VAZ-2114 is an improved version of the “nine”. Almost the same engines were installed on this Lada. However, the main difference is the fuel injection. In the 14th Lada they completely moved away from the old carburetors. However, the new system required new sensors. In order for the motor to work properly, the design contains dozens of sensors. They read the signals and transmit them to the electronic unit. Among such signals, it is worth noting the coolant temperature, oil pressure, CO concentration in the exhaust gases, crankshaft position and air flow.

But there is one more element, without which stable operation of the engine is impossible. This is a VAZ-2114 throttle position sensor (abbreviated TPS). What is this element, why does it fail and how to check it? Let's look at it in our article today.

Characteristic

TPS is a device that serves to convert the angular position of the air damper into direct current. This element is installed on all cars with fuel injection. Information from the sensor about the state of the bypass valve goes to the manifold. The TPS itself can be of different types - film or magnetic (non-contact). It is designed in the same way as an air valve. When the element is open, the pressure in the system is similar to atmospheric pressure. But as soon as the part is closed, the pressure inside decreases - a vacuum is formed.

The VAZ-2114 electronic throttle position sensor has a variable and constant resistor in its design. The resistance of both is about eight ohms. But the output voltage can change. This indicator depends on the position of the throttle valve itself. These processes are also monitored by a special controller. Depending on the signals received from the TPS, the system regulates the amount of air and fuel concentration in the mixture. If the slightest malfunction of the throttle position sensor occurs, the VAZ-2114 will not work correctly. The engine will receive too much fuel. In both cases, the motor suffers significant loads, and the elasticity of its operation is lost.

Purpose, principle of operation and typical malfunctions of the XX sensor

Such an idle speed sensor, the price of which does not amount to a large amount of money, contains 2 main critical components: a bipolar stepper EDC and a cone-section valve, which are combined with each other. The valve moves (extend or retract) according to commands from the electronic control unit, while the cross-section for the passage of the air mixture changes depending on the direction of movement of the valve needle.

If the idle speed sensor needle is extended as far forward as possible, which corresponds to the zero value of the step indicator, then the mixture does not enter the air line of the fuel system. If the needle is retracted, an air flow is transmitted into the fuel system, directly proportional to the degree of opening of the needle and its distance from the valve seat.

Our Internet resource contains a photo of the Lada Priora idle speed sensor so that an inexperienced car enthusiast has an idea of the appearance and location of this device in the power compartment of the car.

The defects of the Lada Priora idle speed sensor include the following facts:

- unstable operation of the power plant at idle speed;

- spontaneous increase or decrease in engine power;

- failure of the unit to operate when the speed is turned off;

- absence of increased speed when starting the engine “cold”;

- drop in idle speed when additional electrical equipment of the vehicle is turned on.

If during operation of the vehicle you hear interruptions in the operation of the power plant in idle mode, then it is necessary to check the idle speed sensor of the Priora car to identify a specific defect.

In the Lada Priora, the idle speed sensor is an actuator-type device that is not integrated into the on-board circuit of the vehicle's ECU. Therefore, it is impossible to diagnose this gadget using an on-board computer. In this regard, if the VAZ Priora idle speed sensor is defective, the “CHECK ENGINE” banner is not displayed on the instrument panel.

However, the symptoms of defects in the idle speed sensor are similar to the symptoms of defects in another sensor - the positioning of the throttle valve, the defects of which are precisely indicated by the error banner in the propulsion system. The way to check the idle speed sensor, familiar to most Russian car enthusiasts, is as follows:

- Shut down the power plant.

- Disconnect the terminal block from the idle speed sensor.

- Using a multimeter, measure the resistance values of the sensor windings, which between connectors A and B, and C and D should be 40-80 Ohms. When measuring resistance values between connectors B and C, A and D, the electronic measuring device should signal an open circuit (show the “infinity” value). With such parameters of the electrical circuit, the device is classified as a serviceable element.

In the Lada Priora, there is little point in testing the idle speed sensor with a standard multimeter. Measuring the resistance values of the winding contacts will help little in finding the defect, because the main problem of such gadgets is the coking of the needle contact, which because of this gives incorrect readings. It is very expensive to purchase a tester for this procedure, so it is suggested to use improvised means from which you can make a homemade tester.

The basis of the electronic measuring device can be a transformer with an output voltage of 6 Volts AC (a component from a mobile phone charger is suitable). If the idle speed sensor is working properly with a voltage of 6 V and a current of 0.6 A, the light bulb should produce a weak light, and if there is a defect (sticking of the rod), the glow will be quite bright.

Signs

There are several symptoms that indicate a malfunction of this element:

- High idle speed. Also, a similar malfunction occurs when the XX regulator is not working. In both cases, the damper opens to a much larger angle. Because of this, a lot of oxygen enters the chamber. And the more air, the faster the mixture will burn. Accordingly, because of this, turnover increases uncontrollably.

