In connection with the introduction of European exhaust emission standards, at the beginning of 2011, the AvtoVAZ concern began equipping Lada cars with the E-gas system. Subsequently, the manufacturer provided Grant with an electronic gas pedal.

The general meaning of the operation of the electronic system is that by moving the gas selector pedal, special sensors are activated, which are located in the gas pedal module (hereinafter referred to as MPG). With each change in the force exerted on the MG, the resistance of the sensors also changes. After which an electrical signal is generated, which enters the ECU, is read, processed, and depending on the degree of pressing and the results of processing, the final operation of the throttle valve is regulated.

We set off up the hill, helping ourselves with the handbrake

If on level ground you can practice the starting moment for a long time and safely, then when starting up a hill you should be especially careful and be sure to use the basic skills you have already acquired. In this case, the risk of a rollback is added to the negative influence factors. As a result, the novice driver holds the car on the slope with the brake pedal, and when the green light turns on, he frantically puts his right foot on the gas, hoping to make it in time, and stalls, rolling back. Of course, none of those waiting behind will like this situation. Therefore, you need to train in deserted places so as not to create an emergency situation.

When you approach an intersection or stop for any other reason on an incline, you need to immediately tighten the handbrake cable. To start, you need to do everything as in the case of starting on a flat road, but release the handbrake only at the moment when the gas pedal is already lightly pressed. You can understand that the handbrake needs to be lowered by the characteristic rush of the car forward; a slight vibration occurs; due to the increase in pressure in the area of traction of the wheels with the road, the rear of the car will squat slightly.

When you approach an intersection or stop for any other reason on an incline, you need to immediately tighten the handbrake cable.

After practicing a few times, you will already know when this moment comes. That is, the car is released from the brake when the gas pedal is partially pressed and the clutch pedal is partially released. After driving a few meters in half-clutch, you can completely release the leftmost pedal.

Separately, a few words need to be said about the difficulties when removing the wheels from the hand brake. This is due to the load on the teeth of the drive lever. It happens that it’s time to get moving, but the button doesn’t want to be pressed with your thumb. In such cases, you just need to pull the handle up a little. This will ease the pressure on the mechanism, thereby allowing you to easily remove the handbrake and drive with half-clutch.

The car pulls to the side

It is clear that not only the brakes can be to blame for a car drifting off course - the wheel alignment angles, the wheels themselves, and the steering can also be to blame. However, quite often questions arise specifically about the brakes, especially if the car pulls sideways when braking. Most often, jammed pistons in the cylinders of one of the circuits are to blame. It is possible that the wheel may brake due to the loosening of the bolts securing the pad guide to the steering knuckle, as well as the pads getting oily or getting brake fluid on them.

Perhaps an ice or salt crust has formed on the surface of the pads, or the pads are simply wet. Or one of the circuits of the brake system does not work - the pedal is low and the braking efficiency is low. Brake disc runout, wheel bearing wear, and brake drum out-of-roundness may also be to blame.

Ignition and injection

During normal operation, the spark plug receives an electrical signal from the distributor or electronic injection system and sends a current pulse to the electrodes in a fraction of a second. Thus, the vapors in the combustion chamber are ignited. However, there are many reasons why a spark plug may stop sparking properly.

There are many methods for detecting and eliminating problems with spark plugs, but it is better to carry out diagnostics from specialists. A novice mechanic can do the following:

- Check the wires going to the spark plugs. Sometimes rough running of the engine is caused by damaged, worn or misconnected spark plug wires.

- Replace the suspect spark plug. Throughout its entire service life, it must retain its original appearance. If the spark plug is damaged, covered with oil or carbon deposits, you should contact a professional to further diagnose the causes of this condition.

Another factor why the spark plug does not generate a spark may be a malfunction of the ignition coil. This important component increases the vehicle voltage to 30,000 volts, which is the main condition for the formation of a spark. Coil defects cause misfires, which manifest themselves as jerking of the car.

Another common problem in the ignition system is contamination of the injector nozzles. This is not a very serious defect, but it also needs to be eliminated. It is advisable to clean the injectors on a regular basis to avoid costly replacements.

