VAZ 2114 engines are equipped with mass air flow sensors (MAF). The VAZ 2114 MAF sensor is one of the ECM (electronic engine control system) sensors of a VAZ car with a fuel injection system.

This device is designed to determine the amount of air required to prepare the fuel mixture. In other words, the sensor “counts” the amount of air entering the cylinders during operation of the vehicle’s internal combustion engine.

Of course, if the sensor fails or does not work correctly, mixture formation is disrupted and the engine runs intermittently. Next, using the VAZ 2114 as an example, we will analyze in more detail what the specified sensor is, what malfunctions of the mass flow sensor are, how diagnostics and repairs are carried out.

Mass air flow sensor VAZ 2114

- Amount of air consumed;

- Reaction time.

The accuracy of measuring the air consumption of the engine allows the controller to determine in what proportion it is necessary to mix air with fuel. If the sensor produces incorrect values, the resulting air-fuel mixture does not correspond to the current engine operating mode. This leads to a decrease in power, an increase in fuel consumption, and a deterioration in the dynamics and response of the car. The response of controllers from different manufacturers to these parameters may differ.

For example, January-5.1, in case of slight overestimation or underestimation of values, determines the error of the mass air flow sensor based on the readings of the oxygen sensor, thus adjusting the duration of fuel injection. Increasing the sensor response time will cause the controller to not keep up, and at the time of acceleration you will notice “dips” of the engine. The same sensor error when using a more sensitive Bosch controller will lead to floating idle speed, although there will be no noticeable dips during acceleration.

Purpose and principle of operation

Many car owners are concerned about how much it costs to purchase such a sensor. It turns out that the DMRV 2114 has a considerable cost, it varies between 2-3 thousand. In this case, you can use both imported products and domestically produced parts. You shouldn’t be surprised that there are corresponding reviews about domestic models.

But you shouldn’t always trust reviews; it’s better to try the products in practice. Although you can find a lot of negative reviews about domestic sensors, they are more affordable.

This sensor allows the engine to operate in different operating modes, involving different loads. If we consider the operation of the device, it consists in creating a working mixture of air and gasoline. More precisely, the mixture includes gasoline vapors. The direct task of the product is to measure two indicators that are interconnected:

- Reaction time.

- The amount of air that is consumed for the reaction.

If the measurements are accurate, the device can determine what mixture the engine requires. This allows the system to obtain information about the required proportions. There are also situations when the sensor does not work correctly, producing incorrect values.

In this case, the mixture created in the system will not correspond to the current operating mode. As a result, power may decrease and consumption will likely increase. Among the possible consequences may be a deterioration in the dynamics of the car and a disruption in the response of the car.

Attention! The response of parts from different manufacturers may vary significantly. It is important to take this point into account when checking the operation of the sensor.

What air flow should be on a VAZ 2114?

A 1.5 liter VAZ 2114 engine with a working mass air flow sensor at 850-950 rpm consumes from 10±0.5 kg of air per hour of operation, and at 2000 rpm - from 19 kg to 21 kg. If the amount of air consumed at the same speed decreases, the dynamics of the car also decreases, but fuel is saved. Conversely, increased air consumption leads to increased dynamics and higher fuel consumption. In this case, it may be difficult to start the engine in cold weather. If the sensor readings deviate from the real ones by 2-4 kg, the engine will begin to become very capricious and “dull”. Disabling the sensor will force the motor to continue operating in emergency mode.

What does a faulty air flow sensor cause?

Operating an engine with an inoperative/faulty flow meter causes detonation of the fuel mixture in the combustion chamber. This affects the operation of the crank mechanism (crank mechanism) and destroys the piston surface, which can cause a “wedge” in the engine.

What indications should a working mass air flow sensor give?

The voltage of the analog-to-digital converter (ADC) of the flow meter when the engine is not running should be 0.996 V. Indicators of 1.016 and 1.025 V are acceptable, but if they reach more than 1.035 volts, it means that the sensing element of the mass air flow sensor is clogged.

We recommend: Chip tuning - what is it, advantages and disadvantages

It is important to know

To accurately determine the degree of deviation of the operating flow meter values from normal values, it is necessary to evaluate the engine operation at different speeds.

