Rear spar

A burst rear element can lead to complete destruction of the entire car body. If during an accident the part is slightly dented, then it is corrected using a special Swedish body control and straightening stand. In case of serious accidents, straightening the parts is impossible; they are completely replaced. Therefore, it is important to carry out preliminary calculations, since changes in shape and material cause changes in the parameters of the automobile body. The rear element changes completely in situations where the part is deformed after an impact; it is not able to provide strength to the body or perform a shock-absorbing function. To perform such an operation, you need to jack up the car and do the following:

- First, those parts that are attached to the spar are dismantled.

- Next, the damaged part is stretched as much as possible (it is advisable to achieve the initial classic position).

- The protective coating is removed from it, the damaged element is cut off (cutting cutters will be required).

- Those places that remain after cutting are treated with a grinder to prevent the corrosion process.

Once the wheel arch, which will be attached to the rear side member, has been prepared, you can begin installing the new part. The fastening points are fixed by spot welding to prevent the part from moving. Welding areas are cleaned with a ground disc and treated with sealant. You can also completely replace the rear part to increase the safety of movement on the vehicle.

Attention! If violations are made during the process of replacing the rear side member, the car will pose a real danger to passengers. We recommend that you entrust the repair of these parts to specialists.

It is not advisable to weld or straighten the rear spar, since rubber wear increases and the condition of the suspension changes.

Preparation for repair

Repairing the underbody of a VAZ involves a set of measures:

- preparation of the necessary material and tools;

- interior dismantling;

- installing the car on a lift or repair plane;

- cutting out rotten elements of the bottom during partial or complete replacement of a part, if it is necessary to completely digest the body;

- patch welding or bottom welding;

- anti-corrosion treatment;

- installation of interior, replacement of sound insulation, additional work.

To repair the body yourself, you will need to prepare the following materials and tools:

- A new bottom or part of it for a complete replacement, metal patches for a partial repair. It is recommended to take industrial steel with a thickness of up to 1-1.2 mm. The standard metal on the body of the VAZ 2114 has a thickness of 0.9 mm for the bottom, 0.8 for the sills.

- Angle grinder, grinder with a set of replaceable discs from metal, for processing a weld seam, stripping metal from corrosion, to a soft attachment for grinding soil.

- Welding machine. For self-repair, it is recommended to use a semi-automatic machine using wire in a carbon dioxide environment.

- Electric drill, set of drills.

- Sound insulation sheets.

- Metal brushes, coarse and fine sandpaper, chisel, set of screwdrivers.

- Zinc-based primer, putty, set of spatulas, anti-corrosive agent for final processing.

The first stage of work is dismantling the interior and lifting the car onto the overpass.

Craftsmen do not recommend carrying out repairs in a pit; it will be inconvenient for the driver to weld the body and treat the surface. The most convenient option is to lift the car on hangers or turn it on its side.

Dismantling the interior

The bottom 2114 is a stamped part that is welded to the reinforcements of the side members and hinged panels along factory lines. Original replicas require no trimming and are ready for installation. Description of replacement in stages:

- The fuel is drained from the car and the battery is removed.

- The electrics are turned off, the front and rear doors are dismantled.

- The chairs and flooring are pulled out, and the sound insulation is removed.

- All plastic lining of the pillars is dismantled, the dashboard must be covered with a thick piece of rags.

- The glass is sealed on both sides with thick paper.

- An inspection is carried out from the inside, rusty areas are tapped with a hammer, and the scale of work is determined.

Features of replacing the front spar

Let us highlight several main reasons for wear of the front part:

- poor quality road surface;

- weakening of the steering mechanism, suspension mountings;

- driving at high speed on bad roads

There is a certain algorithm of actions when replacing such a spare part:

- Use a power screwdriver to remove the door. Soundproofing material and mats are removed from the interior.

- The wing is removed, the front part of the body, as well as the front axle, are fixed.

- The spring is tightened, 3 bolts are unscrewed from the upper ball joint, and the upper arm is dismantled.

Advice! If you can’t unscrew the bolts (they are jammed), you can use a grinder.

- Next, the stretcher is unscrewed, with the help of which the beam and the front spar are attached, and the engine mudguard is cut off using a grinder.

- The front side member, divided into two parts, is separated from the car body.

