If significant play is felt when the suspended wheel is rocked or noise (howling, humming) is heard while moving, the hub bearing may have failed. The noise may become louder when cornering and on bumps. If you have signs of a bearing malfunction, it is better not to delay replacing it, as it may jam. If the bearing jams while driving, this will lead to uneven wear of the wheel tread, possibly damage to it, loss of vehicle control, and in the worst case, an accident. In this article we will talk about how to change the bearing on the rear wheel hub of a Lada Kalina car on your own.

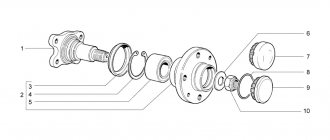

The hub is equipped with a double-row ball bearing 2 (Fig. 1), which does not require adjustment or lubrication during operation, that is, throughout its service life, it does not require any maintenance.

Rice. 1. Lada Kalina rear wheel hub : 1 — mud ring; 2 — hub bearing; 3 - hub; 4 - thrust washer; 5 — hub fastening nut; 6 - sealing ring; 7 — hub cap; 8 — retaining ring; 9 — hub axis

Operations for removing (replacing) the rear wheel wheel bearing Lada Kalina

1. Remove the protective cap...

2. ...and loosen nut 5 (see Fig. 1) securing the hub.

3. Engage 1st gear and place chocks under the front wheels, 4. Loosen the wheel bolts and hub nut. The hub nut is tightened with a large torque, so it is recommended to use, for example, a piece of pipe as a lever.

5. Raise the rear of the car and place it on secure supports.6. Remove the wheel from the bearing to be replaced and the brake drum7. Completely unscrew the hub nut and remove the thrust washer.

8. Install the puller and press the hub off the axle.

9. Clamp the hub in a vice and remove the retaining ring 8 from it (see Fig. 1).

10. Using a puller, press the bearing out of the hub, clean the inner cavity of the hub, press in a new bearing and install the retaining ring. Make sure the retaining ring is completely seated in the hub groove.

11. Press the hub onto the axle using a suitable mandrel, applying force to the inner race of the bearing. Then install the brake drum and wheel. Before installing the brake drum, thoroughly clean the mating surfaces of the hub and drum from rust and scale, since even the smallest particle sandwiched between the mating surfaces will cause drum beating and vibration during braking. To press in the bearing, use the appropriately sized mandrels from the kit. If there are no mandrels, you can use rings from an old bearing.12. Finally tighten the hub nut in the same manner as the wheel bolts with the vehicle on the ground. It is best to use a new hub nut or a nut from another wheel (so that the old, jammed parts B of the nut flange do not fall into grooves A on the shank of the outer CV joint when cored).

13. After final tightening of the hub nut, lock it and install the protective cap in place.

The Lada Kalina car was released in 2004. Since then, the model has been produced in three body types, each of which received its own factory index: sedan (1118), 5-door hatchback (1119), station wagon (1117). In addition, the model range includes two charged versions of Lada Kalina Sport with 16-valve engines of 1.4 and 1.6 liters.

The Kalina engine range includes four engines: two 8-valve 1.6-liter engines, a 16-valve 1.4 and a 16-valve 1.6. Eight-valve 1.6 engines with factory indexes 21114 and 11183 are based on the VAZ-2111 engine. The volume was increased by 100 cubic meters, changing the stroke of the piston, but the diameter of the cylinders remained the same. The larger volume invigorated the engine, but the vibration load increased significantly. Many owners complain about the noise of 8-valve engines. Its main source is the catalytic collector. You can achieve silence by replacing it with a conventional collector without a catalyst. True, then problems with passing technical inspection are likely, since Euro 3 standards will have to be forgotten.

Advice for motorists

- Purchase spare parts only from trusted, reliable retail outlets, ask for quality certificates for products.

- If there are no mandrels for pressing, use rings from old bearings.

- Remember, when pressing, apply all your force only to the outer ring.

- The replacement process is not so simple, but at the same time you save money on service station services and still, you can do it yourself faster than getting the car back from the service station.