For example, for an injection 1.5-liter VAZ 2111 engine, if it is in good condition, at idle (860–920 rpm) the correct readings are 9.5–10 kg/hour, and at 2 thousand rpm - 19 –21 kg/hour. If the flow meter at 2 thousand rpm shows about 17–18 kg, then the car will drive stably. If the values are from 22 to 24 kg/hour, then the vehicle will move steadily, but the fuel consumption per 100 km will be approximately 10–11 liters. In addition, the car will have difficulty starting in cold weather due to fuel overflow when the engine warms up.

Causes of malfunction

Common to most domestic cars, the reason why the VAZ 2114 air flow sensor breaks is hidden in the crankcase ventilation system. It has two circuits that ensure operation with the throttle valve open or closed. If the throttle is buried, crankcase gases are discharged along the line (d=1.5 mm) into the space available behind it. A certain percentage of these gases accumulates in the idle line, where it comes into contact with the film-coated MAF resistor. It is also sensitive to fluctuations in the gas mixture in the intake system. The resin settles on the surface of the resistor, and the sensor begins to “lie.” Because of this, the idle air control sticks, and it begins to jam when starting the engine.

What's the result?

As you can see, if there are signs of problems and the first symptoms of the DMVR VAZ 2114 or another car appear, you should check the device as soon as possible for possible breakdown. In this case, you can quickly diagnose the air flow sensor with a multimeter in a regular garage.

We also recommend reading the article about what a car engine knock sensor is. From this article you will learn about the purpose, design, as well as signs of malfunction or malfunction of the engine knock sensor.

Based on the readings obtained from the device, it is possible to determine the malfunction (if a breakdown is confirmed) or to exclude the mass air flow sensor from the list of possible problem elements. One way or another, it is important to understand that this sensor is actively involved in mixture formation and affects the operation of the engine as a whole.

For this reason, it is necessary to perform regular checks of the ECM, scan for errors, and also pay attention to any failures and symptoms of malfunctions of the sensors of the electronic engine control system (TSP, DPKV, etc.).

Symptoms of a problem

A non-working VAZ 2114 mass air flow sensor leads to the appearance of a number of symptoms in the behavior of the injection engine. The malfunction appears gradually, starting with an increase in fuel consumption and floating speed, ultimately destabilizing engine operation.

From personal experience using a front-wheel drive car as an example, I can say that I encountered the following problem: first the injector icon came on, then the speed began to fluctuate greatly and fuel consumption almost doubled.

You can calculate a non-working VAZ 2114 air sensor using the following criteria:

- failures when idling and under load;

- The internal combustion engine stalls when trying to change gear;

- decreased dynamics, the car accelerates slowly;

- fuel consumption increased;

- engine power has dropped;

- Badly ;

- The Check Engine signal appears.

If the mass air flow sensor is already dead, the Check Engine light may not come on. Then the malfunction can be determined by the error generated by the on-board computer. Diagnostics of the MAF signal level will also help. A low level may indicate the following:

- There is no MAF connection;

- malfunction in the sensor connection circuit (break);

- the ground in the connection circuit is broken or oxidized;

- the signal wires are broken or incorrectly connected, perhaps they are short-circuited;

- engine control unit malfunction;

- DMRV does not work.

Sensor repair

Any electronic device has a huge disadvantage: sensitivity to the slightest power surges, pollution, aggressive environmental influences and many other factors. If even a tiny particle of dirt or dust gets into the air flow entering the engine, it will certainly settle on the sensor, which, being so vulnerable, attracts such troubles to itself like a magnet.

Continuing to work in this state, he is forced to increase the load, as dust ballast interferes with him. Consequently, it starts to fail. Also, if low-quality oil or bad gasoline is poured into the engine, all this first of all has a very negative impact on the electronic device. That is why it is so important to pay attention to air, oil and other filters and not to skimp on the quality of fuels and lubricants poured into the engine.

Having made sure that the VAZ mass air flow sensor is faulty, we move on to the next stage - repair. Repair consists of a good cleaning. But how is the mass air flow sensor cleaned and is it possible to do this work with your own hands? To begin with, you should remember, like a multiplication table, that in no case should you use the following for flushing:

For cleaning, use carburetor cleaning fluid. The most popular in this matter is WD 40, which has good technical properties and is safe for electronic devices. You need to wash the sensor carefully so as not to damage the thinnest plates and wiring.

