If when you turn the ignition key you only hear a loud crash from the engine compartment, do not rush to immediately blame the starter for all your troubles. There may be several reasons for this phenomenon, and a breakdown of the starter retractor relay is just one of the most common malfunctions. Today we will talk about why the starter began to crack and what to do to restore its functionality.

About Bendix starter malfunctions

When the starter torque slips and does not turn the engine shaft, then one of the most likely malfunctions is wear or breakdown of such an important component as the bendix. A unit that ensures decoupling of the starter and the car engine at the moment when the engine starts...

In fact, the name of this part of a car starter is pure amateur performance of domestic drivers. After all, the classic engineering and technical name for the unit that ensures the separation of the starter shaft from the engine shaft at the time of its start is an overrunning clutch.

And this name fully reflects the essence of the action that this part produces. And this mechanism, which is based on the principle of a conventional ratchet, received its popular name in honor of the American inventor Vincent Hugo Bendik, head of the Bendix Corp. corporation.

It was he who at one time invented and patented a unit that allows, at the moment of startup, to disconnect a small electric motor, which spins the shaft of an internal combustion engine.

Overrunning clutch is the real name. It is also called a clutch - ratchet or ratchet

Be that as it may, in order to understand the nature of the malfunction, damage in this mechanism, when the bendix slips (that is, the starter spins idle, slips and slips without engaging the engine), you need to understand the function and principle by which this mechanism works. In fact, everything is very simple.

Read also: Why don’t jocks have it?

It serves as a kind of clutch that works only in one direction, jamming if an attempt is made to turn it in the other direction. Moreover, a clutch that should disengage precisely at the moment when the engine starts. That's when she returns to her seat.

After all, the rotation speed of a car engine shaft is much higher than the maximum rotation speed of the electric motor, which is designed to act as a starter.

What if he doesn't come back

In fact, Bendix ensures long and trouble-free operation of the entire assembly. And if it weren’t for him, then at the moment when you turn off the starter (that is, the car starts), it does not disengage with the engine, which is called “does not return,” then the rotating engine shaft will simply break the starter itself. Which, by the way, sometimes happens when the Bendix malfunctions in the opposite way - that is, the accelerating clutch does not slip, but, on the contrary, sticks and continues to rotate the shaft together with the electric motor. That is, the bendix does not disengage.

The starter turns poorly when cold

If the starter turns poorly on a cold engine, this is a clear sign of breakdown of the dielectric insulation layer in the armature or brush housing. The engine is hot, the starter has cooled down too. Condensation has formed inside the starter. Which gets into weak points of insulation and conducts electric current through itself. This creates a short circuit.

The reason is also that. that cold engine oil is thick and prevents cranking. This creates a lot of resistance for the starter. As a result, the current strength in the starter windings increases. This leads to breakdown of the dielectric layer of wires and subsequent breakdown of air in places where the insulation is damaged.

The armature windings spend potential not on creating an electromagnetic field, but on a short circuit that occurs as a result of a breakdown.

When hot, the engine cranks easier. Less chance of breakdown. The starter starts the engine easier.

Electrical reason

If, when starting the engine, you can hear the starter spinning, but the engine does not engage, then the problems may be localized in the solenoid relay. It is installed on the starter housing and has terminals for connecting the positive wire from the battery and the control contact of the ignition switch. The pull-in relay is a coil with two windings. The first winding here is retracting, the second is holding

The functions of these two windings are different. The effort also varies. The pull-in coil of the relay is necessary to extend the bendix and close the contacts to supply voltage to the brushes of the electric motor. In turn, the retaining winding creates enough force so that the bendix can obtain reliable engagement with the flywheel crown. If the starter just turns at idle, then the retractor winding works fine. You need to look for the problem elsewhere.

If there is an interturn short circuit in the holding winding of the retractor relay, then the bendix is not locked in the position of engagement with the ring, and the gear is thrown back. The torque is not transmitted to the engine, and it does not start - the VAZ starter spins at idle.

Repair involves restoring or replacing the entire solenoid relay. Another excellent solution is to replace the starter entirely with an original device. But this is not a solution for everyone, so experts can advise repairing the unit - disassembling the retractor, making defects, replacing or restoring worn parts

How to fix a rattling starter

The method for troubleshooting depends on what is causing the problem. If the starter cannot work normally due to a discharged battery, it is enough to charge it to the required parameters. Typically, charging is carried out with a current of 0.1C, where C is the battery capacity in ampere-hours. At the same time, highly discharged current sources and calcium batteries should be charged with low currents (1-2 A) to at least 25% charge (this parameter is controlled by the density of the electrolyte). The gentle mode will take more time, but will protect the battery from many negative aspects.