To make it easier to study the repair process, watch the video on the topic “Replacing the Kalina front wheel bearing - VAZ 1118”:

Front wheel bearing replacement process

In order to successfully replace the front wheel bearing on a Lada Kalina car, you will need to acquire the following type of tool:

- head at “30”;

- thin chisel;

- screwdriver;

- pliers that can be used to remove retaining rings;

- a set of mandrels, a wrench and a mount.

Let's get to work.

- Disconnect the terminals from the battery terminals.

- Loosen the hub nut.

- We hang up our Lada Kalina and remove the wheel from the required side of the car.

- Now we move on to removing the caliper and brake disc.

- We unscrew the fasteners that secure the ball joint to the suspension steering knuckle. We disconnect the knot (you will need a pry bar).

- We unscrew the hub nut and remove the axle shaft assembly with CV joint from the splined engagement with the hub.

- Next, we proceed to dismantling the knuckle from the mounting bracket on the shock absorber strut. We perform the action by unscrewing two bolts and nuts.

- Having removed the steering axle, we proceed to pressing out the hub. In most cases, during this manipulation, the hinge is destroyed, and its outer race remains inside the seat in the fist. Here a puller comes to the rescue, with which we remove this clip.

- Do not forget about dismantling the bearing retaining rings, which must be replaced only with new analogues.

- Next, we press the inner race of the bearing off the hub shaft.

- We begin assembly by installing the outer retaining ring inside the steering knuckle seat.

- Using a suitable mandrel, we press in the new bearing.

- Now we install the hub itself. We press it in carefully to ensure the correct seating depth inside the cage.

- The remaining assembly manipulations are carried out using the reverse disassembly algorithm.

Replacing the front wheel bearing on the other side of the car is absolutely identical to the sequence of actions we considered.

Let's sum it up

Replacing the front wheel bearing directly with your own hands does not involve any difficulties, this can be seen even from the video materials. Tuning enthusiasts install bearings on their Kalinas that are included in the hub kit from. This product has improved characteristics and can last up to 60 thousand km. The price for these analogues is also considerable - about 2 thousand rubles. for one set.

Universal puller for steering ends and ball joints Autom-2

with 9% discount

Puller (three in one) of rear and front struts, disassembly of steering rack

with 16% discount

Protective cover for caliper finger for VAZ 2108-21099, 2110-2112, Lada Kalina, Oka

with 19% discount

Dashboard mat for VAZ 2113-2115

with 19% discount

Throttle valve 52 mm for VAZ 2108-2115, 2110-2112, Lada Priora, Kalina, Granta (gasket as a gift)

with 9% discount

Button for turning on external lighting VAZ 2113, 2114, 2115

with 19% discount

Impregnating fluid for zero resistance air filter

with 19% discount

Zero resistance filter in standard housing

with 11% discount

The plastic case contains 23 items for the careful removal and installation of wheel bearings on front-wheel drive vehicles with a diameter of 50, 55, 60, 64, 67, 70, 72, 74, 75, 78, 82, 84, and 88 mm. Suitable for most cars. Can be used for work with industrial bearings.

Manufacturer: Russia. Article: 03261.

Pay for goods by credit card, using QIWI, Yandex.Money or WebMoney and save on your purchase from 4%, avoiding postal and bank commissions

This product was chosen by 23 customers

Designed for dismantling wheel bearings (front and rear).

Manufacture: Russia

Weight, kg: 2.1 Dimensions, cm: 17 x 9 x 8 Volume, m3: 0.00122

Analogue bearings

As an alternative, you can consider the products of two manufacturers:

- "Weber", product catalog code - "BR 1118-3020";

- "Pilenga", part number - "PW-P1313".

The products of these companies have proven themselves well. The cost is approximately 1 thousand rubles. The contents are identical to the original delivery.

In practice, it has been revealed that a bearing from a VAZ-2108 may be suitable for the LADA Kalina hub, but it is a few hundredths of a millimeter narrower. Experts do not advise leaning towards this alternative, since there have been cases when the product rotated inside the hub.

