Design features

The vehicle's exhaust gas removal system allows not only to remove fuel combustion products, but also to increase the efficiency of the power unit, as well as significantly reduce background noise.

To do this, the system uses a component such as a muffler, which is capable of suppressing the noise created by exhaust gases and significantly reducing their toxicity level. All these indicators depend on how the muffler is designed. Regardless of whether the muffler is manufactured in a factory or assembled by hand, its design must contain the following mandatory elements:

- The exhaust manifold articulates directly with the car's engine through a exhaust pipe, which can be equipped with a vibration compensator.

- Exhaust gases from the exhaust pipe enter the cavity of the catalyst, in which the remaining fuel burns out, and the saturation of carbon dioxide decreases.

- From the catalyst, gas flows flow into the resonator chamber, where vibrations are damped and the effect of their pulsation is balanced.

- Then the volume of exhaust gas flows passes through the chambers of the rear muffler, which is designed to reduce noise.

Principle of operation

Before you begin repairing a car muffler or assembling it yourself, you need to understand the basic principles of its operation. If you look at the device in section, you can see many metal or ceramic partitions, heat-resistant wool, and the presence of perforated pipes. The presence of these elements in the muffler design slows down the speed of gas flows. When doing DIY repairs, it is important to replace worn-out elements with high-quality analogues.

In turn, their reduction allows you to smooth out the operation of the motor, taking into account each stroke.

There are no standards for the production of the exhaust system and its individual elements, so mufflers from different car manufacturers can differ significantly from each other.

If you decide to upgrade individual elements of the exhaust gas removal system with your own hands, then you need to take into account some nuances:

- powerful car engines must have a resonator of sufficiently large volume, which will provide the necessary level of exhaust smoothing;

- the number of partitions inside the chambers that smooth out the unevenness of the volume of discharged flows.

Installing a new exhaust pipe

All work is done in reverse order. But there are several features that you definitely need to know:

- Install a new exhaust pipe.

- A new gasket needs to be installed between the exhaust manifold and the pants.

- Be sure to install a new O-ring between the neutralizer and the pants.

- Tighten the nuts on the exhaust manifold studs. Tighten them evenly in a crisscross pattern.

- Tighten the bolts that are on the spring-loaded connection to the converter.

This completes the repair of the exhaust system. The sound will be muffled as much as possible, the car will become almost silent. It is advisable to lubricate the new gasket with a CV joint type compound. This will improve the seal.

Source

Types of noise-absorbing elements

Silencers in cars can be active, which is a fairly simple device, or reactive. In the first case, vibration-resistant materials that can withstand high temperatures are used for their production. Active devices are the most popular because they are easy to use. Their significant disadvantage is their rapid contamination. Silencer reactive devices consist of complex elements of resonator chambers.

As for the rear noise-absorbing chamber of the car, its structure contains many compartments that contain a special filler. It is necessary to reduce the sound of exhaust gases when the car engine is running. Modern car mufflers can use several technologies for absorbing background noise and purifying emitted gases at the same time. They can contain many different materials that provide maximum reduction in the sound of exhaust gas flows, their toxicity level and temperature.

Do-it-yourself muffler repair

The main problem with the elements of exhaust exhaust systems is the appearance of holes due to temperature changes and external impact on the body of the elements. If a hole is found in the resonator housing, pipes or rear muffler, you need to make patches from sheet metal. It is necessary to make a margin of about 10-12 mm from the size of the “fistula”, after which the puncture site must be carefully treated.

Do-it-yourself repairs are not particularly difficult. When applying patches, it is advisable to use semi-automatic welding. In this case, it is necessary to ensure the evenness and continuity of the weld. In the same way, defects in pipes and internal elements are restored.

A car muffler is a device that is designed to reduce the noise level, temperature and toxicity of combustion products. Today we will discuss the exhaust system of a VAZ car, and in this article we will provide answers to such common questions as:

- Design of VAZ car mufflers;

- Design features of a direct-flow muffler;

- How to replace the main and additional muffler of a VAZ.

Composition of the output unit

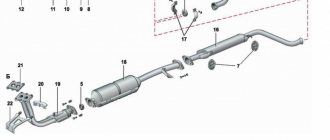

The exhaust system for a VAZ 2110 car consists of the following elements:

- Exhaust manifold;

- Lambda probe;

- Receiving type pipes;

- Neutralizer;

- Two mufflers: main type and additional.

Not all exhaust components are disassembled; some parts, such as the converter, as well as both mufflers, are replaced entirely.

