Interruptions in engine operation sometimes lead to complete failure. Tripletion is the operation of 3 cylinders, which causes many problems. First of all, comfort during movement disappears, the power of the power unit decreases, severe excessive fuel consumption occurs, and unprocessed gasoline vapors are felt in the exhaust gases. Let's figure out what reasons cause the VAZ-2112 engine, which has 16 valves, to trip.

Consequences of engine tripping

A malfunctioning power unit not only leads to discomfort while driving, but also to more serious problems. The fuel that enters the idle cylinder and does not burn flows into the crankcase with oil. The fuel mixture makes the engine oil more liquid and loses its properties.

If the problem in the engine is not corrected immediately, the pistons and rings will begin to wear out over time. The lack of a lubricating film leads to the formation of nicks and scuffs on the cylinder walls. Thus, the appearance of extraneous noise in the engine leads to the need for major repairs.

Ignition

Before checking the entire system, it is necessary to identify the inoperative cylinder. This is done as follows: the high-voltage wires are pulled off the spark plugs one by one.

At the same time, the working cylinders react to this action, the engine begins to wither. If the non-working cylinder is disconnected from the ignition, the engine will not react to this in any way. After determining the inoperative cylinder, unscrew the spark plug. Problems with it or with the ignition system are indicated by the presence of fuel residues on it, the spark plug is “wet”. You can try replacing the spark plug and installing another high voltage. You may find that when you start the engine, it runs fine. If this does not happen, you need to continue checking. The simplest solution is to replace your module with one that is known to work. If this is the problem, then the engine should start working correctly. You can also check with a multimeter . To do this, you need to measure the resistance at the terminals. This needs to be done in pairs. Combine cylinders 1 and 4, as well as cylinders 2 and 3. The resistance should be between 5.2 and 5.5 ohms. The ignition module cannot be repaired; if it malfunctions, it will have to be replaced.

Checking the ignition system

Almost all car enthusiasts begin checking the 1.6-liter VAZ-2112 engine by testing spark plugs. With their help, you can find a cylinder that is not working at full capacity. To do this, you must first remove the high-voltage wire from each cylinder one by one. When you touch a non-working cylinder with this, the nature of the operation of the power plant will not change.

Next, do a spark test to rule out problems with the power supply to it. To do this, return the wire to the spark, place it on the engine so that the electrode does not touch it. Crank the starter until sparking appears. After this, look at the spark plug body and evaluate the signs as a whole.

- If the spark is very weak, and the spark plug visually has a lot of carbon deposits, then the reason for this may be a non-functioning air filter. When it does this, dust gets on it, which mixes with oil and fuel.

- If the electrode of the spark plug is intact, but carbon deposits have formed on its body, then there may be several reasons: incorrectly adjusted ignition (detonation is advanced), an error in choosing a spark plug, or a lean fuel mixture.

- If only the electrode burns out, then the malfunction is hidden in excessive enrichment of the fuel mixture, incorrectly selected spark plug, low compression pressure, air filter impermeability, and delayed detonation.

Inspect the spark plug well; if you find oil in it, then you need to adjust the operation of the caps responsible for its supply. Most often, this malfunction requires replacing the valve stem seals. There should be no cracks on the spark plug body; if there is damage, replace the spark plug, even if it is visually intact.

Additionally, it is recommended to replace high-voltage wires, as they may have microcracks. In this case, the spark is weak, but the spark plug is visually intact. If this element is damaged, you must act according to the list above. The breakdown can be fixed by adjusting the ignition, power and air supply systems.

With a weak spark, the reason sometimes lies in the timing belt - it may be loosely tensioned, which is why it has shifted by several teeth. Also check the on-board computer; perhaps there is an error in its memory, which is why systems related to the power plant do not work correctly.

Causes

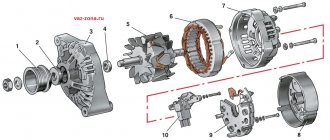

General view of engine 21124 16V.

The VAZ 2112 engine has problems with the 16 valve injector for various reasons. To find out the specifics, the motorist needs to know the design features of the power unit, as well as have some vehicle repair skills.

So, VAZ 2112 has 16 valves and the engine is tripping, what could be the reasons for the effect:

- Poor quality fuel.

- Malfunction in fuel supply elements.

- Malfunction of air intake units.

- Malfunction in the ignition system.

- The problem lies in the electronic part of the car.

Solution methods

Before you begin the process of analyzing the causes in more detail, as well as methods for eliminating the malfunction, it is worth understanding that if the car owner is not sure that he can fix the breakdown or does not carry out the correct diagnosis, then it is better not to get involved himself. In this case, it is recommended to contact a professional car service.

Poor quality gasoline

Poor quality fuel is everywhere.

Troubleshooting on a VAZ can primarily occur if low-quality fuel gets into the air-fuel mixture formation system. Thus, most domestic gas stations do not have a very good reputation due to the fact that they sell fuel that does not meet the standards.

So, if gasoline has already entered the system, it most likely clogged the gasoline supply system, and possibly left its mark on the spark plugs. In the worst case, what all car enthusiasts fear is burnout of the valves or piston mechanism.

Therefore, it is better to take the choice of a gas station seriously, since major engine repairs will cost more than saving on good gasoline. It is recommended to overpay a little for fuel, to regularly change fuel cells and carry out constant repairs.

Fuel cells

The process of replacing a clogged fuel filter.

