Wheel bearings facilitate the rotation of the wheels, they account for part of the car's support, while they fix its axles and bear a high load. This part is an important element of the chassis, and if it breaks, the front wheel bearing of the VAZ classic models will need to be replaced. If this is not done in time, an unpleasant hum will appear, the vehicle's rolling will worsen, and fuel consumption will increase. If the bearing fails, the machine will be unusable.

Causes and symptoms of malfunction

Original wheel bearings on a classic VAZ can last up to 100 thousand kilometers before they require replacement. But there are several factors that negatively affect it, reducing its service life:

- Overheating associated with wheel rotation, especially in winter. A well-lubricated bearing is less likely to overheat; in addition, it is advisable not to get carried away by driving too fast.

- Condition of the roads. This is the main cause of breakdowns, after which the front wheel wheel bearing needs to be replaced. It is he who takes on the load of a dynamic impact when the wheel falls into a hole or hits a ledge on the surface.

- Aggressive environment. If the bearing protection is damaged, dust and dirt, as well as reagents used to treat roads during the cold season, begin to get into it. This quickly damages the bearing.

The main sign that the bearing has failed is a characteristic noise when driving, coming from the front hub. There are other signs by which a malfunction can be identified:

- Having raised the front wheel on a jack, take it on the sides and carefully move it left and right, as if turning the wheel, and then up and down. If you feel play in the wheel bearing with a characteristic tapping sound, it is worn out and requires replacement;

- In neutral gear, spin the wheel, listening to the operation of the bearing; it should not creak, buzz or make other extraneous sounds. Please note that sometimes when turning the wheel you can hear the pads rubbing, this has nothing to do with our problem.

Video: Replacing the front wheel bearing of a VAZ 2106

Once you identify a problem, you need to quickly solve it. Replacing the front wheel bearing is quite a painstaking job, but with minimal skills you can do it yourself, especially since it does not require special equipment. To do all the work, you will need a set of keys, a hammer, a screwdriver with a strong handle or a chisel, attachments for knocking out clips - small-diameter steel rods.

How to repair a car

In this article we will look at how to change the rear wheel bearing of a VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic and how to check the rear wheel bearing of a VAZ.

It was time to change this bearing a long time ago, but for some reason I only got around to it now. On the highway the car still behaves normally, but on the off-road the rear of the car began to wobble, and it began to creak when cornering.

The easiest way to check the rear wheel bearing is to press the outside of the wheel with your foot to wiggle it (you will hear a distinct thud). The wheel will simply dangle.

The procedure for replacing the front wheel bearing on a VAZ classic model

If you begin to hear the hum of the wheel bearing while driving, you need to replace it. To get to the bearing, the front wheel is removed, the hub of which will be replaced. Then the steering wheel is turned towards the removed wheel. This is necessary to spread the brake pads, which is most conveniently done with a long-handled hammer. After spreading the pads, the caliper is unscrewed and moved to the side, and the steering wheel is leveled.

The cap on the central nut is removed with a special device, and if it is not there, with a screwdriver or chisel, lightly tapping it with a hammer. To check the front wheel bearing, you can spin the race again, and you should hear a distinct noise.

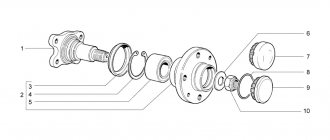

The central nut of the hub is unscrewed, for which you will need a 27 wrench, after which it can be easily removed. To dismantle the bearing, the front hub is placed on a flat surface, after which the inner part is knocked out with a tool. The seat is cleaned and new lubricant is applied. Next, the bearing races are knocked out in a circle so as not to damage the hub. Please note that the oil seal does not sit too deep; there is a thrust ring behind the cage.

Installation begins with the inner race of the new bearing, which is installed in the seat and carefully hammered into place. To bring it into place, we use an old clip, which we put on top. We install the outer clip in the same way; the old clips are carefully removed, serving as auxiliary devices.

Litol-24 grease is filled into the hub from the inside, and the bearing itself is lubricated with it, after which it is placed in the seat, with the cone down, when viewed from the side of the inner race. Then the support ring is installed, this is done with little effort. Next, we attach the oil seal and hammer it in a circle so that it becomes flush with the hub.

The same grease is used to lubricate the outer part of the hub and the bearing, which we carefully install into the seat. Next, the hub is installed; to do this, carefully wipe the axle so that metal shavings or scale do not accumulate in the channel.