Exhaust system of VAZ 2110

Description of individual components

To make the structure of such an element as the discharge system clearer, it is necessary to give a detailed description of all components:

- Neutralizer. A unit designed for effective purification and suppression of emissions of harmful substances into the environment. When driving, a car produces substances such as non-combustible hydrocarbons, oxide compounds of nitrogen and carbon. The work of this system is aimed at eliminating them. The design itself is a combination of two ceramic-type components. The surface of these components is coated with special afterburning catalysts, which include rhodium, palladium and platinum. These substances make it possible to purify exhaust gases emitted into the environment by almost 100%;

- Lambda probe. It is a special sensor whose task is to control the composition and amount of fuel that enters the engine. The lambda probe thereby controls the purifier. If the lambda probe does not work properly, then the entire output assembly will quickly become unusable, after which it will have to be replaced;

- Reception pipe. Designed for forced removal of exhaust gases from the cylinders of a power unit. The pipe is made of stainless steel, and its fastening to the collector is carried out using special pins, of which there are four in total. The studs guarantee reliable fastening of the two outlet pipes and the element. In order to combine the exhaust pipe and the neutralizer, as well as an additional muffler, hinged fasteners are used;

- An exhaust manifold. A component that is cast from pure cast iron. The manifold is secured with four studs in the exhaust pipe. Heat-resistant gaskets reinforced with metal are installed between the manifold and cylinder heads.

- Silencers. Necessary for effectively suppressing the exhaust rate of burnt gases. This is necessary in order to significantly reduce the noise level in a type of transport such as the VAZ 2110. The distribution device in this part of the unit is carried out as follows: the additional one is followed by the main one. These two components are connected to each other by clamps and sealing rings and are covered with a special casing on top.

Nuances of operation

There are some points that need to be taken into account when operating the VAZ 2110 system:

- Under no circumstances should the vehicle be refueled with leaded fuel, as this will cause damage. It is very sensitive to lead compounds;

- When operating a VAZ 2110 car, you also need to monitor the proper, precise operation of the ignition, since its poor-quality operation leads to the neutralizing part being removed from its working condition. Fuel that does not burn when a spark passes during ignition enters the converter and burns out there. For this reason, the ceramic coating of the component quickly deteriorates;

- Frequent malfunctions will sooner or later lead to complete or partial blockage of the output system, in turn to the failure of the engine and its repair or replacement will be required.

basic information

The muffler of a VAZ car always receives increased attention, because its main task is to reduce the noise level, which is important. First, let's look at how the pre-muffler, or as it is also called the resonator, of a VAZ car works. A resonator is considered to be a medium type of muffler, which is located in the middle of the exhaust system. So, the pre-muffler consists of the following main elements:

- Throttle;

- Frame;

- Blind barrier;

- Thermal insulation;

- Perforated tube.

Now let's look at the design of this part of the transport:

- Frame;

- Rear barrier;

- Middle obstacle;

- Front perforated tube;

- Rear perforated tube;

- Inlet pipe;

- Exhaust pipe.

VAZ muffler design

What are the design features of a direct-flow muffler? The main element of this type of muffler is a perforated tube. With the help of perforation, the combustion products that enter the muffler expand quite effectively in its body. Thanks to these actions, the removal of combustion products is accelerated. It is worth paying attention to the fact that high-quality tuning can account for more than eighty percent of a straight tube. This means that when using the presented type of muffler, the level of exhaust system resistance will be about ten percent, and this is much more than without it.

Independent replacement of the main and additional muffler

The exhaust system of every vehicle regularly suffers from the accumulation of dirt, dust, moisture, corrosive and hot gases, as well as impacts. Moreover, applying patches to through holes will help solve the problem only for a certain period of time, and in the end, one way or another, a complete replacement will have to be made.

How to remove the resonator

The resonator needs to be changed only after a new muffler has been installed. The sequence of work aimed at dismantling the device:

- The resonator is secured using a crimp-type clamp and an O-ring.

- The connection to the neutralizer is made using a floating flange, which consists of flared pipes and two bolts.

- The fist is located on the opposite side of the resonator.

The work must be carried out on a cooled engine.

Quite often it is not possible to unscrew the bolts, so to make the work easier, you just need to cut them off using a grinder. Be sure to install new bolts during reassembly. If you don’t have a grinder at hand, then you need to use a penetrating lubricant, for example, WD-40. Apply this composition to all threaded connections, then wait 20-30 minutes.

Unscrew all the bolts and remove the clamps on the resonator. After this, you need to remove the old resonator from the rubber suspensions. Be sure to evaluate the condition of all rubber products. If they show signs of wear, install new ones during reassembly.

