking is carried out very intelligently and the wheels of the rear axle, in the event of emergency braking, are blocked a little later than the front ones. I haven’t done any “somersaults” or tricks with the new braking system yet, it’s a little scary, I’m not used to it yet, and besides, the experts advised not to take risks yet, but just get used to the new braking system and its operation.

That's all for me, I hope that my story in detail will be useful for someone, and someone, following my example, will install a VAZ hydraulic parking brake for themselves. I look forward to your comments and thoughts regarding the above.

Hello everyone! Here is a report on installing a hydraulic handbrake on a classic with standard drum brakes. But my installation has one peculiarity - I completely left the standard cable handbrake. The idea is that by tightening the handbrake cables, the brake pads are separated, reducing the working stroke both when the handbrake is operating and when the brake cylinders are operating. Having thrown out the standard handbrake, we increase the working stroke of the brake cylinders since the pads are not spread apart. Well, the standard handbrake remains for regular use. Who thinks about this, we can discuss it in the comments) I’m not particularly special in jigging, I don’t pretend to be the truth. The handbrake is vertical, adapters for standard brake pipes are included.

Regarding the tubes - when I was looking for information on which tubes to install - few people write exactly which ones are suitable. I checked it myself - in my case (look at how the handbrake is located and how the tubes pass into the cabin) they are used - from the GTZ to the hydraulic handbrake - the front right from 2110, from the hydraulic valve to the hose to the axle - the front right from 2108/09

. But with a caveat - the front tube was barely enough, and the rear tube, as we see, is a little long. But overall everything turned out great.

The place where the tubes pass into the cabin - in this place at the bottom of the tunnel there is a slight recess, just so that there is space and the tubes do not touch the cardan. The hole for the tubes is in a place where there are two metals, so we put rubber bands to protect the tubes both inside and out.

The standard brakes also had a force regulator (sorcerer). I connected the hydraulic handbrake without it. According to the advice found on Drive, we pump the brakes with the hydraulic handbrake depressed. Everything progressed surprisingly quickly.

I'm going out to test. What he was afraid of was that he would over-brake his butt because of the ejected sorcerer. Nevermind, everything is fine, it grabs the front first. The pedal travel became a little longer, which was unusual at first. The handbrake engages very clearly and immediately, at the very beginning of the stroke. There is some inconvenience in this; they installed it with an eye to the full stroke of the handle. There is an idea to try to loosen the cables of the standard handbrake so that the stroke of the rear cylinders and, accordingly, the hydraulic stick handle is greater.

Thus, we get a hydraulic handbrake while fully maintaining the standard cable handbrake

The handle of the stick makes it a little difficult to engage reverse gear, but we’ll just forget about it) Thank you for your attention and I hope my report will be useful to someone)

Installation method No. 1

According to experts, there are two ways to install a hydraulic handbrake on a VAZ. The simplest and most accessible involves performing the following manipulations:

- Another brake cylinder must be installed in the engine compartment. The clutch master cylinder from a VAZ-2101 is ideal.

- Remove the brake fluid expansion tank.

- You will need to make a small adapter yourself. Cut the thread and install the washer (it should have a thread for the fitting).

You begin assembling the entire system from the original GTZ to the clutch cylinder, then to the regulator, handbrake, and rear brake circuit. To connect all the components together, use tubes from the Gazelle car. Just choose those that fit in size. The tubes are fastened to the places where the handbrake cable was fixed.

Installation method No. 2

First you need to do a few manipulations under the hood:

- Unscrew the tube that goes to the left brake mechanism and put a plug on it.

- Unscrew the tube going to the front right wheel. Install it in the hole intended for the right rear brake mechanism.

Before starting work, be sure to drain all liquid. Try to do everything carefully so as not to damage the hydraulic mechanisms. Try not to let the liquid come into contact with the metal, as it will corrode it. Further actions:

- Install a new handbrake between the seats.

- Install the bolt instead of the regulator pendulum. Screw it to the bottom of the body. It is recommended to temporarily remove the front seats so that they do not interfere and do not get dirty during work.

- A tube is laid from the engine compartment along the bottom to the new handbrake.

- You lay pipes from the regulator along the bottom of the cabin.

- Select the tube sizes and install them on the rear axle.

- Attach a flexible hose to the rear beam on the bracket.

- Be sure to install a rubber ring so that the hose does not rub during operation. To make it easier to put on, cut this ring.

- Connect the hose to the tubes. To secure metal tubes, use plastic zip ties.