Very hard pedal

The pedal is tight, the stroke is short when pressed... When braking, the car loses directional stability, trying to go to the side. Most often this happens when the caliper cylinders jam in one of the system circuits. If the car does not skid anywhere, and the trouble is expressed only in a sharply increased force when braking, the vacuum brake booster or the vacuum supply hose may be to blame.

Sometimes increased pedal effort is caused by the use of low-quality brake pads, as well as excessive contamination and oiling of both the pads themselves and the surfaces of the discs or drums. But this happens quite rarely.

It is also possible that the brake pads may completely wear out or break. It happens that an ice or salt crust forms on the surface of the disks. It is also possible that the brake pad linings are of poor quality, as well as severe corrosion of the brake disc (often more on the inside).

Large pedal free play

As a rule, increased free play is accompanied by an increase in braking distance. Most often this happens when the brake system “grabs” air; at the same time, after several presses, the pedal seems to pump up, becoming tighter. Why this happened is a separate question - in any case, the system will have to be pumped, at the same time identifying possible brake fluid leaks.

Sometimes the pedal becomes loose due to swelling of the brake hoses. Broken hose cords have the same effect. But this happens only with left components. Sometimes brake fluid can boil, but this also happens either with a frankly poor-quality product, or with a very old brake fluid that has never been changed at all.

Another possible cause is very large runout of one or more brake discs. In addition, the automatic clearance maintenance device in the drum brake mechanisms may not work.

Adjustment

The adjustment process may vary on different car models, since different manufacturers use mechanisms of different designs. But the same principle can be applied for configuration. As for a specific model, it is better to find information on it in advance.

To begin the adjustment, the first step is to remove the pedal from the holding bracket. Next, loosen the screws securing the cover. One screw holds the cover in a certain position - it must be completely unscrewed. The cover is turned to the side clockwise until the end, then the screws are tightened again.

This adjustment will reduce pedal response time. Some car owners note that after such adjustments, the response speed can even be compared with a mechanical pedal. Adjustment allows you to improve engine performance and improve the start of movement from a standstill.

In cases where a pedal with low sensitivity is needed, it is necessary to rotate the cover in the opposite direction - counterclockwise. The machine begins to respond to presses not so quickly.

Sometimes you can come across harmful adjustment tips - drivers advise placing shims under the lever. This is the wrong approach. Sometimes the pads get caught under the contact pads in the potentiometer, and the machine may lose control as a result.

Adjusting old-style E-gas

The block cover (11183-1108500) is fixed with bolts that are inserted into oval holes. The improvement is this. to loosen the 4 screws and turn the cover in the desired direction:

- Economy mode (counterclockwise). To drive smoothly, to accelerate, you should press the pedal a little more than before. Gasoline consumption is reduced;

- Active mode (clockwise). The car reacts even with slight pressure on the gas pedal. Gasoline consumption increases. The pedal becomes more sensitive and informative.

In other words, we get the same effect as after installing JETTER (Jetter or spur).

It has been noticed that the first minutes after such settings, the idle speed may be increased (about 1300 rpm). But after a minute, the ECU gradually adjusted and the speed dropped to the usual level. If this does not happen, turn on the ignition for a minute and then start the engine.

If necessary, you can easily return to the original position (mark it in advance).

E-gas VAZ 2114 problems

Often the main disadvantages of electronic gas are these aspects:

- Delay in the car's response to pressing the accelerator pedal.

- Problems with floating speed, gas sticking and self-actuating.

- Impossibility of quick car tuning.

The delay is formed due to the fact that the signal from the pedal is first transmitted to the ECU and only after processing, the electric drive on the damper begins to smoothly change its position. In newer cars, this delay has been reduced thanks to better software and faster hardware. The e-gas equipment of the VAZ 2114 can also be reflashed, increasing the power and pedal response speed, but lowering the environmental standard to EURO-2.

Repair e-gas VAZ 2114In early versions, motorists often encountered incorrect operation of the e-gas, the speed fluctuated, there might be no reaction to the gas at all, or there could be sudden jumps in engine speed. All this was the result of faulty wiring made by AvtoVAZ; if such faults occur, it is better to replace it with a braid from PES SKK.

