The automatic transmission that is installed on modern cars is a rather complex unit. For this reason, its service life will directly depend on the quality of service.

Moreover, like any other device, an automatic transmission also has a strength limit, especially taking into account a number of design features. This means that the automatic transmission, depending on the degree of wear and condition, eventually begins to malfunction or fails.

At the same time, it is important to pay attention to certain signs that allow you to identify certain automatic transmission problems in time, after which you can carry out the necessary repair and restoration work at the lowest possible cost.

Self-diagnosis

The automatic transmission may not shift gears due to a lack of oil in the machine. Therefore, I do not recommend rushing to go to a service center to solve this problem. First, conduct a self-diagnosis.

Kicks, jerks and drops

The speed does not turn on, the automatic transmission kicks and does not want to change gears, it stalls for one reason - oil starvation. A lack of oil appears when you don’t look inside the machine’s tank for a long time. Transmission fluid tends to thicken and evaporate if it is not changed in time and the level is not checked.

The following table shows the reason for frequent kicks and jerks of the machine when changing gears:

| Cause | Problem |

| Thick or thin oil, loss of transmission fluid properties | Effective transmission of torque to the wheels is lost, the automatic transmission changes gears slowly |

| Lack of pressure in the machine, stopping of the friction discs, clamping them due to chips stuck between the teeth | Thoughtfulness between shifts, kicks, jerks |

| Burnt friction discs | Does not change gears, the car continues to move when the gear shifter is set to “Neutral” |

| Failure of the torque converter oil pump, burnt solenoids, banal contamination of the valve body | The car goes into emergency mode, does not move, does not change gears |

| The electronic control unit is faulty, the wiring has been chewed by small rodents | Emergency mode, works normally after resetting errors from the ECU, then goes into emergency mode again, resets gears, does not want to change speed |

Read Reliability of Chevrolet Niva automatic transmission: maintenance and malfunctions of the automatic transmission

Kicks and jerks do not always appear due to the breakdown of some component of the machine. For example, in winter at minus twenty, if you feel that the machine is kicking or does not change speed, then it is possible that the oil is not heated to the required temperature. Synthetic fluids are too viscous. Therefore, at first you will feel the car twitching.

It can only be cured by warming up the machine for a long time. Try to drive slowly for the first ten minutes after you start driving. The machine needs a temperature above 70 degrees Celsius so that the oil becomes liquid enough to regulate the pressure in the valves. Shift gears by pressing the brake pedal to disperse the oil.

Sounds from the gearbox

If the modes in the automatic transmission do not turn on, noises are heard, and vibration occurs in the car body, then there may be problems with the torque converter. A gas turbine engine malfunction begins with a barely noticeable hum and vibration, gradually turning into grinding and clanging. Then the machine goes into an emergency state and does not change speed.

Problems whose symptoms include noise and grinding:

- the oil pump seal is broken;

- wear of oil pump gears;

- the engagement of the pump wheel gears is broken;

- low level of lubricant in the torque converter. A leak is possible due to a leaky welded seam after repairing the donut.

Damage to the oil wheel or turbine blades leads to vibration or various sounds. If there are problems with the thrust bearings, then the sound will increase when the gear shifter is switched to “R” mode. The automatic will stop shifting gears

Smell of burning

The smell of burnt oil appears when checking the lubricant level

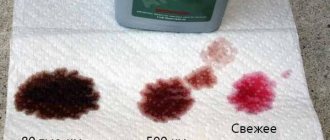

Pay attention to the quality and color of the fluid in the automatic transmission. The machine, after the liquid has lost all its properties due to overheating, can work for a long time

But failure to contact the service center in a timely manner will lead to a rapid overhaul of the automatic transmission.

Read

The design and principle of operation of the automatic transmission torque converter

Tips and tricks

Compliance with the basic recommendations for the operation of automatic transmissions can increase the service life of this type of transmission and improve the quality of operation of the automatic transmission. First of all, the most important recommendation is to control the quality and level of transmission fluid, as well as the use of original fluids or high-quality analogues when replacing.

