Hi all! I think each of you knows how big a role the engine cooling system plays in any car with an internal combustion engine. In this case, one of the elements of the system is a water pump or simply a pump. The car owner is obliged to know the signs of a pump malfunction in order to diagnose them in time and prevent engine overheating with all the ensuing consequences.

If the pump fails for any reason, the consequences for the engine can be catastrophic. Moreover, capital, that is, major repairs, will not always allow you to get out of the most difficult situation.

The main problem is that the water pump does not immediately indicate the presence of a malfunction. Not in all situations a breakdown can be detected quickly enough. Basically, the driver learns about the problem when thick smoke comes out of the engine compartment. Although this can be avoided. I'll try to tell you exactly how.

Symptoms of malfunction

- Noise from the pump when the engine is running. Extraneous sound appears due to bearing wear. It is recommended to replace the cooling system pump after one or every replacement of the timing belt kit. If you neglect service intervals, wear appears on the rolling elements, inner and outer races, which leads to noise and whistling. Often the cause of accelerated wear is antifreeze, which, due to a leak in the oil seal or rubber cuff, gets to the rubbing vapors.

- Antifreeze leak. Like the pump bearing, the oil seal and rubber seal have a limited service life. The appearance of play due to bearing wear will significantly increase the risk of seal leakage.

- Misalignment with respect to timing gears and rollers (the pump becomes askew). Uneven tension distribution leads to accelerated wear of not only the bearing, but also the oil seal. Incorrect installation or a manufacturing defect, in which the pulley rotates misaligned, leads to accelerated wear of the loaded part of the belt. Such a defect, even with low mileage, can cause the timing belt to break and the valves to meet the pistons.

- Engine overheating. When the impeller blades break off, the pump's performance decreases, as a result of which less coolant passes through the small circulation circuit.

Often a decrease in performance is noticed after using a sealant to repair a radiator leak. The poured mixture clogs the cooling system channels and sticks to the pump impeller.

If the liquid has not clogged the coolant drain channel in the housing, then pouring sealant will not lead to a malfunction of the water pump. But you can’t do without removing the pump and flushing the system.

Technical features

First, let's look at the main technical characteristics and features of the water pump; this will allow us not only to make a correct diagnosis, but also to understand why the breakdown occurred. Antifreeze is pumped using an impeller, which is mounted on a shaft. The drive is carried out from the crankshaft of the motor; a belt drive is used for this. Here it is worth clarifying that in practice there are 2 drive methods used for the pump:

- Directly from the crankshaft. This method is used on engines with a timing chain. Usually one belt drives the generator and pump, sometimes the power steering and air conditioning pump are also connected here;

- Another option is timing belt drive. There is one serious drawback here. When the bearing jams in the pump, the belt breaks, which leads to breakdown of the gas distribution system, and under certain conditions, to a complete overhaul of the engine. In this case, you should carefully monitor the condition of the pump.

The pump housing is usually located at the front of the motor. This allows for the most optimal pumping of coolant through the system. It is also precisely this approach that makes it possible to use the crankshaft pulley as a moving element. In addition, placing the part at the front makes it easier to access for repairs. The main malfunctions of the pump are directly related to its technical features; accordingly, this must be taken into account when carrying out diagnostic actions. As a rule, all signs of a malfunction are completely related to the characteristics of the various elements that ensure the operation of your car's cooling system.

How to check the cooling system pump?

By checking the pump without removing it from the engine, we can only indirectly assess its performance. When the volume of pumped coolant decreases, the stove begins to heat poorly. But before removing the water pump to inspect the impeller, we recommend checking the thermostat and also making sure that there is no air lock in the cooling system.

After removal, pay attention not only to the integrity of the blades and where the impeller fits on the drive shaft, but also to the shape of the blades. For example, on the VAZ 2121 over many years of production, impellers were installed that differed in the diameter of the pump wheel, the number and profile of the blades. Installing a less efficient pump on a more heat-loaded engine modification will result in the cooling system fan turning on more frequently and an increased risk of overheating.

Be sure to inspect the engine block where the housing fits and the pump itself. Fogging or a slight leak of coolant from the drain hole does not mean that the pump should be replaced. If a significant leak is detected, try to pinpoint the location of the leak. If the leak is only at the junction of the housing and the engine block, most likely the problem can be eliminated without replacing the pump. It will be enough to apply sealant and install a new gasket.

