With prolonged use, the internal parts of the automatic transmission wear out, which can cause unstable operation of the unit. Various jerks are especially pronounced during gear shifts, but if there is excessive wear, automatic transmission kicks can be constantly present, regardless of the engine operating mode. Such symptoms can be observed both with very complex breakdowns and with minor deviations in the operation of the device, so it is important to know about the distinctive features of the manifestation of problems depending on the cause.

Effect of oil

There are many sensors in any modern car, including automatic transmissions. In this regard, any malfunction will be shown by the on-board computer.

It is necessary to monitor the oil level in the automatic transmission. Lack of oil in the unit is a very common problem that causes shocks and shocks. It is necessary to constantly ensure that there are no leaks that form due to aging of the seals.

Every 40-60 thousand it is necessary to change the oil. Old oil causes gearbox wear and incorrect operation, as its properties are lost. Transmission oil must be of high quality in order to reduce friction of parts. Poor quality fluid also causes wear on the solenoids.

How to properly change the oil in an automatic transmission?

If the transmission shifts jerkily and with shock, the reason may lie in the lubricant itself. How to change and add new fluid:

- Warm up the engine to operating temperature and allow it to cool for about 10 minutes.

- Climb under the bottom of the car and find the drain plug on the gearbox. This hole can be protected by a tray. Place an old container under it to collect waste fluid. Unscrew the bolts on the crankcase or the drain plug.

- Remove the filler or inspection hole cap.

- Wait until all the lubricant has left the system. This will take some time.

- Once the fluid is drained, clean the area around the hole. Also clean the plug itself and assess the condition of the seal on it. If it has fallen apart or is very worn, it must be replaced.

- Replace the cover along with the drip tray (if present). Tighten all bolts.

- Using a construction or medical syringe with a hose, fill the system with the required volume of liquid. It will depend on the specific vehicle. Before replacing, read the service book about exactly how much lubricant is needed. If there is no filler hole, use the inspection hole. Add the substance until it starts to come out.

- Screw the plug into place and start the engine. Perform a test drive and evaluate the quality of the transmission. At first, kicks may be observed when downshifting or upshifting. But with time it will pass. After this, check the box for leaks. If there are traces of oil leakage from the system, this problem needs to be solved.

We recommend: How to drain antifreeze completely: from the engine block, radiator + photo instructions

1. Remove the automatic transmission pan, unscrew the drain plug and drain the liquid from the system 2. Screw the plug into place and fill in new lubricant through a funnel or syringe with a hose

Why did the jerking appear after the replacement?

If the problem recurs after changing the lubricant, it is usually due to the use of the wrong fluid. It does not fit the vehicle. Or you didn't put enough into the system.

Remedy

To solve the problem, you first need to make sure the quality of the oil. In the service book for the car, read what standard of lubricant must be poured into certain boxes. Buy the appropriate fluid and add it to the transmission. You can replace it either yourself or at a service station. If the level of the substance is insufficient, then it is necessary to add it to the system.

Features of automatic transmission operation

Comfort when driving a car equipped with is combined with the periodic appearance of certain problems associated with the complexity of the mechanism and its improper operation. Kicks when shifting gears occur much more often if the car is stored outside or in a cold garage, since in this case the contamination and content of solid particles in the oil increases significantly, which significantly reduces the life of the unit.

It is advisable to store a car with an automatic transmission in a warm garage, or, in extreme cases, warm it up well before driving, and do not touch the transmission during warming up, and do not put it in gear when parked in the cold.

To prevent kicks during switching, it is especially important to carry out automatic transmission maintenance on time, and if malfunctions or breakdowns occur, start solving the problem with diagnostics, and based on the results, deal with them.

Incorrectly selected ATF fluid

Please note that the transmission of a particular vehicle must use ATF fluid of a certain viscosity and with the performance characteristics required by the vehicle manufacturer (or transmission, if the automaker only performs the assembly). Accordingly, you need to refill with the “correct” liquid. Because oil with unsuitable parameters can also lead to jolts or kicks when the car is moving.

