Octane number detonation resistance

About the design and operation of a car How long can you store gasoline in a canister?

NEW Check the gasoline, then fill it up Already on sale wmv Premature combustion of gasoline is accompanied by a characteristic knock caused by detonation waves inside the cylinder. This effect is due to the low resistance of liquid fuel to self-ignition at the moment of compression. Detonation resistance is characterized by the octane number, and a mixture of n-heptane and isooctane was chosen as the standard. Commercial brands of gasoline have an octane index in the region of 70–98, which corresponds to the percentage of isooctane in the mixture. To increase this parameter, special octane-correcting additives are introduced into the mixture - esters, alcohols and, less often, heavy metal ethylates. There is a relationship between the compression ratio and the brand of gasoline:

- In the case of SJ less than 10, AI-92 is used.

- For SG 10–12, AI-95 is required.

- If SG is 12–14 - AI-98.

- With SG equal to 14, you will need AI-98.

For a standard carburetor engine, the CO is approximately 11.1. In this case, the optimal OC is 95. However, methanol is used in some racing cars. SG in such an example reaches 15, and OC varies from 109 to 140.

Optimal cylinder pressure

To determine the moment of critical wear of the cylinder-piston group, you need to know what compression rate is considered satisfactory. Here there is a relationship with the compression ratio - the higher it is, the greater the pressure that occurs in the combustion chambers when the crankshaft rotates.

At the moment there are 3 types of motors with different parameters:

- old power units with a low compression ratio (up to 8.5);

- modern gasoline engines, where the fuel mixture is compressed 9–11 times;

- diesels with a compression ratio of 16–24.

The combustion chamber of a diesel engine is small in size, so ignition of diesel fuel occurs due to strong compression.

The optimal pressure values in the cylinders of various power units were obtained based on repeated practical measurements. When the engine is warmed up to operating temperature, the battery is charged and there are no problems with the starter, the compression in the engine should be as follows:

- On diesel - from 2.4 to 3 MPa. The first indicator is the minimum acceptable level at which the car is able to start.

- The optimal pressure in the cylinders of an injection power unit is 1.4–1.5 MPa. Compression may be reduced to a level of 1.1 MPa.

- In old carburetor engines of VAZ and other brands, the minimum threshold is 1 MPa or 10 Bar. A unit in excellent condition should show a result of 13 bar.

Note. If we analyze the measurement data, we can identify the following pattern: the optimal pressure is equal to the compression ratio multiplied by a factor of 1.4–1.5.

Basic knowledge

Diesel engine compression ratio - what is it?

A flammable fuel mixture of fine particles of hydrocarbons and air is formed in the engine cylinders. Its compression ratio depends on the make of the car, the type of internal combustion engine and ranges from 7 to 10 units. A prerequisite for ignition is the presence of a spark supplied at the maximum compression moment from the spark plugs.

An undesirable phenomenon is unauthorized spontaneous ignition, as should happen with diesel fuel. As a result of such actions, negative factors will appear:

- combustion will occur at an uncontrolled high speed due to micro-explosions formed after ignition;

- the generated energy from the flash will be bidirectional both towards the piston and in the opposite direction;

- due to the fact that the valves are closed, the impact reflected from the walls affects the piston moving upward, resulting in a metallic knock from the impact of the piston pin.

What is compression

When the piston moves upward, it compresses the air-fuel mixture that fills the chamber. In order for fuel combustion to be as efficient as possible, it is necessary to ensure sufficient pressure in the cylinders (this is compression). After all, the higher the pressure at the beginning of the power stroke, the stronger the exhaust gases press on the piston, forcing it to turn the crankshaft. If the engine compression is insufficient, the following happens:

- fuel burns inefficiently, causing engine power to decrease;

- exhaust gases break into the engine crankcase, which leads to oil oxidation;

- Burning gases breaking through the gasket, piston rings or valves damage their surface and further reduce the pressure.

The rotating connecting rod pushes the piston upward. Closed valves, head gaskets and piston rings prevent gases from escaping from the combustion chamber, causing pressure to build up. When the piston has almost reached top dead center (TDC), the air-fuel mixture ignites. As a result of this, the pressure in the combustion chamber increases sharply and begins to look for a way out - through the piston, connecting rod and crankshaft. Thus, the pressure in the combustion chamber is converted into rotation of the crankshaft. Compression determines how much combustion products will push the piston, and how much will go into the cooling or lubrication systems to spoil the engine.

What is gasoline?

About the design and operation of the car Templates if my car is in the way. If my car bothers you sign template print

Gasoline is the lightest of the liquid fractions of oil (a mixture of light hydrocarbons). It is used as fuel in carburetor and injection engines of modern cars, motorcycles and other equipment.

