“Trippling” of the VAZ-2109 engine is a term denoting a malfunction of the power plant that occurred as a result of failure and interruptions in the operation of one of the cylinders. This breakdown is quite common and occurs in engines with both carburetor and injection power systems.

Signs

“Tripling” appears on the VAZ-2109 in the form of:

- Unstable motor operation.

- Strong vibration.

- Power drops.

- Difficulty starting.

- The appearance of “pops” in the exhaust system.

“Tripping” is not a critical engine failure, and the car can be driven, at least to get to the repair site. But you shouldn’t delay repairs, since improper operation of one of the engine cylinders will ultimately lead to serious problems.

Brake booster failure

The vacuum brake booster (VUT) of the VAZ 2109 is not formally related to the operation of the cylinders. But failure of the VUT can lead to failure of the third cylinder. The engine will start to stall.

The vacuum booster is designed to reduce the force on the brake pedal required to effectively slow down the vehicle. To do this, VUT uses rarefied air, which it takes from the intake manifold. The intake hose fitting, equipped with a check valve, is located near the combustion chamber of the third cylinder. It is this cylinder that stops working if the amplifier fails or if the supply hose is damaged.

Due to the damage, atmospheric air is sucked in, the mixture becomes leaner, and ignition does not occur. Often, malfunctions in the operation of the brake pedal are accompanied by a significant increase in the force on the brake pedal; it becomes “dull” and does not provide proper deceleration. It happens that when you press the brake pedal, the engine stops revving and runs normally, but when you release the pedal, the third cylinder fails again. All of these are sure signs of a VUT malfunction, and they require your immediate response.

It is quite simple to make sure that the reason for the failure of the third cylinder lies in the amplifier.

If you have a spare amplifier, replacing the unit yourself is not difficult and can be done by yourself. If you go to the service, be careful: in fact, you are driving with faulty brakes.

Hello! Tell me, please, the car is a nine, it shakes wildly, especially when driving uphill, I’m zero in these matters, maybe I need to change the oil? I bought a car two years ago, I haven’t changed the oil yet, why is the engine running rough? (Basil)

Hello, Vasily. A motor can stall for many reasons, all of which are outlined below.

Identification of an idle cylinder

The method for identifying a bad cylinder depends on the type of engine power system.

In carburetor engines, the determination of a failed cylinder is carried out experimentally. The essence of the method is to turn off each cylinder one by one by removing the tip of the high-voltage wire from the spark plug while the unit is running.

The check should begin with the 1st cylinder on a warm engine and with the speed set at 1500 rpm. If, after removing the tip, the speed drops significantly (the engine stops altogether, since as a result 2 cylinders will be switched off), the 1st cylinder is working normally.

Next, the test is carried out on the following cylinders. If the cylinder is not running, removing the tip will not affect the operation of the motor. After turning off the “drawdown” there will be no revolutions.

This test method is simple and allows you to accurately determine which cylinder is not working. But when doing it, follow safety precautions. High-voltage wires carry electrical impulses with high voltage but low current. These impulses will not cause damage to health, but the sensations are not pleasant.

As for the VAZ-2109 engine with an injector, the experimental method should not be used here (so as not to affect the operation of electronic systems). On such engines, the determination of an inoperative cylinder is carried out by scanning the ECU for errors. Interruptions in the operation of the motor are monitored by electronic systems and recorded in the form of error codes, by deciphering which we find out what caused the disruption of the normal functioning of the unit.

Video: VAZ-2109. The engine is shaking!

Why does the engine of a VAZ 2109 car troit?

The reason that the engine on the VAZ 2109 is misfiring is the uneven combustion of fuel in a single cylinder. The reasons for this may be:

- The ignition timing is set incorrectly.

- There has been a malfunction in the vacuum corrector system for ignition distribution or in the carburetor accelerator pump.

- The spark plugs have become unusable.

- A high-voltage wire has broken.

- Capacitor failure.

- There is a leak in the intake manifold or carburetor.

- Burnt pistons or valves.