Lada 2107 White › Logbook › Hydraulic handbrake for dummies

Hi all. The season was very close, and there was no handbrake at all. As a rule, drifting is impossible without it. And it's inconvenient for everyday use. I started looking for an option that was suitable for me (not conspicuous, horizontal). I found in our area in a store the cheapest option for 2200 rubles, based on the classic clutch master cylinder. Why not ATE? There wasn't enough money because... I bought it and went to a friend’s spare parts store. There they cut off two 170cm brake pipes with fittings that fit the threads in the cylinder. I also took 0.5 brake fluid. Came out another 700r

At first, out of the desire to try it on, I quickly removed the old handbrake and screwed the hydratch onto 3 bolts in its regular place. It looks beautiful, massive, unusual - in general, I got a kick out of it.

Day “X” came, I found some free time. I came to the garage and drove into a dead end. How to connect all this? There is a lot of information on the drive, and in the end my head was a mess. Without hesitation, I wrote to Ne1R in direct message, without expecting an answer. But Slava, surprisingly, quickly responded and advised. That's what I decided to do. Now I will explain with my fingers in photos taken from the Internet:

Next, take the second brake pipe, carefully insert one end into the interior and screw it into hole number 3.

Now, in normal mode, we begin to bleed the brake system and that’s it. It took 2.5 - 3 hours, taking into account pumping (I pumped one). The idea came into my head to hide the copper tubes in the corrugation, which was lying in the garage.

First ride, tests... And I was extremely surprised by the efficiency of braking and the gas pedal and the hydraulic handbrake itself. Parking brake 1-2 clicks and the car stops. Overall, it was worth it. Now it's drift season and I'm just enjoying the efficiency of the handbrake. Let's summarize: Hydraulic handbrake - 2200 rubles Copper brake tube with classic fittings, length 170cm * 2 - 600rub Brake fluid 0.5 l - 100rub Total 2900 rubles and we have a soft, pleasant hydraulic handbrake for the homeless. I was warned that there would supposedly be over-braking of the rear circuit, but there is none, first the front brakes, and then the rear. Provided that I have 14″ brake discs from 2112 at the front, and 13″ at the rear from 2110 on the same brake cylinders. In principle, I expected that all this would work well without a brake force regulator. Thank you all for your attention. If you have any questions, write, I will answer.

Completion of work using the second method

When carrying out repairs, try not to allow the hose to become twisted. This may cause damage and fluid leakage. First you need to tighten the edge on which the thread is external. Then the edge with the internal thread is tightened. How to make a hydraulic handbrake yourself? The final stage looks like this:

- Fix the position of the new system, check the tightness of all threaded connections.

- Fill the expansion tank with brake fluid.

- Bleed the system according to the scheme from the far cylinder to the near one. Add fluid to the reservoir in a timely manner. Otherwise, pumping will need to be done again.

- Check the functionality of the brake system. Are the calipers pressed out normally?

Afterwards, assemble all the disassembled components and replace the wheels. Before your first ride, make sure the brakes work properly. If there are problems, fix them immediately. When driving for the first time, do not accelerate to high speed so that you can at least stop the car with the engine. All of the above methods are suitable for installing a hydraulic handbrake with your own hands on a VAZ of any model, as well as on cars from other manufacturers (including foreign ones).

Lada 2107 Zhigulitta › Logbook › Bucket, HTD, DIY hydraulic handbrake

Hello again to all those who came to read my logbook.

I’ll tell you about buckets, a little about installing rear disc brakes on a classic, and how I made a hydraulic handbrake with my own hands. Let's start with the buckets. These are two twins, original Sparco, size M (180/80), I can’t tell you exactly about the model, since the sticker below only has their number and homologation date. Initially, I took them from a rally training VAZ 2108, in which they sat for a very long time. The covers were very worn and dirty. So my mom and I went to a fabric store and picked out a base for the back and sides. I must say that the fiberglass frame itself is well preserved, there are aluminum pipes inside, and the foam rubber is also without holes and has not dried out. In general, the problem is only in the covers. In two evenings, a cover for one bucket was sewn, the center was on Velcro like the original cover, the sides were glued. It turned out neatly, I’ve been riding for three months now, nothing has come off or peeled off, and the fabric doesn’t mark. The skids for one bucket were Sabelt, for the other there were none, but this is not a problem, they are not that expensive. I took the buckets themselves for 3000 apiece, 1500 for fabric, Velcro and special glue. Now it has already settled well under my weight and there are no folds anywhere (there were almost none), the fabric is not bristling. I mounted it on the factory slides, drilled holes in them for the bolts. Soon I will prepare a mount for them according to Appendix J.

