Modern life never tires of delighting us with various technical innovations. In the automotive industry, engineers are introducing modern technologies everywhere.

The domestic auto industry is no exception, which, although it lags behind leading manufacturers, is confidently reducing this distance. However, innovations are not always successful and reliable.

For example, in the modern version of the Lada Kalina, the electronics do not particularly simplify the driver’s life, but rather, on the contrary, create even more problems. The most common flaw among engineers is the failure of the rear gear of cars of this family.

This article will discuss why reverse gear does not engage on Kalina. Let's consider the main causes of this malfunction, as well as methods for eliminating it. But first, let's take a quick look at how reverse gear is engaged on this car.

Replacing the entire solenoid

In Lada Kalina, the solenoid that is responsible for engaging reverse gear is quite rare, but it can still burn out. This occurs due to too aggressive use of the gearbox or due to a malfunction of the generator. Moreover, there are cases where the transmission was still engaged with a damaged solenoid, but only periodically. The fault can only be eliminated by completely replacing the solenoid. You should not try to repair it - it has a non-demountable structure, filled with resin from the inside. Why the Lada Kalina engineers used such a solution is anyone's guess.

tweet

back Test drive the Lada Kalina station wagon

Forward Lada Kalina turned into Granta

Tags: gearbox, transmission, repair, solenoid, clutch

Backstage adjustment

Often after its repair, the Kalina does not engage reverse gear. The speed at which the pedal is pressed does not matter. Fifth gear will also disappear along with it. To eliminate the malfunction, it is necessary to adjust the position of the rocker. How to do it? You need to find the backstage clamp and loosen it.

Next, the lever is moved to the desired position (reverse or fifth speed). The clamp is tightened. You should check the effectiveness of the adjustment with the engine running. If after this you still cannot engage reverse gear on the Kalina, make the adjustment in first gear. Move the gearbox lever to the appropriate position, having first loosened the bolt. Turn the rocker drive counterclockwise until the lever rests against the reverse gear lock R. By adjusting the seating depth of the rocker on the gearbox driveshaft, you will restore the proper operation of the box.

Video “Repair of the gear shift unit in a VAZ car”

This video shows the process of repairing a gearbox in a VAZ car. The instructions are general and suitable for Kalina cars.

A lot of time has passed since AvtoVAZ put on sale a car called Lada Kalina. Advertising and the hope of domestic car enthusiasts for a bright future did their job - every third Russian chose Kalina as a new car. However, the joy of owning a domestic car ends sooner or later.

After just a few months of operation, the Kalina car showed its rather capricious character. And it just so happened that the owners of the Lada Kalina began to disappear more and more often in the garage, once again doing some kind of repair, rather than driving the car. AvtoVAZ engineers are well aware of the shortcomings and childhood diseases, and are doing their best to get rid of them in the next generation in order to increase reliability. However, the result of the improvements is insignificant. The car still cannot please with its endurance and resistance to wear. It’s especially unpleasant when the Kalina doesn’t start at the right moment. And the car owner is forced to start troubleshooting. Let's try to understand the reasons for the car's reluctance to start.

Reverse gear does not engage: common breakdowns

So, if engaging reverse gear is difficult or completely impossible, this breakdown is a common problem that can be encountered in different vehicles when changing gears.

Moreover, the rear does not engage both on manual and automatic transmissions (the reverse speed of the automatic transmission has disappeared)

Naturally, in such a situation, it is important to discover the cause of the malfunction and eliminate the breakdown, since it is simply impossible to operate the car normally without reverse gear (the vehicle is actually deprived of reverse gear). Let's figure it out

Let's start with a manual transmission and consider the question of why reverse gear does not engage in a manual transmission. First of all, with a manual transmission the reverse gear fails much more often than with an automatic transmission. As a rule, the first signs of problems are a grinding, crackling or crunching sound in the reverse gear when engaged, the reverse gear is difficult to engage, it is difficult to engage the speed after a while, etc.

