There are many reasons why automatic transmission jerks. This could be insufficient ATF fluid level in the gearbox, clogged oil filter, worn friction discs, clogged oil cooler, damaged oil pump, problems with the valve body and/or solenoids. Often, automatic transmission kicks arise as a result of unscrupulous service by the car owner or by the mechanics at the service station who were instructed to do this. Accordingly, in most cases, in order to prevent shocks and kicks in the automatic transmission, it is enough to service it on time and efficiently.

Many automakers deliberately mislead their customers by telling them that the modern automatic transmission on their cars is maintenance-free and there is no need to mess with it. In fact, after purchasing a new car and driving it for about 100 thousand kilometers (of course, this figure is approximate and conditional), shocks may occur when switching automatic transmission modes. The deception on the part of the “officials” is that the car owner will be forced to come to them for repairs. The following are the causes and methods of eliminating and preventing them in order from the most common to the “exotic”.

Insufficient ATF fluid level

The production of ATF fluid in an automatic transmission is one of the most common reasons why an automatic transmission jerks during acceleration or at speed . The peculiarity is that it is very liquid, and it is for this reason that it is not called gear oil. In addition to lubricating and protective functions, this composition performs one more action - it transmits torque from one part of the torque converter to another. Accordingly, the load on the liquid is greater than on conventional oil, and its performance characteristics and level quickly decrease. It is these indicators that lead to the fact that the automatic transmission begins to work in difficult conditions, which ultimately leads to the appearance of jolts and/or kicks.

Accordingly, in order to restore the functionality of the automatic transmission and prevent the occurrence of runout in the future, it is necessary to replace the transmission oil. And do this periodically approximately every 40...50 thousand kilometers. If replacing the ATP fluid does not help, additional diagnostics of the box is needed.

“Automatic” kicks: what does it mean?

An automatic transmission is a complex unit consisting of a large number of mechanisms. Structurally, this transmission is not similar to a manual transmission, a variator, and even more so to a “robot”. This is a separate, independent unit with its own characteristics. “Automatic” makes the process of driving a car as simple as possible, but requires increased attention. Repairing an automatic transmission is much more difficult and financially more expensive than repairing a manual transmission. This is probably the only factor that repels potential buyers of cars with automatic transmission. Also, the “automatic machine” needs special care. If the driver does not monitor the condition of the transmission oil, he is guaranteed to encounter problems with the operation of the gearbox.

- Jerks and jerks - causes and solutions

Various breakdowns of the automatic transmission seriously impair comfort or even prevent further operation of the vehicle. Typically, the car signals transmission malfunctions with jerks and jolts; less often, slipping occurs or one of the gears does not engage at all. Drivers often notice automatic transmission kicks, which in practice look like this:

- when the gearbox selector is moved from position P to position D (or to any other mode), a significant jerk of the car is felt, which was not noticed before;

- right while the car is moving and changing to an up or down gear, the box kicks, that is, shocks are felt in the rear bumper, after which the car sharply rushes forward.

There can be several options for a breakdown: the box kicks only when “cold” or only when “hot”. All this indicates a problem. You should immediately go for a diagnosis, without waiting for the situation to worsen. Delay in this case can cost serious repair costs in the future. Only a competent specialist is able to determine the exact cause of a malfunctioning automatic transmission based on direct signs.

Incorrectly selected ATF fluid

Please note that the transmission of a particular vehicle must use ATF fluid of a certain viscosity and with the performance characteristics required by the vehicle manufacturer (or transmission, if the automaker only performs the assembly). Accordingly, you need to refill with the “correct” liquid. Because oil with unsuitable parameters can also lead to jolts or kicks when the car is moving.

Another common case is that the automatic transmission jerks “when cold ,” in particular, after a long period of inactivity in the cold, for example, in the morning. However, after warming up the problem disappears. This means that the car owner initially selected the wrong oil, which thickens in the cold and does not ensure normal operation of the automatic transmission. Accordingly, you need to choose a thinner oil.