About the installation of the HTD. Along with the suspension, I received a kit for installing rear disc brakes based on calipers from 2108. The kit included a spacer ring, boot, retaining half ring, and plant washer. I agreed with the turner that I would come to him at 13:00 so that he could machine the axle shafts to fit the inner diameter of the brake disc. At 11, I arrived at the garage, drained the oil from the gearbox, removed the wheels, removed the drums, unscrewed and pulled out the axle shafts, and by one o'clock I was at the turner. In 20 minutes and 300 rubles per axle shaft, he did his job and I, happy, went to the garage to install it all. On the way, I stopped at the store and bought new bolts and nuts for fastening the axle shaft, Nivov hoses, banjo bolts, copper washers, two brake pipes and a tee. The following pipes are needed: on the left side we put the pipe from the front brakes of the classic (the short one, between the cylinders), and on the right we put the pipe that goes to the left side (it looks like the letter W). Naturally, the tubes will need to be straightened and bent in place, but they are long enough, especially with hoses from the field. I ran the hoses themselves from the front of the bridge from above (since the caliper is directed forward), and the tubes were in their normal places. Next, we check everything again, tighten the pipes with a special wrench, bleed the brakes (do not forget when installing the caliper that the release should be on top, besides, if the caliper is not new, then it is better to install a new release)

The only thing that needs to be done is to modify the bracket, otherwise it will rest against the axle shaft mounting bolt. I carefully removed the metal with a grinder, trying it on all the time. As a result, I removed a little less than a third of the thickness, but don’t worry, this bracket is designed to work on the front axle of a car, where the load is twice as large, besides, Clubturbo also sells sawed brackets, only they have removed half of the thickness in that place.

Now I would like to talk about the hydraulic handbrake. I did it myself from start to finish, spending a total of about a day on all the work. Let's start with the cylinder. I, like almost everyone else, decided to use the clutch cylinder from the classics. But there is one “but”: in this cylinder there is only one outlet for the tube, and the entrance is from the tank. I didn’t turn to a turner to make a screwdriver for me. I decided to go a different route. I pulled out the lock nut that holds the plastic fitting.

And I went to the store to get a suitable nut, which I was going to weld there. I’ll say right away that the brake pipe does not fit the thread into the clutch cylinder; you need an adapter from GAS. I walked around the store for a long time looking for a suitable nut and found it - it was a wheel nut from a Niva. it fits the threads of the adapters. But there is one trick: there are different nuts. First, of course, we need an open one. Secondly, the nuts themselves differ slightly, quite a bit, but for us the difference is significant. It depends on the diameter of the skirt. There is a taller nut and a wider skirt (it won’t fit), and there is a lower and narrower one (it’s like it was created for this). After you insert the small one, you will understand. It fits just perfectly into this recess, without any gap at all and to the beginning of the hexagon (that is, quite deep).

Next, we disassemble the entire cylinder, taking out all the components and leaving only the cast iron base.

Cost of tuning

Now is the time to draw up a detailed estimate for the spare parts used during tuning of the brake system. The price of all components may vary, depending on whether you are purchasing new or used. Approximate cost:

- Hydraulic brake assembly - cost about 2,700 rubles. You can also find cheap Chinese copies, but decide for yourself whether you should trust them. The quality of such products is very often low.

- Regulator – 400-500 rubles.

- Brake pipes for a Gazelle car – 300-400 rubles.

- Clutch cylinder (main) for classics - about 450-500 rubles.

- And small consumables - copper washers, plastic clamps, VAZ-2101 brake hose, fluid - you will spend about 500-600 rubles on everything.

By conservative standards, the cost of tuning will cost about 5,000 rubles. If this is too much for you, then abandon this idea and simply install a new handbrake cable instead of the stretched old one. Before starting work, it is recommended that you familiarize yourself with the advice of specialists and communicate with those who have already done similar work. They will be able to give you a lot of practical advice regarding improving the brake system on a particular car.

Possible fines

Motorists are naturally afraid of fines for not using the handbrake on their car. And a traffic police officer can bring administrative liability for this.

The Code of Administrative Offenses actually has Article 12.5. Only here some cunning traffic police officers rely on the second part of this article, which prescribes the punishment for driving a vehicle with a faulty brake system. This threatens with a fine of 500 rubles and detention of the car.

In fact, this article is about the handbrake. Only the document clearly states that the parking brake is an exception. That is, according to 12.5 Part 2, you can only be punished for a malfunction of the brake system, but not for problems with the handbrake.