As for the main malfunctions, we can highlight the following:

The clutch does not disengage completely. As you know, the clutch connects the engine and the gearbox, and at the moment of changing gears the driver must depress the clutch pedal and “disconnect” the internal combustion engine from the gearbox. After engaging the gear, the pedal is released, the clutch “closes” and the torque is again transmitted to the wheels.

So, if the clutch is not completely disengaged, the gearbox is not completely disconnected from the engine. This leads to the fact that all gears are difficult to engage. At the same time, on many cars, first speed and reverse do not have synchronizers. As a result, clutch problems are most noticeable when engaging reverse gear.

In such a situation, when trying to engage a gear, a crunching and grinding noise is heard in the box

To eliminate the breakdown, you need to pay special attention to the clutch (condition of the clutch disc, basket, release bearing, etc.). You also need to check the clutch adjustments, the quality of the pedal, etc.

The oil level in the gearbox is low or the gear oil has lost its properties. As practice shows, there is a common misconception among drivers that the manual transmission is filled with oil for the entire service life of the car. In fact, a maximum of 100 thousand km. Even the highest quality gear oil becomes unusable. And this is subject to fairly gentle operation.

If the car is used in difficult conditions (driving around the city, irregular pace, constantly switching speeds “up” and “down”, short trips, temperature changes, etc.), then the oil in the box requires replacement every 50-60 thousand. km. The fact is that the properties of the liquid change, additives are activated, dirt, products of mechanical wear of the box and various deposits accumulate in the oil.

The gearbox linkage needs to be adjusted; the rods or gearbox drive levers are deformed. Often, it is after diagnosing the condition of the rocker that it becomes clear why reverse gear on a Lada and various foreign-made cars (especially old ones or with high mileage) does not engage. Owners of front-wheel drive VAZ models are well aware that a poorly adjusted rocker is the reason why the reverse gear does not engage or is knocked out.

The solution in such a situation is to adjust the manual transmission gate, which can significantly improve the clarity of the inclusions and obtain the necessary softness. Also, in some cases, owners remove the standard mechanism and install a short-throw slide, but in this case you need to be prepared for the need for more careful adjustment. As for the gearbox rods and drives, these elements must be inspected for possible damage or breakage, after which they are replaced.

Design features of the gearbox. Often on budget cars, reverse and first gears do not have synchronizers. The absence of these elements, on the one hand, simplifies the design of the box, but on the other hand, difficulties arise when engaging reverse gear and first speed.

Design features of Kalina with automatic transmission

Lada Kalina cars, which have a 16-valve petrol engine with a volume of 1.6 liters, are equipped with an automatic transmission. The remaining models still have a manual transmission.

The structural replacement of a manual transmission with an automatic transmission led to the fact that the car began to differ in a number of features:

All this is a kind of payment for comfortable driving. Some companies propose to change the design of the automatic transmission and bring it to a sports class. This changes the operation of the entire transmission, and the car becomes very noisy.

How to repair a solenoid?

When the Kalina does not engage reverse gear, you can try to restore the solenoid. Where is he located? If you turn the steering wheel to the right and then look under the car from the left wheel, you can see the solenoid. He is at the checkpoint. The solenoid has a connector and wires connected to it. The connector is removed, and the solenoid is unscrewed by approximately eight millimeters using a “22” wrench.

Note! If you replace the solenoid, you will have to change the transmission oil. But if you have time to plug the hole, then it will be enough to simply add the required amount of lubricating fluid

Experts recommend using Total Transmission oil with a viscosity of 75W80. The required volume is 2.2 liters for box 2180 and 3.3 liters for box 2181 (with cable drive).

Starter

The immobilizer has been checked and does not give any alarms, but the engine still does not want to start. Another reason for this behavior is the starter. It is easy to notice a problem with the starter - you will not hear the characteristic sound of the engine starting. The mechanism simply does not spin, which means the engine will not be able to start. Everything is clear here - you need to remove and check the starter.

