Many cars have front brakes with disc brakes and rear brakes with drum brakes. But there are exceptions to this rule, and not only in auto racing, where all 4 wheels are equipped with disc brakes for the sake of reliability. Manufacturers in other countries equip only budget modifications of cars with drum systems; most of them have all disc brakes. But is it possible to equip a domestic car, for example, a Priora, with rear disc brakes and which ones are better?

Disc brakes

Disc brakes on Priora, according to car enthusiasts, are easy to install and are more efficient than standard drum brakes. Moreover, disc systems have another important quality: precise and uniform operation of the brakes front and rear. The use of disc wheels on the rear wheels reduces the braking distance several times; a brake system of this type does not require frequent maintenance. Excess heat generated during braking is quickly dissipated on the disc system.

According to production standards, Priora is not equipped with an HTD. Only front brake discs are installed on it. This means that by purchasing and installing new rear disc brakes, you are making changes to the design of the car that are not required by the standards. It should be taken into account that the installed brake system will require fine-tuning and tuning, which can only be performed by a qualified specialist and only in some cases by a very experienced driver who has tuned disc brakes more than once. Otherwise, uneven and unclear operation of the system, as well as its overheating, are guaranteed.

Rear disc brakes can be an obstacle to passing inspection because, for the reasons stated above, their installation is illegal. Replacing brake discs will require adjusting the brake force distribution system, often called a “sorcerer” among car enthusiasts. Otherwise, the car will skid sharply after braking.

Which drives are best to install to avoid problems? Experts advise purchasing only certified braking devices, and installing them only at a service station, which will also issue confirmation that the car’s braking system is fully configured and meets all standards. However, even in this case, the owner of non-standard brakes may be found fault with during the next maintenance.

You can install the rear disc brakes yourself, but be prepared for a long setup process and the fact that you will need to do a lot of test drives to find the optimal settings for your car. Well, decide which discs are best from the currently available brands, be it Brembo or Lucas. Brembo discs are very popular in our country and do not require in-depth knowledge in setting up such spare parts. In addition, Brembo kits and discs are compatible with brake units from other manufacturers.

Why do rear pads wear out rapidly?

Several factors influence the wear rate of the rear pads. In the first place here is the driver’s illiterate work with the brake system. Considering the fact that the Priora is equipped with a fairly powerful engine, most drivers prefer aggressive driving with rapid acceleration and sharp braking. With this type of driving, the operation of the car’s braking system leads to the fact that the rear pads wear out very intensively. Many inexperienced car owners, due to ignorance, practically do not use engine braking.

The second factor is the replacement of the rear pads on the Priora with low-quality spare parts. Questionable manufacturers of cheap elements may use low-quality and sometimes simply unsuitable materials to produce the friction layer of linings. This can not only reduce the manufacturer's recommended replacement schedule, but also render the brake drums unusable. Let's look at the main signs that require urgent replacement of the rear brake pads on a Priora.

Sources

- https://VAZremont.com/zamena-zadnih-perednih-tormoznyih-kolodok/

- https://CarsUp.ru/hodovaya-chast/kak-pomenyat-zadnie-tormoznye-kolodki-na-priore.html

- https://mashintop.ru/to/zamena-zadnih-tormoznyh-kolodok-lada-priora-s-abs-i-bez-abs.html

- https://ladafakt.ru/zamena-zadnih-kolodok-na-priore.html

- https://enginehack.ru/zamena-zadnih-tormoznyh-kolodok/

- https://FB.ru/article/466644/zamena-zadnih-kolodok-na-priore-poshagovaya-instruktsiya-osobennosti-sovetyi

Rear disc brakes: installation

Naturally, you need to start by dismantling the standard brake system. If the brakes are on a Priora with ABS, then before that you need to remove a special sensor and the carrier shield clip. Next, you need to thoroughly clean the pressure controller, the hub axle, the trigger ring neck, and remove the handbrake cable. Then the adapter plate and protective casing are installed. The plate connects to the housing in the middle of the hub. All bolts must be carefully tightened with a torque wrench.

With the correct assembly sequence for rear disc brakes, the hub must be connected to the rear beam on both sides. It holds the brake disc. The brake disc caliper is also connected to the rear beam by a faceplate. To prevent the rear axle from skidding when braking the car, know that the diameter of the rear brake discs for the Priora should be smaller than the front ones.

In order for the new brake mechanism to work correctly on the Priora, you need to know that brake discs for VAZs with front-wheel drive have a size of 13 to 14 inches, and based on this you need to choose a caliper, complete with brake pads and a hose.

In order to install brakes on a Priora with ABS, you need to perform the above operations, and then install the traction control sensor on the standard mount. After this, installing the brakes continues in the same way as on a car without ABS:

- We mount the trigger guard guide on the adapter plate, observing the required tightening torque.

- The brake disc is secured to the wheel hub with two rods, and a caliper is mounted on top of it with the fitting facing up. The guide rod bolts are additionally attached to glue and then tightened. Next, you need to adjust the cylinder and install the brake pads.