If there are metal particles in the oil, the oil has darkened and become opaque, or a burning smell has appeared, then the ATF fluid must be replaced (change the lubricant every 40-60 thousand km or at least once every 3-4 years (depending on which comes first);

It is also necessary to warm up not only the internal combustion engine of the car, but also the automatic transmission should be warmed up before driving (this is especially important in the winter, when the lubricant becomes too thick, the oil pump cannot provide the necessary compression of the friction discs, which will lead to abrasion of the abrasive material of the discs, providing traction);

- Automatic transmission emergency mode: what you need to know

What is automatic transmission emergency mode? Why does the automatic transmission go into emergency mode: the reasons why the automatic transmission goes into emergency mode, diagnostics. Read more

- Automatic transmission jolts: main causes of malfunction

A jolt in the automatic transmission, the appearance of jerks when shifting gears of the automatic transmission, jolts of the automatic transmission in place: the main reasons for such malfunctions of the automatic transmission. Read more

- Automatic transmission diagnostics: what you need to know

How to check an automatic transmission: automatic transmission diagnostics before buying a used car or in case of malfunctions and deviations from the norm, methods. Read more

- Malfunctions of the automatic transmission torque converter

Torque converter in an automatic transmission: operating principle and main malfunctions. Signs of problems with the automatic transmission torque converter, gas turbine engine repair. Read more

- Signs and causes of automatic transmission overheating

How to determine that the automatic transmission is overheating: signs indicating overheating of the automatic transmission. How to improve automatic transmission cooling and prevent the machine from overheating. Read more

- Torque converter in automatic transmission: what is it, device...

Automatic transmission torque converter (torque converter, gas turbine engine). Purpose, design of the torque converter, operating principle and features. Read more

Problem in the automatic transmission control unit

The first thing you need to pay attention to when the car does not drive is the control unit. There is no need to disassemble the machine, climb into the valve body or attempt to replace the lubricant

Since the reasons that the car does not drive may lie on the surface. Most likely the ECU is acting up.

Attention! A laptop with a specially installed program for checking the functionality of the automatic transmission and a scanner for reading errors will be an excellent assistant for you. If there are no such tools, then you can try to manually determine the presence of errors in the ECU and understand why the car does not drive

If there are no such tools, then you can try to manually determine the presence of errors in the ECU and understand why the car does not drive.

Signs of ECU failure if the car does not drive may include:

- the car does not start, although the selector lever is in the correct position in the parking lot;

- the symptom is absolutely opposite to the first one - the car starts from any position of the selector lever;

- when switching to “D” the car crawls in first gear and does not change gears, although the speed increases;

- while driving in third speed and when pressing the gas pedal, the car does not reset the gears alternately, but immediately switches to first.

In addition to these problems, different letters of selector knob positions may appear on the monitor when the selector lever is not in the modes indicated on the dashboard. These signs also indicate a malfunction of the control module when the car does not move forward.

All of the above symptoms can develop in an automatic transmission due to improper operation of the electronic control unit. To check if it works correctly, you need to try to do what I described in the next block.

Remedies

The first problem may be lack of energy. Therefore, you need to check the battery for serviceability and supply of the required voltage to all electronic devices. You can do the test with a multimeter. With the ignition off, the battery voltage should not fall below 12 V.

If everything is in order with the battery, then proceed to disassembling the control unit. At the beginning of the procedure for removing the computer, disconnect the wires from the battery terminals so as not to short-circuit the devices.

- Remove the ECU from the car.

- Take it apart.

- Visually inspect the board. It should be free of mold, stains, rust and other deposits that could close the lines of the paths.

- If any are observed, clean the contacts. Use a multimeter to check the functionality of individual capacitors and other devices on the board.

- If you find corrosion on the board or charred ends, replace the electronic control unit.

ECU repair will not give positive results for a long time. After six months you will have to change it anyway.

Self-diagnosis

The automatic transmission may not shift gears due to a lack of oil in the machine. Therefore, I do not recommend rushing to go to a service center to solve this problem. First, conduct a self-diagnosis.

Kicks, jerks and drops

The speed does not turn on, the automatic transmission kicks and does not want to change gears, it stalls for one reason - oil starvation. A lack of oil appears when you don’t look inside the machine’s tank for a long time. Transmission fluid tends to thicken and evaporate if it is not changed in time and the level is not checked.