- Dust and traces of corrosion are removed from all attachment points of the front spar, and then the new part is fixed.

- The mudguard of the car engine and the lower part are welded, the fender is put in place, and the door is attached.

Every car owner must know what the front and rear side members in a car are intended for. A similar tubular structure with a rectangular cross-section takes on the main loads. The maximum of them exist in automobile side members, since they are associated with traction and lifting force. In older car models, designers used rigid longitudinal frames. When assessing the technical characteristics of the spar, it should be noted that this part is important for the car and, if deformed, can have a negative impact on the main characteristics of the car. Collisions and strong impacts lead to deformation of the side members and the appearance of cracks on them.

Damage has a serious impact on the integrity of the entire vehicle: main components, engine, suspension, doors, wings, and other parts. If the wing or car door is damaged, the deformed rear and front side members can “float”, that is, disrupt the geometry of the entire suspension. The car stops “obeying” its owner, and the rate of wear of car tires increases.

During crash tests, some modern Chinese cars demonstrated a sharp separation of the side members from the floor in the cabin. In Chinese models, welding a deformed spar is a waste of time and money. It’s better to immediately go to a service station and entrust your car to professionals who will replace the worn-out part. A significant impact negatively affects the subsequent use of the vehicle and casts doubt on the possibility of safe operation.

You can learn how to pull out the spars from the following video:

Causes and consequences of deformation

Over time, the metal, under the influence of variable loads, succumbs to the effect of fatigue - cracks form on it. After ten years, the seemingly strong structure weakens and loses its former endurance. Neither nitriding nor chemical-thermal treatment helps. When a car gets into an accident, the side members are severely deformed, simultaneously worsening the overall technical characteristics of the car. It is possible that the engine, suspension and transmission parts may be displaced. And the entire body loses its inherent strength and geometry when the spar bursts. That is why, when inspecting a car on the secondary market, a specialist first checks these parts.

It is easier to restore the frame structure. On load-bearing structures, things are much worse: here the spar acts as part of the body, and in particularly unfortunate cases, changing it is pointless or simply impossible.

Bend over time

The spar can be repaired with a slight, not sharp bend. For this, a hydraulic stretching machine or winch is used. A sharp bend with an acute angle is already a loss of the basic shape. Such an element is almost impossible to restore: it is more advisable to replace part of the pipe or the entire beam.

Buckling of a straight bar is a known problem in engineering. The rectilinear shape loses stability over time.

If the side members are bent after an accident

The parts simply become wrinkled and lose their original shape. If the spar is not bent too much, it can be straightened on a slipway or caroliner. If it bursts from an impact, there is no point in repairing it. The only option left is overcooking, partial or complete. The old part is cut off with a grinder, then a new piece of pipe is installed. Anti-corrosion treatment of parts and painting are required.

Along with the side members, after an accident, such parts of the body as door connectors and fenders suffer, the position of the suspension and engine changes, the shape of the suspension is disrupted, and cracks form on the outer part of the body.

Crack or complete break

Small cracks and minor damage can be repaired. A welding machine will help in this case. It is necessary to carefully weld the cracks if the parts are not aluminum or titanium: such spars are difficult to weld.

A complete spar rupture is bad. The entire body structure suffers, especially the load-bearing type. More often than others, the front side members of the car are damaged beyond repair.

The consequences of deformation or destruction of the spar are extremely negative for the car. Incorrect camber and increased tire wear, increased play between body parts, and decreased body safety are just a few examples of a sad outcome. At high speeds, weak body rigidity can lead to loss of control, injury and loss of life.

Spars are checked correctly only on a stand. However, there are several ways to do this without equipment. If the doors or trunk lid do not lock well, or the wheels have improper camber/toeing, visually inspect the parts. The presence of cracks and pockets of corrosion is a reason to urgently seek help from a car service!

What is a spar, what does it look like, and where is it installed?

A spar is a structural unit of a car that looks like a rectangular pipe, that is, a metal profile with a rectangular cross-section.

The part passes through the front and rear of the body, acting as a support. Depending on the body design, an option with side members between the bumpers is possible.

This unit can be composite (assembled from several elements) or integral.

In the classic configuration, two spars are installed (left and right).

Example, left front side member of a VAZ 2110.

Each element is divided into three parts - middle, front and back. The main difference is the location.

