September 20, 2019 Lada.Online 10 776 0

To identify the noise of the clutch release clutch on LADA Vesta, Granta, Kalina, Priora, XRAY AMT, Lada 4×4 cars, a special technique was compiled at AVTOVAZ. Specialists of LADA dealership centers refer to this instruction. The methodology was sent to the Lada.Online website by one of the site’s readers.

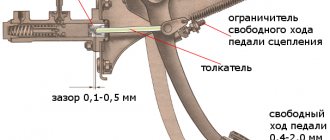

When assessing the malfunction of the clutch release bearing, it is necessary to take into account that at the moment all cars produced by JSC AVTOVAZ use a clutch without clearance, so the clutch release bearing is always preloaded and rotates with the engine running.

Defects that appeared after replacing the clutch

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

How to remove and replace a release bearing

Removing the release bearing

An important rule for the release bearing: it should not “play” or move unevenly or spasmodically.

If repairs are necessary, you will have to disassemble the entire gearbox, because... the required part is inside it. Next, the spring clamp is released from tension, and the bearing itself is removed. To do this, you will need a tool, because you will have to remove it from the spring “legs” of the holder. Remove from the bushing, removing the retaining springs, and disconnect from the coupling. The removed part is inspected for cracks and other external signs of failure. It is more reliable to install a new spare part, since it is relatively inexpensive. After all actions, lubricate. How to lubricate the release bearing? Some people prefer molybdenum grease, others prefer graphite; parts are usually supplied with it when purchased in a store. An important rule for a bearing: it should not “play” or move unevenly or spasmodically. How to lubricate the release bearing without removing the box? You will have to contrive, it is almost impossible to provide good thorough lubrication without removing the gearbox. In any case, if the bearing hums, it is best to replace this part with a new one! Beginning motorists may have difficulties with how to change the clutch release bearing; this is quite a troublesome undertaking if there are no basic repair skills. That's why some people turn to a car service center for help. How much does it cost to replace a throwout bearing? This procedure will cost approximately from 2000 to 5000 thousand rubles.

If after replacing the clutch the car jerks

For example, before the repair, the car did not pick up speed well, it was slipping, and the clutch pedal was activated at the very top. All the signs of a worn driven disc were present. After replacing the disk, the car began to jerk. What could happen after the repairs were carried out?

- The issue may be a defective part. This is not so rare when it comes to non-original spare parts. In Russian-made cars (VAZ, GAZ, AZLK, IZH), defects also occur in factory parts. That is, the driven disk is simply curved. On the clutch basket (drive disc), the pressure petals may be at different levels, then the release occurs unevenly and the car jerks.

- The car may jerk due to clutch adjustment. More precisely, it was not performed after replacing the disk. The linings of the new part are much thicker; in this case, the clutch pedal “takes at the very end”. When starting off, the car moves jerkily, and the gear shifts into gear with a crunch.

- The car jerks due to the replacement of not all the parts that needed it. In particular, the cause of jerking is the worn surface of the flywheel under the driven disk. If the flywheel has not been replaced, there may be jerking when driving, and the car may also slip.

Adjusting the clutch system and release bearing

If the clutch mechanism is not working properly, the car moves jerkily, jumpily, the lever sinks, and various sounds are emitted from the box.

Good performance properties of a car depend on the quality of operation of three motion systems: gas, brake and clutch mechanisms. To adjust the clutch, sometimes it is enough to adjust the drive; in other cases, repair and replacement will be required. Adjustments must be made on time to avoid breakdowns that require large financial costs. The main signs of a malfunctioning clutch mechanism: the car moves jerkily, jumpily, the lever sinks, various sounds the gearbox Ideally, after depressing the pedal, the car should move slowly and smoothly. Sometimes a lot depends on the little things, and it would seem that such a small part of a large machine, like a release bearing, is a drop in the bucket. But in practice, everything is not so; even the smallest particle that has become unusable requires attention. An experienced driver will be able to repair or replace the release bearing; a beginner will most likely go to the nearest service station or try to solve the problem on his own by reading this article. Good luck on the roads!

If there is a noise or whistle after replacing the clutch

Many car owners often complain that after replacement, a noise or whistle appears that was not there before. What could be the reasons for the extraneous sound and why does this happen? » alt=»»>

- The new release bearing turned out to be of poor quality or does not contain enough factory lubricant. A whistling or noise appears when you press the clutch pedal. Many people mistakenly believe that the bearing makes noise when the clutch is disengaged. But this is even illogical, in this state the part does not bear the load, and accordingly the noise (whistle) in this state is minimal.