- Lubricant is applied to the handbrake spring, after which the spring is inserted into the bracket. The bracket and cable are attached to the beam with a screw clamp.

- We install the brake hose and screw its tip into the caliper.

- The final stage is to assemble the brake line, securing the brake pipe to the handbrake.

This is how, in general terms, rear disc brakes are installed on a Priora.

Replacement

Replacement is carried out using a lift or on an inspection pit. Regardless of the location of the parts, we will need the same set of tools. It includes Phillips and flat-head screwdrivers, a deep socket for 7, long-nose pliers and pliers, spanners for 17 and 13. You may have problems dismantling the rear drum, so prepare a socket for 30 in advance. It is recommended to purchase a wrench for the “seventh” head .

Rear brake pads on Priora

- We lift the rear part of the Lada Priora and place additional supports. We remove the drum - it is held in place by two pins, which are shown in the photo below;

We unscrew both fasteners and try to rip off the drum - If it was not possible to dismantle the drum in this way, then remove it along with the hub. This takes longer, but is more convenient, since the unit will not interfere with unscrewing the brake mechanisms;

- We take long-nose pliers and take out the handbrake cotter pin;

Pull the fasteners up using long-nose pliers - Find the right lower spring and remove it. This can be done with a screwdriver or other convenient tool - it should come off the fastening point;

- The next step is to remove the fasteners that hold the rear pads in a vertical position. Small springs can be easily unscrewed using pliers;

- We are trying to manually remove the brake pads. Try moving the top parts of the part apart. If that doesn't work, remove the top spring;

We separate the plates, after which the block will fall down - When all the fasteners are removed, the parts we need will fall. We install new components in reverse order.

If you cannot install the drum after installing the new components, you will need to loosen the handbrake cable. You will find it under the bottom of the Priora.

Front

Before removing the front pads, it is necessary to pump out some of the brake fluid if it is at the MAX level. This can be done using a syringe. Also remove the front wheels.

- Using pliers, it is necessary to bend the edges of the locking plate;

- Now we have access to the bolt - unscrew it with the 13th key. If the bolt rotates, tighten it with a 17 key;

- Raise the caliper body and remove the front brake pads from the guide mounts;

Unscrew the bolt with the 13th key, and hold it with the 17th key so that it does not turn - As you can see, the front parts are easier to remove. Thoroughly clean the landing areas before installing new components;

- The piston should be pressed out with any convenient tool - a wrench, a screwdriver or long-nose pliers. If it is too tight, use a screwdriver for extra pressure; Carefully roll the lock washer antenna

- Replacement is carried out in the reverse order.

When the replacement is completed, you need to press the brake pedal several times. After this action, the pistons will be securely locked.

Brake pads should be replaced on both wheels at once. Then Priora will brake normally even in emergency situations.

Remove the brake drum.

Do not press the brake pedal after removing the drum, as the pistons may come completely out of the cylinder. If the drum cannot be removed...

...then, turning it evenly, we strike the end of the drum with a hammer with a plastic tip (or an ordinary hammer through a wooden block).

Using a screwdriver, we remove the hook of the upper tension spring from engagement with the block...

...and remove the spring.

Using a screwdriver, pry the hook of the lower tension spring out of engagement with the block...

...and remove the spring.

Using a screwdriver, remove the pressure spring from engagement with the block.

Remove the front pad.

Remove the spacer bar. Having disconnected the pressure spring from the rear block...

...and remove the rear shoe lever from the hole in the parking brake cable end. Straightening the cotter pin...

...and remove it from the hole in the parking brake lever pin.

Remove the washer from your finger.

Remove the lever and remove the finger. Install the parking brake lever onto the new pad in the reverse order.

Install new pads in reverse order.

To make it easier to assemble the pressure spring with the block, we use the lower tension spring, hooking its end to the hook of the pressure spring.

While tensioning the spring using a screwdriver, insert the hook of the spring into the hole in the block. Before installing the drum, it is necessary to recess the pistons inside the working cylinder. For this…

...press the pads with two mounting blades, leaning against the shoulder of the brake shield. After installing the drum, press the brake pedal several times to set the pistons to the working position. Adjusting the parking brake.

Disc Brake Maintenance

Service

So, in general terms, we can describe how rear disc brakes are serviced. A set of rear brakes for VAZ, including Priora, will cost about 9,000 rubles. plus service. Disc brakes provide stable and safe driving at speeds over 100 km/h, unlike drum brakes, which can fail in a critical situation. Rear disc brakes are a significant investment in safety.

Priora meets high safety standards, and rear disc brakes significantly increase it even in extreme situations. Ventilated brake discs are particularly effective. This is all the same both when installing brakes on a Priora with ABS and one not equipped with it.