After making sure that there is no more dust or debris in the device, you can, after thoroughly drying it, install it in place. As a rule, after such a simple procedure, the device should work like a good Swiss watch. We have discussed the most frequently asked questions regarding the mass air flow sensor. Now you know why it breaks, what needs to be done to protect it, and what to do if it suddenly malfunctions. We wish you good luck on the roads and good mood!

Checking the mass air flow sensor

Before you start experimenting, take the time to read the service manual. It describes in detail what a mass air flow sensor on a VAZ 2114 is and how to replace it.

We are looking for a sensor. Open the hood and find the air filter pipe. The mass air flow sensor is located on it, which determines the flow of air passing through the filter. I will give several options on how to check the mass air flow sensor yourself.

- Disable the sensor. Disconnect the block with wires from the connector by pressing the latch located below. Start the engine (1500 rpm or more). The controller understands the shutdown of the mass air flow sensor as an emergency condition and prepares the fuel-air mixture based on the position of the throttle valve. Try driving a short distance. If the car accelerates noticeably faster, this indicates a non-working mass air flow sensor. I would like to note that in the disabled state for ECUs Y7.2 and M7.9.7. RPM doesn't increase!

- Replacing the controller firmware. The original ECU firmware could have been replaced with an alternative one. In such a situation, we do not know which algorithm is prescribed in the case of operation in the mode discussed in the first paragraph. The throttle valve has a stop under which you need to place a thin plate (about 1 mm) to raise the speed. Then you need to disconnect the chip with the sensor. If the sensor is faulty, the engine should stall. If the engine is running, then the reason is due to the firmware features: the IAC steps are written incorrectly.

- Voltage measurement. Testing gives good results when working with Bosch sensors. You will need a multimeter. Select the DC voltage measurement mode and set the maximum value to 2 V.

The connection diagram for the VAZ 2114 looks like this:

- yellow – incoming signal;

- gray with white – power output;

- green – grounding;

- pink with black – output to the main relay.

The colors may be different, but the sequence of connectors is the same.

Next, you need to turn on the ignition with the engine off. Connect the red (positive) probe of the tester to the yellow output, and the black (negative) probe to the green. Multimeter probes are inserted along the specified wires directly through the rubber seals of the connectors without damaging the insulation. For prevention, I recommend moistening the probes with WD-40. Intermediates or needles are not recommended due to the additional error they introduce. Measure the voltage. Compare the result with the table:

| Voltage, V | State |

| 1,01 – 1,02 | Good. The sensor is almost new and will last a long time. |

| 1,02 – 1,03 | Satisfactory. The sensor is old, but works properly. |

| 1,03 – 1,04 | Bad. The resource is almost exhausted. Will have to replace it soon. |

| 1,04 – 1,05 | Deplorable. The resource has been exhausted. Suitable for use if there are no alarming symptoms. It is advisable to replace |

| 1.05 – and above | Emergency. The sensor is faulty (possibly for a long time). Replacement is required. |

A newly installed sensor gives an output voltage of 0.996–1.01 V. Over time, it increases. A higher value means a higher percentage of wear.

Voltage data from the sensors is recorded by the on-board computer and can be viewed by selecting the appropriate group of parameters.

- Inspection and cleaning. Use a Phillips screwdriver to loosen the clamp holding the air intake pipe. We remove the corrugation and check whether there are traces of oil and/or condensation inside it, as well as on the inner surface of the sensor. Normally they shouldn't be there. The sensing element of the mass air flow sensor often breaks due to dirt getting on it. This can easily be avoided by regularly replacing the air filter. Reasons for oil getting into the air flow sensor:

- the permissible oil level in the crankcase has been exceeded

- The oil separator of the ventilation system is clogged

Symptoms and troubleshooting

Since the mass air flow sensor is electronic equipment, and a very complicated one at that, most car owners do not dare diagnose it themselves and take it to a car service center the old fashioned way. But quite often, having just connected the diagnostic device to the sensor, the auto repairman declares that the device is completely faulty, it cannot be repaired, and its place is only in a landfill. Rest assured, if you bring in a completely new sensor, the technician will tell you the same thing.