The following table shows the reason for frequent kicks and jerks of the machine when changing gears:

| Cause | Problem |

| Thick or thin oil, loss of transmission fluid properties | Effective transmission of torque to the wheels is lost, the automatic transmission changes gears slowly |

| Lack of pressure in the machine, stopping of the friction discs, clamping them due to chips stuck between the teeth | Thoughtfulness between shifts, kicks, jerks |

| Burnt friction discs | Does not change gears, the car continues to move when the gear shifter is set to “Neutral” |

| Failure of the torque converter oil pump, burnt solenoids, banal contamination of the valve body | The car goes into emergency mode, does not move, does not change gears |

| The electronic control unit is faulty, the wiring has been chewed by small rodents | Emergency mode, works normally after resetting errors from the ECU, then goes into emergency mode again, resets gears, does not want to change speed |

Read How to properly brake the engine on an automatic transmission

Kicks and jerks do not always appear due to the breakdown of some component of the machine. For example, in winter at minus twenty, if you feel that the machine is kicking or does not change speed, then it is possible that the oil is not heated to the required temperature. Synthetic fluids are too viscous. Therefore, at first you will feel the car twitching.

It can only be cured by warming up the machine for a long time. Try to drive slowly for the first ten minutes after you start driving. The machine needs a temperature above 70 degrees Celsius so that the oil becomes liquid enough to regulate the pressure in the valves. Shift gears by pressing the brake pedal to disperse the oil.

Sounds from the gearbox

If the modes in the automatic transmission do not turn on, noises are heard, and vibration occurs in the car body, then there may be problems with the torque converter. A gas turbine engine malfunction begins with a barely noticeable hum and vibration, gradually turning into grinding and clanging. Then the machine goes into an emergency state and does not change speed.

Problems whose symptoms include noise and grinding:

- the oil pump seal is broken;

- wear of oil pump gears;

- the engagement of the pump wheel gears is broken;

- low level of lubricant in the torque converter. A leak is possible due to a leaky welded seam after repairing the donut.

Damage to the oil wheel or turbine blades leads to vibration or various sounds. If there are problems with the thrust bearings, then the sound will increase when the gear shifter is switched to “R” mode. The automatic will stop shifting gears

Smell of burning

The smell of burnt oil appears when checking the lubricant level

Pay attention to the quality and color of the fluid in the automatic transmission. The machine, after the liquid has lost all its properties due to overheating, can work for a long time

But failure to contact the service center in a timely manner will lead to a rapid overhaul of the automatic transmission.

Read

Do-it-yourself diagnostics and repair of Mazda automatic transmission

Most common faults

The main malfunctions that may occur during long-term operation of the vehicle:

- whistling sound;

- there is a characteristic noise when the power plant starts up;

- The automatic transmission does not engage when turned on;

- the car stalls when changing gears;

- the appearance of a specific smell from the selector;

- extraneous knocking noises when changing gears.

A whistling sound may be due to a torque converter problem. Also, you should pay attention to the fuel level in the box. Oil starvation leads to damage to the oil pump gears. If the pumping device fails, it will become impossible for the calipers to move, and extraneous sounds will appear from the gearshift lever.

The valve body ensures redistribution of transmission oil flows and pressure. Slips and impacts are the main signs that the automatic transmission valve body is broken. The valve needs to be flushed if it is dirty.

Possible options for why the hydraulic unit does not work:

- clogging of channels and valves with wear products;

- valve winding break;

- wear of the valve working surface.

It is unacceptable to drive a vehicle if there is a clanging sound from the side of the gearbox when the power plant is idling. It is necessary to check the integrity of the friction clutch discs. This spare part is responsible for blocking the elements of the planetary mechanism.

Automatic transmission repair is necessary if the integrity of the sealing gaskets has been compromised, which may result in oil leaks.

Any automatic transmission repair and restoration work should be carried out using appropriate tools. In particular, a set of heads, mandrels, wrenches, installation tools, etc. is required. Assembling and disassembling the box requires maximum care and precision.

How it works

Both manual and automatic transmissions have a complex design. For their correct functioning, the coordinated work of a large number of parts is required. Of course, an automatic transmission is more complex, but the problem may not be related to the transmission. For example, if you cannot move the automatic transmission selector out of P, there is a possibility that the brake pedal switch is faulty.