The nuances of installing the brake system

On one of the car blogs it turned out that removing the standard rear brakes does not cause any problems, except for the handbrake cables. To remove them, you need to lie down on the ground, otherwise you simply won’t be able to dismantle them without damaging anything.

In such conditions, ratchet wrenches and safety glasses come in handy to prevent dirt from the bottom from falling into your eyes. When installing ABS sensors in place, you need to take into account a small detail: the bushing into which the sensor must be inserted must be removed from the brake shield. All operations for installing brake discs on Priora take about six hours.

Brake hoses are often attached to calipers with banjo bolts. After assembly, the brake system needs to be bled so that an air lock, like the one that sometimes appears in the heating system of our houses, does not get in the way of the brake fluid. A simple device called an aerator allows you to bleed the brakes without an assistant: a tube with a fitting that fits onto the wheel nipple. But there may be problems with the tightness of the connections when using an aerator.

In general, everything works very well immediately after installation. You need to let the parts of the system get used to it, but after some time they can easily withstand emergency braking at 120 km/h. The brake fluid pressure in the rear disc lines, although less than that of the drum ones, is still significant. To prevent its accidental release when pumping on a car with ABS, discharge the pressure accumulator. Turn off the ignition, disconnect the connectors on the brake fluid reservoir.

We bleed ABS brakes only with the pedal depressed (that’s why an assistant is needed), an aerator can also help, as in the above case. If the ABS is of the second type, a scanner is needed that connects to the control unit of this system. Therefore, in this case, it would be more logical to contact a service station.

One of the popular braking systems for front-wheel drive domestic cars is called Tornado. Rear disc brakes of this design demonstrate excellent compatibility with the Priora, are equipped with a special adjustment mechanism, and work well with the standard hand brake and original hydraulics. That's all! Now you can pick up the HDT for the Priora, choose which ones are better, and dismantle it yourself. Good luck!

Source 1ladapriora.ru

Many drivers strive to modernize their car, especially if we are talking about fairly old models that they do not want to exchange for modern cars for one reason or another. When tuning the engine, we must not forget about the need to update the brake system. If your car has drum brakes, when increasing engine power, it is advisable to consider installing a disc system in their place.

Why are disc brakes better than drum brakes?

Replacing disc brakes with drum brakes is advisable if you want to increase the efficiency of the braking system. On most modern mass-produced cars, manufacturers install a disc braking system, and here are several reasons for this:

- The response speed of disc brakes from the moment you press the pedal is significantly higher than their drum counterparts;

- Disc brakes on all wheels operate simultaneously, which allows you to stop the car not only quickly, but also smoothly;

- Improved heat dissipation, which has a positive effect on the performance of the pads and disc.

These are just a few of the benefits of disc brakes that clearly indicate that replacement is worthwhile.

What to consider when replacing drum brakes with disc brakes

Replacing the brake system is a fairly complex job that requires attention. The safety of the driver, passengers and surrounding motorists depends on the effectiveness of the brakes. When changing the type of brake system mechanism from drum to disc, the following points should be taken into account:

- Along with replacing the brakes, it will also be necessary to replace the handbrake with a hydraulic one;

- When choosing a brake system, you need to pay attention to ensure that it meets all the standards required for similar structures on the car where the mechanism is installed. This is an important point, since an incorrectly selected disk system may be less effective, for example, overheating will occur during braking, which will affect the speed of stopping the car;

- When purchasing and installing disc brakes, please ensure that they are certified for use in the Russian Federation;

- After replacing the brake system, since it is one of the basic ones, you will need to undergo maintenance and note information about the design change.

Replacing drum brakes with disc brakes yourself

The technicians of most private service centers are ready to take on the job of replacing the brake system for a fee. But you can do this yourself, if you have the necessary tools.

Please note: If the work is carried out by a professional service center, upon completion you will receive a certificate of quality for the new brake system.

To independently replace drum brakes with disc brakes, you will need a disc brake system installation kit, including: caliper, pads, discs, hose, face washers, bolts and fasteners. In addition, you will need a standard set of automotive tools.

Important: Before you begin, read the instructions that came with the purchased brake system. It contains a detailed description of the units included in the kit, necessary for the operation of the circuit and other information.

Let's look at the basic steps that will need to be performed when installing a disc brake system, but it is important to remember that for each car this instruction will have individual nuances that should be taken into account:

- The first step is to remove the old brake pads. To do this, just read the car's operating instructions. Since this kind of work is standard (the pads are a consumable component and therefore have to be changed frequently), information about it is necessarily contained in the instructions;

- Next, the drum brakes are removed. To do this, you need to loosen and twist all the fastening bolts of the brake elements on the rear wheels;

- At the next stage, it is necessary to remove the nut that holds the handbrake cable, after which you can proceed directly to dismantling the drum. It is worth noting that if the car has traveled more than tens of thousands of kilometers, most likely the drum has become stuck and will need to be torn off. This can be done, for example, with a hammer;

- When the drum is removed, it is necessary to disconnect the brake hose from the brake cylinder and then remove it;

- Next, remove the rear suspension arm hub and flange;

- After this, you can proceed directly to installing the disc brake system. At the beginning of work, secure the flange of the suspension arm, and then the hub with the disk to it. The next step is to install the brake disc, guide pads and the pads themselves. Before installing the caliper, press the pistons inward, which can be done using a large flathead screwdriver. Now you can install the caliper and secure the entire structure;

- Next, connect the brake hose, parking brake cable and caliper to the system.