But any disinterested expert will say that the mass air flow sensor is an almost indestructible device. It may malfunction, sometimes seriously, but this is a completely fixable problem, something that will take no more than an hour. But how to check the mass air flow sensor for performance? Very simple. If, after installing a new sensor on your car, you notice that it works perfectly, then that is where the problem lies. If the situation has not improved at all, then there is no point in wasting your energy, time and money on the empty hassle of replacing a completely “healthy” sensor.

Just above we mentioned such a device as a multimeter. You can understand whether the sensor is working or not by finding out the voltage of the device. If everything is normal, then the multimeter produces 1-1.2 W. If there are any problems, then the scale goes down, the critical mark starts at 0.99 W. If, on the contrary, the voltage is higher than normal, for example 1.037, then this indicates one thing: the sensor is very clogged, and therefore makes errors in the readings. If you clean it, it will work again at the same rate.

First of all, this is a sharp increase in fuel consumption. Here you should not blame the car for its large “appetites”: it is not to blame, and the manufacturer is not to blame, here you just need to “treat” your “iron horse”. Of course, this can happen not only in the case of a sensor failure, but from this fact alone you can come to the right idea: most likely the problem lies in the tiny device.

Also, when the engine loses power, a hot engine will stop starting. The car, previously dynamic and controllable, turns into some kind of monster on wheels, which is constantly lost in control and “freezes”. And finally, if you see a simple Check Engine sign on the instrument panel, then there can be no doubt: this sensor is asking you for an ambulance.

DMRV of VAZ 2114 car

VAZ 2114 cars were equipped with several types of engines: 8 valves of 1.5 liters and 1.6 liters, as well as 16 valves of 1.6 liters. Until 2005, January 5 series ECUs were installed on the motors, then the manufacturer updated the controllers. Since 2006, these machines have been equipped with a January 7 series ECU, or imported analogues of BOSCH 7.9.7. Why do you need this information? Depending on the version of the ECU, mass air flow sensors on the VAZ 2114 were of different types. This causes some difficulties when replacing the sensor, but detailed information can be found in the car's passport.

- Air flow sensors of the 004 series were installed on early versions of cars.

- Then an updated mass air flow sensor was introduced for the VAZ 2114, series 037. The measuring channel on it was modified to reduce air flow pulsations. The new flow meter with modified characteristics is fully compatible with old ECUs with an oxygen sensor, so the replacement did not lead to changes in calibrations in the fuel-air mixture formation system.

- After switching to the January 7 series and BOSCH 7.9.7 controllers, we also had to change the air flow sensor on the VAZ 2114. The new version with index 116 is produced with an updated design. The calibration of the sensor has also been updated, so there is no backward compatibility.

The BOSCH 116 air sensor has many analogues, including the Russian Itelma and Avtel.

Information: There is an opinion among VAZ 2114 owners that the air flow sensor of the 116 series is better than the 037, and it can be replaced to increase engine output. In fact, this is not the case; the calibration of the mass air flow sensor is developed for a specific motor and is taken into account when programming the ECU.

As an example, the graph in the illustration:

Obviously, when the air flow rate is more than 100 kg per hour, the voltage that the VAZ 2114 series 116 air sensor produces changes by 0.2 volts. When the data is read by the engine controller, this makes a significant correction in the proportions of the fuel mixture.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

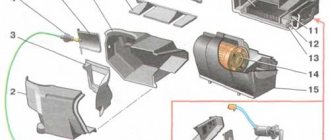

DMRV operation diagram

Sensor pinout:

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

- if the sensor is in good condition, the voltage is from 1.01 to 1.02 V;

- in satisfactory condition - from 1.02 to 1.03 V;

- the sensor resource ends if the voltage is in the range from 1.03 to 1.04 V;

- a value in the range from 1.04 to 1.05 indicates a near-death state; if there are no contraindications, then you can continue to use the sensor;

- if the voltage exceeds 1.05 V, the mass air flow sensor requires replacement.

ADC flow meter readings

Diagnostics of the mass air flow sensor "Tseshkoy" is not difficult and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

We recommend: Cooling system for VAZ 2109 and 21099 (carburetor and injector): design and principle of operation, replacing the radiator with your own hands

They need to be sprayed with cleaning agent and washed. Then let the liquid dry. If dirt remains, the procedure should be repeated. You need to clean the pipe with the same product. It must be free of dirt and oil stains. After replacing the air filter, all parts must be returned to their place. After the cleaning procedure, the functionality of the device can be restored to 80%, the error about the reduced sensor signal level disappears (the author of the video is “24 hours”).