Gasoline is fuel!

Gasoline labeling

In accordance with GOST 54283-2010 in Russia there is a single label for all gasoline. For example, AI-80. It is deciphered like this. A - motor gasoline, I - octane number determined by research method. 80 is the octane number itself. Also, at the end, another number can be added to the name - environmental fuel class, from 2 to 5 (for example, AI-92/4). If there is no letter I in the gasoline labeling, then its octane number is determined by the motor method (A-92).

The quality requirements for currently produced gasoline are determined by the Technical Regulations adopted in 2011. Full title: “On the requirements for automobile and aviation gasoline, diesel and marine fuel, jet fuel and heating oil.”

Unleaded gasoline

Gasoline without lead additives. All gasoline currently produced is in accordance with Technical Regulations.

Gasoline AI-80

Full name: Gasoline AI-80, Normal. Octane number 80, obtained by research method. According to the motor method, it is 76. The quality complies with GOST 51105-97. Fuel class - second. Not leaded.

Gasoline AI-92

Full name: Gasoline AI-92/4, Regular. Octane number 92, according to the research method, 83 - according to the motor method. GOST 51105-97. Not leaded.

Gasoline AI-95

Full name: Gasoline AI-95/4, Premium Euro. Octane number is 95 according to the research method, 85 - according to the motor method. GOST 51105-97. Not leaded.

Gasoline AI-98

Full name: Gasoline AI-98/4, super-euro. Octane number is 98 according to the research method, 88 - according to the motor method. Produced according to TU-38.401-58-122-95, TU-38.401-58-127-95, TU-38.401-58-350-2005. Not leaded.

Gasoline A-92

Octane number determined by the motor method = 72. Corresponds to GOST 2084-77. Currently out of print. Not leaded.

Gasoline AI-76

Complies with AI-80. Octane number according to the motor method = 76. Produced according to GOST 2084-77. Could be either leaded or unleaded.

Gasoline AI-91

Complies with AI-92. Research octane rating 82.5. Produced according to GOST 51105-97. Not leaded.

Gasoline A-92

Produced according to TU 38.001165-97. According to TU 38.001165-87, it was exported during Soviet times. Analogue of AI-92. Not leaded.

Gasoline AI-93

Complies with AI-95. Octane number according to the motor method is 82.5. According to research 93. During the Soviet era, gasoline labeled A-93 was exported, but for the domestic market it was called AI-93. Could be leaded or unleaded.

How to measure compression in cylinders

You can measure compression either in a technical service center or in your own garage. Experts measure compression in the cylinders, both on a warm engine and on a cold one, both with the throttle valve open and closed. Various indicators and measurement methods can more accurately indicate where to look for reasons for decreased compression. For example, if you measure compression with the throttle valve open, you can identify:

- wear and breakage of pistons;

- piston rings coked into the groove;

- burnout or wear of valves;

- cylinder surface defects;

Compression measurements with the throttle closed help identify the following problems:

- poor valve fit;

- valve sticking;

- camshaft cam defects;

- leakage of the head gasket;

If you decide to independently check the compression in the engine cylinders of your car. You will need the following:

- a fully charged and not old car battery;

- compression meter – the actual device for measuring compression;

- spark plug key;

- partner;

Turn off the fuel supply to the engine, remove the air filter, turn out all the spark plugs using a key and do not forget to pre-warm the engine. Measuring compression on a cold engine is a task for the pros.

Next, using a compression gauge, which is a regular pressure gauge with a special adapter, measure the compression in each cylinder through the spark plug hole. One person rotates the engine using the starter, and the second actually measures the compression. There are different compression meters. The attachments in some allow you to screw the device into a candle socket. In other models, you need to press the compression gauge firmly against the spark plug hole. It would be better to take several measurements for each cylinder, and then average their values.

Based on the results of measuring compression in the engine, a decision is made on certain repair work. This could be a major overhaul of the engine, repair or replacement of valves, replacement of the engine head gasket or other engine part. If your compression is normal, but there are some disturbances in the operation of the car, you should look for the causes of such disturbances in other systems and components of the car.

In general, significant decreases in compression in engine cylinders, as a rule, indicate the need for serious repairs.

Fuel modifications and manipulations

Additives can be used to change fuel parameters. With their help, it is possible to artificially increase the octane number. Traditionally, in our country all additives (legal and not so legal) added to technical fluids are called additives. Counterfeit products (often useless and sometimes harmful) have discredited the term.

The difference between 95 gasoline and 92 is that the A92 brand is the “cleanest” product and is a delusion.