In the case of a manual transmission, the gear shifting process depends on the health of the clutch pedal, the clutch itself and other parts. You press the pedal, which engages the clutch release mechanism, and separates the engine and transmission. This allows you to change gears. Synchronizers facilitate smooth engagement of all gears.

In addition, failure of the master cylinder is possible (on some cars the clutch is electronically controlled, on others the system has a hydraulic drive, in which proper operation of the master and slave cylinders filled with liquid is required to change gears). In this case, the car will behave as if the clutch pedal is not pressed.

The automatic transmission does all the work for you. All you have to do is press the gas pedal, and the transmission itself will change gears as the speed increases. This requires many additional parts that are not found in a manual transmission.

The most common causes of these malfunctions are discussed below.

1. Low level of working fluid Both types of transmission require different types of working fluid for normal operation. If its level is insufficient, then there is a possibility that you will not be able to change gears, especially in the case of an automatic transmission. In this case, transmission parts receive significant damage. Even if you can get into gear, the transmission may not be able to move the vehicle.

2. Master Cylinder Fluid Level Low If your vehicle has a hydraulic clutch, the first thing you should check is the fluid level in the master cylinder. Typically, a lack of fluid is associated with a leak in the system (you may find a puddle of fluid under the clutch pedal).

3. Broken clutch cable If the clutch on your car is controlled by a cable, it may have broken. If the clutch does not disengage when you press the pedal, this may be one of the main causes of the malfunction.

4. Malfunctioning brake light switch If you cannot move the automatic transmission selector out of P, the most likely culprit is the brake light switch. It is located under the brake pedal and is designed to activate the shift lock solenoid if the brake lights are not working.

5. Failure of synchronizers If you can engage the gear, but still hear a grinding noise, most likely, the transmission synchronizers have failed. In this case, switching to the next gear should occur without problems.

How to Troubleshoot A mechanic should confirm that the gears are not shifting. This may require a test drive (if the shift does not occur while driving). The mechanic can also read trouble codes stored in the electronic control units through the OBD II connector located under the instrument panel.

Throttle valve

As one of the options, you can answer the question of why the car picks up speed poorly by diagnosing the throttle position. It happens due to long-term use of the car or due to erroneous actions of service station employees, the throttle valve begins to sink or opens only 2/3. The cause may be a bent fuel cable holder. If after checking all of the above options the problem is not solved, there is only one way out - detailed computer diagnostics at a service station.

Theme Options

Prevention of automatic transmission breakdowns

In order for the vehicle owner to prevent malfunctions in the transmission, it is advisable to warm up the car before making a trip. In addition, it is necessary to monitor the transmission oil level. Each individual version of the car has its own deadline. It is important to replace the transmission if, during its routine check, wear products were found in the fuel. Also, oil starvation of the automotive system is unacceptable.

Towing over a short distance helps reduce the working life of the box. The resulting loads will negatively affect the components of the engine and transmission. When replacing components that have expired, you should use original, branded spare parts and filters.

Automatic transmission does not pick up speed

One of the problems faced by owners of cars equipped with automatic transmission is the problem of insufficient traction of the internal combustion engine. When the speed limit increases, the engine speed begins to increase, but the speed is gained slowly, late or not at all.

The same thing happens if the speed limit is lowered - the engine speed begins to decrease, and the speed reduction, accordingly, occurs with a delay. The reasons why the automatic transmission does not fully transmit torque to the axle shafts and, accordingly, to the wheels of the car may be different.

First of all, this is the incorrect operation of the car’s power plant itself and all its systems (ignition, gas distribution system, fuel, etc.). If, through diagnostics, it is revealed that the internal combustion engine develops rated power, but this power and torque are not fully transmitted to the drive wheels of the car, this makes it possible to exclude engine malfunctions.

Automatic transmission slipping is a common problem. When the transmission slips, the automatic transmission may not engage in a timely manner, or when switching to a higher gear, jerks, jerks, and peaks of the automatic transmission may appear.

Reasons for automatic transmission slipping:

Air-fuel mixture

Let me remind you a little about the principle of the internal combustion engine (ICE). Many of the “newbies” think that it runs “purely on gasoline” and that nothing else gets inside the cylinders. BUT this is not true at all. Gasoline is of course an important component, but it will not burn without oxygen, so air (which contains some oxygen) is also supplied inside through the intake manifold.