After completing all the described work and fully installing the brake system, it is recommended to bleed the brakes before operation.

Source okeydrive.ru

Most Lada Priora owners know that the domestic car has front disc brakes and rear drum brakes. It is no secret that the drum braking system was developed a long time ago, back in the middle of the 20th century, and no longer meets current standards.

In the modern automotive industry abroad, you can hardly find drum brakes anywhere; many companies have switched to rear disc systems. The only exception is budget cars, which cannot afford to have a better braking system.

Rear brake discs can be installed on almost any front-wheel drive vehicle of the VAZ family, including modifications with ABS. If you care about your convenience and comfort, then it’s time to think about installing brake discs for the Priora. In addition to comfort, the ZDT system significantly increases the safety of the car, and this is very important on unreliable Russian roads. Let's consider whether it is worth installing disc brakes on the Priora, as well as their advantages and disadvantages.

Purpose, design and principle of operation of the brake system

Page 1 of 3Next ⇒INTRODUCTION

The topic of the written examination work “Brake system of the VAZ 2170 Priora” was chosen because this vehicle system is relevant today. Braking systems, along with steering, are traffic safety systems that ensure the safety and health of drivers, passengers, pedestrians and other road users.

The purpose of this work is to more fully study the operation of the system, assembly techniques and methods for setting up components and the system as a whole, so that high-quality repairs and maintenance do not reduce the reliability and performance of the brake system and the vehicle as a whole.

This work examines the components and parts of the brake system, their design and principle of operation, system maintenance, and describes the basic provisions and safety requirements for car repairs. Lada Priora is a modern car, currently actively produced and modernized by AvtoVAZ. According to the European classification, it belongs to class “C” cars, that is, to the “lower middle class”. The first sedan cars went on sale in April 2007 with the aim of replacing the already rather outdated “tenth” family in production.

The VAZ 2170 Lada Priora is equipped with an injection 16-valve engine of the VAZ 21126-00 model located across the engine compartment with a displacement of 1.6 liters. The engine is equipped with a distributed fuel injection system and an exhaust gas catalytic converter, structurally made in a single block with the exhaust manifold (catcollector).

The length, width and height of the car are 4210, 1680 and 1435 mm (see Appendix 1). The car has a spacious trunk of 360 liters with a folding rear seat. A big advantage is the ground clearance, which is 165 mm, which is more than many foreign cars and is very useful when driving on uneven roads. The car consumes AI-95 gasoline when driving outside the city at a constant speed of 80 km/h in the amount of 7.6 liters for a 16-valve engine.

We can say about the car that it is already a quite decent Russian car, standing close to foreign cars. As for the advantages of the car, these are accessible and inexpensive spare parts, affordable service, cheaper intermediate maintenance, unpretentiousness and stronger, energy-absorbing suspension than foreign cars, excellent price/equipment ratio.

BRAKE SYSTEM OF VAZ 2170 PRIORA CAR

Purpose, design and principle of operation of the brake system

The braking system serves to slow down a moving vehicle with the desired intensity until it stops, as well as to keep it in park. The vehicle is equipped with service and parking brake systems.

The service brake system is designed to reduce the speed and stop the car; it is activated by the force of the driver’s foot applied to the pedal. Its effectiveness is assessed by braking distance or maximum deceleration.

The parking brake system serves to hold a stopped vehicle in place and must ensure that the equipped passenger vehicle remains stationary on a slope of 23% inclusive. The parking brake system also serves as an emergency brake system in the event of failure of the service brake system.

The service brake system (see Appendix 2) is hydraulic, dual-circuit (with diagonal separation of the circuits), with a pressure regulator 11, a vacuum booster 7 and a sensor for insufficient level of brake fluid in the reservoir 5. If one of the circuits of the brake system fails, the second circuit provides braking of the vehicle , although with less efficiency.

One circuit includes the right brake mechanism 1 of the front wheel, flexible hoses 2 and 9, metal pipelines 6, the section of the main brake cylinder 4 farthest from the vacuum booster, the rear (along the vehicle) chamber of the pressure regulator 11, the brake mechanism of the left rear wheel 8. the second circuit includes similar components and parts diagonally from the right front to the left rear; the section of the main brake cylinder 4 closest to the vacuum booster is used.

When you press the brake pedal 13 (see Appendix 2), the force is transmitted to pistons 2 and 3 (see Appendix 3) of the master cylinder. The movement of the pistons leads to an increase in fluid pressure in the system, the pistons of the working cylinders in the wheel mechanisms move and, accordingly, the brake pads are pressed against the discs (drums). Braking occurs.

