Operating a car without a cooling system is practically impossible. In the cold season, the car will work for half an hour, and in the warm season – no more than 5-10 minutes. The pump is used to circulate coolant throughout the vehicle. If the water pump is faulty, fluid stops circulating, causing overheating. What are the signs of a part failure, and when to change the pump?

The temperature of the sensors does not reflect the operating temperature of the engine at all - its indicators are several times higher. They display the temperature inside the cooling system. This means that the liquid heats up to 80-90 degrees.

On a Priora, like any other car, it is impossible to operate the engine without a pump connected to it. It doesn’t matter whether there are 8 or 16 valves in the system, but what is important is that if the timing belt is not securely fixed, the engine will not start. By the way, on both types of engine the location of the water pump does not change. The timing belt itself on the Prior 16 valve version of the engine is longer.

Symptoms of malfunction

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

- Antifreeze leak. Like the pump bearing, the oil seal and rubber seal have a limited service life. The appearance of play due to bearing wear will significantly increase the risk of seal leakage.

- Misalignment with respect to timing gears and rollers (the pump becomes askew). Uneven tension distribution leads to accelerated wear of not only the bearing, but also the oil seal. Incorrect installation or a manufacturing defect, in which the pulley rotates misaligned, leads to accelerated wear of the loaded part of the belt. Such a defect, even with low mileage, can cause the timing belt to break and the valves to meet the pistons.

- Engine overheating. When the impeller blades break off, the pump's performance decreases, as a result of which less coolant passes through the small circulation circuit.

Often a decrease in performance is noticed after using a sealant to repair a radiator leak. The poured mixture clogs the cooling system channels and sticks to the pump impeller.

If the liquid has not clogged the coolant drain channel in the housing, then pouring sealant will not lead to a malfunction of the water pump. But you can’t do without removing the pump and flushing the system.

Tips for choosing pumps for Lada Priora

In the line of any brand there are pumps for different car models, differing in dimensions and design features. When choosing a water pump, you need to take into account the mounting dimensions and materials from which the part is made.

The pump body for cars is made of aluminum. The metal does not corrode and is easy to shape into any shape. Manufacturers most often choose steel for the shaft so that it can cope with the load from bearings, seals and impellers.

Impeller. One of the most important elements of a water pump, on which the performance of the pump depends. It comes in cast iron, other metal and plastic. The cast iron part is durable, but heavy and has thick blades, so its efficiency is inferior to others. Metal is lighter and more efficient, but is susceptible to corrosion. Plastic is the lightest material. Such an impeller is productive, but over time, due to contrasting temperatures, it becomes fragile and begins to slip.

The impeller on the back side of the impeller relieves the shaft-housing seal. Not available on all models, but it helps to increase the efficiency of the pump and increase its service life.

How to check the cooling system pump?

By checking the pump without removing it from the engine, we can only indirectly assess its performance. When the volume of pumped coolant decreases, the stove begins to heat poorly. But before removing the water pump to inspect the impeller, we recommend checking the thermostat and also making sure that there is no air lock in the cooling system.

After removal, pay attention not only to the integrity of the blades and where the impeller fits on the drive shaft, but also to the shape of the blades. For example, on the VAZ 2121 over many years of production, impellers were installed that differed in the diameter of the pump wheel, the number and profile of the blades. Installing a less efficient pump on a more heat-loaded engine modification will result in the cooling system fan turning on more frequently and an increased risk of overheating.

Be sure to inspect the engine block where the housing fits and the pump itself. Fogging or a slight leak of coolant from the drain hole does not mean that the pump should be replaced. If a significant leak is detected, try to pinpoint the location of the leak. If the leak is only at the junction of the housing and the engine block, most likely the problem can be eliminated without replacing the pump. It will be enough to apply sealant and install a new gasket.

Risk of timing belt breakage

The danger with a misaligned water pump timing belt is that there are no obvious signs of failure. First of all, you need to pay attention to the timing belt. If it is pulled to any side, uneven production is observed, it is necessary to check the pump and rollers. The cause of the misalignment may be a manufacturing defect, bearing wear, or uneven fit of the housing to the engine block (dirty, rusty mating planes). Sometimes the malfunction begins to manifest itself after an accident, when elements of the body or attachments hit the pump pulley.