Thus, the spar installed at the front and left is positioned at a level lower than the spar at the rear and the same unit, but only the wing.

The nodes are parallel to each other, but there may be cases where they are located at a minimum angle.

Spar on Nissan Bluebird HU14 SR20VE.

The starting material for production is aluminum or titanium. Sometimes component layers are used to add to the fortress structure. The cross section of the spar has the shape of the letter “P”. At the same time, in places of maximum load the cross-section is larger.

The main advantage of the part is its exceptional strength. These units are able to withstand maximum loads - the weight of the car, luggage, mass of units, and so on.

In addition, the side members cope with all the impacts that they receive when the wheels get into holes or in the event of an accident.

Structurally, these units form a U-shaped staircase frame laid on its side.

This type of design is an integral part of many SUVs and trucks.

As for passenger cars, the ladder principle is not applied in them. To visually see the detail, just look under the bottom of the vehicle.

Body structure of the VAZ 2108, location of the side members.

Purpose

In modern passenger cars, the part serves as reinforcement for the bottom of the body, trunk floor, and mudguards. For many trucks, the spar is needed as the main strength element of the body itself. The front spar serves as an additional shock absorber; it is installed in the deformation absorption zone. It is he who takes the brunt of the impact during movement, thereby increasing the comfort of passengers. To evenly distribute increased vibration throughout the body, engineers install “deformable” zones in the front of the car. Such zones in the longitudinal direction have an insignificant force structure. Manufacturers of passenger cars reduce the thickness of the walls and make additional holes in those places where the load is minimal. Deformation of the side members during an impact leads to a decrease in the impact force of the passenger compartment, increasing the safety of the vehicle. In trucks, the front and rear side members take the impact.

Purpose and tasks

The spar is literally the power part of the car. The purpose of the unit varies depending on the type of vehicle:

- In trucks and 4x4 cars, side members are the main unit that is part of the frame;

- In passenger vehicles, the task of the part is to strengthen the bottom of the car and the lower part of the trunk.

In the first and second cases, the U-shaped unit takes on the weight of the body, components and passengers of the vehicle.

What are they for?

The parts are made of very hard metal and can withstand heavy weight. They absorb shock loads and vibrations received by the car when moving on various roads. Spars are needed to strengthen the elements of the bottom and floor of the trunk (passenger cars) or to completely take on all the loads (trucks, frame SUVs).

Another function of the side members is shock absorption. By taking on vibrations, the part distributes the load across all parts of the machine. Pipes effectively absorb deformation distortions. Therefore, they are made as rigid as possible, but not everywhere. In fact, a modern spar is a structurally very flexible unit with programmable deformation zones. Otherwise, it would not soften the shocks, absorbing them, but transmit them to the cabin.

Thus, the side members of the front part of the car are specially made with a greater ability to deform. Thanks to this, during a collision, the parts absorb the destructive shock wave, preventing it from going further.

Design advantages

Each design has advantages. Thus, “angular” spars allow the wheel to turn at a larger angle, and devices with vertical bending allow the vehicle’s center of gravity to be lowered and the bottom level to be lowered.

Parts with horizontal bending are structural elements that also make it possible to lower the level of the bottom, increasing safety in the event of a side impact.

To increase rigidity, the spars are strengthened with cross members. The latter come in different profiles - in the form of the letter K, X, or be straight.

This type of crossbar is made of a special profile made of reliable and deformation-resistant metal.

To increase reliability in freight transport, cross members and side members are combined with special rivets, and in passenger transport - by welding.

An important point is the fixation of the body on the frame, which occurs using special brackets.

Considering the spar design as a whole, it is worth highlighting the following advantages:

- Minimum weight and torsional rigidity;

- High level of controllability and dynamics, as well as minimal fuel consumption due to the low mass of the unit;

- Greatest passive safety. The latter is possible thanks to special zones that “absorb” excess energy and increase the level of comfort.

Toyota Mark II front side members.

Worth about:

- If one node breaks down, the integrity and connections of the structural elements are disrupted. This is due to the fact that the load is distributed evenly over the area;

- Difficulty in repair. In case of serious deformations, the only solution is to replace the unit.

Basic malfunctions and problems associated with side members, solutions

During operation, the following problems are possible:

- Deformation (curvature) due to exposure to loads over long periods of time. It is worth remembering that the spars are made of metal, which gets tired and damaged over time.