Flushing the sensor will help avoid costly repairs.

Method number 6 - checking with a scanner

Test method:

- Install a diagnostic program on your phone (smartphone), tablet or laptop computer (for example, Torque Pro, Opendiag, BMWhat, OBD Auto Doctor).

- Connect your mobile device or laptop to the diagnostic connector located on the vehicle's electronic control unit using a special cable, Bluetooth channel.

- Launch the diagnostic utility on your phone (smartphone) or computer.

- Wait until the program finishes scanning all vehicle components. As a result, the utility will check the serviceability of each vehicle unit.

- Decipher the error codes that the program will show after the diagnostics are completed.

To perform this method, testers are used:

- K-Line 409/1;

- Scanmatic;

- ELM (ELM) 327;

- OP-COM.

Method No. 7 - checking by Vasya the Diagnosticist

To identify a malfunction of the mass air flow sensor without removing it from the car, you need to:

- Install a program called “VASYA diagnostician” on your laptop (laptop) and run it.

- Connect the adapter to the vehicle's diagnostic port.

- Select the item “Electronics 1” or “01 – Engine electronics” from the “Control unit” tabs to connect to the vehicle’s control unit.

- Go to “Custom Groups”.

- Select 211, 212 (passport value) and 213 (current value).

- Compare current indicators with passport data. If the deviations are high, then it is necessary to replace the mass air flow sensor.

Method No. 8 - using a motor tester

Good to know

This method is used to test frequency-type flowmeters.

To check the mass air flow sensor with a motor tester (oscilloscope), you need to connect it to the sensor (depending on the car brand) and start the engine.

Mass air flow sensor check parameters:

- transient time when the ignition is on;

- air consumption readings at idle and a sharp increase in engine speed;

- voltage in the sensor network.

It is important to know

The output data is individual for different types of engines. Before diagnosis, you should check the current indications with an official representative.

How does the VAZ 2114 mass air flow sensor work?

A modern mass air flow sensor (also known as MAF in English) uses sensitive sensors and a special calculation algorithm to compare the resistance readings of two thermistors. One of them is a reference value, its value is constant. The second (made of platinum-iridium wire) is forcibly heated. The incoming air flow cools the wire, the resistance changes, and to equalize it with the reference, a larger heating current is required. It is the difference in current strength (in this design, voltage is measured using the Ohm's Law formula) that provides information to the ECU.

The measurement accuracy is 1/100 volt, so the slightest malfunction of the mass air flow sensor instantly affects the quality of engine operation.

Removal and replacement

If the VAZ 2114 air sensor was checked, and the check confirmed incorrect operation, then you should think about replacing it. Experts do not advise rushing to throw away a part, even if it is not working correctly. Sometimes it happens that after cleaning the contacts it starts working again. It is worth paying attention to this possibility if you would not like to replace the part.

When it is not possible to revive an existing part, you should go shopping. A new part will not be cheap, it is an expensive pleasure. That is why experienced technicians advise initially checking the functionality of the old sensor before spending your savings. To replace the product, you will need to prepare a flat-head screwdriver, as well as a 10mm wrench.

The sequence of actions should be as follows:

- Initially, the ignition is turned off, the hood is opened, and the negative terminal is removed from the battery.

- Now you have to determine where exactly the sensor is located. Usually there are no difficulties with its location. In the engine compartment you can see the air filter unit; it is made of plastic. This sensor is located on its rear part; it is usually mounted on the air filter pipe.

- Next, the clamp made of metal is removed and the product is connected to a corrugated hose through which air is supplied.

- You will need to pull off the corrugated hose.

- Next, the contact block is removed, and it should be taken into account that there is a button on the bottom of the plug. When pressed, the spring wedge is released. This is necessary to freely pull out the block.

- A pre-prepared 10mm wrench is needed to unscrew the bolts one by one; they are used for fixing. By the way, the second of them is located on the lower part of the case.

- All that remains is to remove the sensor.

VAZ 2114 signs of flow meter malfunction

In addition to the indicator light on the Check Engine, there are symptoms that even an inexperienced driver will notice:

- Unstable engine operation at idle speed: the malfunction manifests itself most clearly when the engine is not warmed up. After starting, the revs fluctuate, and when the accelerator pedal is pressed sharply, the engine stalls.