If a misalignment is detected, the defective pump must be replaced as quickly as possible. Also, do not hesitate to eliminate noise and whistling from the water pump. If wear is critical, the bearing may collapse, thereby blocking the toothed pulley. A jammed pump is guaranteed to lead to a broken timing belt. If on your car the pistons meet the valves when they break, then eliminating the consequences of the malfunction will cost a fairly large sum.

conclusions

In order to verify for yourself that the old pump is worn out and how it differs from the new one, simply take the old and new element and rotate the impeller on them in turn.

Comparison of the operation of the old and new pump. Check for play and ease of rotation.

You can clearly see from your example that on the old element its rotation will occur with interference, while on the new element it will not be necessary to exert excessive effort.

The car engine cooling system pump (water pump) is an important element that prevents overheating of the power unit. The operation of the internal combustion engine is accompanied by significant heating, therefore, to protect against overheating, forced circulation of antifreeze in the system is necessary. A pump failure can cause the coolant to boil and cause engine failure. Today you will learn how to check the condition of the pump without removing the element from the engine, and what to do if a malfunction is detected.

Main reasons

Before talking about the signs of a dying pump that needs replacement or repair, you need to say a few words regarding the reasons for the failure of this device.

In total, there are several main factors that cause this to happen:

- Using low quality antifreeze. About 90% of pumps break down precisely because of this. Such a cooling liquid contributes to the appearance of tarry deposits, which makes the impeller difficult to rotate;

- Corrosion. Again due to low-grade antifreeze;

- Cavitation, that is, the formation of vacuum bubbles that can literally tear out pump particles and destroy the mechanism;

- The result of normal wear and tear. Each device has a limited resource. The best samples last about 200 thousand kilometers;

- Broken fastening. It's simple. The fasteners became loose, the pump became loose and fell apart.

In most cases, it is the car owner himself who is to blame. Drivers are required to monitor the condition of the cooling system, periodically check the pump, and change the coolant on time.

We cannot exclude the problem of manufacturing defects, as well as simply low-quality and cheap pumps that are installed on budget cars or as part of repairs, thereby deceiving the client.

It is not surprising that the timing belt may then fail, the tension roller may rupture, the cylinder head gasket may break through, and other troubles that can cost a lot of money during repairs.

Problems with the water pump can occur on various cars:

- on Kalina;

- VAZ 2110;

- Lada Priora 16 valves;

- VAZ 2114;

- Lada Priora 8 valves;

- VAZ 2115;

- Daewoo Lanos;

- Niva Chevrolet;

- Daewoo Nexia;

- Lada Granta;

- Renault Logan;

- Chevrolet Aveo, etc.

Don’t think that this is a problem exclusively with cheap and budget cars, as well as simple engines like ZMZ 406.

The pump can also be used on more expensive cars. It all depends on how the owner monitors and maintains the car with his own hands, or in a car service center.

The best pump for a prioromotor

If you live in a priorovode, what’s the point of asking here? The people there are much more competent in these matters.

Hepu has good pumps, but there weren’t any for the priorozub. Maybe things have changed now. Someone stupidly ignored the difference in the profile of the teeth and installed them.

IMHO TZA with authentication. And keep an eye on it from time to time. I also have 50 thousand now, everything is original in the timing belt.

Did it rotate smoothly in the store or didn’t you check it?

But I will take an alternative. I have no luck in the lottery

If you live in a priorovode, what’s the point of asking here? The people there are much more competent in these matters.

Hepu has good pumps, but there weren’t any for the priorozub. Maybe things have changed now. Someone stupidly ignored the difference in the profile of the teeth and installed them.

IMHO TZA with authentication.

And keep an eye on it from time to time. I also have 50 thousand now, everything is original in the timing belt.

There are no more checks. And so I appreciate the original technical specification. I took this one for myself.

Signs of trouble

I would like to immediately note that in order to determine faults in the water pump, you will need to remove the unit and disassemble it. Only this method provides a real opportunity to see the resulting traces of corrosion, signs of cavitation and contamination.

Practice clearly shows that this happens on a wide variety of machines:

- VAZ 2107;

- Volkswagen Passat;

- FF2, that is, Ford Focus 2nd generation;

- Lada Granta;

- Kia Spectra;

- Chevrolet Aveo;

- Audi A5;

- Nissan Qashqai;

- Mitsubishi Outlander;

- Toyota Camry;

- Skoda Octavia, etc.