Another common case is that the automatic transmission jerks “when cold ,” in particular, after a long period of inactivity in the cold, for example, in the morning. However, after warming up the problem disappears. This means that the car owner initially selected the wrong oil, which thickens in the cold and does not ensure normal operation of the automatic transmission. Accordingly, you need to choose a thinner oil.

15 best power steering fluids

Review of the 15 best power steering fluids that can be filled. PSF, ATF, Dextron - which fluid and price is best for power steering. More details

Possible solutions to the problem

In most cases, the following techniques help to get rid of kicks when switching an automatic transmission:

- Complete change of transmission oil, it is advisable to fill in the original. When replacing, the tray and magnets are cleaned and the filter is replaced. The pallet must be removed during maintenance work.

- Complete disassembly of the box to clean the valves. The operation is especially important for the line pressure valve.

- Carrying out the two above procedures together with automatic transmission diagnostics. During testing, it is important to check the valve resistance.

- Washing the automatic transmission using a product specially designed for this purpose.

- Updating the control automation firmware. Possible in a service center for new automatic transmissions. This eliminates not only shocks when shifting gears, but also ensures smooth operation and improves fuel efficiency.

Recently, many automatic transmission service centers have been faced with the failure of the step-down resistor, which is present in almost all types of boxes of this type. It serves to reduce the current to the main line control valve, which is controlled by the line pressure solenoid. That is, it participates in the process of softening gear shifting, reducing the current supplied from the control unit to the solenoid.

We recommend: Automotive low beam lamps H7 - a ray of light in the dark kingdom of the road

If it is thrown out of the chain, switching will occur at the maximum pressure that the oil pump can create - too abrupt and uncomfortable, with a kicking sensation. To identify the problem, find the location of the resistor and check its resistance with an ohmmeter. If it differs from the nominal one in one direction or another, it is replaced with a new one or made from parts purchased in a radio store connected in parallel, since a fairly large current will pass through them.

Why does the machine twitch?

There are no units that never break down. The only question is how often breakdowns occur. Basically, the machine fails for the following reasons:

One of the main signs of a malfunction is a violation of smooth shifting, i.e. the machine jerks when it changes to any gear. Jerks can occur both when starting from a stop, and when accelerating or braking, or when engaging a higher or lower gear. The twitching becomes especially noticeable when driving at low engine speeds. The box starts to twitch if:

A torn engine cushion can also cause kicks and vibrations

If it is discovered that the ATF level does not meet the recommended level, then the box requires close attention. Both a lack and an excess of working fluid lead to foaming, due to which the automatic transmission pump is not able to pump a sufficient amount of oil to the rubbing parts. Under conditions of oil starvation, wear progresses. As a result, when you engage any gear, jerks occur, sometimes accompanied by a noticeable impact. If the car is operated most of the time in the city, in traffic jams, when movement occurs mainly at low engine crankshaft speeds, the gearbox will break down much faster.

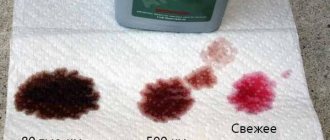

If contamination is detected, then it can be assumed that the automatic transmission parts have already begun to wear out intensively. A change in oil color and the presence of impurities, especially large metal particles, is a signal to immediately visit a service center for diagnostics.

Causes of hot and cold shocks

Car owners notice how the automatic transmission kicks when hot. So why do shocks appear when switching the automatic transmission? Cold and hot shocks may indicate the following common problems:

- insufficient oil level in the automatic transmission.

- The oil poured in, designed to lubricate the parts, is of poor quality, so owners sometimes note that after changing the oil, shocks appeared in the automatic transmission.

- the appearance of incorrect operation of the torque converter (in the absence of adequate locking operation, a kick appears)

To resolve this problem you need to take certain simple steps:

- check the fluid level in the automatic transmission (if necessary, add oil to the required level)

- Completely replace the fluid in the gearbox.

- carry out detailed diagnostics of the unit.