- The piston rings are broken.

- Valves incorrectly adjusted.

- The gasket in the cylinder head has broken.

- The valve stem seals are worn, hardened or destroyed.

- Use of very low quality fuel.

- The carburetor is not adjusted correctly.

- The distributor shaft and the rotary plate bearing are worn out.

- The membrane of the vacuum ignition accelerator has lost its tightness.

- There are other reasons why the engine of the VAZ 2109 troits.

How to eliminate some causes of engine tripping

If during the initial period of movement of a VAZ 21093 car the engine stalls, most likely the accelerator pump or the vacuum corrector of the ignition distributor has broken down. In this case, diagnostics of components is carried out and, if necessary, repair or replacement of elements. To work you will need:

- Wrenches for “10” and “8”.

- Slotted and Phillips screwdrivers.

- Clean rags.

- Copper wire without an insulating layer with a diameter of up to 0.3 mm.

- Compressor.

- Liquid type WD40.

Order of operations:

- The air filter cover is removed. To do this, unscrew the nut with a “10” key and unfasten the spring clips.

- The air filter is pulled out. Use a key “8” to unscrew the four nuts, use a screwdriver to loosen the clamp on the crankcase ventilation hose at the place where it is connected to the valve cover and remove the housing from the air filter.

- The hose is disconnected from the vacuum corrector drive for ignition distribution. The tightness of the assembly is checked by creating a vacuum of air through the mouth.

Checking the tightness of the vacuum corrector drive

- If air passes through, the unit needs to be replaced. Otherwise you need to:

- Look inside the carburetor. The air damper must be completely open. When you press the throttle control lever, a stream of fuel should appear from the two nozzle tubes of the accelerator pump. They should be level, directed into the space between the opening damper and the diffuser wall. The photo shows the holes for the fuel outlet.

Carburetor with cover removed

- If there is no fuel outlet, you need to remove the hoses supplying fuel to the carburetor and drain it.

- The torso is detached to control the air damper.

- The wire located on the idle air solenoid valve is removed.

- Unscrew the screws holding the top carburetor cover.

- The lid is removed and placed with the floats facing up.

- Carefully pry off the atomizer with a screwdriver and pull it out of the socket.

- Use a thin copper wire to clean the atomizer nozzle holes.

- The atomizer is blown with air in the opposite direction of the direction of fuel movement.

- The element is installed in place.

- Without installing the assembly cover, you need to press the drive lever for the throttle valve. Fuel streams should appear from the two nozzle tubes of the acceleration pump.

- If they are not there, you need to check the absence of play in the drive and the accelerator pump drive lever and its ease of movement. To facilitate work, the parts are lubricated with WD40 type fluid. Parts that have become unusable are replaced with new ones.

- The operation of the accelerator pump is re-checked.

- The carburetor is assembled in reverse order.

- If there are no streams again, you need to contact a car service.

The reason that the engine of a VAZ 21093 car is experiencing trouble may be the abnormal condition of the spark plugs. Their price is insignificant and it is better to replace burnt out spark plugs immediately.

The candle is in abnormal condition

This video will help you learn how to change spark plugs yourself. So:

- The operating instructions supplied with the car indicate that the spark plugs should be replaced regularly. Even the presence of a spark on a twisted element at atmospheric pressure does not mean that it is fully operational. Its ignition occurs under more difficult conditions.

- It is not very common for piston rings to get stuck or break. You can check this by measuring the compression. If it is low, then a cylinder head malfunction can be ruled out in a simple way: a little oil is poured into the cylinder and an increase in compression indicates a breakdown in the piston system.

Checking the ignition system

The reason that the VAZ-2109 engine “troubles” is the ignition system. Due to its incorrect operation, the combustion process of the air-fuel mixture is not observed in one of the cylinders, which leads to unstable operation of the engine, severe vibration, and a drop in power.

Interruptions in the ignition system, due to which “triple” occurs, give:

- Candles.

- High-voltage wires and their tips.

- Contacts of the distributor cover (distributor).

