For more than three years, it has been specializing in car servicing. Organizations, not just individuals, can receive high-quality car service. Our work mainly involves GAZELLE and FORD, Mercedes and VOLGA, TaGaz cars. We focus on providing comprehensive services for replacing the engine and automatic transmission with Japanese engines. The service company works on order. Our specialists purchase engines from the Japanese company TOYOTA, JZ or UZ series, with their subsequent installation. Toyota engines are reliable, which is very important. After all, we work only with originals. Toyota engines are the option of choice for Gazelles, as well as other commercial vehicles. The car services various models of minibuses, most brands of light commercial vehicles .

The service center has a wide range of diagnostic capabilities and a diverse range of plumbing tools. The employees of our center are diagnosticians and mechanics, electricians and mechanics with sufficient practical experience. Our specialists are constantly improving their professional level. For this purpose, they periodically undergo specialized retraining. For their professionalism, for conscientious and high-quality work, they receive incentive awards: certificates, gratitude, diplomas. The priority element in the provision of services is the wishes of the customer. We provide an individual approach, paying special attention to all client requirements. Urgency of order fulfillment is achieved by working seven days a week. This allows you to install the engine on the gazelle in a timely manner, eliminating the possibility of long-term downtime of transport associated with commerce.

Allswap - Installation of Japanese engines on commercial vehicles

Why is it profitable to work with us?

× No prepayments. You bring your car for conversion, we do the necessary work. You arrive when ready, test the car, drive it, accept the car in good working order, and only then pay. For cash or by terminal. No advances, prepayments and sleepless nights with the thoughts “did I give to that one?” All calculations are based on the fact of completed work!

× Availability. We always keep several swap kits of Japanese internal combustion engines + gearboxes in stock for installation. We do not sell air!

× Experience. We have been engaged in engine swaps and car conversions for more than 5 years. During this time, our mechanics have seen a lot, but the electrician is simply “space”. It makes no difference to us what engine you plan to install - be it a swap V8 or V6, in-line six - we can handle it.

× Price. Attractive and competitive.

× Deadlines. Installing a Japanese engine with an automatic transmission in Gazelle, Gazelle Next, and Sable takes 5-7 days. In Volkswagen Crafter, Mercedes-Benz Sprinter, Ford Transit - about 7-10 days.

× Consultation. You can contact us in any convenient way and receive detailed answers to all your questions about car conversion.

× Warranty. A month without mileage limitation. You will be able to test the converted car in full.

× Post-warranty service. We will help you with replacing oil seals, gaskets and other consumables, which are always in stock. In addition, if necessary, we will carry out computer diagnostics of the engine or automatic transmission, we will deal with “trips”, “sneezing” and “something is not working”.

× Credit. It is possible to swap an engine from Toyota on credit. Come to us, fill out an online application, and within 10 minutes the bank makes a decision on the possibility of issuing a loan.

× Wide geography. We have already converted cars for clients from cities such as Yekaterinburg, Kurgan, Khanty-Mansiysk, Krasnodar, Moscow, Kazan, Naberezhnye Chelny, Orenburg, Tyumen, Orsk, Ufa, Perm, Saransk, Samara and others, as well as from Kazakhstan (Kostanay , Rudny, Kokshetau, Aktobe, Petropavlovsk, Uralsk, Pavlodar, Astana, Karaganda, Ust-Kamenogorsk).

Tips and tricks

First of all, you should purchase a contract engine and gearbox from a trusted supplier. You also need to be prepared for the fact that after installation, officially “legalizing” such a swap of engine and gearbox can be difficult and costly. The installation itself must be performed by qualified specialists who provide a guarantee for the work done.

As practice shows, it is best to install units on the Gazelle that have previously been successfully installed by one or another company or service station. Often, such organizations independently carry out qualified selection, search and acquisition of the necessary contract units.

- Further, if such an engine and gearbox have already been installed on another similar car before, the installation technology itself will be more or less worked out, the craftsmen will know and take into account possible difficulties and nuances. In some cases, this allows you to avoid certain problems both during installation and during operation.

For example, after installing a 1JZ engine and automatic transmission on a Gazelle (the units were taken from the Toyota Mark II model), the owner encountered a problem. During active engine braking, the torque converter began to actually “block” the gearbox as a result of a lack of pressure. This blocking turned out to be due to the fact that the weight of the Gazelle is much greater than the Toyota passenger model, from where the units for installation were taken.

As a result, when you press the brake, all wheels (including the drive ones) were blocked, which posed a certain danger due to loss of controllability.

We also recommend reading the article about what a contract engine and gearbox are. From this article you will learn about the advantages and disadvantages of such units, as well as what you need to consider before purchasing a contract engine and gearbox.

Also, installing a powerful motor led to the need to remake the cardan and change the axle gearbox. The gearbox was taken from the Sobol model (the fastest), however, this element also turned out to be unable to withstand the significantly increased torque for a long time.

