The main reason that causes the need to replace the pump is the start of a leak in the cooling system. If the car owner discovers a leak, you can continue driving for some time, but it is better to limit it to driving to the nearest service station or to your own garage.

Typically the cause of pump failure is a broken bearing or seal. In such a situation, the damaged part must definitely be replaced with a new and serviceable one.

When to change

- While the engine is running, a characteristic low hum is heard from under the hood (this is a sign that the pump bearing is worn out and needs to be replaced).

- After leaving the parking lot, antifreeze stains remain on the asphalt, which indicates a violation of the pump's seal.

It is not advisable to repair the pump; it is much cheaper to purchase a new one and install it on the car. The operation is not an easy one: in order to change the pump, you will have to remove the above-mentioned timing belt . Read more about this below.

How to determine the need to replace your pump

A water pump can fail for two main reasons - wear of the bearing or oil seal. When the bearing wears out, a distinct hum will be heard, which is a sign that the bearing is humming and the pump needs to be replaced. If a pump with a faulty bearing is not replaced in time, this can lead to it jamming.

The second reason for pump malfunction is leakage from under the seal. If you notice that your antifreeze or antifreeze has begun to run out, one of the reasons is precisely the pump. Check for fluid leaks in the area where the pump is located.

If so, the pump is most likely leaking. In this case, operating the car is not advisable, but is possible provided that you have to constantly add coolant.

Another sign of a pump malfunction is a worn timing belt. If the bearing is broken, the pump may “walk” slightly, which will cause the belt to eat up, and as a result, the timing belt may break and then you will have to deal with the capital of the motor, since the valves will bend.

We recommend: How to drain antifreeze completely: from the engine block, radiator + photo instructions

Basic faults

The main reason for pump failure is bearing malfunction. The following malfunctions of this part can be identified:

- The bearing is jammed. If a whistle or hum appears on the right side of the engine when the engine is running, it is time to replace the pump. If there is a lack of lubrication in the bearing, it stops spinning, which leads to a break in the timing belt.

- Formation of play on the bearing. If, when inspecting the car, you find traces of coolant on the pump body, this is the first sign that the pump has exhausted its service life.

- If there is a smell of coolant in the cabin, a hum when the car is running, or signs of antifreeze leakage, the pump should be replaced.

Replacement

You can replace the pump yourself; for this you will need: a 10mm socket, wire cutters, a screwdriver, a 6-corner bit, and a small ratchet.

- We drive the car onto the overpass, unscrew the crankcase and engine protection, thereby freeing access to the engine. Open the hood and unscrew the cap on the left side of the radiator and drain the antifreeze. If you plan to refill the same liquid, then place a bucket under the radiator.

- We look for a bolt on the front part of the cylinder block and unscrew it. We also drain the antifreeze from the engine into a bucket.

- We remove the plastic decorative trim on the engine; to do this, you just need to pull it up.

- We connect the ratchet with the bit and unscrew the bolts holding the front timing belt cover.

- We align the upper pulleys according to the marks on the rear timing belt cover.

- We unscrew the two timing belt tensioner rollers.

- Remove the belt and gear.

- We unscrew the two upper toothed pulleys and then pull them out.

- Using a 10mm socket, unscrew the 6 bolts on the rear cover of the timing gear drive and pull it out.

- Armed with a ratchet, unscrew the 3 screws securing the pump.

- Using a screwdriver, use a screwdriver to pry up the pump and remove it.

- We clean the pump seat from dirt and remnants of the old gasket with a dry cloth.

- On the new pump, lubricate the gasket seat with a small amount of sealant.

- We put on the gasket and also lubricate it.

- We install the pump on the engine so that the hole in its body looks down into the nearest hole to the filter.

- We tighten the bolts holding the pump.

- The pump has been replaced. We assemble all the parts in reverse order. Don't forget to add coolant.

Possibility of installing an additional water pump on the Lada Priora

One of the disadvantages of the heater on the Lada Priora car is its low efficiency when the engine operates at low speeds in the cold season, due to insufficient coolant circulation. Therefore, the car interior warms up slowly and insufficiently, which causes some discomfort for the driver and passengers.

There are some requirements that must be met to obtain a high-quality result after installing an additional electric pump.

These include the following points:

- the installed product should not create excess pressure in the heater radiator during operation in order to avoid damage to the pipes or the formation of cracks;

- It makes sense to replace the thermostat and install this component with an increased opening temperature (90–95 degrees Celsius) due to the fact that as the speed in the coolant circulation increases, the engine parts will warm up more slowly, increasing wear on the power unit.