The first place to look for a problem is the fuel supply to the fuel mixture formation system. Thus, clogging of the elements can cause an insufficient amount of fuel to flow into the combustion chambers.

First, you need to check the performance of the fuel pump, or more precisely, an element such as a mesh filter. It is located on the pump itself and often becomes clogged due to the use of low-quality fuel. But, as soon as it is changed, the operation of the power unit returns to normal.

It is recommended to replace the fuel filter along with the filter screen of the gasoline pump, since in this case it becomes clogged and fuel cannot fully pass through the fuel lines. The part is placed under the rear right wheel from the bottom. The element is changed within 30 minutes.

The process of cleaning injectors with your own hands.

The third element, which is responsible for supplying the fuel mixture, is the injectors. Their contamination leads to the fact that the engine begins to stall. In order to check their functionality, it is necessary to remove the elements from the engine. Diagnostic operations are carried out on a special washing stand. If during the inspection it is discovered that there are faulty injectors, then they should be replaced. You should not install faulty parts in the power unit, as this will lead back to tripping and even greater malfunctions than the existing ones.

Air supply

The engine may stall due to problems with the air filter.

Normal air supply is the key to the formation of an air-fuel mixture and a normal combustion process. Thus, a malfunction of one or more air supply elements can lead to the engine starting to choke. These include the air filter and throttle valve.

The air filter element must be changed every 20,000 km, since after this it becomes clogged and becomes unusable. But it is necessary to monitor the condition of the throttle valve, since it is unknown when it will become clogged and begin to cause problems. Typically, motorists clean this unit themselves, using special products or a carburetor cleaner.

Ignition system

One of the options for why the tripping occurred is a problem with sparking. So, failure of a spark plug or one of the high-voltage wires leads to the fact that the engine begins to stall. Therefore, it is necessary to diagnose these elements for operability.

Soot on the spark plugs means a malfunction of the motor and the cause of the tripping.

Another structural element that needs to be checked is the injector, since the problem may be hidden in this element.

Electronics problem

Last but not least, the electronics are where faults occur. So, a problem with sensors or the electronic control unit of the power unit can cause tripping.

Burnt out ECU 21124 - January 5.2.

To carry out repair and diagnostic operations, you will need not only standard tools, but also a diagnostic laptop PC, as well as a cable connecting to the ECU - K-line. After connection and synchronization, you can determine what errors exist, or perhaps one of the sensors responsible for the normal operation of a particular node has failed. After the repair, it is recommended to reset all accumulated errors.

Engine power problems

Malfunctions in the engine power system can be caused by the use of low quality fuel. Solving them is quite simple - you need to refuel the car in a trusted place. As a rule, after this the problem is solved. It is important to select the correct octane number of fuel; in the VAZ-2112 it is strictly forbidden to use AI-80, which has now practically disappeared from gas stations.

To get rid of engine vibration, additionally clean the injectors. You will have to disassemble the assembly where they are located and clean the dampers with a special compound. It is strictly forbidden to pour chemical compounds into the fuel tank. It is best to thoroughly flush the unit; it will take more time, but will definitely solve power problems. Additionally, replace the spark plugs.

Nutrition

Often, the cause of engine tripping is the power supply system. First of all, the problem may be caused by low-quality fuel. To check, try changing the fuel. You can also try cleaning the injectors.

Their blockage can also cause tripping. For this purpose, special compounds are used. It is not recommended to pour cleaners into the tank. It is better to make a temporary power supply system; cleaning is carried out according to the instructions indicated on the package. After cleaning the injectors this way, the spark plugs should be replaced with new ones.

Piston system and valves

The valve and piston systems are checked together. Remove the breather hose from the manifold; if white smoke comes out of it, then the engine is definitely stalling due to a piston failure. Disassemble the engine and find the cause. Most often, it lies in the occurrence of rings; to correct this problem, it is necessary to remove the pistons.

If there is no smoke or colorless gas emitted, the problem is hidden in the valves. Measure the compression in them; if the value is less than 11, then the valve is burned out. To replace the valve you need to remove the head and then grind it in.

During normal compression, tripping is caused by incorrect valve adjustment. They may be too tight or, on the contrary, loose. Remember that on the VAZ-2112 the operation of the valve system must be adjusted regularly.

Malfunctions of the crankshaft position sensor

The on-board computer may send incorrect impulses to all vehicle systems. Most often this happens if one of the sensors is faulty. Incorrect engine operation is often associated with a malfunction of the crankshaft position sensor. It needs to be removed for testing.

The test is carried out with an ohmmeter. Readings should be between 550 and 750 ohms. If they are outside this range, then the sensor must be replaced as it is faulty. Usually, after installing a new element, the power plant begins to work normally.

If the on-board computer generated an error for this sensor, then after replacing it, remove the terminal with the minus sign from the battery. This will help clear the ECU memory of the fault record.

Reasons for unstable operation of the VAZ-2112 at low speeds

General view of the 12-series engine

There are not many reasons that accompany the appearance of the jerking effect at low speeds. We can even say that everything is tied to the fuel supply system to the cylinders. So, it is necessary to identify all the reasons that are associated with the problem on the car:

- The problem is hidden in the fuel system.

- Incorrect throttle operation.

- The crankshaft sensor has failed.

- ECU.

Perhaps the reason for the car jerking is worth looking for here. When all the problems have been identified, it is worth moving on to searching for solutions to the problem.