If the Kalina does not start, the first reason may be the battery. It may simply be discharged. If the lights in the cabin and on the dashboard are not lit, the driver will be able to immediately notice this. However, it often happens that everything is in order, but the starter still does not work. For diagnostics, turn on the high beams and get out of the car. Dim headlights are due to the battery. It is discharged, but only to a critical level, when there is not enough power to turn the starter.

If the Kalina does not start, the starter does not turn, the best way out of this situation is to charge the battery. But if the headlights are bright in high beam mode and are not going to dim, then you will have to look for the reason elsewhere.

Mechanical part

If the reverse gear on the Kalina does not engage, the reasons may be in the shift mechanism. The latter has a spring in its design. It breaks often. If the part “falls” to the bottom of the box, it will not interfere with gear shifting. The driver can drive like this for several years, not suspecting that a spring has fallen out of the mechanism.

But if it gets stuck in the grooves, reverse gear breakdowns will be inevitable. Depending on the position of the part, the speed may turn on periodically or not work at all. In this case, you will have to completely disassemble the gearbox and pull the stuck element out.

Oil

The gearbox, just like the engine, contains oil. Its viscosity is thicker than motor oil. On domestic cars, the manufacturer recommends changing the fluid at least once every 60 thousand kilometers. If the reverse gear on the Lada Kalina does not engage, check the lubricant level in the box. If the mileage of the car is more than 60 thousand, drain the old fluid and use new one.

How to replace the solenoid switch

The solenoid may become sour in the open position; in some cases, lightly tapping its body helps. It is typical that sticking occurs when the car is standing on a steep incline. Breakdowns also happen on the road, and if the sensor fails and it is impossible to engage reverse gear, you can temporarily unscrew it a little from the box (about 7 turns), then the fault will appear. But you need to understand that this is a temporary measure; when the solenoid fails, it needs to be replaced.

Before making a replacement, it would be a good idea to check the sensor; this is quite simple to do. It is necessary to disconnect the wires from the chip, apply 12 volts to the contacts, at the moment of supply, a noticeable click should be heard in a working solenoid.

Before starting work, prepare:

- container for transmission oil;

- key to 36;

- sealant.

A similar operation must be performed on a pit or a car lift; the oil from the gearbox may not be drained, but it is better to do it anyway in order to do the job more accurately. We replace the part in the following order:

Starter or wiring problems

You can use a multimeter to test the wiring. The red wire is connected to the starter contact, the black wire to ground. In a normal situation, the device will show from 12.5 to 14.5 V. If the reading is less or even zero, then there is something wrong with the wiring.

The first step is to clean the contacts, check the integrity of the wires and fuses.

If the check shows that there is current, then the starter will have to be replaced. If the latter makes clicks but does not rotate, then the starter motor has failed. If everything is the other way around, then the problem is with the retractor coil.

Why the Lada Kalina stopped turning on: reasons and solutions

Failure of the locking mechanism fuse

Since this device in the Lada Kalina is of electronic origin, it is first of all worth examining the electronic systems. To do this, you need to check the condition of the corresponding relay and fuse, which are located in the mounting block. Its cover is located under the handle for turning on the dimensions. Open it and evaluate the functionality of the fuse responsible for the operation of the transmission reverse lock circuit.

The documentary designation of the required element is F21. The current rating of this component is 10A. The location can be seen in the photo below.

To determine the true cause, remove the fuse from its socket and carefully analyze the condition of the jumpers. If the part is damaged, the integrity of the jumper will be compromised.

Option to solve the problem: replacing the fuse with a new one is the only way.

Magnetic switch failure

As a rule, such breakdowns are not so common due to the fact that the magnet itself is a fairly durable spare part and has a sufficient working life. However, if the reverse gear fails, it would not be superfluous to check it too.

The procedure is as follows:

- Remove the cover from the manual transmission lever.

Stage 1: removing the protective casing

- Locate the connector that connects the lever and separate it.

- To check the operation of the reverse gear in stand-alone mode, close the contacts using a wire.

Where do you need to close the contacts?

- Engage reverse gear.