We put the hub in place, wipe it, and put the washer on and tighten the nut. Please note that the kit includes two nuts. On the right side there is a left-sided one, on the edges of which there are marks. On the right side, which goes to the left side, there are no such marks. When installing, the nut is initially not fully tightened, after which we reinstall the brake caliper and wheel.

When adjusting, the hub nut is tightened until it stops and then loosened slightly. When the wheel rotates, no extraneous noise should be heard or play should be observed in any of the planes. If the wheel makes about two and a half turns, the nut is tightened normally. To prevent the nut from unscrewing, it needs to be capped. Litol-24 is filled into the protective cap before installation; it is seated in place with light blows of a hammer through a special clip, which can be used as a suitable piece of pipe. After this, the wheel nuts are finally tightened.

Adaptation kit for wheel bearing 2108 for VAZ 2101-2107

- Engine Crankshaft

- Flywheel

- VAZ cylinder head

- Sports camshafts

- Sport timing valves

- Cylinder head components

- Belts | Timing gears

- Gaskets | Oil seals

- Intake system

- Throttle valve

- Clubturbo pistons

- TDMK pistons

- Federal Mogul pistons

- Piston rings

- Connecting rods

- Engine mounts

- Inserts for VAZ engines

- ACL earbuds

- Oil catchers

- Oil crankcase

- Oil pump

- Miscellaneous

- Turbo Turbo kit

- Turbochargers

- Turbo manifold

- Bypass valves

- Westgates

- Intercooler for VAZ

- Intercooler kit

- Piping kit (air ducts)

- Turbo parts

- Adapters for installing an oil cooler | sensors

- Straight pipes

- Blocking

- Vacuum booster

- Clubturbo suspension

- Silencers for VAZ

- Control units | Wiring

- Filler necks

- Moto kits Turbo

- Adapters for installing sports steering wheels

- Keychains

- Bumpers tuning for VAZ

- Hoses | tubes

- Thermal insulation

- home

- Catalog

- Transmission

- VAZ drive

- Adaptation kit for wheel bearing 2108 for VAZ 2101-2107

What bearings to put

When a wheel bearing requires replacement, the question immediately arises of which part to install. Many people advise using original components. However, today the quality of parts leaves much to be desired and the issue of choice remains quite relevant.

Table: type, installation location, and size of bearings

| Installation location | Bearing type | Size, mm | Quantity |

| Front wheel hub (outer support) | Roller, conical, single row | 19,5*45,3*15,5 | 2 |

| Front wheel hub (inner support) | Roller, conical, single row | 26*57,2*17,5 | 2 |

| Rear axle shaft | Ball, radial, single row | 30*72*19 | 2 |

Manufacturer's choice

When choosing a manufacturer of a wheel bearing for a VAZ “Seven”, we can recommend SKF , SNR, FAG, NTN, Koyo, INA, NSK. The companies listed have many locations around the world. These products are of high quality and meet the most stringent requirements.

Among the domestic manufacturers that supply bearings for cars of the Togliatti plant, we can highlight:

- CJSC "LADA Image" - manufactures and sells original Lada wheel bearings through secondary markets;

- Saratov plant - produces parts under the SPZ brand;

- Volzhsky Plant - uses the Volzhsky Standard brand;

- Vologda plant - sells products under the VBF brand;

- Samara plant SPZ-9.

Checking the hub

Set the car to the handbrake and lift it with a jack, grab the top and bottom of the wheel, and rock it in different directions. There should be no backlash or knocking.

Spin the wheel; no extraneous sounds should be heard during free rotation. The wheel should rotate smoothly without difficulty. If play, knocking or irregular rotation accompanied by a crunching sound is detected, it is necessary to replace the bearings.

Before proceeding with the replacement, you need to purchase in advance the spare parts that will be needed during the repair:

- bearings, internal and external;

- stuffing box;

- new lubricant;

Tool

To carry out this operation you will need the following tool.

1. Special puller for dismantling and installing bearings of both hubs on VAZ cars with front-wheel drive.

Without such a tool, removing the old and installing new bearings is hardly possible.

2. It is necessary to have a mandrel, which can be a small fragment of a metal pipe of suitable diameter. This device is useful for knocking out the hub itself.

3. A 30mm wrench head with a strong and sufficiently long wrench. You will also need a 19 and 17 socket wrench.

4. It is also necessary to have wheel chocks to prevent the car from rolling. Of course, you can’t do without a wrench that unscrews the wheel nuts.