Some unscrupulous sellers often obtain higher octane numbers through chemical impurities and octane correctors. The opposite can only be proven through laboratory testing.

Although, judging by the application, they should increase power, reduce consumption and reduce the detonation properties of gasoline.

There are situations when a car cannot drive without additives. This happens when pouring low-quality gasoline. This is determined by a decrease in power and the appearance of extraneous sounds from the engine compartment. In this case, additives from a trusted manufacturer can save the situation.

Adding fuel additives

Like caries, it can slowly corrode the fuel system.

But there are no additives on the market that reduce its level in gasoline. Therefore, when filling in the “de-watered” mixture of “pseudo A95”, the motorist risks more than when filling up with high-quality A92.

What is normal engine compression?

It is clear that for different engine models with different characteristics, including compression ratio, the normal compression value will be different. Normal compression on different cars can range from seven to eleven atmospheres. And this is for gasoline engines. Modern diesel engines have significantly higher compression. Here the normal range is from 25 to 32 atmospheres. The fact is that the very design of diesel engines and modern units especially, assumes high operating pressure in their cylinders. After all, diesel fuel, as you know, ignites not from a spark, like gasoline or gas, but from compression. Consequently, excellent compression for a gasoline engine will be none at all for a diesel engine. And there is simply no point in comparing them.

Using low octane gasoline

The car manual indicates the engine type and recommended fuel. The use of a low octane combustible mixture leads to premature burnout of the fuel and sometimes destruction of the structural elements of the engine.

It is also important to understand which fuel supply system is used. For mechanical (carburetor) type, compliance with the requirements for engine rating and coolant is mandatory

In the case of an automatic or injection system, the fuel-air mixture is adjusted electronically. The gasoline mixture is saturated or depleted to the required RON values, and the engine operates normally.

How is compression measured?

To take the measurement, you will need an assistant and a device called a compression gauge. This device is produced in various modifications. But the device operates on one principle - it measures the pressure in the combustion chamber. Compression measurements are carried out only on a cold engine. Unscrew the spark plugs from a gasoline engine or the glow plugs from a diesel engine and insert (screw) a compression gauge into the first cylinder.

Have an assistant nearby to turn on the ignition and turn the starter on your command. Measurement time 2–3 seconds. Look at how much the device showed and compare it with the required value. Then repeat the same operation on other cylinders. The difference when measuring compression on a cold and hot engine reaches 2–5 atmospheres.

Gasoline octane recommendations

- If you use fuel with a lower octane rating, then shock loads in the form of detonation knocks and ringing will inevitably increase and, as a result, engine wear. In addition, the consumption is higher and the meaning of saving is lost.

- 2. If you use gasoline with a higher octane rating than is provided for by the engine design, then the gasoline will burn longer, giving off more heat.

- Fuel with a higher octane number usually burns at a lower temperature and more slowly. Due to the combustion rate being lower than the calculated one, it may happen that during the exhaust phase, a still burning mixture will be released through the valve instead of exhaust gases. Consequently, engine parts will overheat, especially valves, and oil consumption also increases. It is interesting that by ear the engine often begins to run quieter and smoother (due to thermal expansion, the gaps are selected), but at the same time the engine runs into wear and tear.

- For example, 100 gasoline burns too slowly for your compression ratio. Therefore, it does not burn out completely and smokes. There is no point in filling up with 100 if the car runs well at 95.

If the engine does not have an ignition angle control system, then pouring high-octane fuel can again ruin the spark plugs and lose some power, as the ignition will be delayed.

What does compression depend on?

The cylinder during compression/combustion strokes is a closed system consisting of:

- piston;

- piston rings;

- cylinder walls;

- cylinder head gaskets;

- valves

Damage to any of the elements that form this closed system leads to a decrease in pressure. If the piston is cracked, burned out or otherwise damaged, exhaust gases will leak, which will negatively affect the power and service life of the engine.

Most often, pressure drops due to worn or coked rings.

Wear of the rings occurs due to friction against the walls of the combustion chambers. Exceeding the engine temperature leads to an increase in the size of the rings, when their locking ceases to cope with its duties, they leave scratches on the cylinders, destroying the honing. Incorrect composition of the air-fuel mixture, malfunction of the ignition or fuel injection systems lead to the fact that the rings are covered with a layer of unburned resins, due to which they lose mobility and the lock stops working. The ring freezes to its maximum size, because the lock is clogged with resin, so it cannot shrink. When starting a cold engine, the friction between the ring and the cylinder walls is too great, causing damage.

