- 1. The design of a CVT gearbox and the principle of its operation 1.1.

- 1.2.

- 1.3.

- 2.1.

- 3.1. Pros and cons of a CVT box

To improve the convenience of driving, automakers began to install automatic transmissions instead of classic mechanics.

This gearbox allows the driver not to be distracted from the road situation while changing gears. Hydromechanical and continuously variable transmissions are the most popular automatic transmissions. There is a competitive struggle between them, and the question, variator or automatic - which is better, is still relevant. Both automatic and CVT transmissions have their advantages and disadvantages, so neither type of transmission can completely displace its competitor.

The design of a variable speed transmission and its operating principle

The operating principle of the variator gearbox is based on a smooth change in the gear ratio depending on external conditions. The design of a V-belt variator involves changing the diameter of the pulleys. Structurally, this is realized by the convergence and divergence of two cones mounted on the shaft. The main factors that determine the diameter of the pulley at the point of contact are load and speed.

A variator with a V-belt design includes several main parts:

- Clutch system. The first continuously variable transmissions used a torque converter for connection to the power unit, similar to that used in automatic transmissions. Subsequently, automakers began experimenting with centrifugal and electromagnetic clutches to increase transmission efficiency.

- Shafts with mounted cones of variable diameter. They work under high loads, so they are made of high-strength steel.

Rice. — “V-belt drive”

- Belt or chain. Serves to transmit force between pulleys. It is made of metal strips connected by special shaped parts.

- Transmission fluid. Car manufacturers do not recommend using regular oil for automatic transmissions. Special lubricants are produced for cars with a CVT (for example, DiaQueen CVT, used for Mitsubishi).

Rice. — “Original oil in CVT”

- Hydroblock. Serves to direct the oil supply to the required channel. Lubricant is pumped using an oil pump.

- Filters. As a rule, there are several of them: coarse and fine oil purification, as well as a pair of magnets that catch small metal chips. Filters can be installed both inside the variator and outside its housing.

Rice. — “Fine oil filters”

- Radiator. The CVT operates with more heat than an automatic transmission. Therefore, to prevent thermal destruction of the oil and its additives, cooling using a radiator is required.

- Electronic control unit. Algorithms for selecting the optimal gear ratio and issuing commands to control the variator are assigned to the electronics of the continuously variable transmission. It maintains constant communication with the main ECU module and processes information coming from sensors. The variator control unit can be located both in the variator housing itself and outside it.

How to care for automatic transmission

By following the rules listed below, the service life of the automatic transmission will be longer:

- In the cold season, it is good to warm up the car before driving.

- Monitor the oil level in the box and change it promptly.

- Accelerate smoothly.

- Slowly brake.

- Frequently inspect the sensors and the box itself.

- Complete maintenance in a timely manner.

If an extraneous sound appears in the gearbox, further operation is not recommended, but you must contact specialists to carry out repairs if necessary.

Types of variators

According to their design, the following types of variators are distinguished:

- V-belt, which is most widespread;

- chain, which is an analogue of the above type, but with a chain instead of a belt;

Rice. — “Chain variator”

- toroidal, which, due to its complex design, occupies no more than 5-7% of the continuously variable transmission market.

The main difference between a toroidal continuously variable transmission is the absence of a V-belt or chain drive. Torque in such a variator is transmitted using special rollers and cone-shaped disks. Changing the position of the rollers leads to a change in the gear ratio.

The advantage that a CVT with a toroidal transmission has is greater torque than a V-belt design can withstand. This is only possible when using steel of the highest strength and wear resistance, which affects the price of the unit, increasing it.

Working principle of CVT

As mentioned above, in a CVT gearbox there are physically no fixed gears , but there are virtual ones created at the software level. They are needed for manual control, for example, when maximum traction of the car is needed and speed is not important (driving on a snowy section of the road).