Note! Often, when the battery is discharged, car owners try to start the engine “from a tow”. Note that this method is only suitable for the simplest power units, but not for injection engines. Launching the latter “from the pusher” often leads to a failure of the electronic control unit software.

In this case, the ECU begins to behave unpredictably - for example, request permission to start from a disabled immobilizer. The situation can only be corrected by reflashing the “brains”, and this, as you yourself understand, is an additional and completely unjustified expense.

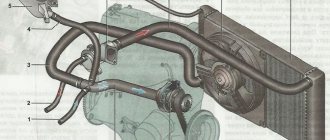

In the case where the cracking of the solenoid relay occurs due to poor contact with the vehicle ground, it is enough to simply restore the electrical connection. To avoid problems in the future, it is recommended to remove the tire that connects the engine to the body and clean the contact pads with sandpaper. A thin layer of technical Vaseline or VD-40 universal lubricant will help prevent their oxidation.

If the source of the malfunction is the retaining winding of the starter solenoid relay, then try to repair it. If this is not possible, then a decision is made to replace the solenoid relay assembly. As you can see, even a novice driver can cope with finding the fault that is causing the starter to crack.

Other signs of a Bendix malfunction

The starter is very susceptible to harmful environmental factors - moisture, dust, dirt, oil. Consequently, his isolation is broken and he refuses to work. It is necessary to remember that the part works in conjunction with other elements and is subject to “avalanche failures”, when a malfunction in one unit entails a breakdown in others. Other reasons that can cause starter failure include:

- wear of the relay winding - the starter shows no signs of life at all, the armature does not turn;

- wear of the stator or armature winding - the starter rotates the motor extremely slowly, while the crankshaft also rotates slowly;

- problems with the manifold - slow cranking of the engine and crankshaft;

- brush wear - no current is supplied to the relay, the starter does not make noise.

You may notice that the same symptoms indicate different problems. You can carry out the diagnosis yourself, but in order not to aggravate the situation, you should still turn to professionals.

If you discover certain problems in the functioning of the starter, do not delay solving the problem. Such a malfunction can lead to the failure of more serious components of the overall mechanism. It is better to carry out minimal repairs than major ones.

Checking the starter

First of all, without having certain skills and abilities, it is better to contact a service station, where experienced specialists will determine exactly what caused the starter to fail.

The initial check of the starter is carried out by measuring the voltage in the wire going to the control contact of the solenoid relay when turning the car's ignition key. In operating condition, the voltage should be 12 - 24 Volts (depending on the type of vehicle when testing the starter of a car or truck). The neutral position of the ignition key in the lock means that the voltage on the solenoid relay control wire should disappear.

This happens when the Bendix gears wear out or the flywheel teeth wear out. This problem can only be solved by replacing the bendix or flywheel assembly. If the solenoid relay, gear and overrunning clutch (Bendix), as well as the flywheel and combustion lock are all fine, but the problem remains, then the starter must be removed for repair or replacement.

Why the starter cracks: finding and eliminating the cause

If when you turn the ignition key you only hear a loud crash from the engine compartment, do not rush to immediately blame the starter for all your troubles. There may be several reasons for this phenomenon, and a breakdown of the starter retractor relay is just one of the most common malfunctions. Today we will talk about why the starter began to crack and what to do to restore its functionality.

Causes of malfunction

Before we begin to study the causes of the malfunction, we remind you that hereinafter we are talking about the crackling noise of the starter, which is most similar to the loud rattling of the contacts of an electromagnetic relay. If you hear an unpleasant metallic grinding noise from under the hood, then it appears due to poor engagement of the overrunning clutch (starter Bendix) with the flywheel teeth - that’s a completely different story.

Most often, the starter crackles when you turn the ignition key for three reasons:

Low battery

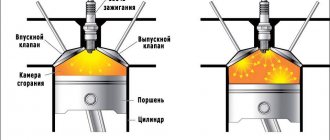

To understand the cause of the crackling noise due to a discharged battery, let's remember the starter device. When you turn the ignition key, the voltage from the on-board network is supplied to the coil of its solenoid relay. The electromagnetic forces that appear in this case cause the armature of the device to move. It closes the power contacts that connect the starter motor to the battery, and in addition, causes the Bendix gear to engage with the flywheel.

When the battery is discharged, its energy may be enough to attract the metal core - cranking the crankshaft is out of the question. As soon as the starter contacts close and power is supplied to its electric motor, the voltage drops to such an extent that the electromagnet is unable to hold the metal core. Under the action of the return spring, it tends to take its original position and opens the power contacts. The restored voltage contributes to the repeated retraction of the anchor, and the situation is recreated many times.