Formation of soot and varnish deposits

A non-optimal composition of the air-fuel mixture, an incorrectly set ignition or fuel injection timing, and incorrect valve timing lead to the air-fuel mixture burning as it passes through the valves. Because of this, the ground surface of the valves burns and loses its tightness, which leads to a decrease in pressure, and then to a further increase in damage. When overheating, driving for a long time at low speeds and high gears, during a sharp start or long-term operation of the engine in a power mode close to maximum, the likelihood of burnout or breakdown of the cylinder head gasket increases. If damage to the gasket connects the cylinder and the oil or cooling channel, then hot gases enter the corresponding system, sharply reduce the life of the antifreeze or oil, and the coolant and oil impair fuel combustion in the cylinders.

Engine compression and diagnostics

Checking engine compression, as well as some indirect signs, allows you to accurately determine not only engine damage, but also determine what reason led to this. The measurement must be made on a cold engine, which will require a device called a “compressometer”. This device is sold at any auto store.

If the measurement shows a difference in compression in the cylinders of more than 0.5 atmospheres, the rings need to be replaced. If the measurement showed a decrease in compression in all cylinders by 0.5 atmospheres also against the background of a drop in engine power, an increase in fuel consumption or gray smoke from the pipe, then the problem is in the rings and valve stem seals. If the measurement shows that the pressure is noticeably lower than it should be (the difference is more than 3 atmospheres), and bluish or white smoke comes from the exhaust pipe, then the alarm indicates a broken cylinder head gasket.

If the measurement showed a drop in compression below 6 atmospheres in one or more (not all) cylinders, the problem may be a burnt-out valve.

If the measurement shows normal compression, and dark (from barely noticeable bluish to thick black) smoke comes out of the exhaust pipe, and the engine power is reduced or fuel consumption has increased, the problem is the incorrect operation of the spark plugs, injectors or carburetor. If the oil level drops, the problem is damage to the oil scraper rings or caps. If you know what caused the compression to drop, you can get away with minor repairs. If, according to the measurement results, the compression in all cylinders is the same and lower than it should be, add 10–15 ml of engine oil to the cylinders. An increase in compression indicates the need to replace the rings.

Self-determination

In garage conditions, it is difficult to independently design fuel monitoring stands. This requires more compact equipment. An octane meter will come to the aid of motorists. This device detects the number of octane units and displays the data on the built-in display.

The operating principle of the mobile device is based on comparing tested gasoline samples with programmed reference parameters of different brands. The calculations use the dielectric constant of motor gasoline.

The octane meter is quite convenient and easy to use during measurements. After a short period of time, he displays the result on the screen. The disadvantage is that such equipment is not certified in our country. This means that you should not rely completely, trust the result 100%.

What should you measure?

To assess the technical condition of the cylinder-piston group and the tightness of the valves, a diagnostic device is used to measure compression. The kit includes the following parts:

- dial pressure gauge with a scale of 0–2.4 MPa (for diesel – 0–4 MPa);

- a flexible pipe with a tip that is screwed into place of the spark plug;

- Check Valve;

- manual air release valve;

- nozzles - adapters for various threads.

The simplest version of a compression gauge is a pressure gauge with a check valve and a rubber nozzle in the form of a cone. During the measurement process, the device must be pressed against the spark plug hole and held by hand, and not screwed in.

How can you change the compression ratio?

Magnification methods:

- Boring of cylinders and installation of larger pistons.

- Reducing the volume of combustion chambers. It is carried out by removing the metal layer from the side of the plane where the head meets the block. Due to the softness of aluminum, this operation is best done on a milling or planing machine. A grinding machine should not be used, as its stone will constantly become clogged with ductile metal.

Ways to reduce:

- Removing a layer of metal from the piston bottom (this is usually done on a lathe).

- Installation of a duralumin spacer between the head and the cylinder block between two gaskets.

Relationship between compression ratio and compression

Knowing the value of the compression ratio, you can calculate what compression should be in the engine. However, the reverse assessment will not correspond to reality. Since compression also depends on the wear of parts of the cylinder-piston group and the gas distribution mechanism. Low engine compression often indicates significant engine wear and the need for repair, and not a low compression ratio.

Turbocharged engines

Air is pumped into the cylinders of a turbocharged engine by a compressor at a pressure slightly greater than atmospheric pressure. This means that to determine the compression ratio of such a motor, you need to multiply the value that you get as a result of the calculation using the formula by the turbocharger coefficient. Turbocharged gasoline engines operate on fuel with an octane rating higher than gasoline, which is consumed by the same engines without turbines, precisely because their ξ coefficient is higher.

https://youtube.com/watch?v=QBU5RolKDUI

Higher compression in the engine also means higher thermal efficiency

It is important to note that heat production and heat loss during the engine operating cycle are directly related to its efficiency (we are talking about the coefficient of performance - efficiency). Moreover, the efficiency is mainly influenced by the compression ratio of the engine. It's all about two ideas. First, any thermal energy entering the system must be converted into mechanical or waste energy. Second, thermal efficiency is simply the result of engine operation (power and force) divided by heat transfer.