When and why does the machine twitch?

The automatic transmission has long ceased to be a component of the transmission of only expensive prestigious cars. Now this is a common unit, available in many simpler car trim levels. Even an inexpensive car will delight the owner by not having to press the clutch when starting and changing gears. Along with comfort, automatic transmission brought to the mass of motorists its own specific forms of failures and their symptoms. When the automatic transmission jerks, that is, when accelerating, shifting or starting, when driving at low or high speeds, jerks are clearly felt, this is a reason to visit a service center for diagnostics.

Causes of shocks when shifting gears

It happens that shocks appear when switching to a lower or higher speed. Let's look at the causes and solutions to the problem.

Insufficient fluid level in transmission

Lack of lubrication will lead to incorrect operation of the unit as a whole. If it becomes more difficult to switch gears from first to second or third, you need to diagnose the oil level.

Remedy

The problem of automatic transmission kicking when hot when there is a lack of fluid can be eliminated by adding it to the system.

It is important to consider one point. When adding oil to the transmission, you can only use the fluid that is already in the transmission. If the lubricants are different in composition, this can lead to their mixing and loss of properties. As a result, a complete replacement of the substance will be required. It is necessary to diagnose the lubricant level in the transmission and make sure that the cause of the shortage is not related to its leakage. This problem can occur when the seals or sealing elements wear out. You will need to drain all the oil from the system and then refill it.

A detailed video on the topic of eliminating transmission fluid leaks using the example of a Mercedes car is presented below (the material was filmed by user StaniSlav B.).

Dirty transmission oil

Contaminated fluid in the gearbox often causes jolts and kicks. Deposits usually form as a result of mixing different oils or when using the same lubricant for a long time.

We recommend: Self-repair of VAZ-2103 engine

Remedy

This type of problem can be eliminated by thoroughly cleaning the gearbox. For this purpose, special flushing oil is used. Depending on the amount of dirt in the system, this process may need to be performed several times. You need to do the following:

- Warm up the engine to operating temperature.

- Place an old bucket or cut-off bottle under the transmission. The container will be used to collect used lubricant.

- Unscrew the drain plug or bolts on the oil pan, wait until all the fluid comes out of the system, and screw it back.

- Having previously read the instructions on the packaging label, fill the gearbox with flushing oil in the required volume. Turn on the engine and perform a test drive.

- Drain the lubricant from the system again and check its quality. If necessary, clean the unit again.

- Add new oil to the box.

Detailed instructions for cleaning an automatic transmission yourself using the example of a Mercedes Vito are presented by the Secret Garage channel.

Insufficient heating of the transmission fluid

The reason why the automatic transmission kicks when hot may be due to insufficient heating of the lubricant. Because the fluid temperature is too low, the main components of the transmission unit cannot heat up. This contributes to the formation of tremors.

Remedy

The only solution to the problem is to warm up the box to operating temperature.

Wiring from the ECU

The operation of the automatic transmission is controlled by the ECU - an electronic engine control unit. Using electrical signals along laid wires, it transmits information to the solenoids on how to behave at a particular moment in time. Quite rarely, but this can happen in older cars: the wiring oxidizes or breaks completely, and contact may be lost on one or more wires.

All this leads to incorrect operation of the gearbox, which can also result in jolts and incorrect gear shifting. It is worth noting that this is a fairly rare breakdown, and it can only be calculated using electronic error and malfunction scanners.

A few important details

Many drivers simply do not follow the rules for operating automatic transmissions. This is especially true in the winter. After all, not only the engine needs to warm up, but also ATP, even though it is more fluid than motor oil. Therefore, if you are not a supporter of warming up the engine at idle, then do not turn the engine to too high speeds until the temperature needle leaves the blue zone. Viscous oil does not provide proper lubrication and spreads worse throughout the system; you need to understand this and not force your automatic transmission.