The first part of Article 12.5 of the Code of Administrative Offenses is relevant. Here we are talking about the same 500 ruble fine. But it is important that the employee does not have the right to detain the vehicle.

The traffic police inspector does not have the right to stop the car to check the serviceability of the handbrake. Stopping is allowed only if there are visually noticeable faults.

If you have been issued a fine, then you have the opportunity to pay not 500, but 250 rubles. This penalty is included in the list of items that are eligible for a 50% discount if paid within 20 days after the ruling is issued. Just wait until your receipt appears in the traffic police database.

Sources

- https://cartore.ru/85-regulirovka-stoyanochnogo-ruchnogo-tormoza-svoimi-rukami.html

- https://autostuk.ru/tros-ruchnogo-tormoza-zamena-regulirovka.html

- https://uremont.com/publications/articles/regulirovka-trosov-stoyanochnogo-tormoza-central-nym-natyazheniem

- https://marshal.ru/articles/prichiny-po-kotorym-ploho-rabotaet-ruchnoy-tormoz-v-avtomobile

- https://okeydrive.ru/kak-podtyanut-ruchnik/

- https://motorltd.ru/kak-podtyanut-ruchnik-svoimi-silami/

- https://neauto.ru/pochemu-na-avtomobile-ne-derzhit-ruchnik-i-chto-delat-v-takoj-situacii/

[collapse]

Do you need rear disc brakes?

The answer is ambiguous, since disc brakes have clear advantages over drum brakes. If you are already tuning the system, then do not be lazy and install discs on the rear axle. Their advantages are even in the smallest details - replacing pads is much easier than on drum pads (and the cost of the set is lower). Wheels from the 2109 model are ideal for the rear wheels of front-wheel drive VAZ cars. There are minimal alterations, everything becomes as if it were “original.” But if your budget for tuning is limited, then you can use a standard system. Drum brakes work relatively well, and the use of hydraulics will forever eliminate the need to tighten the cable. And the car will stand normally on any slope without rolling down.

Tension

So, having understood the diagram, you can begin the procedure of tightening the handbrake cables.

Stretch

The tensioning procedure is as follows.

- Place the car on an overpass or pit. If you don’t have a garage and you have the opportunity or desire to carry out the procedure at a service station, use a jack. The rear of the car is raised on a jack. The most extreme option is a curb onto which the car is driven and all you have to do is crawl under it.

- Engage the gearbox in first gear and put the car on the handbrake by pulling the lever up.

- The ideal number of handbrake clicks is from 2 to 5. If there are fewer or more clicks, it is easier to take appropriate measures to tension the cable.

- If there are less than 2 clicks, then the cable will need to be lengthened. If there are more than five clicks, then the cables are shortened.

- Lengthening the cable means relaxing it. To do this, unscrew the locknut. When tightening the cable, the locknut must be tightened in reverse.

- Before you start looking for the required nut on the bottom of the car, release the handbrake lever all the way.

- Take a 13mm wrench under the car and head down.

- Find the handbrake cable equalizer. This is the same element from which the main handbrake cable is divided into two cables.

- In some cases, it is simply not possible to gain access to the equalizer, since the muffler holders made of rubber are in the way. In such a situation, it is better to remove them. This is not difficult to do, but working with the handbrake will be much easier.

- Now there are two nuts in front of you. One is a simple nut and the other is a lock nut. Having two keys in your hands, fix the nut with the first one, and with the second one begin to unscrew or tighten the locking nut. Be careful that the nut does not start to turn.

- Taking into account the condition of the handbrake and the need to loosen or tighten the lever, turn the locknut in the appropriate direction. Remember what is the optimal number of clicks.

- Tighten or unscrew the locknut to obtain the required degree of tension.

Examination

But if you twisted the nuts there, this is not a guarantee that the handbrake now works perfectly. This needs to be clearly verified.

To do this, it is enough to go through a successive stage of verification activities.

Stage

Explanation

Spin the wheels after tensioning is completed

The wheels are lifted one by one on a jack. When the handbrake lever is turned off, they should rotate freely without obstacles. By squeezing the brake, the wheels should lock.

Drive up a slight slope, stop and engage the handbrake

The fact that the wheels do not spin when suspended is good. But you need to make sure that the handbrake holds the car even when exposed to gravity.

If the check shows that the handbrake still does not hold, even if the cable was tensioned exactly according to the instructions, the handbrake is probably simply worn out and the cable needs to be replaced.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.