- Reduced engine power. This may occur due to improper preparation of the working mixture. It contains more oxygen than it should. As a result, the motor does not have enough energy to produce torque. Along with this, the acceleration dynamics of the car drop noticeably.

- Jerks when pressing the accelerator pedal. The essence of the problem is simple - when you press the gas, more air enters the cylinders. And since its concentration is already higher than normal, dips are observed and the engine cannot reach normal speed while moving.

- Spontaneous engine shutdown while driving. This also occurs due to the high concentration of air. There is not enough fuel in the combustion chamber to produce the piston stroke. Because of this, the engine troits and simply stalls.

РџРѕСЂСЏРґРѕРє замены ЂПЋЗ РЅР° РџСЂРёРѕСЂРµ SЃР°РјРѕСЃС‚оятельно

Прежде S‡РµРј начинать данный ремонт, необходимо SѓР±РµР ґРёС‚СЊСЃСЏ РІ том, что отсутст вует пЃтанке РЅР° колодке жгута датчика. Лучше всего полностью отключить RїРѕ‚ание автомобиля, отсоединив клемму “-” РѕС‚ Р° ккумуляторной батареи.

валее необходимо отсоединить S€S‚екер РѕС‚ ДПлЗ, как этР* наглядно показано РЅР ° фото ниже, предвароотельно немного отжав фиксато SЂ RІРІРµСЂС….

Теперь РїСЂРё помощи крестовой отвертки отворачиваем РґРІР° РІРента крепления датчика Рє дроссельному SѓР·Р»Сѓ. Приведенная картинка РЅРеже РІСЃРµ демонстрирует РЅР°РіР»С ЏРґРСРѕ.

R”аДее вынимаем R”ПДЗ, РЅРµ RїСЂРёРєР»Р°РґС‹РІР°СЏ R±RѕR»СЊС€РёС… усилий.

Обратите вниманве, что РІ месте SѓСЃС‚ановви данного Рґ атчРеРєР° находится SЃРїРµС†Реальное поролоновое кольцо (прокладка), которое должРЅРѕ быть S†РµР»С‹Рј Рё невредимым. РџСЂРё SѓСЃС‚ановке РЅРѕРІРѕРіРѕ датчика еще SЂР°Р· РІ этом SѓР±РµРґРёС‚Р µSЃСЊ.

Замена ДПДЗ осуществляется РІ обратной последовательности, Рё сложности РїСЂРё выполнении ремонта РІСЂСЏРґ лвозникнет. " Рё, чтобы купить S‚акой же.

Causes

Previously, we looked at the reasons for the incorrect operation of the power unit. As you can see, failures occur due to incorrect air concentration in the mixture.

But for what reasons does the throttle position sensor itself fail on a VAZ-2114? Among the causes of TPS malfunctions, the following should be highlighted:

- Burnt contacts. When the damper opens, the moving contact of the sensor begins to move, contacting the resistive field. With prolonged use, the field is destroyed and contact disappears. The signal can no longer be transmitted to the controller, causing the system to not operate normally.

- Oxidation of contacts. And if in the first case they cannot be restored, then in this situation you can try to return the sensor to functionality. So, to restore oxidized contacts, spray VD-40 lubricant into the block and into the space under the cover. This lubricant contains anti-corrosion additives that eat away rust. In half the cases, this helps bring the sensor back to life.

- Wear of the TPS substrate. However, it is present in the design only if a special coating consisting of a resistive layer is provided.

- Incomplete closing of the damper. In this case, you can file the seat of the VAZ-2114 throttle position sensor with a file, and the engine will work properly again.

Throttle Position Sensor Repair

You have decided to repair this sensor, for example, to fill a microcrack in one of the contacts with conductive glue. Theoretically, this is doable, but if the problem is in the resistive layer, then it is impossible to restore it.

One of the options for extending the life of the unit is cleaning and flushing. Gasoline, WD40, and carburetor cleaning fluid are used for operation. Cleaning dirt from the outside is not difficult. But the assembly itself, its internal part, with its contaminated channels remains untouched. Therefore, it is necessary to completely disassemble and wash the part.

It is recommended to carry out this procedure periodically. Using cleaning sprays, a Phillips screwdriver, a throttle gasket (for a 1.5-liter engine), O-rings for the receiver (for a 1.6-liter engine), and keys, perform the following steps:

- We completely dismantle the module - remove the corrugation and the pipe channel from the filter. It is recommended to drain the antifreeze

- pull out the adsorber with the pipe (remove the fasteners of the unit, disconnect the cable from the accelerator, thereby removing the throttle valve)

- Having removed the unit, we disassemble it into components, first the meters - TPS and IAC. We clean it using WD40 or its equivalent, wash the damper on all sides, blow out the holes so that no moisture remains, and assemble the assembly in the sequence, but in reverse.

This is not at all difficult to do if there are no problems with disassembly. Gaskets and rings are replaced with “new” ones.