The main brake cylinder 4 is attached to the housing of the vacuum booster 7 on two studs. A translucent polyethylene brake reservoir 5 with an insufficient fluid level sensor is inserted into the holes in the upper part of the cylinder on rubber seals. The tank has markings for maximum and minimum fluid levels. Two bolts are screwed into the bottom of the cylinder to limit the movement of the pistons. The connections are sealed with copper gaskets. A plug is screwed into the front part of the cylinder (along the direction of the car), which serves as a stop for the return spring and is sealed with a copper gasket. The pistons in the master cylinder (see Appendix 3) are arranged in series. The one closest to the vacuum booster operates the left front and right rear brakes, and the one closest to the plug operates the right front and left rear.

The high-pressure rubber sealing rings (cuffs) of the master cylinder and rear wheel cylinders are interchangeable (nominal diameter 20.64 mm). The low pressure sealing ring is grooved, installed on the piston in contact with the vacuum booster rod.

Vacuum booster 7 (see Appendix 2) is located between the pedal assembly and the main brake cylinder 4 and is attached to a bracket, which, in turn, is fixed to the front panel of the body on four welded studs. A diaphragm-type vacuum booster operates on the principle of a pressure difference in the vacuum and atmospheric chambers, as a result of which, when you press the brake pedal, additional force is created on the piston of the master brake cylinder. Rubber diaphragm 8 (see Appendix 4), together with valve body 17, divides the vacuum booster cavity into two chambers: vacuum A and atmospheric B. Chamber A is connected to the engine intake manifold through a tip check valve and a hose.

Valve body 17 is plastic. At the exit from the cover, it is sealed with a corrugated protective cover 11. The valve body contains rod 2 of the main cylinder drive with a support sleeve, piston 10, valve 15 assembly, return springs 13 and 14, respectively, of the pusher and valve, pusher 12.

The amplifier is of a non-demountable design; if it fails, it is replaced. The simplest way to check the serviceability of the amplifier: on a car with the engine stopped, press the brake pedal several times and, holding it down, start the engine. If the amplifier is working properly, after starting the engine the pedal should move forward. Failure to operate or insufficient efficiency of the vacuum booster may be caused by a leak in the vacuum supply hose from the intake manifold.

The brake pedal is a suspended type, fixed on the same axis with the clutch pedal, rotates in two plastic bushings, and is equipped with a return spring. The brake signal switch is located above the pedal; its contacts close when the pedal is pressed. The free play of the brake pedal when the engine is not running should be 3-5 mm; it is adjusted by moving the brake signal switch with the locknuts loosened.

The pressure regulator (see Appendix 5) is installed under the floor and is attached with two bolts to a bracket in the left rear part of the body. The front bolt also secures the pressure regulator actuator fork bracket. Due to the ovality of the holes for its fastening, the bracket together with the lever can be moved relative to the pressure regulator, changing the force with which the lever acts on the regulator piston. As the load on the rear axle of the car increases, the elastic lever is also loaded, transmitting force to the piston. When the brake pedal is pressed, fluid pressure tends to push the piston outward, which is counteracted by the force exerted by the lever. When the system comes into balance, a valve located in the regulator isolates the rear brake cylinders from the main brake cylinder, preventing further increases in braking force on the rear axle and preventing the rear wheels from locking ahead of the front wheels. As the load on the rear axle increases, when the traction of the rear wheels with the road improves, the regulator provides more pressure in the wheel cylinders and, conversely, as the load decreases, the pressure drops. There is a hole in the regulator body that is closed with a plug. Leakage of brake fluid from this hole indicates leakage of the regulator O-rings.

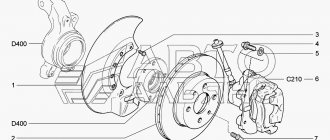

The brake mechanisms of 1 front wheels are disc, with a single-piston floating caliper. Some cars are equipped with pads with an electric wear indicator.

The floating caliper (see Appendix 6) of the front brake consists of a caliper and a wheel cylinder, which are held together by two screws. The cylinder is secured with two bolts to the guide pins installed in the holes of the shoe guide. Lubricant is placed in these holes. Rubber protective covers are installed on the fingers. The brake pads are pressed against the guide grooves by springs. The cylinder contains a piston with a rectangular rubber sealing ring. Due to the elasticity of this ring, a constant optimal gap between the brake pads and the disc is maintained.

Brake discs are cast iron. The minimum disc thickness during wear is 10.8 mm, the maximum permissible runout (at the largest radius) is 0.15 mm.