Thus, an air-fuel mixture is prepared, this is gasoline + air. Either in the intake manifold, or directly in the engine cylinders.

It is this that burns inside, forcing the pistons to move, and they, in turn (through the connecting rods), rotate the crankshaft - work happens.

Fast overtaking

In order to overtake several cars, it is more convenient to use manual control: this allows you to quickly lower the gear and gain the desired speed. Switching the engine to kick-down mode takes 1.5-2 seconds, acceleration begins after another 3 seconds. The situation on the road will change - it will be too late to maneuver.

When the maximum set speed is reached, the automatic will begin to reduce speed and shift to lower gear to protect the transmission. With a manual transmission, the high acceleration speed in a lower gear is maintained until the end of overtaking. When the maneuver is completed, you can return to the automatic transmission.

Breakdown in the torque converter

The car does not drive if you do not monitor the machine:

do not change the oil after the time specified by the manufacturer or experienced mechanics at the service station; wash the old automatic transmission filter and put it in place; Do not install an additional radiator on older cars; Do not pay attention to noises, shocks and jerks when idling and changing gears.

Problems not resolved above will lead to breakdown of the automatic transmission torque converter. This failure cannot be determined through diagnostics with a scanner. It is necessary to open the automatic transmission “donut” and visually inspect every detail.

Signs

New car owners often cannot distinguish the signs of a torque converter failure. And they blame it on bad oil, low-quality fuel. In fact, there are several symptoms due to which the car does not move due to a breakdown of the gas turbine engine:

- When you turn it on, you will hear noise in the automatic transmission. As the speed develops, it will disappear;

- The car starts, but does not drive. The splines on the turbine have worn out. By the way, the first symptom indicates the beginning of abrasion of these slots;

- you hear a metallic knock when you try to switch modes, and the car does not move;

- chips and other wear products on the dipstick;

- the engine stalls, the car does not move when you try to switch from one speed to another.

I have listed only some of the causes of malfunctions, due to which the car does not drive, related to the torque converter. When they appear, you should definitely visit the service center, so as not to completely change the “donut” later.

Remedies

What we can do to fix the problem and what you need to pay attention to if you understand automatic transmissions:

- You will have to remove the machine completely from the car.

- Disassemble the automatic transmission, pull it out and clamp it in a vise.

- Saw it in half.

- Examine seals, gaskets for cracks, holes in solid rubber. Replace them.

- Carefully inspect the turbine, pump wheel, and blades of these parts for wear or breakage. Replace if necessary.

- Assemble the torque converter and carry out balancing work. They are made on a special stand.

After the balancing is completed, you can install the gas turbine engine on the automatic transmission. And check whether the car runs or not after repair.

When you press the gas it doesn't even go to D

Hydraulic unit

It may also be the culprit that the car does not move when you press the gas. How do shifts occur in an automatic transmission? Due to the “play of pressure” of the oil, the opening and closing of the necessary valves in the automatic transmission.

If the oil pressure drops, switching is impossible. Because of this, we press the gas in D mode, but the car does not move. He just stands still and accelerates. The problem may be entirely in the valve body or individual valves.

How is pressure checked? In the diagnostics there is a corresponding parameter called “automatic transmission internal pressure”. It shows oil pressure. If it is less than nominal, the box needs to be disassembled.

In addition, you need to make sure that the oil level is correct and there are no leaks, since without oil the machine will not work at all. Often the reason for the lack of oil pressure in an automatic transmission is oil leakage through the seals or sealing joints.

Due to the drop in oil pressure, the clutches are not pressed, which leads to slippage. Due to this, they burn even faster.

What to do if the automatic transmission kicks?

A typical cause of jerking is dirty transmission oil. Over time, it becomes saturated with impurities and small metal elements, which significantly deteriorates its quality and leads to inadequate functioning of the system. Everything is simple here: the oil needs to be changed, and after that the automatic transmission needs to be washed thoroughly. It is better to do this using a washing machine. In the future, it is worth changing the oil on time.

This is interesting: Troubleshooting and troubleshooting if the oil pressure light comes on at idle

If the root of the problem is a malfunction of the friction discs, it is better to replace them, which will require a complete disassembly of the automatic transmission. It is not so easy to perform this procedure manually.