But here there are possible options. If the reverse gear engages freely after completing all the manipulations, then the reason is in the magnetic switch. However, before disassembling the box and removing the magnet, it is worth analyzing the operation of the plastic ring: it should rise easily and without distortion until it clicks. Due to its wear, the ring may not move the required distance, and this may also result in reverse gear failure.

A solution to the problem: replacing the reed switch (magnet) or ring with new ones.

There is no voltage supplied by the solenoid to the manual transmission lever

This is most often the cause of malfunction of the reverse gear locking mechanism on Kalina. And here we must thank the AvtoVAZ engineers, who placed the wire supplying power from the solenoid to the lever in an unusually bad place - under the bottom of the car. He has to endure a lot: the action of reagents that are generously sprinkled on roads in winter, and water, and snow, and flying sand and gravel, and sudden temperature changes. Considering the lack of any adequate protection for this element, it is not surprising that it fails quite often. In most cases, wire rupture occurs at the point where it connects to the spar. Dirt and sand accumulate here, which act as rough abrasives, thinning the part.

Option to solve the problem: replacing the wire.

Solenoid faulty

This is evidenced by the absence of voltage at the solenoid contacts. To check the fact itself, you need to disconnect the contacts and test each of them with a multimeter. Performance indicators - 2.2 Ohms. If there is no voltage on one or the other wire and the parting shows “0”, then we are talking about a burnt-out solenoid winding. You can check this this way: switch the multimeter to ringing mode and repeat the voltage test procedure. If in this case both wires are “silent,” then it was the burnt winding that caused the failure of the reverse gear locking mechanism.

Solution to the problem: replacing the solenoid.

What to do if Kalina does not go in reverse (video)

Defects in the design of the Lada Kalina are the root cause of frequent car malfunctions, including in our region. This is eloquently evidenced by the most common cause - an unprotected wire located in the wrong place

Therefore, when repairing the reverse gear locking system, you should first pay attention to this option.

Hello! My name is Ann. I am 25 years old. By education, he is a teacher of Russian language and literature. I specialize in automotive topics. At different times I wrote for car repair shops and a noise insulation center. I try to develop and learn new things.

Technical features of the gearbox

The input shaft, which is a block of drive gears, is in constant engagement with similar elements of the front gears. The secondary shaft has a hollow structure that allows oil to be supplied to the driven gears. This mechanism has synchronizers and driven bearings.

Kalina gearbox device

When repairing a Lada gearbox, special schemes are used. The radial clearance of roller bearings is no more than 0.07 mm. For ball analogs, this figure should not exceed 0.04 mm. Oil is supplied through an oil sump, which is located in the area of the front bearing, fixed behind the secondary shaft. You can adjust the tension by selecting the desired thickness of the rings. The last parts are installed in the crankcase. The driven gear of the Kalina gearbox is attached to the differential flange. The box communicates with the atmosphere through the saloon located at the top of the structure in question.

If noise appears in the gearbox during operation, the bearings will need to be replaced. Sounds that occur when releasing/pressing the clutch pedal indicate the need to replace worn elements. The gearbox is controlled through a drive consisting of a lever, a ball joint, and a switch rod. To prevent the gears from switching off on their own, the cable structure is equipped with a reaction rod, one end of which is connected to the motor, and the other to the lever.

Repair of the Lada Kalina gearbox is carried out when the seals of the internal joints fail. Before replacing them, drain the oil, disconnect the front wheel drive, and remove the parts with a screwdriver. To press the new oil seal, you will need a suitable mandrel.

The switching system is equipped with 3 axes. One has a three-arm shift and gear selector lever. The second axis has brackets that block rotation. The gearbox is replaced after 75,000 km. If the rocker and cardan are out of order, they need to be replaced with new ones.

Troubleshooting in the electrical part of the Lada Kalina

A break in the wire of the switch on the Lada Kalina car occurs quite often, this is due to the fact that the switch often changes its position, and accordingly, the wiring is not at rest. Checking whether the solenoid itself is working is quite simple; here you need to:

If a fault appears, it means that everything is in order with the switch itself and the manual transmission, it’s all a matter of electrical wiring or poor contact of the plug. After such a diagnosis, the paperclip will need to be removed; driving constantly with the contacts closed on the connector is highly not recommended.