The brake mechanisms of the rear wheels 8 are drum-type, with two-piston wheel cylinders and automatic adjustment of the gap between the shoes and the drum (see Appendix 7). The automatic clearance adjustment device is located in the wheel cylinder. Its main element is a steel spring split ring mounted on the piston with an axial clearance of 1.25-1.65 mm. The thrust rings (2 per cylinder) are inserted with an interference fit, providing a shear force along the cylinder surface of at least 35 kgf, which exceeds the force of the brake pad tension springs. When the brake linings wear, the pistons move the thrust rings by the amount of wear. If the cylinder mirror is damaged due to mechanical impurities in the brake fluid or corrosion (the presence of water in the brake fluid), the rings may “sour” in the cylinder, and one piston (or even both) will lose mobility. In this case, the cylinders must be replaced at the same time (it is advisable to also replace the brake fluid). If the rear brake drums are worn out (ovality, runout, scuffing), they can be bored. In this case, the internal diameter after boring should not exceed 201.5 mm.

The mechanically actuated parking brake system The parking brake drive consists of lever 2 (see Appendix 8), cables 10. The front ends of the cables are connected to lever 2 through equalizer 7 and rod 6. The rear ends of the cables are connected to the brake pads of the rear wheels through release levers 15 and bars 13. Lever is fixed using a latch 3 with a toothed sector 4.

When the handle is lifted up, lever 2 moves forward rod 6 with a cable equalizer, which is secured at the end of the rod with nuts 8 and 9. Cables 10 of the left and right brakes move forward levers 15, which release the brake pads. The pads are pressed against the brake drums and the rear wheels are braked.

1Next ⇒

Site search:

Advantages and disadvantages of rear disc brakes

Rear brake discs are installed on foreign cars not only because of their high efficiency, but also to ensure simultaneous and uniform operation of the braking system. If any mechanism operates more sharply or slowly, this will entail a loss of control over control.

Disc brake unit

- The braking distance is reduced several times.

- Brake response time is noticeably reduced.

- Frequent maintenance is not required, brake pads can be replaced without much effort.

- Increased security.

- Uniform operation of the braking system.

- Unsprung masses are noticeably reduced.

- Fast heat dissipation, which is essential at high speeds or when cornering sharply.

- The need to constantly tighten the handbrake is eliminated.

- Aesthetic appearance.

- They do not freeze in the cold season after washing (a similar problem is observed in drum brakes).

It is worth remembering that the Volzhsky Automobile Plant does not install rear disc brakes on the Lada Priora, based on its standards. By replacing drum brakes with disc brakes, you will be making changes to the stock configuration of the car, which will affect its technical characteristics.

Rear disc brakes have their drawbacks. For each brand of car, good braking systems are developed over a considerable period of time, based on the technical characteristics of the model and certain standards. In other words, the stock brakes are always well balanced and tuned.

A typical mistake of inept installation

Buying a new brake system and simply installing it will not achieve the desired result. Rear disc brakes need to be adjusted and their functionality checked in the field. Otherwise, you will encounter problems such as uneven operation of the brake system, which will lead to skidding, whistling, squeaking and even overheating.

Possible brake malfunctions and solutions

Increased brake pedal travel:

— Leakage of brake fluid from the wheel cylinders

Replace failed parts of wheel cylinders, wash and dry pads, discs and drums, bleed the hydraulic drive system

— Air in the brake system

Remove air from the system

— Rubber sealing rings in the master cylinder are damaged

Replace the rings and bleed the system

— Damaged rubber hoses for hydraulic brakes

Replace the hoses and bleed the system

— Increased runout of the brake disc (more than 0.15 mm)

Sand the disc; if the disc thickness is less than 10.8 mm, replace it

— Fluid leakage through the O-rings of the pressure regulator pusher

Replace O-rings

Insufficient braking performance:

— Oiling of brake pad linings

Clean the pads with a wire brush using warm water and detergent. Eliminate the cause of fluid or grease getting on the brake pads

— Jamming of pistons in wheel cylinders

What are the risks of installing a non-standard brake mechanism?

Installing brake discs on a Priora does not always have a good effect on the car. Of course, the costs will pay off and you will get the desired effect, but at the same time, some problems may arise.

- You may fail your MOT inspection as it is illegal to tamper with the car's standard equipment, although rear disc brakes have a number of advantages over drum brakes.

- Since the rear disc brakes are very conspicuous, a meticulous law enforcement officer on the road may well find fault with the presence of non-standard mechanisms installed on the car. But in most cases this is rarely paid attention to.

- There may be problems fitting a standard cable handbrake. Installing a hydraulic brake will help here, allowing you to brake at high speed, but weakening over time if used as a parking brake. Some car enthusiasts completely refuse to have a handbrake and even manage to pass MOT without any problems.

- If you get into an accident, the scales will tip against you due to the presence of non-standard spare parts in the car, even if you are not the culprit.

Having installed rear disc brakes on the Lada Priora, you need to start adjusting the brake force distribution system, which is called the “Sorcerer”. If this is not done, the rear brakes will apply faster than the front brakes. This will lead to unwanted skidding, worn tires, squealing and overheating of the disc brakes.