Car muffler tasks

Pipe. Exhaust, but a pipe. It’s a simple device at first glance, but a lot depends on the exhaust system. Not only the aesthetic sound of the exhaust, but also the dynamics of the car, fuel consumption, comfort in the cabin, and the presence of vibrations. Therefore, if someone asks in the middle of the night why a muffler is needed in a car, every self-respecting motorist will answer without hesitation:

- to reduce the noise level of the engine;

- to reduce the temperature of exhaust gases;

- to remove exhaust gases outside the vehicle;

- to reduce the level of harmful emissions into the atmosphere.

Although the last point is rather conditional.

The exhaust pipe works in hellish conditions. The temperature of the exhaust gases at the outlet of the exhaust manifold can reach 800 degrees, or even more. Therefore, the metal from which the muffler is made must not only be durable, but also have some heat-resistant qualities. In addition to temperature, enormous pressure acts on the walls of the exhaust system, and the high speed of movement of exhaust gases causes significant sound vibrations.

Description of individual components

To make the structure of such an element as the discharge system clearer, it is necessary to give a detailed description of all components:

- Neutralizer. A unit designed for effective purification and suppression of emissions of harmful substances into the environment. When driving, a car produces substances such as non-combustible hydrocarbons, oxide compounds of nitrogen and carbon. The work of this system is aimed at eliminating them. The design itself is a combination of two ceramic-type components. The surface of these components is coated with special afterburning catalysts, which include rhodium, palladium and platinum. These substances make it possible to purify exhaust gases emitted into the environment by almost 100%;

- Lambda probe. It is a special sensor whose task is to control the composition and amount of fuel that enters the engine. The lambda probe thereby controls the purifier. If the lambda probe does not work properly, then the entire output assembly will quickly become unusable, after which it will have to be replaced;

- Reception pipe. Designed for forced removal of exhaust gases from the cylinders of a power unit. The pipe is made of stainless steel, and its fastening to the collector is carried out using special pins, of which there are four in total. The studs guarantee reliable fastening of the two outlet pipes and the element. In order to combine the exhaust pipe and the neutralizer, as well as an additional muffler, hinged fasteners are used;

- An exhaust manifold. A component that is cast from pure cast iron. The manifold is secured with four studs in the exhaust pipe. Heat-resistant gaskets reinforced with metal are installed between the manifold and cylinder heads.

- Silencers. Necessary for effectively suppressing the exhaust rate of burnt gases. This is necessary in order to significantly reduce the noise level in a type of transport such as the VAZ 2110. The distribution device in this part of the unit is carried out as follows: the additional one is followed by the main one. These two components are connected to each other by clamps and sealing rings and are covered with a special casing on top.

Sound absorption technologies

The exhaust system, and in particular the muffler, can use one or several sound absorption technologies:

- change in gas flow cross section;

- changing the direction of gas movement;

- surface absorption of sound waves.

Depending on which frequencies predominate in the engine exhaust sound spectrum, this sound reduction method is used. For example, to suppress low frequencies, it is effective to use several resonator chambers with different volumes. The use of different sections of input and output pipes combats high frequencies well. But in principle, a muffler, like a good musical instrument, is customized exclusively for a specific brand of engine. Then the noise reduction efficiency is much higher and there is less power loss.

conclusions

Please note that before purchasing new exhaust system parts, it is necessary to inspect it in advance. So, as soon as a visual inspection of the general condition of the exhaust system can give a complete answer to the presence of any malfunctions.

The operation of VAZ cars is often accompanied by various breakdowns and malfunctions of various parts and systems. The 2110 exhaust system is no exception, failures of which can be eliminated by replacing the muffler or other components.

Car muffler diagrams

A cross-section of a car muffler allows you to see exactly how the sound reduction function is implemented in each specific muffler. In direct-flow mufflers, for example, the method of changing the direction of gas movement is never used, and a standard muffler uses turns from 90 to 360 degrees. The change in the amplitude of sound wave oscillations is realized by perforating the internal pipes. It is these internal pipes, their diameter, diameter and frequency of holes that can drown out noise in almost the entire frequency spectrum.

But only the integrated use of these methods can guarantee high efficiency of the entire exhaust system as a whole. Therefore, modern cars use from one to six different mufflers. The main ones are the resonator and the main muffler.

High-quality direct-flow exhaust system VAZ 2110-2112

VAZ 2112 16 valves technical specifications

Car tuning is not only work to improve and modernize its appearance. Tuning includes all work that improves the performance of a car. An integral thing when boosting an engine is the installation of a direct-flow exhaust system. Moreover, this moment cannot be treated carelessly.