Risk of timing belt breakage

The danger with a misaligned water pump timing belt is that there are no obvious signs of failure. First of all, you need to pay attention to the timing belt. If it is pulled to any side, uneven production is observed, it is necessary to check the pump and rollers. The cause of the misalignment may be a manufacturing defect, bearing wear, or uneven fit of the housing to the engine block (dirty, rusty mating planes). Sometimes the malfunction begins to manifest itself after an accident, when elements of the body or attachments hit the pump pulley.

If a misalignment is detected, the defective pump must be replaced as quickly as possible. Also, do not hesitate to eliminate noise and whistling from the water pump. If wear is critical, the bearing may collapse, thereby blocking the toothed pulley. A jammed pump is guaranteed to lead to a broken timing belt. If on your car the pistons meet the valves when they break, then eliminating the consequences of the malfunction will cost a fairly large sum.

Bearing check

The easiest way to check is a pump whose pulley is in an accessible place and is rotated by a drive belt. It is enough to grab the pulley with your hand and shake it in different directions (video check). If there is a malfunction, you will feel a lot of play. To determine that the noise or whistle when the engine is running comes specifically from the cooling system pump, remove the drive belt and unscrew the pulley by hand. A worn bearing with washed out lubricant will rotate with noticeable noise and rolling motions.

Checking the pump, the pulley that is rotated by the timing belt, is somewhat more difficult. Overcoming the tension force of the belt, you can try to shake the gear in different directions. But to fully check and evaluate the smoothness of rotation, the timing belt will still have to be loosened.

The main cause of breakdowns

If the oil seal or rubber seal leaks, the coolant washes the lubricant out of the bearings. The problem will get worse if you use cheap antifreeze or water instead of high-quality antifreeze. The lack of anti-corrosion additives and minimal lubricity will very quickly “kill” the pump bearing.

But it is much more important to use high-quality antifreeze for a long service life of the oil seal. At the point of contact with the drive shaft, the rubber seals must be lubricated, which does not happen when using aggressive antifreeze or water.

The cooling system is designed to prevent overheating of the power unit. In this case, it is the pump that is responsible for the quality of operation of the entire system. It is located and attached differently on different car models, but the driver must know the basic methods of diagnosing, repairing and replacing the part in order to quickly restore the operation of the cooling system if necessary.

Shaft defects

Among the signs of a malfunctioning water pump, one should note the presence of deformation on the shaft. Upon inspection, it may appear bent or completely destroyed. If it is broken, it means the overload was sudden. Also, imbalances lead to similar consequences.

If the material from which the shaft is made has changed color (most often it acquires a blue tint), this indicates the gradual destruction of the shaft. This occurs due to excessive heat. The reason for this failure is the misalignment of the drive belt. This leads to shaft deformation or even fracture. Due to insufficient quality maintenance, significant vibrations appear in the system.

In this case, the pump is changed, and the belt drive is also checked. All elements of its system need to be inspected. You also need to evaluate the condition of the fan that is located on the pump (if it is provided in the engine system). If it is bent, other deformations are visible on it, this can destroy the shaft. Wear of the fan coupling and spacer ring also lead to a similar outcome.

Why does the car pump break?

What is a pump and why can it break? This question is asked by many novice car owners on thematic forums on the Internet. This is the name of the pump that circulates coolant in the engine cooling system.

In other words, the cooling of the engine during operation depends on the pump - if the pump suddenly fails, then the antifreeze will simply stop circulating through the system, as a result: overheating of the internal combustion engine.

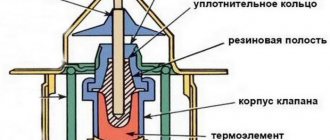

Structurally, the pump consists of a housing with a low-pressure pump placed inside it

Conclusion

Based on everything written above, we can easily say that the life expectancy of the machine’s engine, as well as its service life, directly depends on the condition of the pump. After all, if this element of the engine cooling system is in a faulty condition and the driver decides to leave his garage, we can say with confidence that this will not lead to anything good. The motor will most likely overheat or boil, it’s good if it doesn’t have to be completely changed. So it won’t hurt to look under the hood a couple of times, listen to the sounds coming from there and be a little vigilant; this will save you from trouble more than once, and will also save a lot of money.

How to check it yourself

There is an easy way to diagnose a water pump. There is no need to remove the product from the engine. To check the pump on the vast majority of car models, you must:

Start the engine, warm it up to normal operating temperature (usually this indicator varies from 87 to 100 degrees).

After this, pinch the upper pipe that comes from the radiator with a gloved hand. If the pump is working properly, you will immediately feel the antifreeze pressure inside the pipe. If the pipe is pressed without difficulty, there is no circulation in the cooling system, that is, the pump does not work.