Thus, the relationship between thermal efficiency and compression ratio can be calculated using the equation.

Here's what the equation for this relationship looks like ( n is thermal efficiency, r is compression ratio, and γ (gamma) is a fluid property):

Now let's go back to our diagram above. When you provide more piston stroke between top and bottom dead center, you increase the compression ratio. By doing this, you shift PV up and to the left on the diagram and increase the temperature ( Qh in the graph above ). Moreover, the temperature increase will be greater than the heat loss ( Ql ).

In other words, you extract more energy from the combustion process of the fuel mixture per engine cycle. By the way, here is one interesting video by video blogger Jason Fenske, who talks in simpler terms about the relationship between compression ratio, heat transfer and efficiency (engine efficiency):

So, as you've probably figured out by now, the thermal efficiency of an engine increases as the compression ratio of the engine increases. These are the laws of physics, namely the laws of thermodynamics. This becomes especially clear from the equation given above.

Accordingly, the higher the compression ratio of the engine, the more horsepower it produces and the less fuel it consumes. For us, this means a heavier wallet due to the money saved at the pump and more adrenaline when accelerating.

To understand this, you need to rent some old American inefficient car with a naturally aspirated V8 gasoline engine that has a low compression ratio. After driving such a car for several days, you will understand that the car “eats” like an elephant, but in return does not produce good power, which modern four-cylinder and even three-cylinder engines show today.

For example, Mazda's famous Skyactiv-G engine is very efficient in terms of not only power, but also good economy. This is largely due to the high compression ratio. Also, a number of other manufacturers began to produce modern engines with a high compression ratio. So, today Mazda, Nissan / Infiniti and Toyota and others have begun to produce engines with a very high compression ratio of 14:1.

You won’t believe it, but engines with such a compression ratio seemed fantastic until recently. By the way, thanks to this compression ratio, automakers do not need to equip engines with turbines in order to achieve compliance with modern standards of efficiency, environmental regulations, and power requirements.

Why does a higher compression ratio mean that the car must be fueled with a high octane rating?

But why haven’t most automakers today switched to producing engines with a high compression ratio, if such power units allow such outstanding power unit efficiency results to be achieved without turbochargers? It's all about the laws of physics.

Many high compression engines require premium fuel or high octane gasoline.

For those who do not know or do not remember what octane gasoline is and how it helps avoid detonation in the engine, we advise you to read our following materials:

Which gasoline is better?

Why premium gas is a waste of money for most cars

How much energy is in different types of fuel

Low octane fuels, compared to high octane fuels, are more likely to spontaneously ignite due to the higher temperatures and air pressures in high compression engines. We know that ignition of the fuel-air mixture should occur when it is really needed, and not vice versa. This uncontrolled ignition of fuel is called detonation. This is very harmful for any internal combustion engines. The fact is that excessive detonation reduces torque and can cause irreparable damage to the car engine.

A high compression ratio increases the risk of severe engine detonation. This is why engines with high compression ratios tend to run on high-quality or high-octane gasoline.

The main reason for the risk of self-ignition of the fuel-air mixture in engines with a high compression ratio is exceeding the permissible pressure, which leads to a sharp heating of the fuel mixture. This ends up causing the fuel to burn prematurely before the spark plug even ignites it. We repeat, pre-ignition of fuel is very bad for any engine.

To reduce the risk of fuel pre-ignition, Mazda has worked extensively on the high-compression piston and exhaust designs of gasoline engines (14:1 cylinder compression ratio). For example, the Skyactiv-X engine was equipped with special pistons that have a cavity in the middle, which prevented a splash of oxygen-rich fuel around the area where the fuel mixture was ignited from the spark plug.

It is precisely the problem of self-ignition of fuel in engines with a high compression ratio that today prevents the mass distribution of this type of engine throughout the automotive industry. You can read more about the Mazda engine here

Video comparison of car characteristics on 95 and 92 gasoline

The question of which gasoline is better for a car - 92 or 95, today is not only not rhetorical, but it can even be called inappropriate. Of course, the quality of fuel at Russian gas stations, as before, does not shine, this is especially felt in the outback, because control there is minimal, and they mix whatever they can into the fuel. But still, the problem with high-quality refueling of a car is not limited to this alone. Some motorists drive an old car, while others drive a new one just purchased at a car dealership.