- Hall Sensor.

These items should be checked in the same order.

Candles are one of the most common causes of tripping. Exhausted life, incorrect clearance, “breakdown” of the housing and penetration of the impulse to ground - these faults of the spark plug lead to failure or malfunction, which affects the operation of the motor.

You can verify that a spark plug is broken by replacing it with a known good one or swapping it with a spark plug from another cylinder. Replacing the spark plug can eliminate the malfunction of the power unit.

In addition to the spark plug, you should check the condition of the contact in the tip (which is put on the contact nut of the spark plug). It is made of copper and oxidizes over time, which leads to disruption of contact between the wire and the spark plug, and causes “triple” to appear.

In search of the cause, the high-voltage wires are checked next. Over time, the braiding of these wires loses elasticity and cracks, which is why voltage pulses “break through” to the ground, not reaching the spark plug.

A simple way to check the wires is to start the engine at night and open the hood. In the dark, “breakdowns” in the form of sparks are visible. If sparks are noticeable, replace the wires.

Next, look at the distributor cap and the slider. Gradually, the contacts on the slider and in the lid wear out, and they may also oxidize, which leads to loss of contact and interruptions in the operation of the spark plug.

Due to a malfunction of the Hall sensor, there is a failure in the formation of pulses supplied to the switch. Because of this, the operation of the ignition system is disrupted, in which the pulse from the coil to the distributor is missed, and from it to the spark plug.

Do not forget that an incorrectly set ignition timing is another reason for engine tripping. Therefore, in search of the cause, we be sure to check the setting of this angle and carry out adjustment work.

Troit carburetor engine, reasons

— When starting the engine, on “choke”, the speed is stable, without “chuck” on a warm engine, the idle speed is unstable until it stops.

Often, unstable engine idle speed is accompanied by increased fuel consumption and loss of power and throttle response.

The carburetor is faulty or not adjusted

— The idle speed adjustment with the “quantity” and “quality” screws of the fuel mixture is broken

Adjust the idle speed using these screws. By rotating the screws clockwise we increase the fuel supply to the cylinders, counterclockwise we decrease it. Normal idle speed for engines 2108, 21081, 21083 of VAZ 2108, 2109, 21099 cars is 750-850 rpm.

— The carburetor solenoid valve is faulty

We check its serviceability for a “click”. We remove the wire tip from the valve terminal and put it on again; a “click” should be heard. This shut-off needle is pulled into the valve body and opens the hole for fuel to pass through. There is no click - the valve is faulty, or there is no current flowing through the wire.

— Foreign air is “sucked” into the carburetor, excessively leaning the fuel mixture

The culprits may be - a hose from the vacuum brake booster to the intake manifold (1), rubber sealing rings on the “quality” screw (8) and the solenoid valve (4), a slipped or burst tube to the housing of the vacuum ignition timing regulator on the distributor (2), leaky housing or damaged diaphragm of the vacuum regulator housing (6), deformation of the carburetor seating surface (5), or wear of its gaskets, crankcase ventilation tube (3), gasket under the intake manifold (7).

— The channels and jets of the carburetor idle system are clogged

— Low fuel level in the carburetor float chamber

— The air filter element is clogged

The degree of contamination should be quite high. Replace it with a new one.

The power system before entering the carburetor is faulty

— Fuel pump is faulty

— Filters in the power system are clogged

This is a filter on the fuel intake in the gas tank, a fine fuel filter and a mesh filter in the carburetor.

— Damaged elements of the power system

Ignition system is faulty

— Spark plugs are faulty

— The distributor (cover, slider) is faulty

— High-voltage wires are faulty

— The ignition timing is not set correctly

Engine faulty

— Thermal clearances in the valve mechanism are broken

— Marks in the timing system are shifted

— Wear of the piston group (breakage or sticking of rings, wear of cylinders)

— Burnout of valves

Notes and additions

— Before you begin to identify the causes of engine “triple” at idle, it is necessary to conduct a visual inspection of its engine compartment. A loose wire, a chip not fully inserted, a kinked hose, etc. will not allow the engine to work normally, and will take away the time and effort of the car owner spent on troubleshooting.