Replacement cost

Not everyone takes on a water pump with their own hands if it must be replaced. They prefer to go to service centers or just some garage-type workshops, where prices are usually lower.

It is important to note that the cost of replacement directly depends on the car make, model and availability of the spare part itself. In some cases, replacement is carried out in literally 20 minutes. In other situations, craftsmen spend several hours. Moreover, most of the time is spent on getting to the pump and removing it.

All this has led to the fact that price tags vary greatly, depending on certain conditions and circumstances. In one case, you will pay about 1000 rubles. In another you will have to pay 5-6 thousand. And this does not take into account the cost of the newest pump for your car.

Should I change antifreeze after replacing the pump?

A question for those who want to save money everywhere and on everything. If I answer this briefly, I can confidently say that yes, the coolant needs to be changed. Please also pay attention to the question regarding mixing antifreeze in the cooling system. It will be useful and important to know all the nuances.

If we talk about the necessity of replacement, then everything is extremely simple. To begin with, in the vast majority of cases it is impossible to replace and remove the pump without first draining the antifreeze from the system. But some people want to save money; they drain the coolant into a clean container, install a new pump, and then pour the old antifreeze back in.

A big mistake, since any water pumps for cooling systems are characterized by increased demands on the quality and purity of the liquid. Therefore, you should absolutely not use previously drained antifreeze, even if you just recently changed it, even before the pump failed. Do not attempt to filter or strain the coolant. Just buy a new can of quality antifreeze that is suitable for your car and fill it up. There simply cannot be any other options. Remember this. Otherwise, you will soon have to spend money on a new pump again.

To ensure that the water pump lasts as long and reliably as possible, make it a rule to use only high-quality compounds. As you remember, 90% of pump failures are related precisely to the quality of the coolant used. I think it will not be difficult to draw the appropriate conclusions.

Have you encountered a water pump failure and how early were you able to identify the presence of malfunctions?

Thanks to everyone who reads us! Don't forget to leave comments, ask questions and invite your friends to join us!

(

1 ratings, average: 5.00 out of 5)

Did you like the article?

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

Basic faults

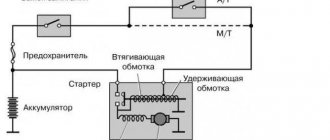

The main reason for pump failure is bearing malfunction. The following malfunctions of this part can be identified:

- The bearing is jammed. If a whistle or hum appears on the right side of the engine when the engine is running, it is time to replace the pump. If there is a lack of lubrication in the bearing, it stops spinning, which leads to a break in the timing belt.

- Formation of play on the bearing. If, when inspecting the car, you find traces of coolant on the pump body, this is the first sign that the pump has exhausted its service life.

- If there is a smell of coolant in the cabin, a hum when the car is running, or signs of antifreeze leakage, the pump should be replaced.

Timing belt

How would you act on your own without clear instructions in the service book? On both an 8-valve and a 16-valve engine, I would change at least the pump, and better yet, the belt and tensioner between the 60th and 70th thousand kilometers. According to the period, if the mileage is small, for the sixth year of operation.

hi guys))) please tell me when to change the pump on a Priorika 16 cl? I changed the belt, and now I regret that I didn’t replace the pump... what is its service life? When replacing the belt, I twisted it without jerking, there is a small play but it doesn’t leak ) mileage 61000

Now that I'm tired of washing the gray insert

by Adminrive · Published 10/07/2014

In general, who is from Moscow

by Adminrive · Published 07/30/2015

Why is replacement needed?

The pump is an important part of the car; if it breaks down, the car engine will stop cooling, which will lead to serious malfunctions:

- Engine overheating. Failures in the cooling system lead to engine overheating.

- Broken timing belt. A jammed bearing or play formed on it leads to damage to the timing belt.

- Valve failure. A broken timing belt bends the valves, the engine fails and requires serious repairs.

You can continue to operate the vehicle if there is a slight coolant leak and if a hum has recently appeared. But you should understand that a small leak will develop into a large one, and the bearing will soon jam, and the cheaper the pump, the sooner this will happen. It is better not to let the engine overheat and promptly replace the pump on the Prior.