- If you get into an accident, the part may be severely damaged. In such situations, many car parameters are violated. So, in the event of an accident, it is possible that the suspension or power unit may shift in relation to the body part, the location of the wings or doors may change, the geometry of the body will be deformed, obvious cracks may appear on the outside, and so on.

If there is obvious damage (cracks appearing) in the part, the integrity of the structure is also destroyed.

That is why after an accident it is worth making sure that there is no deformation of the components. In practice, in 90% of cases after an accident, the front side members have to be repaired.

The method of restoration is determined taking into account the severity of the problem and damage to the damper section. So, the spar, which is part of the frame, is easy to change. If the assembly is part of the supporting body, then restoration work may be useless.

The possibility of repair depends on the degree of deformation:

- If the damage is minimal, the assembly is pulled out on a special stand, after which the parameters of the part are checked;

There may be situations where the replacement is not complete. In this case, new parts are attached by welding. The use of couplings to connect structures is prohibited.

We must not forget that the main function of the spar is to strengthen the body, so during the repair process maximum attention is paid to strength.

On the other hand, excessive strengthening of the unit leads to a decrease in shock-absorbing functions, which is unacceptable.

So when repairing, you should take this parameter into account and try not to overestimate the level of rigidity.

Functionality of the spar frame

We told you what a spar is and what this part looks like. Now let's talk about its purpose in a car.

The name of the part translated from French means movement along the length of something. This term is used to designate many engineering structures of this type, for example, to name parts of railway, aviation and ship transport. Load-bearing structures of this type are found in almost all cars, with the exception of those cars where the frame itself acts as the main load-bearing element.

Spar device

In the classic design of passenger cars, the spar is located along the length of the body and is designed to strengthen it in those places where the driver and passenger seats are installed, and where heavy elements of the vehicle are secured. In a certain sense, the spar frame acts as a damper between the suspension and the body part - a certain amount of energy that is received from the road and should be transferred to the body is absorbed by the load-bearing element. If the body had such high rigidity initially, then the people in the cabin would perceive all the impacts much more strongly than with this design.

Therefore, to prevent such an effect, the spar in the car is made in such a way that it can soften impacts, and not just be completely deformed from this . To solve this problem, there are special design solutions that provide this in different ways:

- Some parts of the spar have been slightly reduced in thickness, and the section size has been changed.

- Technological holes are drilled in places that carry the least static load.

- Special folds are made to allow the spar frame of the car to be removed, for example, in the event of an accident or a strong impact. Therefore, body parts where people are present suffer less. The supporting structure absorbs kinetic energy and carries the entire load. Thanks to this, the impact transmitted to the car body is felt much weaker.

Front spar

In terms of strength and reliability, any of the side members cannot be compared with other vehicle parts. This element is focused on the extremely serious load created not only by the mass of the car itself, but also by constant movement on Russian roads. This part is capable of withstanding the shock load that occurs when a wheel falls into a hole for a very long time.

Through any other bank according to the issued invoice (non-cash payment)

ONLY for legal entities

Payment is made by transferring funds to a current account.

Payment on an invoice for LLCs and individual entrepreneurs (RF)

Note ! we work “without VAT”

Buy right spar amplifier assembly (11180510137699)

The final cost of some products may differ; it will be announced by the manager when confirming the order. We apologize for any inconvenience caused.

The VAZ-2109 is a car that is not distinguished by a strong body; iron quickly succumbs to corrosion, and almost all body parts rust. Replacing the front spar is required when its metal is rotten in different places; the part is also replaced if it is severely deformed after an impact (accident).

Purpose of the spar

The spar is a load-bearing body element, which is a beam, serves as the basis for fastening the components and components of the car, and also plays the role of a shock absorber, softening the impact, absorbing deformation. The “nine” is equipped with paired front and rear spars; these body elements experience significant load.

If a car can move without problems with a dented fender and a rusty door, then the car should not be driven with a deformed front spar (PL). If this part is damaged, quite serious problems may arise:

- tires will quickly begin to be eaten away;

- the car is poorly controlled;

- the body loses strength and collapses.