In some cases, a break is detected immediately after lifting the gearbox cover, but often the wires fall off in the area of the locking device solenoid. To carry out diagnostics, you should install the VAZ Kalina on a pit or a car lift and conduct a visual inspection. Most often, a break occurs in the immediate vicinity of the sensor, since this place is not protected by anything - dirt and moisture, crushed stone and pebbles fly from the road.

When the wiring is still in the factory braid, it is sometimes difficult to detect any damage. The contact may periodically disappear and then appear again, the defect turns out to be floating, in which case it is necessary to open the insulating protection.

It is also worth noting that such a defect is common on Kalina and is typical for this car; such a breakdown can occur even on a car with a relatively low mileage (40-50 thousand kilometers). The problem occurs because:

- the wires are too short, they should be made a few centimeters longer;

- The insulation is of poor quality and often cracks in the cold.

So, before looking for faults in the mechanical part, you need to check the electrical part.

Reading the instruction manual

The instructions included with Kalina-2 hatchbacks and station wagons say the following:

According to reviews, 3 seconds will be enough. By the way, the blocking stops working not after 3 seconds, but earlier. But if you switch immediately, there is a risk of breaking the gear teeth. All this, of course, is true only for the break-in period.

As the owners themselves say, reverse gear is engaged perfectly even on a car with “zero” mileage. But the driver is required to show dexterity: having squeezed the clutch to the maximum, the pedal is then moved back a little. The handle moves to the desired position and the pedal is fully released.

Clutch pedal response zones

You can also turn it on “through neutral”. This method is the most reliable. Release the pedal when the handle is in neutral and you are guaranteed to be able to shift into any gear. Actually, the method is suitable for any car and any manual transmission. But regarding AvtoVAZ products, the advice sounds like this: take a 3-second pause.

Dismantling and repairing the locking mechanism

About theory.

The solenoid power circuit in the Lada Kalina car includes a switch ring located in the gear selector handle. The device operates as follows. By lifting the ring, the driver activates the power supply to the solenoid, which in turn causes the reverse speed control unit to unlock. Access to activating this transfer is now open. When the lever is moved to the required position, the limit switch located on the Lada Kalina transmission housing is activated. This allows you to activate the rear brake lights and an audible warning signal sent through the interior speaker.

Reverse does not engage - reasons

- Before you start drastic actions and disassemble “anything and everything”, check the gear shift lever itself, this may be the reason. The linkage and cardan are quite often the cause of this breakdown. The splines could also be worn out or the clamp loosened. In this case, you will need an inspection hole.

- A faulty release bearing is an option. Although it is unlikely, since in this case all gears without exception would be engaged with a characteristic crunch and with great effort.

- Reverse gear may stop engaging due to problems in the reverse gear locking mechanism; in order to confirm or refute this, remove the gear shift knob along with the dashboard between the seats and perform a visual inspection.

In my case, the problem was precisely the faulty wiring of the transmission lock solenoids (break or fracture), how I solved this issue, read on.

How to check and repair the reverse gear locking mechanism of a Lada Kalina with your own hands?

Theory:

Power comes to the solenoid through a switch ring located on the gearshift knob. It works like this: you lift the ring, thereby turning on the solenoid, the rod is pulled into the solenoid, which leads to unlocking the reverse gear. You can then engage reverse gear by moving the gear shift knob. Next, the “limit switch” located on the box is turned on, and the rear stops are turned on, and an intermittent sound signal is turned on in the cabin.

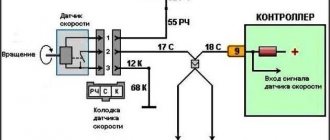

Here is the solenoid control circuit:

Through fuse F21, +12 Volts are supplied to solenoid L1, using switch S1 on the handle, the circuit is closed to ground, after which the solenoid coil is activated.