What is an electronic gas pedal

E-gas, unlike a mechanical pedal, is something akin to a module that includes many electronic components. The mechanism is almost perfect, with an established information transmission system. It is not directly connected to the engine - the control unit does all the work. Electronic pedal technology is simplified as much as possible, therefore it is reliable and better integrated with other latest car systems.

Electronic gas is a more effective technology that allows you to more accurately calibrate the fuel supply on modern injectors. It is often called a button, the change in angle of which is transformed into an electrical impulse by means of a microchip. The signal is sent to the ECM. The intensity of fuel flow varies depending on the specific position of the pedal.

What actions to take if a clutch malfunction occurs?

how to adjust the clutch on a Priora if there are not enough threadsImportant for the motorist to know

It is extremely important to listen to your vehicle. Timely detection of a breakdown and its elimination (the sooner the better) will help to avoid more serious consequences. Fixing a clutch malfunction means replacing the entire system or its individual element

Another disadvantage: only experienced and fanatical car owners will be able to cope with this task on their own. Most drivers who do not have their own garage and certain skills are unable to replace the unit and have to go to a service station

Fixing a clutch malfunction means replacing the entire system or its individual element. Another disadvantage: only experienced and fanatical car owners will be able to cope with this task on their own. Most drivers who do not have their own garage and certain skills are unable to replace the unit and have to go to a service station.

Another disadvantage of a unit malfunction is the cost of replacing it or replacing individual elements. If you have a foreign car, be prepared for huge costs.

Have you discovered a clutch malfunction on the road, what to do in such a situation? You need to immediately go to a car service center, because you won’t be able to drive such a car for a long time. But what to do if the service station is far away and there is no one to tow it? A trick like double-depressing the clutch pedal will help you.

When upshifting, you need to depress the pedal, shift to neutral and release the pedal. Then we depress the pedal again, switch to a higher gear and release it again. When downshifting, you need to depress the clutch pedal, go to neutral, release it, add gas, depress it again, downshift and release the pedal again.

If you still decide to repair the clutch system yourself, here are brief instructions for locating the fault: the most important thing is to correctly and very carefully disassemble the unit basket, inspecting all the discs, pay attention to worn parts, determine the condition of the springs and the number of oils The important part is inspecting the release bearing. Most often, many malfunctions are associated with it.

Most often, many malfunctions are associated with it.

Most often, many malfunctions are associated with it.

The important part is inspecting the release bearing. Most often, many malfunctions are associated with it. But it’s best, if a malfunction is detected, to sign up for diagnostics and service by experienced technicians at a car service center in Moscow

Yes, the price will be high, but the quality of the work matches this!

But it is best, if a malfunction is detected, to sign up for diagnostics and service by experienced technicians at a car service center in Moscow. Yes, the price will be high, but the quality of the work matches this!

You can make an appointment for clutch repair or replacement in Moscow by calling the phone numbers below or by leaving a request on our website. Within a short time, the manager will contact you and answer all your questions.

If the article was useful to you, tell your friends about it!

Where is the idle speed sensor for the Lada Granta: photo and video

Car : Lada Granta. Asks : Roman Chebotarev. Question : Where is the idle sensor located on a Lada Granta car?

I started the car in the morning, but the engine was running hot. The tachometer needle jumps from 1000 to 1500, and then goes to 500 and the engine stalls. It shakes a lot. I try to apply the gas, to no avail.

I went to a car store and they recommended that I pay attention to the idle speed sensor. They said that there are several types, and that I should unscrew the old one and bring it to them. But I don't know where it is.

Please tell me where to look for this sensor, under the hood?

Location of the idle speed sensor on the Lada Granta

The following two tabs change content below.

The Lada Granta with an electronic pedal does not have an idle speed sensor! That's why they sent you from the store to remove yours. There is only one idle speed sensor, you can’t go wrong if you have one, of course.

This is what the electronic pedal looks like

Finding out which pedal you have is easy. If you have a throttle cable under the hood, then you have a regular pedal. So, if you do not have an electronic pedal, then the sensor is located on the throttle valve assembly, or rather in its lower part.