If the condition of the spar is not the most critical, it can be welded, the geometry can be corrected on a special stand (slipway); in case of severe deformation or if there are cracks, the body element should be replaced. But it should immediately be noted that it is very difficult to do such work with your own hands - here it is important to accurately install the part, you must use welding. If the body element is installed incorrectly, the geometry of the body will be disrupted and the work will have to be redone.

Repair and replacement

If the conversation turns to repairing side members, then this usually refers to the front elements, since the rear side members are deformed much less often. To restore an element, a special stand is required. In addition, most of the car will need to be disassembled. However, even very experienced specialists can find it quite difficult to cope with this task . At the same time, replacing a spar element is also a long, labor-intensive and expensive procedure.

If the main part of this element has retained its normal condition, the deformed areas can be replaced using gas welding. But there is no need to have any illusions that this will restore the original qualities. The strength of the spar after these actions is significantly reduced, which means that the most important functions will be performed much worse. The spar with a ladder frame is much easier to change. But if the spar is very “deteriorated”, replacing it is pointless - in this case the whole body will have to be replaced.

Replacing the spar

If it is possible to repair or replace the spar, it is extremely important that the new element has the same overall dimensions as the damaged part, without exceeding them.

Important! Having set a goal to increase the strength of the spar element, the car owner risks significantly reducing its shock-absorbing properties, and with constant impacts, with this option, very serious problems arise.

What is a spar? How will the technical condition of a modern car change if problems arise with this spare part? Where is this element located? We will try to find complete answers to these questions to help beginners.

The cost of the front side members of the VAZ-2109

The right front spar is very similar in design to the left one, but the parts are not interchangeable, they seem to be a mirror image of each other. Body parts for the “nine” are sold in almost every specialized auto store; you can buy a front spar for an average price of 1,800 to 2,200 rubles.

You can also purchase a PL repair insert; it can be useful if the entire body part does not change and needs to be repaired. The average cost of an insert on the right or left side is 800-1000 rubles, like the spars themselves, the repair inserts from the “nine” are identical and fit on models 2108, 21099, 2113-14-15. There are no side member reinforcements as such for the front part of the body on the VAZ-2108-09-099; rigidity is added to it by the lower radiator frame (“TV”), which is a connector and is welded in front between the left and right load-bearing parts of the body, and the front wing mudguards.

What it is

A spar in a car is a durable body part that is part of the load-bearing frame. The spars are usually located in pairs along the body, closer to the sides. In other words, these are the remains of a supporting frame, which designers abandoned in the mid-twentieth century in favor of a monocoque body. Without spars, it is impossible to impart proper rigidity to the spatial structure of the body.

In addition, the supporting body must have strong places to which certain units can be attached - either heavy or subject to significant loads. Therefore, it is to the side members that the engine, gearbox, suspension arms or subframe are most often attached. Externally, the spar is a longitudinal part of a box-shaped or similar profile, which is located in the lower part of the body, most often under the bottom and in the engine compartment. Small A and B-class cars may not have solid side members along the entire bottom; their role is played by reinforced sills, and the side members themselves can only be seen under the engine compartment and at the rear, in the places where the rear suspension is attached.

The main reasons for the destruction of the front spar

As noted above, the submarine bends from impact and rusts over time. The following also have a destructive effect on this body element:

- constant engine vibrations, especially if the engine or gearbox mounts are loose;

- driving a car on bad roads;

- extreme driving.

Since the side members are practically the skeleton of the body, a large load falls on them. All vibrations and shocks are transmitted to these elements; as a result, the body parts cannot withstand, become deformed, and cracks appear on them.

Wear of parts

Constant increased loads lead to deformation of the side members over time. First of all, this concerns the front spar, since it is subject to significant load from the car engine. The rear side members also gradually crack, losing their performance characteristics.

If such elements “get tired,” the position of the car doors may be disrupted (“wedging”), the position of the connectors of the car body parts may change, the position of the power unit will change, as well as the geometry of the suspension itself.

Currently, many passenger cars are equipped with an integrated design in which longitudinal side members are embedded in the floor.