- With a sharp release of gas, the speed does not decrease, but remains at around 2-3 thousand for some time.

- Even with a warm engine, there is a noticeable decrease in power. When fully loaded, a lower gear is required; the car does not pull uphill and accelerates slowly on the highway.

How to independently check the VAZ 2114 MAF sensor the “old-fashioned way”? The technique is as follows:

- you need to remember the sensations of the engine running on a familiar route with different modes: uphill, acceleration, etc.;

- turn off the engine, remove the negative terminal from the battery and disconnect the mass flow sensor connector located on the side of the brake fluid reservoir;

- start the engine and travel along the same route.

If the engine behavior has noticeably worsened, then the failure is not related to the flow meter. If you do not feel the difference, that is, the motor works the same with and without the sensor, then an in-depth check of the mass air flow sensor is required.

Diagnosis of failure

If the air flow sensor breaks down, the symptoms of the malfunction can be very different. First of all, fuel consumption will increase; another symptom may be floating engine speed.

In addition to these signs of failure, the following can be identified:

- failures in the operation of the power unit;

- slower car acceleration, poor dynamics;

- the power unit can turn off when changing gears;

- decrease in power and increase in gasoline consumption;

- a heated internal combustion engine is more difficult to start;

- the Check light appears on the control panel.

The last symptom may not appear if the controller fails completely. How to check the MAF on your own? Diagnostics consists of identifying the impulse.

If the impulse is low, this indicates:

- possible short circuit or broken wiring;

- regulator failure;

- incorrect operation of the ECU;

- oxidation of contacts;

- that the controller is not connected.

Clogged air flow regulator

How to check the MAF sensor on a VAZ

The most reliable way is to use a diagnostic scanner (at least at the ELM-327 level). We connect to the OBD port and look at the flow meter performance indicators on the computer.

If you don’t have a scanner, you can take the basic parameters with a multimeter. To diagnose and repair the VAZ 2114 mass air flow sensor with your own hands, you need to know the pinout of the contacts.

For example, consider a contact block for a VAZ 2114: a modern 8 or 16 valve engine, BOSCH mass air flow sensor (or its equivalent) version 116.

- We don't need contact No. 1; this is an air temperature sensor.

- Contact No. 2 - 12 volt power supply. If the on-board voltage regulator malfunctions, the air flow sensor may malfunction.

- Contact No. 3 - ground.

- Contact No. 4 - power supply for the mass air flow sensor electronics, an important parameter, the voltage must be stable.

- Contact No. 5 is the same “floating” voltage with which the ECU calculates the volume of air passing through the intake manifold.

The supply voltage is checked with the block disconnected. We turn the ignition key, but do not start the engine. With respect to ground, we measure the voltage at contact No. 2 (12 volts) and contact No. 4 (5 volts). This indicates the serviceability of the ECU and the integrity of the wires and contacts.

Checking the signal voltage on pin No. 5 is carried out with the connector connected, with the ignition on (do not start the engine!).

- voltage is within 0.99-1.02 volts - the sensor is working;

- voltage within 1.03-1.05 volts - replacement will be required soon;

- more than 1.05 volts - the mass air flow sensor does not operate normally.

Measuring voltage in the sensor

When repairing the mass air flow sensor in a VAZ 2110 with your own hands, you need to check the device using a special diagnostic device. If this is not possible, use a regular voltmeter. The scale should allow you to measure voltage with an accuracy of 0.01 volts. Measurements are taken between the sensor input and ground. The input is indicated by a yellow wire, and ground is usually indicated by a green wire. The optimal value is a voltage in the range from 0.99 to 1.01 V. If the mark shows a value higher, it’s time to repair the mass air flow sensor. To clean the sensor, you must first remove the unit mount. The factory fasteners look rather tricky; it makes sense to replace them with standard ones and a regular screwdriver.

The solvent will be carburetor cleaner. This is also convenient because the tube of the aerosol can fits perfectly into the resistor channel. We clean the resistor in several passes. Important: do not use matches, toothpicks, sharp sticks, or elegant rollers. Even a jet of compressed air can cause harm. After assembly, check the voltage again. If it is in the desired range, then the repair was successful.