1. The 10A fuse we need, F21, is located 8th on the left in the fuse block. Take it out and check it with a tester. If the fuse is defective, replace it with a new one of the same rating.

2. Now it's time to check the switch, to do this, lift the cover on the handle, after which you will see the connector connected to the switch. Carefully turn it off.

3. Using a paper clip, you need to close the contacts of the connector from which the wires go down under the Kalina floor. Now try to engage reverse gear; if it does, the switch is faulty. If not, continue troubleshooting.

4. Remove the connector from the solenoid, install two pins in it, then use a tester to measure the voltage, the device should show 12 volts. In addition, you need to load it with a light bulb. A 5-Watt 12 V is suitable for this; if the light bulb does not light up, you have an open circuit, and the voltage is explained by the resistance formed due to copper oxide. As practice shows, 99% of breaks and fractures occur in the harness, in the place where the clamp is installed on the pallet.

5. Remove the clamp by squeezing its fasteners from below.

6. Disconnect the connector from the stop switch and remove the entire harness. Remove the electrical tape from the corrugation and remove the wires. If the wire is broken or broken, you will notice characteristic signs.

7. Using wire cutters, pinch off the wires and connect others of similar cross-section and diameter. It is better to solder the twist itself and insulate it or use heat shrink. If desired, you can put on another corrugation, the main thing is that moisture does not penetrate, otherwise the problem will very soon recur. I personally threw away the clamp, if you need it you can leave it. Secure the harness with a plastic clamp.

8. Connect the connectors and check the operation of the solenoid. Failure of the solenoid itself is a fairly rare phenomenon; to check it, connect a tester; the resistance should be 2.2 Ohms. If there is still a problem, you will have to drain the oil from the box. There is a way. in which it is fashionable not to drain, but here a certain skill is required, the main thing is to sharply plug the hole with something, and then screw in a new one. A little oil will, of course, spill out, but you can add it back. When installing a new solenoid, do not forget to lubricate the threads with sealant, if this is not done over time, oil will begin to ooze along the threads.

If previous checks did not lead to anything, there are several options left, namely:

- The mechanism for fastening the gear selection mechanism has failed;

- The fixing bolt has been cut off;

- The spring in the gearbox has broken.

The worst thing is that each of these three points requires mandatory dismantling of the gearbox, and this is already in the category of “serious repairs”, which is not always within the power of an ordinary driver, and it will take much more time than in the case of a rocker or lock transfers.

That's all I wanted to say! I hope I helped solve the problem. If after all the above manipulations and checks you still do not engage reverse gear, seek help from a specialist or go to a service station.

What to do if it is whole?

If reverse gear does not engage (Lada Kalina), the reasons may lie in another part. To diagnose, you need to disassemble the box cover. Below it there is a connector connected to the solenoid switch. We turn it off and connect the contacts directly. Check to see if reverse gear is engaged. If not, remove the solenoid connector and measure the voltage in it. When the voltmeter shows values less than 12 V, it means there is a short circuit. You can also check using a test lamp. Its power should be from 3 to 5 watts. If it does not light up, it means that the wires in the circuit have burned out. We are looking further. We close the contacts of the connector that goes down under the floor of the car. This can be done using a metal clip. Next, turn on reverse. If it turns on without problems, it means that the short circuit occurred here. If the element is in good condition, remove the connector from the solenoid. Using two pins and a tester, we measure the voltage. The ends of the tester are applied to the pins. In most cases, breakage occurs due to a fracture of the harness and oxidation of copper. Most often, the wire frays at the place where the clamp is installed on the mechanical box pallet. How to check it?

Reverse gear of Lada Kalina is not blocked

A break in the wire of the switch on the Lada Kalina car occurs quite often, this is due to the fact that the switch often changes its position, and accordingly, the wiring is not at rest. Checking whether the solenoid itself is working is quite simple; here you need to:

- Carefully pry off the gearshift lever housing with a screwdriver and lift it up;

- disconnect the plug located inside the console;

- take a metal paper clip and insert its ends into the connector going to the blocker;

- lower the cover and try to engage reverse gear.