Kicks while accelerating

Unstable operation of the box while the car is moving can be caused by:

- clogged oil filter;

- the need to change the oil;

- incorrect positioning of the gearbox selector;

- damage to electrical wiring.

You cannot operate a car with an automatic transmission in winter without first warming up the engine and gearbox. A sudden start of movement with not warmed up oil leads to rapid wear of parts and the appearance of kicks when the speed increases.

Oil filter

Even in the most modern and technologically advanced automatic transmission, where the drive gears are adjusted to each other with very high precision, metal shavings still form in the transmission fluid over time. This is due to the banal wear of metal parts. And the more wear, the more chips. Well, wear and tear is determined by the mileage and operating conditions of the car.

Accordingly, the oil filter in the automatic transmission system becomes clogged over time and cannot pass the required amount of oil through itself. This leads to a decrease in operating pressure in the system , which causes friction discs to suffer. They do not stop at the right moment, and are not clamped with the necessary force. Accordingly, the discs begin to slip , which is the reason for the appearance of shocks when changing gears, both when accelerating and when braking the car. In the worst case, when there is very little oil and the load on the discs is high, they can also burn out.

This situation is especially relevant when the automatic transmission jerks “on hot” . That is, when the engine and transmission system themselves are very hot, and then low pressure and an insufficient amount of ATP fluid occur.

The conclusion suggests itself - it is necessary to monitor the condition of the transmission oil filter, use high-quality ATF fluid with the parameters specified by the automaker. And of course, change the filter and the oil itself on time.

High temperature and low valve pressure

Before identifying the reasons for the incorrect operation of the machine, you should make sure the quality of the oil being poured. The duration of operation of the box, as well as the degree of wear of components and assemblies, depends on this.

The oil in the box is in constant interaction with rubbing parts and is exposed to high temperatures. Such conditions reduce viscosity and change the structure of the liquid. Therefore, after traveling a distance of about 50,000 kilometers, the transmission oil must be changed.

The filter in the automatic transmission also gradually deteriorates, and its particles enter the oil, changing its composition and properties. In addition, particles contaminating the filter reduce its throughput. This entails a decrease in pressure in the box and deterioration in the performance of the clutches. This is exactly the case when the driver feels the automatic transmission kicking when it’s hot.

Friction discs

The clutches in an automatic transmission act as a clutch. Their task is to start or stop the necessary gear. Friction discs compress and decompress. And they are driven by transmission fluid, which circulates through the system under pressure. Accordingly, if the pressure is not enough, then the discs are not able to compress and unclench with the required force. That is, they simply slide and rub against each other, and if there is a lack of oil, they heat up and burn.

In the case when one or more friction discs are critically burnt , while the other clutches are still in more or less normal condition, shocks occur when shifting on a specific pair of gears . For example, when moving from first to second, from second to third, and so on. Moreover, this can happen both when increasing gears and when decreasing them, that is, when braking the car.

In turn, this leads to rapid aging of the ATF fluid. For this reason, it also burns, becomes black and loses its properties. It also acquires a specific burnt smell . In a completely “neglected” case, when the friction discs are significantly worn out and/or simply burnt, the gears in the gearbox will not be able to stop or start if necessary. This situation leads to the fact that when switching gears of the automatic transmission, kicks or twitching are felt. You can also often hear unpleasant crunching sounds coming from the gearbox.

If the discs are critically worn, then gear shifting is completely impossible. Another option is that when you put the car in neutral, it still continues to move. Wear of the friction discs is a very serious breakdown, and without dismantling the automatic transmission and opening it, repair is impossible.

Gearbox faults

Gearbox malfunctions will differ due to their design features, but both manual and automatic transmissions have typical signs of failure of certain components. The table contains a description of the main symptoms and solutions to problems Read more

Oil cooler

The purpose of the radiator in an automatic transmission system is to cool the ATF fluid. When its performance characteristics decrease, the oil becomes very hot and burns. This not only spoils the fluid itself, but also affects the operation of the automatic transmission as a whole for the reasons described earlier.