The design of a car engine starter and its operating principle

The main components of the starter:

- electric motor;

- solenoid relay;

- gear with bendix;

In a nutshell, a flywheel with a ring gear is installed on the engine crankshaft. When the starter is turned on, the starter gear meshes with the flywheel crown and the electric motor turns the crankshaft. After the engine starts, the starter overrunning clutch disengages the gear from the shaft when the engine speed exceeds the starter speed.

- If we take a closer look at the starter, its electric motor consists of a housing, inside of which there is a stator and a rotor rotating in two bushings.

- The brush assembly consists of three or four brushes, which are supplied with voltage from the battery. The brushes, in turn, connect to part of the rotor and supply voltage to it, causing the starter motor to rotate.

- The gear and bendix, located on the rotor shaft, moving forward and backward along it, engage with the flywheel. The solenoid relay turns the electric starter into operation.

The solenoid relay is an electromagnet with a coil and a core. The core, under the influence of the electromagnetic field, begins to move to the side, while the fork connecting the core and the bendix pushes the bendix and gear along the shaft forward to engage it with the flywheel.

The relay has two contacts, one of which is supplied with voltage from the battery, and the other is connected to the brushes of the electric motor. When the core reaches the end of the relay, with the gears already engaged with the flywheel, the copper plate located at the end of the core closes these two contacts and voltage flows to the electric motor.

As for the types of starters, there are:

- A starter with a gearbox, which consists of several gears and is mounted directly to its housing. The electric motor of such starters is highly efficient and consumes much less current when starting the engine. It is installed on cars with diesel engines and on gasoline cars with more powerful engines.

- A starter without a gearbox, having high resistance to loads, ensures quick starting of the motor due to instant connection with the flywheel crown after current is applied.

In this case, starters may differ from each other, but not significantly. In most cases, their difference lies in the mechanics of automatic gear disengagement.

It usually takes a few seconds for the engine to start. But in practice, malfunctions may occur when, after the first turn of the key, the engine does not start, after starting the engine, the starter spins along with the engine, etc.

Starter crackling when trying to start the engine

There are several reasons for this behavior. In order to understand the reasons in more detail, you need to know the starter design and operating principle. It consists of an electric motor, on the shaft of which an overrunning clutch with a drive gear is installed. In everyday life, the clutch and gear are called bendix. The design also includes a starting relay with a solenoid. This design is called a “traction relay”. It is connected to the clutch by the starter activation lever. This design works as follows

.

When turned on, the electric motor begins to rotate the bendix. At the same time, the traction relay, having activated, moves the overrunning clutch forward using a lever. As a result, the gear meshes with the teeth of the flywheel and spins the engine. After the engine starts, the overrunning clutch is activated. This protects the starter from damage. When the power supply to the device is turned off, the relay stops working and the starter bendix returns to its original position.

Passenger car starters usually use a roller-type overrunning clutch.

There is only one reason for the grinding noise at startup. For some reason the Bendix cannot fully engage the flywheel. Therefore, when starting the starter, a grinding sound of skipping teeth occurs. This problem needs to be fixed as quickly as possible. Otherwise, the flywheel and starter gears may be damaged. You need to check the following points:

- First, check the starter mounting. Sometimes vibration can cause the mounting bolts to come loose. In this case, the starter becomes warped and the gear loses full contact with the flywheel. In any case, remove the starter and check the condition of the bendix;

- Sometimes the problem can be caused by gear wear. In this case, the starter's performance decreases. When starting the engine, you will hear the grinding sound of the bendix moving around. Over time, the starter will not be able to turn the flywheel at all. After removing the part from the machine, you can see the gear wear with the naked eye;

- Sometimes the Bendix does not move well along the shaft and simply does not reach the flywheel. In this case, remove it. You need to coat the shaft with any motor oil (5w30 or 5w40 or whatever you have on hand). Also check the operation of the traction relay.

there is a problem somewhere in the starter

A crackling sound when starting can also occur due to problems with the starter's power supply. It appears when the positive wire is loosened. If there is poor contact, a spark discharge occurs, which is what produces a crackling sound. Check the wire. Tighten it if necessary. Flywheel

. The cause of the grinding noise may be in the engine.

If the flywheel teeth are worn too much, they cannot form full contact with the starter gear. As a result, you can hear an unpleasant grinding noise. It is advisable to replace the flywheel. Otherwise, wear on the bendix will increase and you will have to change it regularly.

Since we're talking about the flywheel, read our two materials on this topic:

- “Pros and cons of a lightweight flywheel”;

- “Independent replacement of a dual-mass flywheel with a single-mass one.”

Roller mounting bolt (timing) Conclusion

Diagnostic and troubleshooting methods

Why does the alternator belt whistle when starting the engine or air conditioner?