TWOKARBURATORS VK -More information on the topic in our VKontakte group

Malfunctions of the CPG and timing belt

Problems in the cylinder-piston group and gas distribution mechanism are another reason for interruptions in engine operation. This malfunction occurs when:

- occurrence of rings;

- piston burnout;

- burning of the valve plates and their seats.

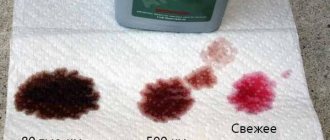

Malfunctions of the CPG and timing, due to which the engine “trips” appear, are determined by measuring compression in the cylinders. A cylinder that operates intermittently has a lower compression rate than the rest.

Next, we establish the reason for the drop in compression. To do this, pour 20-30 g through the spark plug hole of the cylinder. engine oil, after which we take compression measurements again.

An increased compression ratio indicates the occurrence of rings. We eliminate this problem by decarbonizing the motor.

If the repeated measurement again shows low compression, you will have to remove the cylinder head to determine the cause of the malfunction.

The reason for the “triple” of the power unit can also be a breakdown of the cylinder head gasket. Due to this malfunction, a loss of compression occurs in the cylinder due to depressurization of the combustion chamber.

The term troit engine VAZ 2109 means

The term “troit engine” appeared in the era of automotive development, when vehicle power plants were equipped with four-cylinder engines. If, for one reason or another, the working cylinder stopped functioning, then three cylinders remained in operation, which during operation made a characteristic sound, as if the engine was stalling in a damped mode.

Engine compression measurement for VAZ 2109

Subsequently, despite the complication of the design of the piston group and the increase in the number of cylinders, the term “troit engine” remained in use among car enthusiasts.

Elimination methods

It is worth understanding that tripling on a carburetor power unit will occur not only while driving, but also at idle speed. In this case, the motor will make sounds like popping noises. But the car will twitch only while driving. So, it’s worth going directly to the analysis of the process of diagnosing and troubleshooting.

Carburetor

Unlike injection engines, a carburetor is a rather finicky thing that is sensitive to fuel and the technical condition of parts. Therefore, many motorists know that the power unit can stall precisely because of the carburetor. This version of the car was equipped with an injection element marked Solex, with which many are familiar.

To cure the shaking and jerking of the car, you will have to sort out and clean the carburetor. The cleaning process occurs manually or using a special oven that heats the cleaning liquid. But, as practice shows, most car enthusiasts who clean carbs with their own hands do the process completely manually.

Also, when overhauling, you will need a Solex carburetor repair kit, designed for cars of the VAZ 2108-21099 family.

Calibration data for the carburetor installed on VAZ 2108, VAZ 2109, VAZ 21099 vehicles

After the carburetor has been rebuilt, it needs to be adjusted. Adjustment is carried out using quality and quantity screws until the optimal ratio of fuel supplied to the chamber for forming the air-fuel mixture is achieved.

If for an injection engine the poor quality of fuel is even more or less tolerable and you can drive, then for a carburetor engine it is a disaster. Bad fuel not only clogs the jets, but also quickly damages the fuel pump.

Poor quality gasoline can be identified immediately, since the engine begins to “chug”, traction disappears, and if you open the float chamber of the carburetor, the liquid called gasoline will be sticky and will not pass through the nozzles well.

To eliminate the problem, you will have to disassemble and clean the entire fuel system, including the removal of the fuel tank. After cleaning, you need to fill in, albeit expensive, but high-quality gasoline and drive 50-60 kilometers to clean the valve mechanism and piston group.

Although this may no longer help, since the valves and pistons are burned out, and this is precisely the reason. Then a major overhaul of the engine will be required.

Fuel pump and filter

Another reason that the engine starts to stall is an insufficient or intermittent supply of fuel to the carburetor. In this case, the problem will lie precisely in the fuel pump or a dirty filter element.