The main reason why the radiator gradually fails is the replacement of transmission fluid under pressure . When performing this procedure on so-called high-pressure apparatuses, the system is installed in the gap between the cooling radiator and the automatic transmission itself. Next, the old oil is removed from the system under pressure and new oil is poured in its place. However, the process does not imply either replacing the oil filter or washing the transmission pan, including the radiator. Therefore, a situation arises when dirt from the bottom of the sump is forced to the top and clogs individual elements of the transmission, in particular, the radiator, oil filter, valve body, and solenoids.

The radiator consists of many small pipes and honeycombs, which simply become clogged with dirt. And as the temperature rises, it burns to its walls, which significantly reduces the efficiency of the oil cooler.

Accordingly, in order to get rid of shocks when changing gears in an automatic transmission, one of the options is to clean the ATF cooling radiator. From now on, it is advisable not to change the ATF fluid under pressure, but to change the filter along with it, and also clean the radiator (magnets). This will cost more, but in the long run it will extend the life of the automatic transmission as a whole.

Trouble starting and driving

If the automatic transmission kicks when starting to move or during a long, monotonous trip, then it is most likely necessary to replace the solenoids. Another common cause of problems at the start is wear of the friction pack. And if you can install new valves yourself, then you can replace the friction elements only at the service center.

It is important not only to maintain your car in a timely manner, but also to regularly check the condition of the engine and the level of all fluids. Before you start driving, you should periodically look under the hood to make sure there are no oily stains and that all elements are intact and securely fastened.

Oil pump

In fairness, it is worth noting that the pump very rarely fails. Depending on the design, the pump can be installed in one of two places:

- directly behind the valve body;

- below on the pallet, unwinding with a chain from the drive shafts of the automatic transmission.

The design of the pump is very reliable, however, if there is mechanical damage or a manufacturing defect, it can also break. Accordingly, under such conditions, the transmission fluid will stop circulating at operating pressure or at all. The pressure will drop, which will lead to jerking when shifting gears, and in critical cases - complete failure of the gearbox.

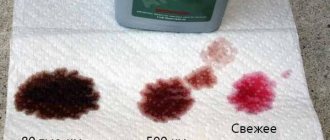

Checking the oil level in the automatic transmission

To obtain the most accurate results, you need to check the transmission fluid level both in a warm state and in a cold state, using a dipstick. Before checking, you should pay attention to the car manufacturer's recommendations in this regard. Many devices have o and “HOT”; you need to navigate according to the scale that corresponds to the condition of the oil.

The procedure is carried out with a warm transmission or after starting the engine for 3 - 5 minutes, after which you can begin:

Hydraulic unit

The second name for the hydraulic unit is hydraulic plate. This part of the automatic transmission is the control part, and consists of many small channels through which ATF fluid directly moves under pressure. Briefly, it can be noted that each gear has its own channel with liquid, which, under pressure, causes the clutches to compress or decompress.

Accordingly, if the mentioned small channels become clogged with dirty liquid, then the pressure will not be enough for normal operation of the clutches. They will not be able to compress and unclench normally, and jerks or jolts will appear in the behavior of the car.

The reasons for this are still the same - using dirty oil (delayed replacement), replacing ATF fluid under pressure. Cleaning the mentioned channels is possible only by dismantling and disassembling the gearbox, and this can be quite expensive.

Another reason associated with the valve body is plate wear . The fact is that the hydraulic unit consists of two plates, between which there is a special plate. The ball-shaped rod from the solenoid rests against it. This ensures that the pressure is closed (fixed). There is a hole in the specified plate, which is blocked by the specified ball. Over time, the hole breaks, which leads to minor jolts when changing gears on an automatic transmission. In order to get rid of this problem, it is necessary to grind the mentioned plate, or replace it with a new one in case of significant wear. In any case, it is necessary to dismantle the gearbox for detailed diagnostics and repairs.

The box jerks when accelerating

Sometimes it happens that the automatic transmission kicks when it’s hot and jerks while accelerating the car. Below we will look at why this happens.

Causes

What causes the car to jerk when accelerating:

- Some components of the transmission unit have worn out.