How Electronic Throttle Control Works

Compared to the cable throttle, two parts were added to the E-gas:

- damper rotation motor;

- second (control) throttle position sensor (TPS No. 2).

TPS No. 2 operates in “antiphase” with the first one - its signal increases or decreases by the same amount as the signal from the main TPS No. 1.

Electronic throttle valves may differ in the percentage of opening in the de-energized state and the type of TPS.

- Fully closed in a de-energized state - one spring for full closure.

- Slightly opened by 5-7% - two springs, the balance point is in the slightly opened zone. This allows the engine to operate at low speeds in the event of a complete failure of the throttle electronics. Such dampers are more modern than completely closed ones, with which, if they break, the engine will not work at all.

- With contact TPS - inside slider variable resistors.

- With contactless TPS - there are no rubbing moving contacts inside, the output signal is generated electronically.

Working principle of E-gas:

The driver presses the accelerator pedal. The degree of pressure is converted through sensors into an electrical signal and transmitted via wires to the computer. The ECU controls the closing/opening of the damper using PWM power through a motor

Both the duty cycle of the PWM and the polarity change. Based on signals from the TPS, the position of the damper is analyzed and the control signal is changed if necessary. Errors in the operation of the throttle valve are monitored.

Advantages and disadvantages of electronic gas for Grants

The system is designed in such a way that there is no need for mechanical parts connecting the accelerator itself and the throttle assembly. This approach provides a number of advantages, such as:

- reduced fuel consumption and reduced exhaust toxicity;

- instant response from the control unit to manipulations with the accelerator;

- soft pedal stroke;

- smooth distribution of engine speed.

There are also some disadvantages that car enthusiasts face. These include:

- a smooth increase in engine speed when you sharply press the gas pedal;

- low maintainability of the unit in case of failure of its components (replacement of the assembled unit);

- some inconveniences when modifying the engine.

Operating principle of the electronic gas pedal

In general terms, the principle of operation of such a pedal can be described as follows:

- The driver presses the electronic gas pedal, changing its position.

- Special sensors analyze the angle of deflection of the pedal from its original position.

- The received information is sent from the sensors to the electronic control unit.

- Based on this information, the ECU generates one or another command to the throttle valve.

- The damper opens to the required angle.

Article on the topic: Knock sensor - assessing malfunctions!

As can be seen from the information provided, the operating principle of an electronic pedal is much more complicated than a mechanical one. This is not just a lever that tightens and loosens a cable, but a full-fledged electronic module connected to sensors and other components.

Other features of the functioning of gas pedals of this type include the following points:

- A rheostat is used as the basis for electronic pedals from a variety of manufacturers.

- To transmit a signal from the pedal to the ECU, special tracks with a group of conductive contacts are used.

- To ensure high accuracy, the transmitting contacts are duplicated in many cases.

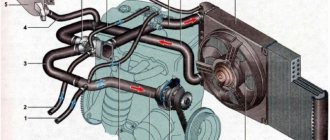

Throttle assembly Lada Granta

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

How to check the electronic pedal on Vesta with a multimeter

To diagnose the condition of the accelerator pedal, it is not necessary to completely disassemble it, but you will still have to remove it. We already know that the resistor is the main working element in the E-gas pedal, so we will check it using a multimeter in resistance measurement mode.

Checking the resistance of the E-gas resistor tracks

We have already figured out how to remove the electron gas above; now all that remains is to take two multimeter probes and install them on pins 2 and 4, as shown in the diagram. When pressing the pedal, we should observe a smooth decrease in resistance. In the same way, we check contacts 4 and 3. There are two conductive paths installed inside the pedal. Let's check the second by measuring the resistance on pins 1 and 6, then on pins 6 and 5.

Articles and prices of the E-GAS pedal Lada Vesta

If the resistance changes abruptly or the conductive track does not ring at all, this cannot be treated and the pedal must be replaced. The price of a new VAZ pedal with catalog number 8450030628 is about $22 for 2022. There are also non-original pedal units on sale with factory part numbers Ricor Electronics 2170-1108500-01 at approximately the same price. They will ask for the same amount for the E-GAS BOSCH 2170-1108500 pedal.