Sometimes skillful owners take on the grinding of brake pads themselves, reducing their contact with the brake discs by up to 50%.

Selecting rear brake discs for Priora

One of the main advantages of installing brake discs yourself is significant savings in money, about 10,000 rubles.

Important: when carrying out installation, it is better to purchase devices with a certificate and install them in specialized service stations, which also provide certificates stating that the brake system is adjusted and meets all standards. However, this will not provide any guarantee that you will not be picked on during maintenance.

If you still decide to install the brake system yourself, then you need to decide which brake discs are best to install. Of course, you can go to the auto parts market or look for suitable ones on the Internet. It is also possible to adapt front disc brakes from the same Priora or any other car of the VAZ family. If you're a speed enthusiast, you might be interested in ventilated brake discs, which provide much better cooling and help prevent overheating.

Spare part from a reliable brand

The most common and high-quality solution in Russia are Italian Brembo brake discs, which are widely used throughout Europe and are certified by the German Federal Bureau of the Automotive Industry. Brembo has a wide range of discs, among which you can find those that suit you, including price. In addition, Brembo has official technical support in Russia.

Brake discs from this company can be installed in conjunction with any other pair, since they do not require in-depth adjustment. If you have extra money, you can also buy Brembo MAX front brake discs, which are produced specifically for cars of the VAZ family, including Priora.

Thanks to the presence of a special wear indicator, brake discs will be replaced in a timely manner. There is a notch on the disc that completely disappears when the disc wears out, allowing you to determine its reliability at any time.

Brake cylinder repair in Lada Priora

The front left brake cylinder has gone sour. I solved the problem - I shook it with a jack. For disassembly, TORX heads E12 and E14 were needed. E14 will help us remove the top bracket from the brake machine itself, and E12 will help us remove the bracket - the base of the brake - in order to get to the brake disc. I started disassembling it, and the brake system of the left front wheel gave me problems again - the bolt under the Torx E12 was licked off.

A little upset that I would have to go to a service station to remove it, after thinking about it, I realized that there was a solution. I threw two extension cords out of the window into the yard, fortunately I live on the first floor, and sawed off this ill-fated bolt with a grinder. After 15 minutes it was already removed from the bracket using a socket to remove the rear shock absorbers.

The cylinder itself was squeezed out of the brake machine with a compressor, complete with a cone-shaped nozzle for inflating probably mattresses, it was ideal for this task, although it doused me with a fountain of brake fluid due to an incomplete fit. I advise you to first squeeze the cylinder out of the brake machine, and then remove the bracket from it, otherwise the cylinder may fly out far or hurt.

Everything was very dirty, and since I wanted them to look good, I cleaned all the parts before painting. For cleaning, I used a screwdriver with a narrow attachment, about 6-7 mm in thickness - a brush.

Zigger used the paint, covered each detail with three layers of paint and 2-3 layers of varnish, I hope it will last a long time)

The brake cylinder was in poor condition, but in my opinion did not need to be replaced. I sanded it with 1000-1500-2000 sandpaper and water, almost all the dirt was gone.

That's how he was.

I also updated the boot and the inner rubber ring in the brake machine itself. This repair kit amazed me with its price of only 26 rubles for both brakes.

During assembly I used specialized mounting paste for brake cylinders. ATE 03.9902-0501.2 For Liqui-Moly 7656 guides, red.

By the way, the cylinder entered by hand. He sat down tightly.

The rear drums were cast iron Brembo max. I advise you to paint them right away, because... They just rust at lightning speed. The brake discs are also Brembo max, the pads were left old, the front is ATE, the rear is VIS (VazInterServis), the pads were sanded before installing the attachment on them. I also updated the brake fluid and filled it with SINTEC SUPER DOT-4. I would also like to mention the myth that if all the brake fluid leaks from the brake barrel, the brake system will have to be pumped at a service station. - Myth. When working on the right wheel, I plugged the pipe poorly and everything leaked out of the barrel. Before assembling it back, I noticed this and filled it in; just during assembly, brake fluid had already started oozing from the bleeder fitting - in general, everything returned to its place and quite quickly.

It took a little less than a liter to completely pump the ABS system (on all 4 wheels). Light liquid flowed from all the cylinders + for some time each brake cylinder was additionally pumped for moral satisfaction.

I also replaced the springs in the rear brakes with an ATE kit

This is what it looks like in the end:

The pedal felt softer, you need to get used to it, there were more brakes, you began to feel some kind of reserve that was not there. On asphalt, old aluminum drums, when braking with a handbrake, could not grab the wheels at low speeds, cast iron can. There was wear on the aluminum drums - waves could be felt to the touch both on the drums and on the pads; they did not fit each other quite correctly. The number of handbrake clicks also decreased by 1. Overall, I’m satisfied. But a lot of effort was spent on high-quality painting.