- The automatic transmission often kicks into gear as a result of violation of operating rules. Therefore, before using your car with an automatic transmission, it is recommended to carefully study the service manual for the car.

- Twitching may occur due to a violation of the timing or quality of maintenance of the unit.

- Making mistakes when changing the oil in the gearbox.

Remedy

To get rid of the twitching problem, do the following:

- Diagnose the quantity and condition of the lubricating fluid. If necessary, replace it and flush the transmission. The level must be normal.

- Carry out a detailed inspection of the condition of the unit. It is not recommended to disassemble the automatic transmission yourself, especially if you do not have experience in this. You can go to a service station or do a computer check. To do this, you will need a PC, software and a diagnostic adapter. The scanner is connected to the computer and a special connector, after which the program is launched. This method will allow you to identify fault codes that will indicate problems with the transmission.

- Be sure to familiarize yourself with the operating features of the gearbox. Study the service book and take into account all the nuances described in it.

You can learn more about diagnosing the fluid level and adding oil to the automatic transmission from the video (material published by the Live Video Blog channel).

Solenoids

Solenoids regulate the supply of transmission fluid to the valve body channels mentioned above. They are special valves that open and close at the right time. They work with the help of rods included in their design. The return stroke of the rod is ensured by a mechanical spring.

Over time, the solenoid (or solenoids) can fail due to mechanical failure or simply old age. Accordingly, they either do not close or do not open the channel. The latter happens more often, that is, the solenoid leaves the desired channel in the closed position constantly. Often the solenoids do not work smoothly, but jerkily, and they get jammed. Accordingly, this affects the operation of the entire automatic transmission; it jerks when switching, and in all modes.

The situation is aggravated by the fact that solenoids in modern cars are often made of plastic. Accordingly, at high temperatures they can melt, lose their geometry and stop working correctly. There are no such problems with metal solenoids. To repair solenoids, it is necessary to dismantle the valve body, clean and adjust it, including the solenoids.

How to identify box kicks

“Kicks” of an automatic transmission are short-term twitches of the car, accompanied by dull blows in the pedal area, and reminiscent of driving along noise strips. Most often, such twitching can be felt when moving the gearbox selector from the parking position to any other, as well as during long driving, when there is a need to accelerate sharply, for example, to overtake, or stop in front of a pedestrian crossing. After some time, the automatic transmission jerks stronger and more often, which means critical wear of parts, serious damage to working units, and calls into question the possibility of further operation of the car.

Wiring from the ECU

The operation of the automatic transmission is controlled by the ECU - an electronic engine control unit. Using electrical signals along laid wires, it transmits information to the solenoids on how to behave at a particular moment in time. Quite rarely, but this can happen in older cars: the wiring oxidizes or breaks completely, and contact may be lost on one or more wires.

All this leads to incorrect operation of the gearbox, which can also result in jolts and incorrect gear shifting. It is worth noting that this is a fairly rare breakdown, and it can only be calculated using electronic error and malfunction scanners.

Electronic control unit

In even rarer cases, the culprit that causes the automatic transmission to kick is the electronic engine control unit. In particular, its firmware may simply fail. However, in such “exotic” cases, not only jerks when changing gears, but also other malfunctions may appear. For example, the engine speed will be unstable, when the lever is mechanically switched to a certain mode, the box will not respond to this, and so on. In this case, it is necessary to perform computer diagnostics of the electronic unit. Moreover, in this case, it is advisable not to use the machine, but instead to bring a diagnostic device (preferably a laptop with the necessary program) directly to the machine. It is advisable not to reflash the control unit yourself. Firstly, this requires special hardware and software, and secondly, this is a responsible matter, and it is better to entrust this to specialists who provide a guarantee for their work.

Additional reasons

In some cases, it is not the gearbox that is to blame for automatic transmission kicks, but a poorly tuned engine. In particular, the throttle valve, spark plugs, injectors, air filter, engine oil. This is especially true for the throttle valve. It is advisable that it be clean to ensure normal air passage. Same with the air filter. In general, the integrated work of the elements listed above ensures a reduction in shocks during shifting and eliminates lengthy gear changes in automatic transmissions.