The direct-flow exhaust system of the VAZ 2110-2112 facilitates the exit of exhaust gases, and accordingly makes the engine run easier, relieves the load from it and increases its power.

Many people simply install a direct-flow muffler (rear), fortunately, there are many offers on the market of ready-made “direct-flow” muffler, as they are popularly called, which are installed on standard mounts.

Such a muffler does not give any result other than a menacing sound, because it has standard pipe diameters and, accordingly, throughput. Yes, it has some effect, but it is almost unnoticeable. In order to achieve a tangible result, it is necessary to change the entire exhaust system completely.

The first thing to be replaced is the exhaust manifold and the exhaust pipe (“pants”). Instead of these two parts, a “spider” is installed - a part that combines both the functions of the exhaust manifold and the exhaust pipe.

Ideally, the spider should have a polished inner surface of the pipes and equal distances from each of the four entrances to the exit. The outer diameter of the pipes installed at the factory as a standard exhaust system is 42-44 mm.

The direct-flow system involves the use of pipes with a diameter of 48-50 mm. This size difference increases throughput by 30%. Agree, the difference is significant.

Instead of a standard resonator and catalyst, it is best to install an intermediate pipe. They are available for sale, but their fastenings do not always correspond to those on the exhaust pipe, so they often have to be reworked.

That is, the flange can be cut off from the old catalyst and welded into an intermediate pipe. If you do the installation yourself, then take into account the fact that such work must be done only “in place” - the flange must be turned exactly at the angle at which the mating part of the “pants” is located.

To do this, connect the cut flange to the pants, align it with the intermediate pipe and place several welding points. After this, you can remove the intermediate pipe and completely weld the flange connection.

At a time when the VAZ engine experiences heavy loads, during sudden acceleration or driving at high speed, it experiences strong vibration, which is transmitted to the exhaust system.

As a result, severe wear of the exhaust system occurs, which threatens breakage and cracks. To prevent this from happening, it is best to install a metal compensator, or as it is also called - corrugation.

A metal expansion joint is welded in place of one of the pipe gaps, preferably as close to the “spider” as possible. To do this, you need to cut a piece of pipe 30 mm shorter than the length of the corrugation, and install a metal compensator in its place, so that it fits 15 mm onto the pipe on each side.

After this, weld the joints. All work must be done in the same way as with the flange - first, grab the corrugation by spot welding in the installed state, then remove the part and weld it completely.

Installing the rear part of the straight-through muffler is a separate matter. As a rule, all standard direct flows on the VAZ 2110-2112 have the same appearance. If you want to really stand out, you can install a universal forward flow.

So you can select almost any limit switch based on appearance, sound, diameter of the incoming pipe and the material from which it is made - black steel, alloy or stainless steel. When installing a universal direct flow, you will have to contact a service station so that they weld an incoming pipe of the required diameter to it, and possibly trim the bumper.

Installing a direct-flow exhaust system on a VAZ 2110-2112 is not just a whim, but a necessary necessity if you really decide to increase the power of your car.

Main elements of the exhaust system

The muffler resonator is installed immediately after the exhaust pipe and the catalyst, and its task is to level out pulsations of the gas flow. In cross-section, it looks like a perforated pipe placed inside a metal chamber of a larger diameter. The pipe can change its cross-section on the way from the inlet to the outlet of gases.

The main muffler may have a more complex design and has the main function of noise reduction. Modern systems can have almost all noise reduction schemes in the rear muffler can. The chamber through which the main pipe passes can have several sections, each of which has noise reduction at its own level. Typically, these chambers are filled with heat-resistant fiber material, which further dampens vibrations and absorbs sound vibrations.

The design of a car muffler is constantly evolving, and we try to follow the news from the design bureaus of the most progressive automakers and tuning studios. Stay with us, and let your mufflers only please the ears of avid motorists. Happy travels to everyone!

Impact shield

The fender shield for the exhaust pipe of a power transformer is designed to protect the surface of an adjacent device, which is located at a distance of closer than 30 m, from oil flow: otherwise a fire may occur.

For a single transformer, a shield is not needed; it is enough to simply deflect the exhaust pipe in the required direction. Instead of a fender shield, it is allowed to provide a screen made of fire-retardant material, which is used as basalt wool, compositions based on calcium or aluminum silicates. The height and width of the part must be 300...500 mm larger than the parts of the adjacent unit. The configuration and thickness of the shield are not regulated.