If a fault appears, it means that everything is in order with the switch itself and the manual transmission, it’s all a matter of electrical wiring or poor contact of the plug. After such a diagnosis, the paperclip will need to be removed; driving constantly with the contacts closed on the connector is highly not recommended.

When the wiring is still in the factory braid, it is sometimes difficult to detect any damage. The contact may periodically disappear and then appear again, the defect turns out to be floating, in which case it is necessary to open the insulating protection.

It is also worth noting that such a defect is common on Kalina and is typical for this car; such a breakdown can occur even on a car with a relatively low mileage (40-50 thousand kilometers). The problem occurs because:

- the wires are too short, they should be made a few centimeters longer;

- The insulation is of poor quality and often cracks in the cold.

So, before looking for faults in the mechanical part, you need to check the electrical part.

Another malfunction is exactly the opposite of the one described above, in this case the locking does not work, and reverse gear is engaged in any case, regardless of whether the ring is raised or not. Driving a car without a gearbox lock is not very comfortable; there is a risk of ruining the gearbox (especially for beginners) by engaging reverse gear while driving instead of the lowering first gear. There are also several reasons for the problem:

- the button contacts inside the manual transmission handle are stuck;

- there is a short circuit in the wires going from the box to the lever;

- The solenoid is stuck.

Checking the condition of the push-button contacts of the blocker is quite simple: lift the cover of the gearshift lever and disconnect the plug. If the guess turned out to be correct, it will be impossible to turn on the ZH.

Restoring functionality

Reverse problems can occur throughout the reverse indication circuit. Therefore, you should not rush to drive the car onto an overpass and change the sensor. To begin with, it is worth checking out the more accessible places (but no less important).

Let's start with the ring on the gear lever. In principle, some craftsmen can easily disable both the sensor and the gearbox lock in 1 hour. But you shouldn't do this. This is not just a display system. It is also a security system. And since they did it (they didn’t save money on it), then this is a reasonable requirement. And any safety requirements, as you know, were written by those who neglected them.

The thing is that first gear and reverse gear are switched in the same way in the Lada Kalina: “toward and forward.” But the first speed is engaged simply, and the reverse with the help of a ring. Some protection “from accidents”. This is why you need a reverse sensor.

If you lift the cover that covers the gearshift lever, then under it you will find several wires running from the ring to special connectors. These wires are specially made not solid, but through a connector, because they are always in motion (the lever is pulled all the time). That's why they often break. It's worth checking them out first.

However, most often the Lada Kalina loses reverse gear due to the wires that lead from the sensor attached to the gearbox. There the wire is in “street” conditions. That is, it is influenced by all weather conditions that exist in the environment. Moreover, this is the bottom of the car. Sand, pebbles, dirt, moisture, etc. fly there. Of course, this is not directly under the wheels of the car, but closer to the middle, but still there is some constant impact.

These wires are easy to find. Lada Kalina does not have a very complicated gearbox. Therefore, the only electrical wires that go to the transmission are the reverse sensor wires. You should check them (or better yet, “ring” them, since every electrician knows that it is often impossible to see a break in a braided wire). If everything is in order here (rather rarely), then the reverse sensor itself should be changed.

ECU

This is another popular problem when Kalina does not start. ECUs are the “brains” of the car; they themselves are quite reliable, and if you don’t touch them, then no problems will happen. However, most often the ECU is flooded.

This often happens when antifreeze leaks. This has already been discussed in the section on the immobilizer. When installing an alarm system or when pulling car wires, they forget to install the plugs - water gets into the ECU. Repairing an electronic unit is a futile exercise.

In the new generation, this problem was solved, and now the ECU is located in a different location. However, now another problem has appeared - if the drain hole, which is located next to the cabin filter, is clogged, then water can enter the computer through the holes.