Diagnostics

Most often, drivers complain about the following problems with electronic gas:

- The speed fluctuates (standby mode);

- The engine does not respond to gas (emergency operation);

- Pedal play.

If in the latter case the malfunction may be purely mechanical, then in the first two there is clearly a problem with the electronics. In this case, the initial diagnosis of the electronic gas pedal can be carried out independently, but for this it must first be dismantled:

- Disconnect the block with wires;

- Using a “10” wrench, unscrew the three nuts securing the pedal;

- Remove the pedal.

To check the condition of the moving contacts and conductive paths of the gas pedal position sensors:

- Using a multimeter in ohmmeter mode, check the resistance between contacts “4” and “2”. Slowly move the gas pedal, at this time the resistance should change smoothly.

- We also check the resistance between contacts “4” and “3”.

- To check the conductive paths of another sensor, we measure the resistance between two other pairs of contacts: “1” and “6”, as well as “6” and “5”.

If there is an abrupt change in resistance on any of the pair of contacts described above, we can say with confidence that the E-gas pedal is faulty. It will need to be replaced as a whole with a new one.

Please note that when installing the pedal in place, the nuts must be tightened with a torque of 6-8 Nm.

Lada Granta electronic gas pedal malfunction

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the wiring harness connection block). In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts. There are other possible causes of the malfunction:

— no supply voltage is supplied to the throttle assembly;

— signals are not received from both throttle position sensors;

— The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place

(move to the side of the road, leave the intersection, etc.).

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 rpm, despite the fact that the engine is warmed up to operating temperature), the engine at this will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, gradual wear of conductive paths and moving contacts occurs. Over time, wear can reach such an extent that the sensor cannot function correctly. The presence of two sensors increases the reliability of the entire unit.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode. In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

The reserve mode allows you to drive your car to the repair site under your own power.

Electronic gas pedal Lada Granta

On modern cars, instead of the usual cable drive for throttle control, a so-called “electronic gas pedal” is installed. In such cars, the throttle position is controlled electronically. When you press or release the gas pedal, information about this goes to the control unit (ECU) and only after processing and adjustment is a command given to the throttle module. The pros and cons of such a system, as well as signs of malfunctions, will be discussed in this article.

Replacing the idle air regulator Lada Kalina 8 valve

The idle speed sensor in the injection system of the Lada Kalina model is a special electronic device. Such a component can be found in any other car that runs on gasoline and has distributed injection. The design of the sensor is represented by an electric motor, paired with a conical needle by the manufacturer. Note that the device is controlled by an ECU.

The idle speed sensor rarely experiences malfunctions, but if such a fact occurs, it causes a malfunction in the idle speed of the engine. They begin to “float”, and the engine, in turn, ceases to function normally. As a result, achieving a timely return to operating temperature after a cold start becomes problematic.

Functional features

The main purpose of the sensor discussed here in Lada Kalina is to measure the main parameters in the intake system and adjust the speed. This is done by sending pulses to the engine control module, which, based on the data received, adjusts the volume of injected fuel.

Due to the fact that the specified idle speed regulator acts as an actuator, determining its failure is a very difficult task. This is due to the lack of a useful self-diagnosis function in the Lada Kalina.

The device is designed to control the volumes of air that are directed through the intake tract into the combustion chambers of the engine. Here, the air mass (also measured by the mass air flow sensor) enters through a special channel, bypassing the throttle valve, which is closed in idle speed mode.

This idle speed regulator is involved in warming up the 8-valve engine, ensuring that the unit reaches its operating temperature in a timely manner.

When the ignition is turned on, a rod “crawls out” from the regulator and reaches a specially designed hole. This is called the initial position of the sensor.

Next, we outline the primary functions of this device:

- adjusting the optimal air mass;

- participation in warming up the engine 8 valves;

- determination and adjustment of the number of revolutions.

We determine the malfunction ourselves

The regulator is designed to maintain idle speed in a given range and ensure correct and timely warming up of the engine.

Although malfunctions in the functioning of the engine in this mode rarely occur on the Lada Kalina, practice has made it possible to establish a certain set of signs indicating a malfunction of the regulator.