NISSAN gearbox for Gazelle | Diesel for Gazelle

Our team has mastered the installation of an alternative gearbox on “native” Gazelle engines.

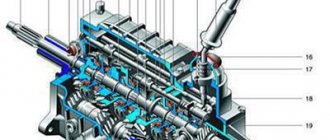

We carried out the necessary work on joining and testing gearboxes from imported cars, which, in our opinion, are more suitable than the original gearbox. A little history. The gearboxes installed by the manufacturer are inherited from the Volga passenger car. During the creation of the GAZelle light truck, the plant followed the path of maximum unification of spare parts and assemblies with existing models of domestically produced vehicles. This is how a gearbox from a passenger car appeared on a commercial truck. As a result, the installation of this box entailed a number of problems that GAZ never bothered to eliminate until recently. For example, the junction between the gearbox and the cardan is made in the same way as on the first Volgas: it is a splined connection in the rear gearbox stocking, which was justified on the “solid” GAZ24 cardan, which did not have an outboard bearing. The movement of the rear axle was compensated by a movable splined joint. Subsequently, the plant made changes to the design, adding an outboard bearing, but did not redesign the gearbox, which led to another problem: the outboard bearing, in addition to its direct responsibilities to support the articulated cardan in the radial direction, also took on axial loads created by movements rear axle. But life did not prepare him for this. The heir to this advanced design was the GAZelle, in which the outboard bearing became a consumable.

In addition to the “childhood” diseases of the cardan, GAZelle was forced to settle for a passenger gearbox. Everyone knows how difficult life is for a GAZelle in modern realities. Many are honestly mistaken, considering the GAZelle to be a lorry, as it was originally positioned among the people. If we calculate the difference between the total weight and the curb weight recorded in the PTS, and also take into account that the curb weight of GAZelles in life is always higher than in the PTS, we will get the real rated carrying capacity of the GAZelle. In some cases, the rated carrying capacity will not exceed not only one and a half tons, it will even be less than a ton. And they load it “like an adult,” often no less than Valdai. In order to somehow bring the real and actual load capacity into line, the owners strengthen the frame and suspension with standard means, adding a channel to the side members and additional sheets to the springs. The issue with the “weak link” in the form of a passenger gearbox, which lives in these conditions for an extremely short time, remained open until recently, because our industry did not offer a ready-made solution for replacement. Today we offer you to install two gearbox options

- Nissan manual transmission from FD35 engine (contract)

- Manual transmission BAF 1044 (new)

Currently, the installation of manual transmission on Gazelle with engines: ZMZ - 406,405,409 has been mastered. UMZ - 4216. Cummins isf 2.8

These gearboxes are designed for trucks with a carrying capacity of 2400-3200 kg, which is quite consistent with the actual load of a GAZelle in Russia. These gearboxes are designed for 345 N.m. (150hp). Unlike the aluminum car box, imported ones are made in a cast iron body. “Fleshy” wide gears, even at a glance, evoke much more confidence than the narrow Volgov gears. Also, powerful bearings are installed in these boxes, which is unattainable in the GAZel box body.

The imported gearboxes we offer for Gazelle from a truck have “traction” characteristics. This will relieve the engine during acceleration and reduce engine speed on the highway. By installing an imported gearbox from us, you can install a higher-speed gearbox in the rear axle. Which will lead to an increase in speed and a decrease in revolutions. Comparison of gear ratios of the Gazelle gearbox and our proposed imported gearbox:

When will the market see GAZelle with automatic transmission?

Vehicles of the GAZelle Next family have firmly entered the world of domestic transport: designed specifically for Russian conditions, affordable and repairable, they are able to effectively solve all the problems facing modern carriers.

There is, however, a nuance. Manufacturers are delaying equipping the GAZelle with an automatic transmission, despite the fact that the market demand for this modification actually formed several years ago. Both private consumers and carriers from large cities have long been talking about the need to switch the GAZelle Next to an automatic transmission. The advantages of automatic transmission over manual transmission play an important role primarily for those involved in commercial passenger transportation: an automatic transmission, firstly, allows the driver to better maintain control over the road, and secondly, reduces the level of noise produced, but the smoothness on the contrary, it increases movement.

In addition, an automatic transmission is not only a way to increase the level of comfort and safety, but also an opportunity to reduce the influence of the human factor on the operation of vehicles. Using an automatic transmission reduces the number of mistakes that can be made in difficult road conditions or stressful situations for the driver. It is this (and also ease of maintenance, ease of driving on slippery or snowy roads and compliance with the modern urban environment) that makes the appearance of an automatic transmission on the GAZelle a welcome innovation for many users of light commercial vehicles.

It is not surprising that every year voices about the urgent need sound louder and louder, but they have not yet found a response from manufacturers.