To solve this problem, you can install an additional water pump in the cooling system of the power unit, which will qualitatively improve the heating of the car interior even when the engine is idling. This technology is not new. Engineers have been using it for a long time. Examples include German cars BMW or Mercedes Benz.

Device selection

As a rule, devices from various manufacturers are suitable as an additional water pump for the Lada-Priora car.

These, for example, could be brands from:

- Bosch company;

- ;

- .

Video: positive effect of installing an additional electric pump on the Lada Priora

However, most often the Lada Priora is equipped with an electric water pump, which is installed on Gazelle cars. This may be an old or new design, but the principle of operation is the same for both: due to the vacuum at the inlet during operation of the product, a pumping force arises, which drives the coolant through the system. In fact, the pump from the Gazelle car is a classic centrifugal pump.

The design of the new pump version is much more successful and causes fewer complaints from car enthusiasts. And it is also less noisy during operation. The main problem that motorists encounter when using such an electric pump is its leakage.

Installation and connection of an additional electric pump

To equip a car with an additional electric water pump, you will also need a regular relay that has normally open contacts (this can be an ignition or starter relay from a VAZ 2105, VAZ 2108). It is necessary to close contacts No. o86 and No. o30. And you will also need a reinforced hose and clamps for clamping the pipes.

An additional pump can be installed in any of the gaps in the supply or outlet pipes of the car’s heating stove.

Installation of an additional electric pump is quite simple, and the efficiency of the heater increases significantly

The pump is fixed in the Lada Priora in the following places:

- stud for fastening the washer reservoir;

- studs located next to the battery;

- on the engine shield.

The device can be connected to a wide variety of systems.

It could be:

- recirculation button;

- SAUO stove block;

- heated mirrors;

- other convenient places.

Purpose of the pump

LUZAR brand pump for Lada Priora

The main task of the pump is to ensure continuous circulation of antifreeze throughout both the large and small cooling circles . This ensures continuous removal of excess heat from the running engine and prevents overheating. The pump is located to the left of the car engine, near the timing belt. It can be seen simply by opening the hood.

Standard part - article number, price

AvtoVAZ installed parts with the catalog name “Pump. Water pump" for Lada Priora 16 valves and number 2109-01307013-00. Price: about 2,000 rubles.

Operating principle of the device

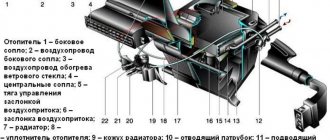

The pump design is quite simple. It consists of the following parts:

- Frame;

- Bearing;

- Impeller;

- Stuffing box;

- Shaft;

- Cardboard spacer;

- Drive pulley hub;

- Pulley.

The timing belt smoothly rests on the device pulley, which clings to the teeth. When the engine starts, the camshaft starts moving, and then the belt begins to move. The pulley turns slowly, causing the shaft to move. The shaft, unwinding, transmits torsion to the impeller through a series of bearings and seals.

The impeller is installed between two tubes: the input flow comes from the radiator, and the output goes into the cooling jacket.

The part itself is a flat circle with applied arc-shaped “petals” that take up the liquid and throw it towards the cooling jacket. So, turning over and over again, they accelerate the flow of antifreeze inside the circuit.

Recommendations for selecting and replacing a pump

When choosing a pump, be sure to purchase one that is suitable for your motor. A pump for a 16 valve engine is not suitable for an 8 valve engine. The difference in replacing the water pump is that on an 8 valve engine there is 1 pulley, and on a 16 valve engine there are 2 pulleys. . By the way, from this article you can learn how to replace the fuel pump on a Lada Priora.

At the slightest sign of pump malfunction, it is recommended to inspect and replace it. Otherwise, the car's cooling system will be disrupted and engine overheating will be inevitable. And its repair will require more serious financial investments.

A little about the difficulties of repair

The cooling system performs an important function. Replacing its components, and especially the pump, must be approached responsibly, carefully weighing your strengths. To carry out the work you will need:

- understanding of the operating principles of the node;

- a set of keys, including for the tension roller;

- assistant;

- availability of 6-8 hours of free time.

The main difficulty of replacement is the inaccessibility of the attachment points. Carrying out the work requires the ability to adjust the valve timing.

Why do you need an assistant? Some operations, such as tensioning the timing belt, cannot be carried out alone.