Prevention of breakdowns and cleaning of the air flow sensor of the VAZ 2114

The flow meter sensor is located in a vulnerable place: exposure to temperature changes, moisture, dust.

Precision electronics located in the measuring channel fail when foreign objects enter.

- untimely replacement of the air filter;

- the use of so-called “zero” filters;

- loose connection of the mass air flow sensor with the air duct flanges;

- moisture entering the air intake;

- Debris left in the ductwork or filter housing after repairs and maintenance.

How to clean the mass air flow sensor if contamination does not render it inoperable

The sensor must be removed, the protective nets removed, and blown with clean compressed air. If there is dried dirt or oil stains, washing with special means for mass air flow sensor is required. Of course, it is necessary to clean the air duct itself with the filter housing.

In most cases, such prevention brings the flow meter back to life.

Cleaning instructions

As practice shows, cleaning the mass air flow sensor is one of the most effective methods of restoring the functionality of the controller. Therefore, if the sensor breaks down, it is not necessary to change it, especially since such a pleasure today is not cheap. This procedure is necessary because over time it becomes dirty and shows other parameters.

So, how to clean the mass air flow sensor at home with your own hands:

- You will need a Phillips head screwdriver; use it to loosen the clamp securing the line from the air intake.

- Next, dismantle the corrugation and visually assess the condition of the system. You may see condensation or traces of engine fluid under the corrugation.

- Carefully inspect the inside of the controller. If everything is normal with the system, then there will be no traces of leaks or contamination. As practice shows, the sensitive element often breaks precisely due to an excess of contamination. In order not to avoid problems of this kind in the future, it is necessary to periodically replace the air filter. This procedure is carried out in accordance with technical regulations. Engine fluid may enter the controller as a result of an increased level of consumables in the crankcase. Accordingly, this occurs as a result of a clogged oil separator in the ventilation system.

- The regulator itself is fixed with two bolts on the line. The removal procedure is carried out using an open-end wrench. At this stage, if you are sure that the device has failed, you can replace it.

- You can see the entrance on which there will be a sealing rubber band designed to protect the device from the suction of dirty air flow. If you do not have a seal, it may have caught on the filter element. Accordingly, this will lead to the regulator input grid being contaminated.

- Clean the mesh using available materials. To do this, you can use a regular toothpick or toothbrush. After cleaning, the seal can be put back and the regulator can be put back in place.

Necessary tools and spare parts

Before starting work, you should clarify which part number is stamped on the body of the old mass air flow sensor. Different sensor options were installed on different 2114 engines. Two types of article numbers are common - 037 or 116 . Getting to the room without dismantling the case is problematic.

After determining the part number, you can begin preparing the tools and spare parts that will be useful for replacement:

- A flat or Phillips screwdriver for removing the air filter housing;

- New metal clamps (in case of breakage or wear of the old fastening);

- Spanners for unscrewing fastening nuts;

- A working mass air flow sensor to check changes (as soon as you are sure that there is a problem with it, purchase a new one).

Checking with a multimeter

Of the entire list of sensors in a car, the DMRV is the most expensive. Its cost in auto parts stores reaches 3000-4000 rubles. There is also a possibility of purchasing a counterfeit or inappropriate spare part model. Before the replacement procedure, you should make sure that the element gives the correct readings on the multimeter. A step-by-step check of the sensor using a multimeter looks like this:

- To begin, set the multimeter to DC measurement mode (readings up to 20 V);

- Use a red probe to connect to contact number 5, and connect a black probe to the third contact;

- Without starting the engine, turn the ignition key to the last position.

For a convenient interpretation of the readings from the multimeter, we will provide a complete table of voltage showing the wear of the part.

This element is quite sensitive to dirt, oil and other debris. To prevent its early failure, you should change the air filter more often and monitor the wear of the engine piston group. When there is a lot of wear, oil begins to seep into the intake system, which makes it impossible to take accurate readings of the incoming air. You can change the mass air flow sensor yourself in a matter of minutes, so there is no need to rush and purchase a new part. Often the problem with floating speed and periodic engine shutdown at idle lies in other malfunctions. Make sure the wiring is intact, the readings are correct, and only then proceed to replacing the element. Below we present the air volume indicators that correspond to the normal operation of the 2114 engine.