How to replace the front spar on a Nine

Replacing the front side members 2108-09 must be done on a slipway; in a regular car service without special equipment, it is very difficult to perform such work, and in some cases it is simply impossible. Before starting body repairs, it is necessary to partially disassemble the car, remove from the car:

- front optics and bumper;

- hood;

- radiator grille;

- expansion tank;

- radiator;

- front wing (on the side where the submarine changes);

If the car's hardware is sufficiently rusty that you have to additionally change (repair) other body elements, you may have to remove the gearbox and engine. The body repair itself is performed in the following order:

- the old spar is cut off (usually using a grinder or a gas cutter) so that the new part “falls” into place better, a beveled cut is made;

- the new submarine is cleaned of transportation soil;

- At the seat, rust, dust and dirt are removed from the metal; a grinder is used for this. A good result can be achieved by using a sandblasting machine; to remove traces of corrosion, a rust converter is needed;

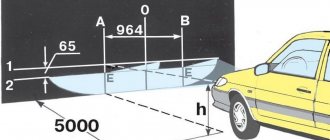

- The new spar is butt welded, first tackling it in several places. Before final welding, the geometry of the body is checked; if the work is not done on a stand, the correct installation of the part is verified using control points:

- after welding work, the metal surface is cleaned again, degreased, the weld seam is treated with mastic, and primer is applied;

- After the primer has completely dried, the replaced body part is painted in the color of the body, and the car is assembled.

As a rule, one body element on a car is rarely changed; along with the submarine, a new “TV”, upper radiator frame, and panels (mud flaps) of the front wings have to be installed. And the front spar on the nine is not always completely changed; most often it is cut off along the “glass”.

Advice from professionals on operating a vehicle's side member

- Evolution of the frame.

“At first, hardwoods were used for the frame, and sometimes metal pipes. In the 1910s frames with an open profile began to be used on trucks.

If you know English terms, then it won’t be difficult to understand what a side member looks like on a car. It is often called staircase because it looks like a staircase. Elements located longitudinally are usually made from an open profile. Cross beams can be different in shape: K- and X-shaped, perpendicular. Frame pieces can be connected to each other using welding (in passenger cars), rivets (in trucks) or bolts (made to order).

The cost of replacing the front side member of a VAZ-2108-09 in a car service center

Since replacing a submarine is not an easy job even for an average car service center, not all craftsmen undertake it, especially since not everyone is eager to begin restoring the body of a used Nine. Mostly, small auto repair shops carry out minor and medium body repairs, while large auto repair centers do not want to deal with domestic cars at all. Prices for body work from auto repair companies and private owners are most often approximate; often the final cost of the repairman is announced closer to the end of the repair. The fact is that “pitfalls” may unexpectedly appear, and as a result of their identification, the work is delayed and becomes more complex.

Some car service centers indicate two values in the price list at once - the upper and lower limits; in large cities or the capital, they charge from 3,500 to 9,000 rubles for replacing the front side member; usually, work from private repairmen in garages costs less. Often, along with the submarine, it is necessary to change the wing splash guard, sills, and repair the bottom; some auto repair shops note in their prices that the cost of repairs in the price list is indicated without painting.

Repair of the front side member of the VAZ-2109

The main reasons why submarines have to be repaired are the appearance of cracks on the body element. In some cases, the spar bursts in a circle, the metal rots through and through, if the part itself is not yet in a completely deplorable state, patches are put on it, and the iron is strengthened using spot welding. If the spar is pulled away as a result of an accident, it is pulled out on a stand. You can try to pull out the submarine without a slipway; in garage or field conditions, craftsmen carry out a similar operation using a strong metal chain, a hand winch and some kind of support, for example, wood.

In this case, the rear beam must be fixed so that the car does not move forward; it should be pulled carefully, constantly checking for deformation of the rear axle. If the beam bends due to excessive force, it will have to be replaced. Only professionals can say whether it is worth repairing a car after damage to the spar; in some cases it is easier to sell the car for spare parts than to restore it.

A brief excursion into history

The development of the spar and the creation of various body elements are closely interrelated. This is not surprising, because on the first vehicles only frames were used as support.

At first they were made of wood, but over time they were replaced by durable metal structures.

In the last century, in the 1920s, Auburn developed the first spar frame with an "X" cross member.

Over time, the parts were improved and became one with the bottom of the vehicle.

At the present stage, spars are an integral part of the machine design, regardless of the type of supporting system.

As already mentioned, side members occupy different positions in the car. Here, a lot depends on the characteristics of the body (truck, passenger car or truck).