Therefore, it is recommended to check these elements for functionality. If necessary, repair the fuel pump and replace the fuel filter.

A missing spark is a sign of a malfunction of the ignition system. Namely, spark plugs, wires or a coil could have failed. Spark plugs are checked on a special spark plug stand, but if there is none, then it is necessary to inspect the elements for damage, measure gaps and resistance. If a malfunction is detected, replace damaged parts.

During the diagnostic process, high-voltage wires are measured for resistance and also inspected for damaged insulation. If you find that one or more wires are broken, they should be replaced. The new wire should have a resistance of 5 ohms.

Air filter

The air filter has repeatedly caused the tripping effect. So, this element must be changed every 20,000 km. It is untimely replacement that leads to problems with the formation of the air-fuel mixture.

If the VAZ 2109 engine carburetor begins to triple and twitch, or traction disappears, then the reason should be sought in the formation of the air-fuel mixture or the ignition system. You can even fix this problem yourself, since the motor is quite simple in design.

Air supply

Excess air or lack of it is the reason that causes engine tripping. Occurs due to the system losing its tightness. The power unit begins to suck in air, the electronics do not take this process into account, and as a result, the functioning is disrupted.

Injector nozzlesEveryone will be able to check the air system, since there is nothing complicated in the procedure.

- The inlet hose located near the air filter is blocked.

- Pressure is created in the system.

- The location of the leak is checked by reducing the pressure.

It is clear that if the pressure does not drop, then the system is completely sealed. On the contrary, if the air comes out with a hiss, then this will not only verify the leakage, but also determine the specific location of the leak.

As for the lack of air, this is due to a dirty air filter. The latter loses its capacity. What should be done. Remove the filter and evaluate the operation of the power unit without it. If there is no difference, then the air filter is not doing its job at all and needs to be replaced.

Insufficient air may also be due to throttle problems.

It is also important to clean and check it in a timely manner. It is advisable to carry out the procedure during each scheduled maintenance, simultaneously with the replacement of filters, oil, etc.

d.

Injector temperature sensor

As mentioned above, the cause of engine tripping on the injector can be sensors. They send impulses to the electronic unit. If the signal is erroneous, then the electronics are not able to correct it. For example, if information is received that the engine is cold, but it has been running for an hour, the electronics will send an order to the injectors to inject enriched fuel assemblies. As a result, tripping and a lot of other troubles will arise, including in cold weather.

You need to check this way. First, test the information from the sensors and count the errors. Compare readings with standard values. If there are large deviations, then the cause of the tripling will be found.

Air supply

Excess air or lack of it is the reason that causes engine tripping. Occurs due to the system losing its tightness. The power unit begins to suck in air, the electronics do not take this process into account, and as a result, the functioning is disrupted.

Injector nozzles

Everyone will be able to check the air system, since there is nothing complicated in the procedure.

It is clear that if the pressure does not drop, then the system is completely sealed. On the contrary, if the air comes out with a hiss, then this will not only verify the leakage, but also determine the specific location of the leak.

As for the lack of air, this is due to a dirty air filter. The latter loses its capacity. What should be done. Remove the filter and evaluate the operation of the power unit without it. If there is no difference, then the air filter is not doing its job at all and needs to be replaced.

Insufficient air may also be due to throttle problems.

It is also important to clean and check it in a timely manner. It is advisable to carry out the procedure during each scheduled maintenance, simultaneously with the replacement of filters, oil, etc.

d.

Injector temperature sensor

As mentioned above, the cause of engine tripping on the injector can be sensors. They send impulses to the electronic unit. If the signal is erroneous, then the electronics are not able to correct it. For example, if information is received that the engine is cold, but it has been running for an hour, the electronics will send an order to the injectors to inject enriched fuel assemblies. As a result, tripping and a lot of other troubles will arise, including in cold weather.

You need to check this way. First, test the information from the sensors and count the errors. Compare readings with standard values. If there are large deviations, then the cause of the tripling will be found.