GAZ Group, a giant of the Russian transport market engaged in the production of GAZelle, announced plans to automate “Nexts” back in 2022. The automotive community received the information positively: in interactive polls, the absolute majority of users were in favor of the appearance of such a car, demonstrating their support for the automakers’ idea.

Conveyor production of GAZelle Next with automatic transmission was supposed to begin at the end of 2022 or a little later, but domestic drivers and carriers were not destined to see GAZelle with an automatic transmission either during the designated period or after it. For economic reasons, the appearance of an automatic transmission for GAZ was postponed indefinitely.

The automotive community has even developed a kind of tradition - every year they go to Internet pages with news and video reviews dedicated to a potential new product and report that it has not yet appeared on the market. Some users even leave their comments “from the future,” assuring that in 2029 a GAZelle with an automatic transmission will remain just a dream or, at best, a plan.

As for the implementation of plans and the present time, at the beginning of September 2021, the International Exhibition of Commercial Transport “ComTrans-2021” took place in Moscow. The exhibition, considered the largest event of this nature in Russia and Eastern Europe, opened its doors to an interested audience and business and for several days demonstrated to the public various models of trucks, buses, special equipment and trailers, as well as a wide range of suitable components, spare parts, equipment and supplies for repairs.

GAZ Group did not ignore this major event and presented its own stand at the exhibition, where it presented many upcoming new products. Among the innovations shown were automatic transmissions, but exclusively for city buses and medium-duty trucks.

The automatic transmission, albeit only in its demonstration, pre-conveyor form, has been installed on such vehicles as the mid-class buses CityMax 9, CityMax 12, Vector Next and LiAZ-4292, as well as trucks that are extremely popular in their segment. GAZon Next" and "Sadko Next". The GAZelle we are interested in, despite a long-standing public request, was left without any high-profile announcements.

CEO and President Vadim Sorokin commented on this choice as follows:

“The creation of an automatic variable transmission allows us to better solve the problems associated with intercity transportation. Therefore, today we present to you “Sadko Next”, which, in my opinion, is the great-grandson of the famous GAZ-66 car. Initially, we planned to update the line of models for traditional buyers, but we saw that this model turned out to be so popular and interesting that it came into the focus of attention of private companies involved in off-road tourism. We saw interest in this vehicle from hunters and fishermen, wealthy people who need to transport boats and other equipment.

They are already accustomed to a certain level of comfort and want everything in life to correspond to it. We were so fed up with the constant question, “Will this car be built with an automatic transmission?” that we said, “Yes,” and did it.

As for the GAZelle Next... I remember 2015, when I drove around Strasbourg in this car with an automatic transmission from Punch and, together with other specialists, compared its behavior on the road with a Mercedez-Benz. The only difference that our German colleagues could find was that our all-wheel drive car was better.

But we need to understand who our client is. These are not only large carriers, but also private owners, family businesses with a small fleet of 5-10 cars. The key point for them is the cost of the car, and automatic transmission increases fuel consumption, and therefore financial costs.

We had two options: either produce a less efficient and expensive car, or concentrate on reducing the cost. We chose the second path - and began to refine the Gazelle Next with a two-liter engine and a six-speed manual transmission as the most popular option on the market.”

It turns out that the GAZelle Next family is not yet counting on an automatic?

The only change implemented by manufacturers in recent years is the aforementioned replacement of the five-speed manual gearbox with a six-speed one that is also manual. This model has been available since last year on the GAZon Next and Sadko Next models, and since this year on the Valdai Next, GAZelle NN and Sobol NN models. The need to strengthen the gearbox has been brewing for a long time, but although the replacement can reduce fuel consumption in the city and on the highway, as well as increase the service life of the engine, it will not solve problems related to safety and comfort, and therefore fundamentally important for passenger commercial transportation.

Thus, the company is not going to switch the Gazelle Next to an automatic transmission in the near future. And this is despite the fact that last spring the manufacturers registered with the Federal Institute of Industrial Property all the documents necessary to automate the GAZelle Next, and at one of their factories they opened a new section - specifically for the production of automatic transmissions.

It is at this site that automatic transmissions are currently being developed, produced and tested for those cars, samples of which the GAZ Group presented to the international community at the September exhibition.

For GAZelle Next, instead of independent production, import intervention was planned: initially, according to plans from 2017 and documents from 2022, the long-awaited six-speed automatic transmission for GAZelle was to be produced by the French company Punch. Apparently, Western economic sanctions have pushed back and continue to push back this opportunity, or the company simply does not see public demand and interest among domestic consumers.

The only alternatives are buying imported models that have all the required characteristics, accepting existing realities, or a new expectation. We hope that, contrary to the ironic comments of Russian drivers, not until 2029!

If you find an error, please select a piece of text and press Ctrl+Enter.