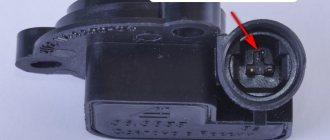

Diagnostics

You can do it yourself. However, checking the VAZ-2114 throttle position sensor should be carried out using a special device - a multimeter. It needs to be switched to voltage measurement mode and connected to ground. The red probe should be connected to the positive terminal “A”. It is located on the housing of the TPS connector. Please note that measurements are taken with the ignition on. Otherwise the value will always be zero. Turning on the ignition, look at the results. The voltage at the terminal should be five volts. A slight error of around 0.3 V is allowed. If the voltage is less than 4.7 V, the element is faulty and must be replaced.

If the multimeter shows zero when the ignition is on, there may be an open circuit and the voltage simply does not reach the sensor. But if everything is in order with the wires, then the VAZ-2114 throttle position sensor controller itself has failed. Signs of its malfunction are a complete absence of voltage at the TPS terminals.

Design

The sensor is a simple electrical component – a resistor. When the sensor axis is rotated, the resistance in it changes. The sensor is put on the damper shaft and when it opens, the moving part of the sensor rotates along with the damper.

Due to its design, this sensor fails quite often. Its moving tracks fray and the contact disappears, thereby causing the sensor to malfunction.

There is another type of sensor without a mechanical part. Such a sensor has an electrical circuit inside it with a large number of different radio components.

The electronic type of TPS is devoid of mechanical “sores” and is not subject to rapid failure due to rubbing of the tracks.

Diagnostics: method No. 2

You can also check the operation of the element without disconnecting its connector. To do this you will need the same multimeter. We will use it to check the presence of voltage to the sensor. When the ignition is turned on, a smooth increase in voltage from 0.8 to 4 V will be noticeable at the terminals.

At the same time, you need to rotate the plastic sector of the air damper. The sensor connector must be connected. And the voltage is checked by piercing the wire with a multimeter probe.

Car service nuances

It's no secret that many car owners prefer repairs at service stations. There are many reasons for this.

If you need to clean your throttle body, you won't have to pay a lot of money for it. Today such a service costs about 500 rubles.

Which to choose?

Please note that the VAZ-2114 throttle position sensors cannot be repaired. This element changes entirely on the car. There are several:

- "ScheAvtoelektrika".

- "Omega".

The latter is installed on the Lada from the factory. It lasts long enough. When choosing, you need to pay attention to contactless elements. They cost about 600-900 rubles.

But they last a very long time, as noted by reviews. You should not buy resistive sensors. They are unreliable and quickly fail. As for the throttle position sensor of the VAZ-2114 “Kaluga” (the same “Autoelectric”), it is contactless and sells for a thousand rubles. Reviews about it are positive. The only drawback is the high price. But it is fully justified by the resource of this sensor model.

Types of TPS

There are several Russian manufacturers of this mechanism.

TPDZ Omega

- DPDZ "Omega" (Moscow);

- "Schetmash" (Kursk);

- non-contact TPD (Kaluga).

Often motorists install sensor number 1 – Omega – on the VAZ 2114. But the TPS from the VAZ manufacturer is film-resistor, sometimes they do not last very long and repeatedly cause problems for car owners.

Contactless units operate on the magnetic resistor effect, they are an order of magnitude more expensive than all previous options, and are famous for many years of uninterrupted service and high labor efficiency. Equipped with a rotor and starter inside. The first part is made of anti-magnetic material, and the second part is made of a sensitive magnetic field, which allows the mechanism to work for a long time without interruption.

Replacement

Changing this element is quite simple. You need to open the hood and determine the location of the sensor.

Next, use a screwdriver to press out the plastic latch and remove the block with wires. After this, unscrew the bolts securing the sensor to the throttle body. Along with the old TPS, the gasket is also removed. A new one made of foam rubber is installed in its place. Then the new sensor itself is mounted on it. It is secured with the same two bolts. It should be tightened tightly in order to eliminate unnecessary vibrations (from which the part may not work correctly). After this, we connect the block with wires and make the first start. The engine operation should stabilize.

Setting the throttle position sensor

Now it's time to configure the sensor. With the throttle open, we try to turn the device drive or pull the accelerator cable. If it doesn’t work, it means the sensor was installed incorrectly. We remove it again and mount it at a right angle to the damper axis. It is adjusted manually. Often the controller's memory retains the same data that does not allow the valve to open completely. Then you need to disconnect the battery terminals for a while or reset the settings on the on-board computer.

After the above actions, if the valve is open by at least one degree, then the TPS must be replaced. This will be the best decision.

Replacement is performed with the engine turned off. It is necessary to disconnect the negative terminal from the battery and the sensor clamp. Using a screwdriver, unscrew the two screws that secure the sensor to the throttle. The sensor has been removed.

Make sure that the throttle valve is closed. Don’t forget about the O-ring; as a rule, the “new” spare part comes with it. We put the ring on the throttle pipe, do not forget to remove the old one, tighten it with screws until it seals. All that remains is to connect the connector and secure it with a latch. To reset the old sensor parameters to the ECU, disconnect the battery terminals.