Many car enthusiasts, leaving home in the morning and starting the vehicle engine, have encountered a grinding and crackling sound when starting up. In this case, the malfunctions are different and it is worth understanding what sound means what.

Starter, flywheel and solenoid relay

Perhaps it’s worth starting our consideration with the fact that a grinding noise appears during the start-up of the power unit. As it was found out earlier, the issue here is in the starter or flywheel. So, if the grinding noise continues until the engine starts, this is due to wear on the bendix or flywheel crown.

To be more precise, the teeth of one or the second element are worn out, and the part does not adhere well to the part. Also, the issue may be in the solenoid relay, which does not fully pull the bendix, which does not grab the flywheel.

To eliminate the malfunction, it is necessary to dismantle the starter and inspect the condition of the bendix, namely its teeth. If there is characteristic wear in the form of “licking” of the teeth, then it is recommended to replace the part. But that's not all. Also, since the starter has already been removed from the vehicle, it is worth checking the solenoid relay.

Low compression

Another reason when the starter idles when cold is the internal combustion engine itself. If the engine compression is insufficient to properly compress the fuel mixture, then the engine will not be able to start. Also, the crankshaft may rotate with resistance - this also affects starting.

Some of the simplest reasons are everything related to the human factor. For example, an empty tank or low fuel level. In some cars, the tank is made in such a way that if the car is parked on a hill and the fuel level in the tank is low, the pump cannot pump in the required portion of gasoline. The engine cannot be started. The same applies to candles. The starter can turn the engine until the battery runs out, but the engine will not start due to faulty spark plugs.

Methods for emergency engine starting if the starter does not work

If the starter does not show any signs of life - it does not click or make any sounds at all - you can start the engine directly. Not the best method, but suitable in an emergency situation when you urgently need to start the car.

Let's consider the algorithm of actions for starting the engine directly using the example of the popular Lada "Ten" (VAZ-2110). You need:

- Put the car in "handbrake" and set the gear to neutral.

- Turn the key to turn on the ignition.

- Open the hood - further work will take place in the engine compartment.

- Remove the air filter from the driver's seat to gain access to the starter contacts.

- Disconnect the chip that goes to the contact group.

- Using a metal object, you need to short-circuit the starter terminals. For example, a screwdriver or a piece of wire is suitable for this.

If other components are working properly and the battery is sufficiently charged, these simple manipulations will start the car. Replace the air filter and the chip leading to the contact group.

It's funny that after starting directly, the engine, as a rule, will continue to be started simply with the ignition key. But this does not mean that the problem is solved. The breakdown cannot be done anywhere and you need to identify it and fix it.

Causes

Why is there a crackling and grinding sound when starting the engine? This question is often asked by beginners and not-so-motorists. Many people are frightened by the strange sound heard when starting the engine. Although in many cases this is not a difficult problem. But it still needs to be eliminated, and for this it’s good to know where to look for the problem. There are several places that produce crackling and grinding noises during startup:

- Starter;

- Flywheel;

- Roller mounting bolt (timing).

Knowing the main places of breakdowns, you will quickly find out where the main problem is. For a more accurate diagnosis, open the hood and ask someone to start the engine. If there are problems with the starter and flywheel, a cracking noise will be heard from the rear of the engine when the bolt is unscrewed at the front.

The starter bendix does not turn

There may be several reasons for this situation. First of all, you need to pay attention to the battery. It may either be discharged or faulty. There are several ways to find out if the battery is at fault:

- the solenoid relay clicks, the lights on the panel do not light up, and the starter bendix does not turn;

- certain clicks are heard, but the lights still go out;

- the system shows no signs of life.

In this case, you just need to charge the battery, but try to figure out why it was discharged in order to prevent similar problems from occurring.

Problems can also be caused by a faulty solenoid relay. There are several signs here:

- you can hear the characteristic buzz of the starter, but the engine does not rotate;

- the starter does not make noise;

- the relay is activated, but the engine does not crank;

- Bendix does not engage the flywheel.

Checking the relay is simple - you need to apply voltage directly to its control terminal. If the engine starts, then, most likely, the relay contacts have burnt out. Clearing the nickels will correct the situation.

Conclusion

Grinding and crackling noises in the power unit indicate that some engine parts have failed. So, the grinding noise is accompanied by a malfunction in the starter or flywheel. As for the crackling sound, the situation is much more complicated - most likely the problem is hidden in the crank mechanism or in the cylinder head.

If such malfunctions occur, it is recommended to contact a car service as soon as possible, so as not to cause more trouble than already exists.

PS How can I find Vladimir Gertsev (electrovovik)?

Thanks to all! Started up!