So we figured out the main reasons why the automatic transmission kicks. You also know what to do in such cases. The main thing is not to panic. All problems can be fixed. Often it is contaminated oil that has not been changed for a long time that causes kicking. If you continue to drive like this, the situation will worsen. Therefore, if you could immediately limit yourself to cleaning the pan, changing the oil and filter, then after some time you will have to go through the box. Keep an eye on the automatic transmission, and it will delight you with its long service life.

What to do

If the engine jerks at idle, the cause should initially be determined. Then replace the damaged unit.

For carburetor models, the primary diagnosis begins with the throttle and the combustible mixture formation unit itself. Usually on old foreign cars and VAZs the root of evil is located here.

If the problem arose on a modern VAZ 2114/15 or on an “exotic” model like 1JZ-GE. The source of the problem may be inside the sensors. First of all, the DPKV, temperature sensor, temperature control system and others are checked. If everything is in order, you need to move on. High-voltage wires, spark plugs, and the ECM are diagnosed, and the ECU is checked last.

The car jerks at idle and when driving

If the problem occurs not only while parked, but also while driving, it is necessary to check the ignition, carburetor, and serviceability of the throttle valve.

For the injector, diagnostics of the fuel rail, its pressure, tightness, and the condition of the injectors are appropriate.

Also in both cases, the electronic part is diagnosed: control units, distributor, wiring, spark plugs.

The malfunction is caused by a failure, incorrect operation, of one of the vehicle systems.

The injector jerks

Main reasons:

- injectors or individual fuel supply elements are clogged;

- ignition coils are not working properly;

- The ECU and sensors are not functioning correctly.

The carburetor jerks

Everything is simpler with a carburetor. Here's what you should check:

- throttle valve condition;

- filters;

- spark plugs;

- distributor;

- Is the fuel pump working correctly?

At idle the car jerks and stalls

If the engine does not idle during a cold start in winter, there is nothing terrible - the block will warm up and everything will return to normal. However, if there is a failure after warming up, there may be several reasons for the breakdown.

- Idle air control failure.

- Clogged, throttle malfunction.

- The carburetor and jets are clogged (the injectors are checked for the injector).

- The fuel supply pump is faulty.

- The air/fuel filter is worn out.

- Failure of the electronic sensor MRV, TPS, DPKV.

The car shakes at idle

If vibration is transmitted to the car body, the first step is to check the wear of the power plant mounts. Squashed cushions do not reliably hold the engine in place, which causes severe shaking, deviation of the internal combustion engine from the nominal position and, as a result, vibration.

Other causes of shaking are described above.

The car shakes and jerks at idle

The process of engine tripping is a consequence of the malfunction of one or more cylinders. A similar breakdown is caused by a failure of the spark plug or a breakdown of the high-voltage wire.

- With the engine running, remove the spark plug cap from the first cylinder.

- After 3-4 seconds, install the element in place.

- Consistently repeat the procedure for all boilers.

During the check, you must listen to the sound of the engine. If the growling gets worse (the system doubles), the compartment is fine. If the result is neutral (nothing has changed), it is worth checking the line completely for serviceability.

The primary source of failure may be the following reasons:

- incorrect mixture setting - the cylinder floods;

- spark plug or wiring is of poor quality;

- occurrence of rings;

- piston wear.

Diesel car jerks at idle

There can be only three reasons here.

- The cylinder compression has dropped. As a rule, this occurs due to burnout of the cylinder head gasket and wear of the piston group elements.

- Injector problems - poor mixture supply, blockages, intake failure.

- Malfunction of the injection pump.

The car on gas jerks at idle

If a breakdown is detected, it is strictly not recommended to interfere with the unit yourself. You must contact a qualified gas fitter.

Interruptions on a cold engine

If the engine stalls at idle and then levels out after warming up, don’t worry too much. When cold, the power plant does not have normal clearances and can operate unstably. After reaching the design temperature, the motor stabilizes and stops twitching.

If the vibrations are strong and prolonged

When vibration in the engine does not disappear, but persists for a long time, this may indicate problems:

- wear of the piston group;

- violation of internal combustion engine fasteners;

- incorrect operation of the fuel system;

- ignition problems.