- difficulties starting the unit;

- when the gearbox is in the neutral position, “floating” engine speeds are observed;

- when switching transmission stages on the move, the engine stops without authorization;

- Once the unit begins to warm up at low outside temperatures, the speed is not able to overcome the 1500 per minute mark, which “delays” the time it takes to reach operating temperature.

Observant owners of Lada Kalina testify to a decrease in speed after turning on the air conditioning compressor. This often leads to the engine stopping, and the lubricant pressure symbol in the unit lights up on the instrument panel.

The most common breakdown is instability of speed. For mileages exceeding the 50,000 mile mark, and if such symptoms appear, we first recommend cleaning the cavity of the throttle assembly. Only after this can the regulator be replaced. This device cannot be repaired, so this action becomes a non-alternative measure.

- Kalina 2 or Priora

- Replacing the front wheel bearing Kalina

- Replacing the handbrake cable Kalina video

Replacing the sensor is not characterized by any difficulties and allows you to do it as quickly as possible, the main thing is to know where it is.

Replacing the idle speed sensor

The sensor replacement begins, we dismantle the device.

- We remove the engine screen from the LADA Kalina and disconnect the cable connectors from the corresponding blocks on the throttle unit and the idle speed controller.

- To disconnect the heating pipes, you will need to partially drain the antifreeze. We carry out the indicated manipulations.

- To dismantle the device itself, we need a regular screwdriver with a cross-shaped profile.

- We remove the pipe leading from the crankcase ventilation system. We do this by loosening the clamps and moving them. We are temporarily putting this hose aside.

- We repeat such manipulations with the refrigerant supply pipes (if they have not been previously removed) and the purging of the absorber circuit.

- Using the key set to “13” (the head is more convenient), we remove the throttle block. It is attached to the inlet receiver with nuts.

- Let's look at the gasket. If damage is found, we must replace it, otherwise the intake system will receive unwanted air leaks.

- Installation of the regulator in the LADA Kalina car is also simple and is carried out with an eye to the reverse sequence of manipulations during disassembly.

- It is important to pre-measure the needle here. The optimal position will confirm the exit from the regulator body to a length of at least 23 mm. For measuring action we use a caliper. If the required value is not achieved, then you will need to “recess” the valve itself into the regulator body. Here we connect the positive contact of the device to the corresponding terminal of the battery (you will need a temporary cable).

We apply the bare edge of the element to the negative contact. The needle moves slowly, and therefore quite a lot of such touches will be required.

Let's sum it up

Having completed the assembly process, we check the correct functioning of the valve-regulator on the LADA Kalina car. If the idle speed is within the specified limits, then the device is installed correctly, and no third-party air leaks are observed in the intake system.

Description of the problem

In general, there was a terrible downpour, puddles on the roads, and general floods in the yards.

Heavy rain could affect the operation of the car's electronic systems

But we had to go, my wife and daughter were in the shopping center, and the queue for the minibus, according to them, was huge. I am inclined to believe that the minibuses simply stalled (we have old, decrepit Gazelles in our city).

We have one place that is constantly flooded. I look, and there are new Kia Sid floating on the radiator grille in the water, well, I’m taller, I thought that nothing would happen. Here, as luck would have it, the traffic light is still red, and the intersection is straight, only a pedestrian crossing, on which there is no one at all, since it is knee-deep in water. Most people pass it, even on red lights, quietly. And I’ve only been driving for a month, I’m not used to breaking rules yet. Has stopped.

Belt whistled due to water ingress

My Granta is standing there, waiting for the green light, and then the alternator belt started whistling, as if it was slipping. I see the voltage on the on-board computer jumps, from 13 Volts to 11.8, and there is a whistle under the hood. The light turned green and I was off. I started, drove out of the puddle, accelerated a little and the whistle disappeared. The voltage on the on-board computer screen leveled out to 13.6.

Among the current consumers, my headlights were on, the rear window was heated, the tape recorder was working quietly, and the heater was turned on at second speed to blow the windshield.

I got to the shopping center, stopped, and waited for my wife and daughter. The engine begins to vibrate and bleed a little. I went home already on the detour, there are fewer puddles there. I dropped everyone off and decided to go to the garage.