A quick overview of wheel ball bearing pullers

It is impossible to choose a universal kit for all types of car repairs, since the range of actions is limited:

- a variety of shapes, sizes for charging to the starting position;

- limited work space.

Cup - “Force 9T0311”

- Internal mandrels 34-80 mm.

- External mandrels 44-90 mm.

- The dimensions of the outer diameter of the cups are 44-90 mm.

- Rod (stud) with nuts.

- The plates fit a wide range of sizes.

- The steering knuckle remains in place.

- The set is included in the workshop press kit.

- Pressing-pressing takes place in one step.

Three-jaw – “KS TOOLS 630.3002”

Garage tool. Suitable for use in restricted access work areas.

- Long life if you follow the manual.

- The articulated design of the paws engages securely.

- Removing stuck parts from shafts and machine axles.

- Wide grip range - 20-230 mm.

- Maximum force - 4.5 tons.

- Screw rod dimensions: M18 x1.5 x 240.

- The dimensions of the bolts for the hinges are 19 mm.

Two-grip universal – “Kukko K-2030”

The tools from the set of the German manufacturer Kukko are well-thought-out forms of gripping mechanisms. On the traverse, the paws move along guides, and the suspension screws fix the specified position.

- Grasp the paws at an angle parallel to the axis of the tension force.

- Reliability of engagement.

- Maximum tension - 5.5 tons.

- The legs rotate 180 degrees.

- Wide grip range.

- Double acting.

- Suitable for use in confined spaces.

Hydraulic pullers

You can also find hydraulic pullers on the market. The operating principle of hydraulic SSPs is similar to jacks. Designed for repair shop mechanics, no muscle power required, speeding up the repair time. Pay attention to the quality of the metal, the rotation of the screw rod, and the condition of the hinges.

- the force of influence on the pressed-in unit reaches 20 tons,

- operation time is reduced,

- the share of physical costs is reduced.

- limitation of the working area of application,

- the price is higher than a mechanical tool.

Reviews

| № | Positive |

| 1. | Gennady: I’ve been actively using the car for two years, there are no comments on the chassis or suspension. Once I replaced the rubber boot on the left CV joint. |

| 2. | Kirill: I have driven the car over 80,000 km, I can say that the CV joint still has service life, but it is necessary to prepare for repairs. In general, the parts are maintained within the period specified by the manufacturer. |

| 3. | Vyacheslav: the car is a year and a half old, I bought it at a dealership, no complaints. I systematically carry out technical inspections, buy original consumables, and do not skimp on preventative maintenance. |

| 4. | Dmitry: replaced the “grenades” only at 90,000 km. The service station master said that the mileage is good, not every car gets that much mileage. I believe that careful driving contributed to extending the life of the vehicle's chassis. |

| 5. | Leonid: I’m pleased with the build quality of the car, there are no complaints. Breakdowns happen, but they are insignificant, I fix them myself. |

| 6. | Vasily: if you don’t take into account minor flaws, then the car is good, better than previous generations. |

| 7. | Victor: I drove Grant for a year and a half, didn’t do any repairs, visited a service station only for diagnostics. |

| Negative | |

| 1. | Ivan: I replaced the right CV joint for the first time at 45,000 km, after which the left one needed repairs. In general, the workmanship is low, I am dissatisfied with the machine. |

| 2. | Alexander: standard CV joints are weak and poorly made. After purchasing a car, experts recommend installing foreign analogues. True, the cost is 15% more expensive than domestic ones. |

| 3. | Vladlen: after two years of active driving, I can’t say anything bad. Minor defects are present, but they can be easily fixed. |

Conclusion

Provided that the equipment is used moderately on uneven road surfaces, the average service life of CV joints is 85,000 km.

Review of manufacturer prices for front and rear hinges

How to choose and buy quality parts

Service center specialists strongly recommend purchasing consumables and components exclusively from specialized stores, representative offices, and official dealers.

To a lesser extent, you need to use the services of unverified suppliers who sell spare parts at an unusually low cost.

When purchasing, check the catalog numbers with the actual data specified in the operating instructions for the technical device. If such a brochure is not available, consult a specialist.