The causes of shocks when switching an automatic transmission may be the cushions on which the engine and transmission are mounted. The fact is that the motor and the box attached to it in the car’s design are mounted on special “pillows”, which are two metal plates with a rubber insert located between them. Over time (including under the influence of vibrations), rubber loses its properties, in particular, elasticity and does not work properly. This leads to shocks when changing gears. You can get rid of this by replacing the pillow/pillows with new ones.

On many older cars, the automatic transmission is controlled by a cable. The same goes for the accelerator pedal. Accordingly, you can try to adjust the switching of individual speeds at certain parameters - speed and torque. However, it is unlikely that you will be able to do this on your own; it is better to seek help from a car service center.

In old automatic transmissions used in foreign cars produced in 1990...2000 (mostly four-speed), brake bands were used instead of brake clutches. This is due to the simplicity and low cost of the design. However, the problem is that they failed quite quickly. And this was reflected, in particular, when switching not between all gears, but only between certain pairs of them. For example, between 1 and 2, 3 and 4. A classic example of such a box is an automatic transmission from Ford, model 4F27E. Repair in this case is impossible, and such a breakdown can only be “cured” by completely replacing the brake band.

Anti-kick additives in automatic transmissions

The market for modern automotive chemicals is extremely saturated, and among the products presented on it, in the context of the above material, it makes sense to mention special additives for automatic transmissions. They are intended for the following purposes:

- increasing the smoothness of the transmission, in particular, shifting between gears;

- increasing the service life of both individual transmission elements and the automatic transmission as a whole;

- reduction of box operation noise;

- restoration and further protection of individual elements of the vehicle transmission;

- restoration and further protection of plastic and rubber parts of the box;

- cleaning ATF fluid from metal shavings and other debris, which allows you to increase the service life of the oil filter;

- prevention and elimination of transmission fluid leaks from the system;

- as a result, the elimination of jerks and shocks when operating an automatic transmission in a car.

Representatives of such protective additives in automatic transmission oil are: Ormex, Liqui Moly ATF Additiv, Hi-Gear HG7012.

Such additives are used for automatic transmissions every 20 thousand kilometers.

, but no more than three times on the same oil.

However, in fairness, it is worth noting that such additives have both their fans and opponents, since the compositions have more disadvantages than advantages. Therefore, whether to use additives for automatic transmissions or not is entirely up to the car owner to decide.

Results

The first thing you need to do when you experience jerks or kicks coming from the automatic transmission when shifting is computer diagnostics. The identified errors (if any) will show how serious the problem the car owner is facing.

In order not to remove the box, you can replace the transmission fluid and oil filter in it (but do not use pressure replacement). If the problem was in the liquid, this should be enough to eliminate the shocks. If changing the oil does not help, you will have to dismantle the gearbox and perform diagnostics in a car service center. This procedure is quite expensive, but necessary.

To avoid problems with the automatic transmission in the future, try to monitor it, periodically change the oil and filter, and do not use the automatic transmission in critical modes.

Ways to remove excess oil

With a slight overflow, the problem is not acute, so there is no need to panic. When an excess of liquid is detected in a timely manner, there is no need to involve service employees in the process. If a motorist has poured oil into the automatic transmission when replacing it, he is able to completely cope with the task on his own. Often the solution is to remove the oil filter. When the liquid completely drains from the filter element, it is replaced. If such manipulations do not help eliminate the problem, the excess amount of lubricant is removed by sucking it out.

To remove excess oil yourself in this way, you will need a 10 cc syringe and a dropper. Next, we perform a number of simple steps:

If the volume of oil poured is more significant, then the excess will need to be drained through a special hole.

The procedure for removing excess grease is quite simple, so even a novice motorist can cope with it. The main thing is to observe the condition of monitoring the fluid level, so as not to cause troubles associated with a lack of lubricant. It is necessary to check the volume and condition of ATF at the intervals established by the car manufacturer's regulations or more often in the presence of unfavorable operating conditions of the vehicle.