It goes without saying that their engines prefer different fuels. If with new cars everything is more or less clear: fill up with the fuel recommended by the car manufacturer and drive safely, then with used vehicles everything is not so simple.

Old cars may not have a book indicating technical recommendations, and secondly, the previous owner of the car could have upgraded the power unit for a different type of gasoline or even converted it to gas.

Symptoms of low engine compression

Actually, we have already talked about the signs of decreased compression in car engines. Another thing is that the car can trip and shake for other reasons, with engine compression, which have nothing to do with it. However, if the engine begins to consume oil, if its operation has become unstable, and even for no apparent reason, you should measure the compression in the cylinders of your car. Also, a decrease in compression can be caused by a drop in traction, an increase in fuel consumption and an increase in vehicle acceleration time. As for the difference in compression in different cylinders of the same engine, as long as this value does not exceed one atmosphere, there is no problem. If the difference is greater, the motor should be repaired.

A few words about American and turbocharged engines

I was also bombarded with the following questions: “I bought a car imported from the USA, it says that you need to use AKI 91 gasoline. What is this, and what kind of fuel should I choose?”

The US market has slightly different standards; their classification is not like ours (that is, “research”). The abbreviation AKI means a conditional, average designation of two indices ((“research” + “motor”)/2).

If we bring it closer to our standards, we get something like this:

AKI87 = AI92

AKI89-91 = AI95

AKI93 = AI98

I would also like to note the turbocharged options; in the last article I said that it is recommended to use at least “95” in them.

Let's think logically, why 95 and 98? Turbocharged engines use much larger volumes of air and fuel, the mixture in them must be richer, and from the points above we understood what ENRICHED fuel is, it gives us more octane. Think for yourself - WHY BUY A TURBO, AND FURTHER FEED IT WITH LEAN MICHES, it’s just not designed for that! The amount of air must strictly correspond to the caloric content of the fuel.

It is also worth noting that when using the “92”, as many manufacturers indicate, the “required temperature regime” may be violated, which may lead to the failure of some components, in particular the “turbine” itself.

Therefore, in TURBO, only what the doctor ordered, otherwise it is fraught with repairs.

Now there is a video version of the article, VERY USEFUL.

I’ll end here, I think it was useful, sincerely YOUR AUTOBLOGGER.

Factional composition

The basic performance characteristic and at the same time the main pricing parameter of motor gasoline is its resistance to detonation, expressed by octane number. It is the octane number of motor gasoline and the corresponding price per liter that is primarily of interest to the driver when entering a gas station. In addition to this parameter, the operational properties of motor gasoline are characterized by:

- fractional composition;

- saturated vapor pressure;

- density;

- sulfur content;

- water-soluble acids and alkalis;

- actual resins;

- compounds of lead, iron and manganese.

At an oil refinery, incoming oil is divided into fractions based on boiling points. For example, a fraction with a boiling point from 40 - 50 °C to 140 - 150 °C is called gasoline fraction or straight-run gasoline. However, the gasoline fraction cannot be used directly as fuel for cars, since it is impossible to simultaneously achieve all the parameters established by the standard. Modern motor gasolines are a mixture of components obtained as a result of complex technological processes of oil refining. Depending on the brand, motor gasoline is prepared on the basis of straight distillation gasoline, catalytic cracking and catalytic reforming, hydrocracking of vacuum gas oil, and alkylation products. But we won’t go into production details.

Compression ratio and octane number of gasoline

Compression ratio - resistance to self-ignition

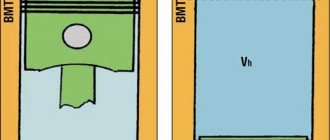

The physical ratio of the total volume of the cylinder at the moment the piston is at dead center to the working volume of the internal combustion chamber is characterized by the compression ratio (CR). The indicator is described by a dimensionless quantity. For gasoline drives it is 8–12, for diesel drives it is 14–18. Increasing the parameter increases power and engine efficiency, and also reduces fuel consumption. However, high values of SG increase the risk of self-ignition of the combustible mixture at high pressure. For this reason, gasoline with a high SG rating must also have a high detonation resistance - octane number (ON).

What do you mean by compression?

One of the main characteristics of the engine, given in the car’s operating instructions, is the compression ratio. This is a dimensionless coefficient showing how many times the air-fuel mixture is compressed before ignition. It is calculated as follows: the volume of one cylinder (including the combustion chamber) is divided by the piston stroke. This parameter is constant and changes only with deep tuning of the engine - boring the cylinders, installing a different crankshaft, and so on.