- The clutch basket has unevenness and roughness at the tips of the pressure petals. Typically, spare parts from Russian manufacturers have such a defect. It should be noted that as the parts are ground in, the whistle that appeared initially disappears. You can temporarily eliminate the noise by lubricating the petals with lithol. But this can be done without disassembly on GAZ cars; on front-wheel drive cars, to perform a similar procedure it is necessary to dismantle the gearbox.

- It is possible that before replacing parts, the car owner did not pay attention to extraneous noises such as whistling, as he was expecting repairs. But after replacing the clutch, extraneous sounds remained, which the owner of the car did not expect. Noises are often caused by the gearbox. If, when the clutch is depressed, the unpleasant sound disappears or noticeably subsides, then most likely this indicates wear on the gearbox input shaft bearing.

- The driven disc linings have roughness. A rustling noise occurs when changing gears. There is no need to worry too much ahead of time - the new parts will get used to it, and the defect will disappear during the operation of the car quite quickly.

- The input shaft bearing in the crankshaft may also make noise. When disassembling the car, you should do an external inspection of the bearing. If it is very dry, it must be lubricated with lithol or other suitable lubricant. It is better to replace a clearly worn part immediately.

Signs of a faulty release bearing

To be confident in your car, rule out the following signs of trouble:

- when squeezing the clutch, a repeated knock or noise appears (the release bearing is humming), but with uniform movement without changing gears, these sounds do not exist;

- There are difficulties with shifting gears, most often this applies to reverse gear;

- changing gears becomes impossible.

All of the above factors require diagnostics for malfunction. The question arises: how to check the release bearing? It's not difficult at all. You need to listen to the sounds made when squeezing the pedal; extraneous noise in the area of the box will indicate a breakdown. The characteristic “death” squeal in the car is the main sign that the part needs to be changed urgently, otherwise a situation will arise when the release bearing jams at the most inopportune moment. If you feel that the release bearing is noisy or whistling when it is cold, then evaluate all the risks, and when deciding whether it is possible to drive with noise, it is better to answer - no. On average, it operates without breakdowns for about 150 thousand km; this part is highly durable and reliable.

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. » alt=»»> Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.

Removing and installing the Lada Priora clutch

Replacing the clutch.

Instructions for clutch repair, troubleshooting Lada Priora 2170, procedure for removing and installing the disc on Lada Priora cars. Maintenance and repair of transmission Lada 2170, 2172 Priora. Wheel drive. Replacing the VAZ 2171 clutch. You will need: an “8” wrench (a socket head is more convenient), a large screwdriver...

...a mandrel for centering the driven disk (can be made from the input shaft of the gearbox by removing the gears).

1. Remove the VAZ 2170 gearbox (see “Removing and installing the gearbox”).

2. If you are installing the previous VAZ 2171 pressure plate, mark in any way the relative position of the disc housing and the flywheel in order to install the pressure plate in the same position as before removal (to maintain balancing).

3. Install the mandrel into the pressure plate hole.

You can dismantle the clutch without a mandrel, but at the same time hold the driven disk: it may fall out of the clutch housing.

4. While holding the flywheel from turning with a screwdriver, remove the six bolts securing the clutch pressure plate housing to the flywheel. Loosen the tightening of the bolts evenly: each turn of the wrench, moving from bolt to bolt along the diameter.

5. Remove the clutch housing assembly with the pressure plate.

6. Pull out the driven disk along with the mandrel.

7. Cracks on the driven disk parts are not allowed. Check the wear of the friction linings 1. If the heads of the rivets 2 are recessed to a distance of less than 0.2 mm, the surface of the friction linings is oily or the rivet joints are loose, then the driven disk of the Priora fret must be replaced. Check the reliability of the damper springs 3 in the sockets of the driven disk hub; if the springs are broken, the disk must be replaced.

8. Check the runout of the driven disk if warping is detected during a visual inspection. If the runout exceeds 0.5 mm, replace the VAZ 2172 disk.

9

Inspect the working friction surfaces of the flywheel and pressure plate of the Lada Priora, paying attention to the absence of deep marks, scuffs, nicks, obvious signs of wear and overheating. Replace defective components

10. Using an external inspection, evaluate the condition of the disc spring 1 of the pressure plate. Cracks on the spring are not allowed. The contact points of the spring petals with the clutch release bearing must be in the same plane and have no obvious signs of wear (wear should not exceed 0.8 mm). Otherwise, replace the pressure plate assembly. If the rivet connections of 2 parts of the casing and the pressure plate of the Priora fret are loosened, replace the pressure plate assembly.