I started the engine, the revolutions jumped to 6000, I was already scared. Then they dropped to 1000, the engine sneezed and died. The check engine light on the dashboard came on. It started again, it idles, but pressing the gas pedal does not respond. I try to start, it idles and doesn’t respond to the pedal at all when driving. So I drove to the garage in second gear, well the 21116 engine is torquey and drives like a tractor.

I repeated the experiment in the garage. I started it up, tried to press the gas pedal, nothing happened, the revs were like a glove, the engine icon was still on.

How I solved the problem of gas pedal failure

- I took a smoke break and decided to remove the terminal from the battery.

- I reset it and waited five minutes. He swore that he forgot the diagnostic adapter at home.

- Reconnected the terminal and started it.

- “Jackie Chan” stopped burning, the engine reacts to the gas pedal with a vigorous increase in speed. The engine really didn’t start at first, it started only the second time.

I left the garage, circled along the pit line, and came back. There were no signs of damage. Now I'm afraid to drive in the rain.

What could it be? Now I’m subconsciously afraid that if I start the engine, my Lada Granta won’t want to go anywhere in rainy weather. How likely is this situation to happen again?

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

Conditions for carrying out the idle speed adaptation process

Before starting training, a number of prerequisites must be met:

- travel by car for 10 minutes;

- ensure that the battery voltage at idle is at least 12.9 V;

- warm up the gearbox;

- The wheels of the vehicle must be straight, the steering wheel must be in the middle position;

- engine temperature – 70–95 °C;

- all devices that put a load on the car’s electrical network (heated windows, headlights, etc.) should be turned off;

- The automatic transmission selector is set to N or P.

In order for the factory wiring of the Lada Grant to serve for a long time and not break, experienced experts strongly recommend following a number of simple rules.

- Periodically check all contact connectors and terminals for oxidation and rust. Such damage to the connections can cause a short circuit and a critical decrease in the conductivity of the line, which is perceived by the on-board computer as an error or breakdown.

- Use only original consumables and electronic components. The use of counterfeit products does not guarantee the functionality of the circuit. At the same time, some elements, when damaged, cause a voltage drop in the network, which becomes a direct cause of failure of other equipment or a fire.

- Use special oil to treat contact groups. The fluid is sold in auto shops or electronics stores. After treatment, the contacts are covered with a moisture-impermeable layer, which increases their service life by 2-3 times.

- Carefully monitor the charge level and condition of the battery. The wiring of the Lada Granta critically perceives a significant voltage drop in the on-board circuits. As a result, this may cause damage to the firmware of electronic control units.

Symptoms of a faulty electronic throttle

Like any other part of the car, the throttle control system can also be subject to damage and wear.

There are signs and symptoms to watch out for to protect your vehicle from further damage.

- The car may have jerks and dips during acceleration, and it may jerk when accelerating. Possible misfires. If you notice any of these symptoms or rough shifting, there may be a problem with the electronic throttle.

- Problems with the electronic throttle control can cause problems when shifting gears. This could be a sticky feeling or slow shifting between gears. There may be a problem with getting out of a certain gear, as if it is stuck.

- Another sign of an ED malfunction is problems with displaying power characteristics. This means that the car will display incorrect data or data that is not possible in the current situation.

- The engine may stall for no apparent reason. This could be a sign of a serious problem and could even cause engine damage, so this problem needs to be fixed as soon as possible.

- An additional sign that may indicate you need to have your E-Gas checked is if you experience rapid and unintentional increases in speed while driving. This is a big safety concern because it can happen when you are behind another car or on a turn.

- The Check Engine light may be on on the dashboard. This is a sign of some kind of malfunction detected by the ECU. You can find out the error and the cause of the malfunction using a diagnostic scanner or an ELM327 adapter with the Torque program.

- The final symptom of a faulty electronic throttle control is a sharp increase in fuel consumption. If you realize that you cannot drive as many kilometers on the same amount of fuel as before, this is a clear sign that you need to have your car diagnosed.