Uninformed car enthusiasts confuse the compression ratio with compression - the real pressure created by the pistons when the crankshaft is rotated by the starter (200-300 rpm). The characteristic changes as parts wear and is measured in the following units:

- Atm (atmosphere);

- kgf/cm 2 (kilogram-force per centimeter) = 0.97 Atm;

- MPa (megapascal) = 9.9 Atm;

- Bar = 0.99 Atm.

To identify a malfunction of the main engine elements, you need to measure the compression in all cylinders and compare the obtained values with the optimal value. Why does compression decrease during engine operation:

- The working surfaces of the rings, pistons and cylinders wear out, and the gap between them increases. When the crankshaft is turned by the starter, the piston does not have time to “pump up” the pressure in the combustion chamber - part of the air escapes through the cracks into the crankcase.

- The valve plates gradually burn out, do not fit tightly into the seat and allow gases to pass through.

- A “stuck” valve or a completely burnt-out piston does not allow pressure to be created in the cylinder.

- Scratches and scuffs on the cylinders also lead to gas leaks.

These processes occur similarly during engine operation: the fuel does not burn out, gases penetrate into the crankcase, and oil into the combustion chamber. That is, the compression value reflects the real picture inside the engine.

What is the octane number of gasoline

The main characteristic of gasoline is the octane number. Strict methods are used to determine it. The octane rating of gasoline determines its detonation resistance and is calculated as the ratio of the mixture of isooctane and n-heptane.

Isooctane (2,2,4-trimethylpentane) has minimal potential for spontaneous combustion at high pressure. In fact, n-heptane has the opposite characteristics, since it can flare up even with a slight increase in pressure. It is customary to distinguish several types of ochres:

- research;

- motor;

- actual;

- road

They are differentiated by the method of definition. The first two types are laboratory. The actual value is obtained after connecting the running engine to the diagnostic stand. The road one turns out to be as close as possible to reality, since it is detected on a moving car.

Before determining the octane number of gasoline, you need to know that a mixture consisting exclusively of isooctane is given an octane number of 100. If the fuel contains only n-heptane, then it is assigned an octane number of zero.

Is it possible to change the brand of gasoline and what will happen if you mix 92 and 95

And yet, which gasoline is better: 92 or 95? It is unlikely that such a formulation of the question can be considered correct. Provided that the gasoline is of high quality, the brand to which the engine control parameters are set is good.

After all, if, for example, the octane number of gasoline is significantly lower than recommended, then the ignition process in the combustion chamber will occur earlier than expected, when the intake valves are not yet closed. Not only will part of the thermal energy (and therefore the power developed by the engine) be wasted, but the detonation processes themselves will add problems: unstable engine operation, accelerated wear of rubbing parts, increased carbon formation.

Almost the same problems will arise in the opposite situation, only now ignition will occur with a delay, causing the same negative consequences.

It should be noted that modern cars provide for adjustment of engine operating parameters to change the octane number in a certain range. The Electronic Engine Control Unit (ECU) continuously monitors:

- gasoline/air ratio in the air-fuel mixture;

- fuel injection timing;

- moment of ignition of the fuel mixture;

- detonation;

- engine speed,

and, if necessary, adjusts the parameters and operating mode of the unit. But the possibilities of the ECU are not limitless, and if the difference in octane number is significant (for example, 80 gasoline is poured instead of 95), the electronics cannot cope with it.

Gasoline grades 92 and 95 differ slightly in basic parameters (octane number is no more than 3%). Therefore, on modern cars, if necessary (for example, the tank is empty, and the gas station only has a 92nd tank), it is possible to replace it for a short period. A short period because at low and medium speeds the difference in the grade of gasoline will not affect, but at high speeds it will still appear.

Experts also do not recommend pouring 92-octane gasoline into engines with a small combustion chamber volume (and also turbocharged ones). The fact is that an increase in power (or rather specific power) in modern engines is achieved by increasing the compression ratio, and when this indicator is more than 10.5 (and often the compression ratio reaches 12), the requirements for the anti-knock properties of the fuel increase - in other words, for the value octane number.

On the contrary, if the compression ratio is less than 10.5, then the engine operating parameters are configured to use 92-grade gasoline, and when using 95-grade gasoline instead, some loss of power is possible due to later ignition of the fuel mixture.

Another important argument for using the brand of gasoline recommended by the manufacturer in a new car is maintaining the right to warranty repairs during the appropriate period. A formal refusal to warrant engine repair may rightfully follow the results of a fuel analysis if it turns out that the brand does not correspond to that specified by the car manufacturer in the operating instructions. And then a savings of three to four thousand rubles (average value per 15,000 km per year) can result in much greater losses of money, time and nerves.