If the shocks occur due to insufficient heating of the transmission fluid, this is a seasonal problem. With the onset of warmth it will disappear by itself. But still, you should not abuse driving with an unheated system, as this can lead to wear of the components.

Problems with faulty wiring are solved by eliminating breaks, if any, or cleaning oxidized contacts. If a fault is detected in the step-down resistor, it should be replaced.

If the oil pump does not create the proper pressure, this problem is solved by adding working fluid to the tank. You can also try changing the cuffs on the lid.

There are many possible reasons for automatic transmission jerking. The main thing is to carry out automatic transmission maintenance on time, and then it will work for a long time and without unpleasant shocks.

Carburetor cars

The first step is to disassemble and clean the carburetor itself. In this matter, you will be helped by instructions for repairing and servicing your car, which are very easy to find on the Internet. The carburetor should be disassembled with care so as not to lose small parts: springs, screws, nuts and washers.

All metal parts needed:

- Collect in one container, preferably metal or glass;

- Fill with cleaner;

- Let it sit;

- Rinse them with water and wipe with a dry cloth.

The outlets in the carburetor must be cleaned using compressed air or a special aerosol. Do not try to clean these holes with metal tools, as this may cause them to become deformed. After cleaning and drying all parts, the carburetor should be assembled and adjusted using the same repair and maintenance instructions for your car or the almighty Google.

The next thing we check is the fuel system. We need to see if it is clogged:

- Gasoline coarse filter;

- Fine filter;

- Gasoline pump.

If there is visible contamination, the parts need to be cleaned or replaced with new ones.

Next, it is recommended to check the electrical circuit of the car:

- Ignition coils;

- Spark plug tips;

- BB wires and spark plugs at the time of breakdown.

If necessary, replace faulty parts. The candles, of course, can be cleaned, but this will not bring any tangible results. If it does happen, it won't last long.

Correctly set ignition is also of considerable importance. You can configure it yourself (if you know how). If you have never encountered this, you can read literature on this topic or ask your comrades for help, or again, the omnipresent and omniscient Internet will help you.

After carrying out the above steps, the problem should be resolved. If this does not happen, then you should contact professionals.

Automatic transmission does not change gears: reasons

Depending on the brand and manufacturer, automatic transmissions may have some differences, but the main causes of shifting problems are common. Let's start with the fact that the most common mistake leading to automatic transmission failure is turning on the drive mode “D” without stopping when moving in reverse. The same can be said about engaging “R” when driving forward.

Also, many car owners in urban driving mode, during short stops at traffic lights or in traffic jams, often switch the automatic transmission selector to the “N” position.

You need to understand that the “neutral” mode, which unlocks the wheels for the possibility of short-term towing or rearranging the car in the event of some kind of malfunction. For an automatic transmission, there is no need to use it during everyday use of the car, as this causes increased wear.

If the driver of a vehicle equipped with an automatic transmission does not adhere to the operating rules, then very soon he will encounter problems in the operation of the automatic transmission: the automatic transmission does not change speeds, when shifting there are shocks, kicks, impacts or jerks, etc.

Automatic transmission does not shift gears: signs

When driving, the automatic transmission selector is in position “D”, but the car refuses to respond to manipulations with the accelerator pedal and simply does not drive. In this case, the driver switches the automatic transmission to manual mode (if equipped), and gears may begin to shift.

When the automatic transmission selector is switched to “S” mode (if this mode is provided in this transmission), there is no change in the nature of the gear shift. In order to achieve the desired result, the driver must switch to manual control mode of the automatic transmission.

- While the car is moving, when switching from manual control of the automatic transmission to automatic mode D, the speed drops and the box does not switch.

- When changing gears in an automatic transmission, only reverse gear is engaged,

- There are often cases when the car simply does not start even with the automatic transmission selector in neutral.

- There is no forward movement, the car “slips” in place. The reverse speed is normal.

- The automatic transmission does not shift above third gear or only third gear is engaged.

- When the selector is switched to the “D” or “R” position, the car does not move.

- At the beginning of the movement, the transmission slips, however, after gaining speed, the car drives normally.

Often such malfunctions in the operation of the automatic transmission lead to the ECU turning on the emergency mode of the automatic transmission. If a car owner encounters one of the problems described above, first of all, it is necessary to conduct computer diagnostics of automatic transmission faults.