Causes of the phenomenon

Drop in speed and failure of the gas pedal

There are few reasons for the phenomenon of “failure” when pressing the gas pedal. It often appears after unsuccessful engine chip tuning and is accompanied by an increase in fuel consumption, but there are other problems directly with injection. So, let’s look at the main reasons for the “failure” effect:

- Injectors. The fuel distribution system directly affects engine performance.

Identifying and eliminating ECU errors

Condition of the candles. On the left the mixture is too rich, on the right it is too lean.

These are all the main reasons that can lead to gas pedal failure.

Dips during acceleration

Once the causes are considered, we can consider how to deal with the problem. So, let’s describe step by step what needs to be done when the gas pedal has dips during acceleration:

- The first step is to check the spark plugs. The appearance of carbon deposits or spark plugs that are too clean indicate that the mixture is not adjusted correctly. It is worth adjusting the correct amount of fuel mixture.

- Ignition wires can also cause the vehicle to malfunction.

- A clogged throttle can lead to failures during acceleration.

- The condition of the air filter affects the formation of the mixture, so it is worth changing it on time.

Air filter clogged

Dirty fuel filter

Dirty fuel filter

- ECU errors can also lead to accelerator failures.

- The last reason is clogged injectors. They need to carry out diagnostics, check functionality, and also clean and replace faulty elements.

Thus, the causes of failures during overclocking have been identified and can be eliminated.

Gas leaks at idle

At idle, there are fewer reasons for failures, but they will have to be eliminated, since the car simply will not start normally, or stall after starting the engine. So, let's look at the work plan step by step:

- Checking the spark plugs. If the element fails, it is necessary to replace it.

Attention! It is recommended to change all four spark plugs to ensure smooth engine operation. Before installation, you should adjust the gap using a feeler gauge, which should be 1 mm for 92 gasoline

Checking and adjusting the spark plug gap using a feeler gauge

- We change the fuel filter, it is located under the bottom of the tank, and also carry out diagnostics on the fuel pump. If malfunctions are identified, they should be eliminated.

Clogged filter in the gasoline pump

All these reasons can cause dips to appear at idle (more precisely, when switching from idle to driving mode).

What's interesting about the cable?

A cable drive is used, as a rule, in cars equipped with a carburetor, which is no wonder, the carburetor is the most mechanical component, here the injection of the fuel mixture is also mechanical. In addition, when carburetors were popular, the industry could not yet provide its products with a large number of sensors, sensors, and other smart electronics. Everything was simple: the pedal is pressed, the cable is pulled, the carburetor flap is opened slightly. The harder you press the pedal, the wider the throttle opens, more fuel mixture flows in - higher speed, higher power. And everything would be fine, the system works stably, but in cold weather it begins to show its worst side. Starting the engine in winter for many turned into torture, trying to catch the moment when the spark coincides with the required amount of mixture, playing with the choke, if you overdo it, the spark plugs will burn out. And this situation was almost universal.

Replacing the gas pedal on Grant

The replacement procedure is quite simple and does not require special technical means. In order to dismantle the unit you will need: - A key for 10.

Sequential steps to replace the gas pedal of a Lada Granta:

1. The first step is to remove the negative terminal from the battery. 2. Next, you need to move to the driver’s side of the car. 3. Above the gas pedal, find and disconnect the contact chip that is connected to the sensor connector.

4. After that, take a 10mm wrench and unscrew the three fastening nuts. When there is insufficient internal space, it is most convenient to use a socket wrench. 5. Remove the pedal from the special mounting pins. Reinstallation is carried out in a mirror sequence.

Adjusting the sensitivity of the gas pedal

"Note! Not only the pedal and its module take part in controlling the operation of the throttle valve; the throttle control unit plays an important role. Therefore, this product should also be given special attention in cases where the MPG is in a known good condition, but problems with engine speed remain.”

How to adapt

After this, turn on the ignition for 30-40 seconds. Clicks will be heard, when they stop, turn off the ignition. Next, you need to wait 4 minutes for the main relay to turn off. For some reason it turned off earlier for us.

Now you need to drive in 2nd gear 6-7 times at rpm from 1000 to 4500. When you release the gas, you need the car to coast down to reduce engine speed. After the full number of repetitions, adaptation is completed.

How to install a horn signal with a compressor on a Lada Granta