Is it possible and in what proportion to mix these two brands? Is it possible to fill a tank with remaining gasoline of one brand of another brand? It would seem that such mixing would create fuel with certain average properties. Actually this is not true.

95 gasoline contains a larger amount of light ether additives and, thus, it is lighter than 92 gasoline. When mixed in the gas tank, two fractions of fuel are formed: 95 gasoline on top and 92 gasoline on the bottom, and they are consumed in the same order. So mixing 92 with 95 does not give any new practical effect.

In the case where the car is designed to use exclusively 95 gasoline, and if necessary, is filled with 92 gasoline:

- if there is some loss of power, but the engine runs stably at low and medium speeds without any extraneous sounds, there is no reason to worry until the next refueling. It is only necessary to observe a quiet driving mode;

- When the engine is running, a loud clicking sound is heard, very similar to the knocking of valves - a clear consequence of detonation processes, which, with prolonged use of such gasoline, can lead to negative results. In this case, it is advisable to change the fuel as soon as possible (tip: how to drain gasoline from the tank).

Long-term use of 95 gasoline in cars designed for 92 gasoline with a compression ratio of less than 10.5 can also result in a loss of engine power.

Higher compression in an engine means more power but more pressure

The above figure shows the PV pressure -volume diagram for an ideal typical gasoline engine. This graph clearly demonstrates what happens in an engine when it burns an air-fuel mixture (in our example, gasoline + oxygen).

In the graph above, curve 1-2 shows the progress of compression.

Line 2-3 shows fuel combustion.

The upper curve 3-4 shows the progress of expansion.

And line 4-1 shows the heat dissipation when the exhaust valve in the engine cylinder head opens.

If we describe everything in more technical language, then this diagram should be understood as follows:

In the diagram, curve 1-2 shows the compression stroke, in which pressure ( Y-axis ) rises and volume ( X-axis ) falls as the piston compresses the air-fuel mixture inside the cylinder, approaching top dead center.

Line 2-3 shows the heat generated during combustion of the fuel mixture. This line shows how quickly the pressure and temperature of the burned fuel increases.

Curve 3-4 shows the increase in engine cylinder volume and pressure drop when the gas produced during combustion of the fuel mixture exerts a force on the piston, which begins its movement down the engine cylinder (expansion stroke).

Line 4-1 shows heat removal from gases formed during fuel combustion. When the pressure inside the cylinder returns to ambient pressure, the exhaust valve opens.

Finally, line 1-5 shows us the exhaust stroke (the engine's exhaust cycle), during which the piston again moves upward inside the cylinder (toward top dead center) to compress the air-fuel mixture again to repeat the cycle.

The area within lines 1-2-3-4 shows us how much work was done by the engine in just one cycle. A higher compression ratio of an engine means that the two vertical lines in the graph above will move to the left and up, leaving a larger piston stroke range, which translates to more power being produced compared to an engine with a low compression ratio. That is, an engine with a high compression ratio will do more work in one cycle than an engine with a low compression ratio.

And the thing is that in engines with a high compression ratio, more pressure is generated during the combustion process, which moves the piston down the cylinder with greater force. However, in this case, more heat is released inside the engine.

About burning gasoline

I would like to explain a little how gasoline of different octane numbers burns; we need this to understand the power and small savings.

- 76 (80) gasoline - burns quickly and does not last long, I would even say explosively. It flared up quickly and went out quickly.

- 92nd - ignition is not so explosive, but gradual, that is, the flame spreads much “softer”, and combustion also takes a little longer.

- 95-98 - it becomes clear that the higher the octane, the softer the spread of flame in gasoline (if I can say so), more evenly or something. YES, this fuel burns longer.

Therefore, performance on high-octane types seems softer and the engine runs quieter. IT DOESN'T APPEAR, in fact it is so.

What can happen if you mix fuel?

This cannot be done, since neither 92 nor 95 mix completely in the gas tank. The mixture 95 + 92, as many believe, allows you to save money, but you should also remember that significant damage will be caused to the engine, especially if it is designed for 95 gasoline and higher. This will happen because this pair of types of gasoline has different densities. 92 filled in a ratio of 50% to 50% will sink to the very bottom of the gas tank, and 95, on the contrary, will rise. So, until one type of fuel runs out, the second will remain in the tank. And again, we return to what has already been said above about the harmfulness of 92nd fuel.

If the car is designed for 92-0 gasoline and higher, then 95 can be filled. The engine will not suffer from this.