About the results: I tested the brakes under the same conditions, and measured braking using the Multitronics on-board computer. BC can measure braking from 100. Before intervention in the brakes, the braking distance turned out to be 42 meters, and after 29 meters. Yes, the testimony is interesting and even very interesting. Sports cars stop in the same way and even worse, I don’t pretend that the readings are true, but the braking distance has improved by 31%, and that’s something!

Repair of the brake fluid sensor float in Lada Priora

The brake fluid sensor float malfunctioned for 3 weeks at -5 -20. Came to visit. Started popping up

Installation of the HTD on Priora

- Stage 1

The rear drum brakes need to be removed. If you have any difficulties, you can refer to the Lada Priora service manual. Carefully remove the hub from the lever while still assembled. The brakes on a Priora with ABS are removed by first removing a special sensor with a clip from the supporting panel. Disconnect the connector and prepare the necessary spare parts for installation along with the ABS sensor fasteners.

Clean the pressure controller, its spare parts, the disc release ring journal and the hub axle. The presence of dirt on the coating can affect incorrect balancing. Unscrew the screw that holds the cable brackets and remove it.

Installing new brakes

- Stage 2

Proceed with the installation of a special adapter plate, a cover with protection against dirt and the hub axle. It is necessary to connect the adapter plate to the housing right in the middle of the beam and the hub axle. There is no need to remove the hub from the axle. The bolts are attached to the flanges using screws with groovers. The bolts must be tightened using a torque wrench, which is designed to regulate the tightening torque. It should be 5.6 kgf/cm. If the tightening is less than necessary, this will eventually lead to deformation or even complete destruction of the disks, making it difficult to unscrew the bolts.

- Stage 3 (brakes on Priora with ABS)

Attach the 9 mm plastic sensor spacer. Install the ABS bracket and the sensor required for its operation using the standard fasteners and screws. Install the ABS sensor into the trigger connector and connect it. Check whether the sensor is touching the rotor coating; to do this, simply spin the disk. The gap should be about 1 mm.

The guide caliper bracket is installed on the adapter plate using screws with groovers and washers. The tightening moment should be 5.6 kgf/cm.

Attach the brake disc to the hub using two guide rods and begin installing the caliper. It must be installed with the fitting facing up. Apply glue to the rod bolts, insert the first one into the armhole and tighten thoroughly. Adjust the cylinder and attach the brake pads. Tighten the second bolt taking into account a tightening torque of 2.5 kgf/cm.

Apply lubricant to the handbrake cable spring and insert it into the armhole of the bracket. Attach the bracket and cable to the beam using a screw clamp, first disconnecting it and threading it into the bracket itself.

It is necessary to disconnect the cable from the handbrake and remove the mudguard. Remove the cable from the caliper and dismantle it by unscrewing the fastening hardware. The brake cylinder must be carefully brought in by turning it with a wrench and thus checking whether the pads pass freely between the caliper and the brake disc. It is worth taking a closer look to see if the protrusion on the block fits into the opening on the caliper piston. Pass the cable through the armhole of the holder and secure the protective rubber cover.

The cable loop is put on the handbrake trigger. The brake hose is attached parallel to the surface of the beam arm flange, and the hose tip is screwed into the caliper using a hydraulic rod.

- Stage 8

Finally, you need to connect the brake line. Bend the brake pipe so that the tip can be positioned at the hole in the handbrake cable bracket. Insert the tip of the hose into the opening of the bracket, fasten the brake pipe to it and securely fix the structure.

Check again to make sure everything is securely fastened and screwed down. All elements must be connected correctly.

Maintenance Recommendations

After the installation of the HCD is completed, grinding and heating of the working coating may occur, which is caused by the grinding in of new spare parts. Do not try to brake hard until you have driven 350-550 km so that the new parts can get the necessary break-in.

In combination with rear brake discs, it is advisable to install Brembo MAX front discs on the Priora. This will allow you to achieve the highest quality of uniform braking. In addition, front disc brakes will give an organic and aesthetic look to your car.

Source expertvaz.ru

| 1 | To service the rear disc brakes, the machine is placed on a jack and the rear wheels are removed. The caliper fingers are unscrewed, then the bracket is attached to the steering knuckle (to simply replace the pads, the bracket attachment does not need to be removed). Next, you need to check the working thickness of the brake disc. If it is no less than 17 mm, everything is fine. |

| 2 | The retaining plates of the brake pads are cleaned, and a special lubricant is applied to the pads themselves. |

| 3 | Lubricant is introduced into the brake caliper through special holes in it. |

| 4 | New pads are installed. |

| 5 | Reassemble the entire system in reverse order. |

Checking the rear brake pads of Lada Priora

It is better to check the rear pads on an overpass or inspection pit. On the brake mechanism shield you can see a special inspection hole closed with a rubber plug.

We take out the rubber plug and assess the condition of the pads. The thickness of the working surface of the pad must be at least 1.5 mm . If less, such pads require replacement.

If you find chips or grooves on the pads, it is also advisable to replace such pads, as braking efficiency decreases.