Place of the switch in the light switching circuit

On cars with manual transmission, voltage to the lamps when reversing is supplied through a limit switch (the so-called frog), which is screwed directly into the gearbox housing. When reverse gear is engaged, the switch button is pressed inside the gearbox. The contacts inside the “frog” bridge, and current begins to flow to the lamps.

On the circuit diagram for turning on the reversing lights, we can see that on the VAZ 1118 Kalina, the current from the battery through the ignition switch (No. 2) is supplied to fuse F1. Passing through the fuse that protects the switching circuit, “+” goes to the limit switch (No. 10). The contacts are in a normally open state and close only when reverse gear is engaged. Thus, current begins to flow to the light bulbs. The second contact of the lamps is connected to the “–” battery through the common ground contact of the lamps.

On cars with automatic transmission, the role of the limit switch lies with the selector position sensor. Information about changing the location of the gearshift knob is transmitted to the engine ECU, the light control unit.

How to check the "frog"

- Remove the headlight switch chip.

- Turn on the ignition.

- Using a small piece of wire, connect the contacts of the reverse gear sensor connector to each other.

If the reverse lights are on, then the problem is in the “frog”. Some drivers disassemble the switches, clean the contacts, after which the device continues to work properly. It is up to you to judge the appropriateness of such measures. But keep in mind that on many cars (including VAZ models) the limit switch is located below the oil level in the gearbox. We recommend simply replacing the power sensor. To minimize oil loss, jack up the car on the side where the end switch is installed.

On some cars, the reversing lights do not light up due to incomplete activation of the limit switch. The problem can be solved by installing a thinner washer under the “frog”. To make sure that the switch is working, check with a multimeter in ohmmeter mode whether the contacts close when you press the button.

Checking the circuit

The essence of diagnosing the reason why the reverse lights do not work comes down to identifying the section of the circuit where the voltage is lost. To do this, you can use a regular control light. Continuity testing is done with an ohmmeter, so you need to know how to use a multimeter.

You can start checking directly from the limit switch connector. Turn on the ignition. Connect one contact of the control light to an unpainted metal part in contact with the body, and the second to the “+” connector.

- If power comes in, check the reverse sensor.

- If after installing the “jumper” in the connector the lights do not light up, then the problem is in the section of the wire circuit going from the connector to the lights. Ring the wire to the point where it divides into light bulbs on the left and right sides. Most likely, the reason is the break.

To find the pinout of connectors, light contacts, and wire colors, be sure to study the electrical diagram of your model and vehicle configuration.

The lamps are constantly on

If the lights on your car are constantly on or come on regardless of whether reverse gear is engaged, the cause will be among the following breakdowns:

- short-circuiting the “+” going to the reverse gear sensor and the light bulb wires from the switch;

- the wire going from the connector to the lights has a short to “+” (this happens if the wires in the harness fray);

- The sensor is stuck in a closed state.

Relay location

The relays are in the same block as the fuses.

K1 - headlight washer

. If the washers stop working and this relay is working properly, check their nozzles. Sometimes they become clogged or damaged.

K2 - electric windows

. Check this relay together with fuse F2. See F2 for troubleshooting.

Short circuit - starter relay

. If you turn the ignition key and the starter does not turn, it may be the relay. Check its contacts and clean them if necessary. Next, you need to check the battery terminals so that there is reliable contact between them, and if necessary, clean them. Also check the contact group of the ignition switch, there may be no contact there.

K4 - additional relay, heated rear window, heater switch, wiper and washer switch.

K5 - relay-breaker for turn signals and hazard warning lights

. If the direction indicators or hazard lights do not work, check this relay together with fuses F1 and F3.

K6 - windshield wiper relay

. Check together with fuse F4.

K7 - high beam relay

. Check together with fuses F14 and F15.

K8 - sound signal

. Check together with fuse F6.

K9 - fog lights

. Check together with fuses F16 and F17.

K10 - heated rear window

. Also check relay K4 and fuses F4 and F8.

K11 - heated seats

. Also check fuse F18.

K12 - reserve

.