11. Assess the condition of the priora compression spring support rings. The rings should not have cracks or signs of wear. Otherwise, replace the pressure plate assembly.

12. Before installing the clutch, check the ease of movement of the driven disk along the splines of the input shaft of the Priora gearbox. If necessary, eliminate the causes of jamming or replace defective parts.

13

Please note that when installing the driven disk into the pressure disk housing of the VAZ 2170, the more protruding part of the hub should be directed towards the pressure spring

14. When installing the clutch, first install the priora driven disc using a mandrel...

15. ...then place the pressure plate casing on the three centering pins and screw in the bolts securing the casing to the flywheel.

- 16. While holding the flywheel from turning with a screwdriver, evenly tighten the clutch-to-flywheel bolts: each one turn of the wrench, moving from bolt to bolt along the diameter. The tightening torque of the bolts is indicated in Appendix 1.

- 17. Remove the mandrel and install the gearbox

- 18. Install the lower end of the clutch release cable on the Priora gearbox and restore the original adjustment of the clutch release cable (see “Replacing the clutch release cable on a Lada Priora”).

Before restoring the original cable adjustment, it is necessary to restore the wear compensation mechanism for the linings of the VAZ 2171 2172 clutch disc to its original state, since if the clutch disc is completely worn out, the wear compensator slider will remain in the lowest position. After installing a new, unworn driven disk, the length of the threaded part of the lower end of the cable may not be enough to restore the initial position of the cable.

To bring the wear compensation mechanism to its original position, by installing size L (see “Replacing the VAZ 2170 clutch release cable”) between the driver and the clutch release fork lever, move the clutch pedal up until it stops - the spring of the mechanism will automatically return the slider to its original position. Then check the L size again and adjust if necessary.

vazclub.com

Vibration that occurs after replacing clutch elements

There are few reasons why vibration occurs after replacing a clutch. Vibration usually appears in two forms:

- The pressure plate (clutch basket) is not balanced;

- During assembly, the driveshaft was installed in a different position from the original installation (but this only applies to rear-wheel drive or all-wheel drive vehicles).

By and large, on cars with front-wheel drive, you can inaccurately secure the wheel drive (CV joint), and the movement of the car will be accompanied by vibration and knocking, but this does not happen often.

If the clutch basket creates vibration, you can try moving it to a different position. As a rule, the pressure plate mounts are symmetrical. On many models, the basket is attached to the flywheel with six bolts, and the basket can be placed in three positions. In one position the vibration may disappear completely or be minimal. But it is better to exchange the warranty part immediately for another one. This will be less hassle for the car owner.

Hello, I have a Getz 1.3 volume, I began to notice that when you release the clutch pedal a dull whistling sound appears, press the pedal a little, the whistle disappears. Despite all this, the clutch works fine, no complaints. Of course, you can ignore this, but this whistling is a little disturbing. Maybe you had a similar problem, I'm looking for advice. Thank you all in advance.

to ivan nikitin:

Good day. Most likely the issue is the release bearing or the input shaft bearing. Check, change, the problem should disappear.

to ivan nikitin:

I support Rain. The issue is the release bearing.

to ivan nikitin:

I think that problems with the clutch release, on the contrary, would appear when the clutch pedal is pressed. First you need to check the presence of oil in the box. Most likely the primary bearing. In my opinion there is nothing more. But in general, when you release the pedal, the sound should change anyway. Maybe they just didn't pay attention before. Try comparing it with some other car.

Hello.

I had this problem on 1.3, 2004 GV.

This is not a release bearing! This is a clutch release fork. I had such a sound, a very nasty whistle. I changed the release bearing but there was no point, I changed the master and slave cylinders of the clutch, the whistle went on and on and then, with the engine running, I noticed that the clutch slave cylinder was not working. completely adjacent to the clutch fork. I removed the clutch slave cylinder and pulled a beautiful black rubber band onto the clutch release fork, put the clutch slave cylinder on, pumped the clutch and started the engine. The sound disappeared forever.

How to extend the resource?

To increase the service life of the device, you must drive on smooth roads. In our country, it is problematic to comply with this condition. Keep in mind that uneven roads destroy not only the vehicle’s chassis, but also the clutch system. Therefore, regular off-road driving is also dangerous for bearings. Don't make mistakes when operating your car. When the car is stopped at a traffic light, there is no need to depress the clutch pedal and engage first gear if you do not plan to move. This should only be done at the beginning of movement, since the part operates under high load conditions. Regular lubrication will increase the service life of the device.

Loading …