Thermostat

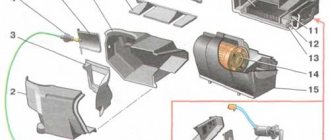

Next you need to go to the thermostat. "Priora" (16 valves), in which replacement of the thermostat itself does not need to be replaced, remains as before not running. The next step is to remove the temperature sensor from the element body. It is used to control the temperature of antifreeze. Now, of course, loosen a few fixing bolts and freely pull the thermostat out. The sealing gasket is removed from the studs. After which we need to extract what remains to be done for our client to make candles. With all this, such an act as replacing a pump is a fairly simple mechanical unit, which consists of several main parts. The design of the pump consists of several elements, one of which is

Replacement

You can replace the pump yourself; for this you will need: a 10mm socket, wire cutters, a screwdriver, a 6-corner bit, and a small ratchet.

- We drive the car onto the overpass, unscrew the crankcase and engine protection, thereby freeing access to the engine. Open the hood and unscrew the cap on the left side of the radiator and drain the antifreeze. If you plan to refill the same liquid, then place a bucket under the radiator.

- We look for a bolt on the front part of the cylinder block and unscrew it. We also drain the antifreeze from the engine into a bucket.

- We remove the plastic decorative trim on the engine; to do this, you just need to pull it up.

- We connect the ratchet with the bit and unscrew the bolts holding the front timing belt cover.

- We align the upper pulleys according to the marks on the rear timing belt cover.

- We unscrew the two timing belt tensioner rollers.

- Remove the belt and gear.

- We unscrew the two upper toothed pulleys and then pull them out.

- Using a 10mm socket, unscrew the 6 bolts on the rear cover of the timing gear drive and pull it out.

- Armed with a ratchet, unscrew the 3 screws securing the pump.

- Using a screwdriver, use a screwdriver to pry up the pump and remove it.

- We clean the pump seat from dirt and remnants of the old gasket with a dry cloth.

- On the new pump, lubricate the gasket seat with a small amount of sealant.

- We put on the gasket and also lubricate it.

- We install the pump on the engine so that the hole in its body looks down into the nearest hole to the filter.

- We tighten the bolts holding the pump.

- The pump has been replaced. We assemble all the parts in reverse order. Don't forget to add coolant.

At the slightest sign of pump malfunction, it is recommended to inspect and replace it. Otherwise, the car's cooling system will be disrupted and engine overheating will be inevitable. And its repair will require more serious financial investments.

Job

You should start replacing the pump with preparatory work. To do this, drive the car into the inspection hole. This option is more convenient compared to the overpass. Drain the antifreeze. Remove the terminals from the battery, this is done to prevent an accidental short circuit. You also need to remove the belt from the generator. Some drivers remove the wheel and fender liner, but this is not necessary:

- The first cylinder is installed at top dead center. To do this, remove the right mudguard. At the same time, the front cover is dismantled. After which the crankshaft is turned (strictly clockwise) so that the marks on the pulleys and the engine coincide. Then remove the plug from the clutch housing. The mark on the flywheel must completely coincide with the one located on the motor;

- The crankshaft pulley is removed; to do this, an assistant must keep it from turning by inserting a mounting blade into the hole in the clutch housing. To unscrew the pulley you will need a 17 key;

- After which the camshaft is removed, to do this you need to hold the pulley with a special device. You can do without devices. Shift into fifth gear and press the brake pedal. Thus, you can remove the camshaft pulley without any problems;

- Remove the bracket;

- The back cover is removed;

- Next, use a hexagon to unscrew the pump. Then it is removed using a slotted screwdriver;

- Be sure to ensure that the old gasket is removed. Sometimes the gasket may burn. Cut off the remains and clean the pump landing area;

- Next, the installation site needs to be lubricated with sealant and a gasket is installed. Afterwards it is lubricated with sealant again. Install the pump. It must be placed with the number facing up;

- Reassembly is in progress.

During the assembly process you need to pay attention to some nuances. First, you need to pay attention to the installation of the pulley according to the marks. This is an extremely important point. You should also carefully tighten the timing belt. To do this, use a special key to turn the roller until it is offset with a mark - a rectangular protrusion. Next, the bolt is tightened with a torque wrench with a certain force. Article on the topic “How to set timing marks.”