The most common V-belt CVT (installed on 95% of modern cars) can be based on one or two belt drives. The transmission is formed by two pulleys (driver and driven), connected to each other by a V-belt. This design received the corresponding name - a V-belt variator. There is also a V-chain stepless gearbox, in which a steel chain is used instead of a belt. The most famous variator with a chain is Multitronic, developed by Audi engineers.

Video

The gear ratio comes from the drive pulley, which is connected directly to the motor, to the driven pulley, which is connected to the drives and wheels. Each pulley consists of a pair of conical disks, which move and move apart during the operation of the box. By increasing or decreasing the diameters of the pulleys, the number changes. In practice, the operation of the variator looks like this:

- At the beginning of the movement, the cones of the driving pulley are moved apart, and the cones of the driven pulley are brought together, and the engine is loaded to a minimum;

- As the speed increases, the opposite situation occurs: the cones of the drive shaft gradually converge, and the cones of the driven shaft diverge. As a result, the gear ratio changes downward, which is important for reducing traction and increasing speed on the driven shaft. The pulleys are displaced due to the spring and centrifugal force created by the hydraulic drive.

As you can see, the operating principle of the variator is extremely simple, but extremely effective.

READ ALSO How to properly operate a variator? DSG - robotic gearbox from Volkswagen PowerShift - robotic gearbox from Ford

What is the difference between a CVT and an automatic transmission?

The main difference between a CVT and a classic automatic transmission is the absence of jerks when accelerating. This is due to the fact that the CVT transmits torque during acceleration without the steps that are typical for an automatic transmission.

The differences between a CVT and an automatic transmission are due to the fact that a hydromechanical transmission requires time to switch a pair of working gears. Because of this, the dynamic acceleration performance is worse. The absence of a break in the kinematic connection during acceleration of a car with a CVT allows the continuously variable transmission to accelerate faster.

The engine, if the car has a CVT, operates in a more gentle mode. This is due to the smooth maintenance of crankshaft speed, since acceleration of the car occurs mainly due to a change in the transmission gear ratio. As a result, drivers who switched from automatic and manual transmissions have a poor sense of car speed at first.

Pros and cons of a CVT box

The advantages that cars with CVTs have include the following:

- low fuel consumption - continuously variable transmission has higher efficiency;

- smooth ride, not accompanied by jerks that occur in an automatic transmission when changing gear ratios;

- gentle engine operation.

Despite all the advantages of the variator, its design is not without drawbacks. Because of this, the continuously variable transmission never took a leading position in the auto industry. The disadvantages of the variator are:

- complex repairs that many car services do not undertake;

- limited belt life, the cost of which is quite high;

- complex electronics and high sensitivity to control unit errors;

- high cost of oil.

The pros and cons of a CVT transmission allow them to remain in demand among a narrow circle of car enthusiasts. As a rule, driving with a continuously variable transmission is rarely dynamic. The variator does not like sudden starts from traffic lights and slipping.

Pros and cons of automatic transmission

An automatic transmission has the following advantages over a continuously variable transmission:

- high reliability;

- lower repair cost compared to a CVT;

- ease of repair.

The disadvantages of automatic transmission are:

- changing gears leads to jerking;

- speed is gained more slowly;

- The efficiency is lower, which leads to increased fuel consumption.

It is impossible to say unequivocally which transmission is better. It all depends on the preferences of the individual motorist. If the more important points for the driver are smooth running and optimal fuel consumption, then the choice should be made in favor of the CVT. If the key criteria are durability and higher maintainability of the transmission, then you need to choose an automatic transmission.

Flaws

In the recent past, with the advent of continuously variable transmissions, the owners of these cars began to have various types of dissatisfaction.

- Drivers complain about CVTs regarding the sound emanating from the belt, which moves inside the box. But the transmission mechanism is in good working order and works flawlessly at high speeds.

- You need to get used to this working feature and not pay attention. Acceleration of a car is accompanied by increased engine operation at maximum speed. Some car enthusiasts note that the high engine speed mode is delayed even when the speed is reduced. This is also one of the features of CVTs.