The main causes of automatic transmission malfunctions

The list of main automatic transmission problems includes:

- Wear of the friction discs of the forward clutch, wear or breakage of the clutch piston cuffs, wear or breakage of the clutch rings, sticking of one of the valve body valves (no forward movement).

- Worn friction discs, clutch piston cups or breakage of clutch oil sealing rings. The spline connection in the drum body is broken (the automatic transmission does not shift above third gear).

Failure of the brake band or breakage of the piston cuffs of the brake band itself. The brake band piston rod is damaged (the car does not move when the selector is switched to the “D” or “R” position).

- Wear of the turbine wheel hub splines in the torque converter or wear of the forward clutch clutches (vehicle slipping).

- The control valve in the centrifugal speed selector is stuck or the helical gear on the speed selector shaft has failed.

Tips and tricks

As you can see, if the automatic transmission is pushed, there may be several reasons, ranging from breakdowns of the gearbox itself or malfunctions of the ECM sensors to torn cushions (gearbox supports).

In other words, if the car jerks when switching the automatic transmission, the culprit may not be the gearbox at all, but bad fuel, problems with the power supply or ignition system.

If all the checks have been completed, but the cause of the failure has not been determined, then the transmission itself should be checked. Additional signs of problems with the automatic transmission are that the transmission goes into an “accident” (the automatic transmission goes into emergency mode), the automatic transmission jerks constantly and is noticeable when cold/hot, the automatic transmission slips, etc.

In such a situation, you should immediately visit a service station for in-depth diagnostics, since the gearbox itself is likely to break down. In this case, kicks and jerks may indicate problems with the clutches, gas turbine engine, valve body and other automatic transmission elements.

By the way, if it is not possible to immediately go to a service center, you should stop using the car until diagnostics and repairs are carried out, since further driving can lead to rapidly progressing breakdowns and serious and costly repairs of the automatic transmission.

Also, some drivers, especially those who do not have much experience in operating cars with automatic transmissions, immediately mistake light jolts from the automatic transmission for a malfunction. It should be remembered that the “classic” automatic transmission is not a continuously variable transmission (unlike CVT variators), that is, the transition from one stage to another is felt to a greater or lesser extent.

This means that for automatic transmissions, slight jolts when switching, especially when cold, are often the norm. Moreover, many automatic transmission modifications (regardless of the country of manufacture) are characterized by stronger shocks in certain modes.

For example, the transmission may push harder when the gas pedal is lightly pressed when shifting up from 1st to 2nd gear. At the same time, there may not be such shocks when moving higher (from 2 to 3, etc.). Also, the shocks will not be felt even from 1 to 2, if you accelerate more intensely, that is, press the accelerator pedal harder.

So, such light jolts of the automatic transmission are considered to be a feature of the unit’s operation. In simple words, the official dealers of different brands and experienced automatic transmission repairmen often do not consider this a malfunction, much less a reason for repairs. In this case, the boxes themselves also normally maintain their declared resource.

If another person gets behind the wheel, gear shifting may be “hard” for a certain time, accompanied by jolts, etc. In this case, you can wait until the ECU independently adapts to the new driver or reset the operating parameters of the adaptive automatic transmission stored in memory.

https://youtube.com/watch?v=gRnwSqm2bF8

Parking

To ensure the safety of the car when parked, it is imperative to engage first (1) or reverse (R) gear and, if the car is parked on a slope, the parking brake. If the car is on an incline and the gear is engaged, you must wait until the number of the engaged gear disappears from the display, and only then release the brake pedal (by this time the clutch will be fully engaged).

If the gear is in neutral (N) and you are about to engage a gear that is suitable for parking the vehicle, you should turn on the system and, while holding the brake pedal depressed, engage first (1) or reverse (R) gear.

Problems with engaging first gear and troubleshooting methods

Below is a list of breakdowns that can cause the gear lever to shift gears poorly:

Operating principle of gearbox synchronizers

New synchronizer for the gearbox You can find out how to do this below: Replacing gearbox elements is carried out in several stages. We will not describe them in detail, since all actions are individual for each individual car. Moreover, if you have never encountered such a procedure, you are unlikely to be able to perform it yourself: Recommendations on what to do if it is impossible to engage first gear were given by a Ukrainian driving instructor.