- The CVT is considered boring and boring . This type of transmission is suitable for people who save fuel and who are little interested in power, speed and dynamics. For this reason, car manufacturers equip sports cars with a different transmission.

- A new type of motion transmission is installed on modern cars that are not designed for the transportation of goods or sports racing. This selectivity is explained by the inability of CVTs to cope with high torque. Loads can damage the design characteristics of the transmission.

- Maintenance is marked with a minus sign . This is a serious drawback of CVTs. The financial costs of repairing CVT boxes (variators) are enormous. This is explained by the fact that the parts for such a mechanism are expensive. In addition, repairs must be carried out by a highly qualified specialist who understands the intricacies of this type of mechanism.

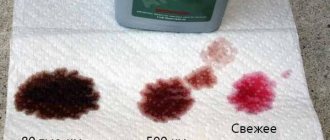

- The variator is demanding when it comes to changing oil and filters . Approximately once every 30,000 kilometers, the transmission needs to be filled with fluid specifically designed to improve belt performance. This product is considered scarce and expensive.

Automatic or CVT: which is more reliable?

Taking into account the above information, the question arises, which is better, a CVT or an automatic, as well as which gearbox is more reliable. Let us immediately note that at the initial stage, when the CVT variator just appeared on the market, in terms of reliability, such a gearbox was much inferior to an automatic transmission in terms of reliability. The fact is that at that time the “classic” automatic transmission was represented by 4 and 5-speed automatic transmissions, which were distinguished by their relative simplicity and reliability of design.

The service life of such units (subject to proper maintenance and compliance with operating rules) was about 250 thousand km. and more. As for the variator, such a box lasted no more than 150 thousand km. Please note that the reason for such a short service life was not always the variator itself. The fact is that the owners operated a car with a CVT in the same way as a car with an automatic transmission, that is, the features were not taken into account separately and the rules for operating and maintaining CVT were not followed.

If it was necessary to repair a variator, which was less common, attempts at such repairs often ended in failure. The design was less well studied than the automatic transmission, and there were no spare parts, equipment and experience. As for official dealers, instead of repairs, owners were only offered an expensive replacement of the entire gearbox with a new assembly.

This situation has had a greater impact on the fact that CVTs are traditionally considered less reliable than automatic transmissions. This is partly true, but today the situation has changed a lot. On the one hand, the CVTs themselves have become more reliable (for example, units such as X-Tronic), and on the other hand, the legendary automatic transmission has greatly lost ground in terms of service life and reliability.

We also recommend reading the article on how to drive a CVT. From this article you will learn how to drive a CVT correctly, as well as what you need to know and take into account when operating a car with a CVT gearbox.

The main reason was that automatic transmissions increased the number of gears (to 6, 7 and even 8). As a result, the design became much more complicated. The torque converter locking has also become actively used to increase efficiency.

Also, the boxes became officially unserviceable. Even if they wanted to service the automatic transmission, it became more difficult to drain the oil from the automatic transmission, car owners lost the ability to have simple and easy access to automatic transmission filters to replace them, etc. All this does not in any way add to the reliability of the automatic transmission.

It turns out that today you need to choose the type of transmission on a new car not based on reliability, but taking into account the conditions under which a particular car will be operated, how the car will be maintained, etc. If the operating conditions are difficult, it is better to look towards the automatic transmission. In the case when the car will be operated in normal mode (for example, within the city) without high loads, it is quite possible to purchase a CVT.

If we talk about the secondary market for used cars, in this case it is optimal to give preference to automatic transmission. Even taking into account the fact that a car with a CVT is initially cheaper than one with an automatic transmission, the possibility of the need for wear and repair of the CVT cannot be ruled out.

So, if an automatic transmission can be repaired relatively simply and relatively inexpensively, in the case of a CVT, certain difficulties may arise. Although there are more experienced CVT repair technicians, the cost of CVT repair can still be very high.