You can check the functionality of the pump in a minute, especially if under the hood is clean and there are no liquid leaks

During the check, you need to be as careful as possible, since the coolant can become very hot, which affects the temperature of the pipe.

Cavitation, bearing damage

When considering the symptoms of a motor pump failure, you should pay attention to such a negative phenomenon as cavitation. This is the process of formation of air bubbles in antifreeze. They damage the internal surfaces and individual parts of the pump. As a result, scratches remain on them. Then they rust.

Air bubbles appear in the pump inlet. When the pressure in the system increases, they are destroyed. This process causes significant system damage and can cause engine failure. Therefore, it is better not to save money and buy a new pump. It will be much more reliable than a refurbished pump.

It is very important to install it correctly in its original place. Particular attention is paid to seals and proper tightening of fasteners. In some cases, a special sealant is used for joints. Eliminates leakage. However, it is not always possible to use the presented material. This will prevent you from later loosening the engine mounts to secure the timing belt on some car models.

If you know the signs of a bad pump, you can replace it on time. First you need to remove the cover from the timing belt. If necessary, the tensioner will need to be loosened and removed. Then reduce the mounting force on the generator. Its belts and timing belt have been removed. The hose from the pump can be disconnected. Then the antifreeze is drained. After this, you can remove the protective cover and pump.

After installing the new pump in place, align the alignment marks. This is necessary because the crankshaft can move relative to the camshaft.

In what cases is repair possible?

Repair is a procedure that is not always advisable. This is explained by the fact that the product itself for most models is not expensive at all. That is, it is easier to buy a new pump than to waste time and effort on repairing the old one.

Repair is not recommended on those models where it is driven by a hydraulic timing belt. The fact is that after repair the part may not be as reliable as a new product, which will affect the production of the belt.

Any repair work that is in principle possible is based on replacing the oil seal, bearing or impeller. These consumables are freely available and cost pennies. However, it is still more advisable to completely replace the pump than to repair it. This is due to the fact that access to this unit on some cars involves using an inspection hole and unscrewing the engine mounts. That is, for the sake of minor repairs it is necessary to carry out rather complex preparatory work. Therefore, it is easier for car owners to immediately install a new pump.

In this case, repair is not advisable, since the bearing is badly damaged and the pump rod has begun to play.

Other verification methods

First you need to remove the plastic cover and the timing belt cover. To remove the upper parts that separate the pulleys from the cylinder block, follow these steps in sequence. This is only possible after removing the camshaft timing belt and pulleys (sprockets and support pulley). Only after this can the pump be disassembled.

To gain access to the bottom cover mounting bolts, remove the right wheel. The pump can then be disassembled. Then follow the same steps as in the previous step. If the pump is installed incorrectly, it will leak. Therefore, it is important to follow the manufacturer's instructions.

Malfunctions in the operation of the pump occur, significant play on its shaft, failure of the seal, wear of the impeller (corrosion or cracking). All these shortcomings lead to the fact that the water pump in the car does not work properly, due to which the engine cooling system does not maintain the required pressure, which in turn leads to an increase in the temperature of the coolant to the boiling point. . You need to buy a new pump and install it in place of the old one.

There are only six main symptoms of a “dying” pump, by which we can say that the pump has partially (or even completely) failed and requires replacement. So, these symptoms include:

Do-it-yourself pump replacement on VAZ cars

As mentioned above, the replacement procedure will look different on different car models. This is due to the location of the unit in the engine compartment and the design of the car itself. The easiest way to perform the replacement is on VAZ cars.

To replace the pump you only need wrenches

The replacement procedure is as follows:

Wait until the engine cools down. It is prohibited to carry out work immediately after stopping the engine, as you may get burned.

Prepare a set of wrenches and a container to drain the old coolant. It is necessary to change the pump together with antifreeze (antifreeze), since the old liquid gradually loses its cooling properties during use.

Unscrew the antifreeze drain plug (the plug is located on the engine block). After this, unscrew the cap on the radiator to quickly get rid of the old fluid. Place containers under the drain points.

When the antifreeze (antifreeze) stops dripping, loosen the generator belt tension rack. After this, remove the belt, since otherwise it will be impossible to get close to the pump.

Preparing the tools

Regardless of what specific problem arose on your car, the only solution to fix it is to replace the pump. This work on a VAZ 2114, VAZ 2115 can be done independently, since the convenient design of the machine makes it possible to carry out all stages of work without special skills.

First you will need to prepare a simple tool:

- wrenches 10, 17 and 19;

- socket head 10;

- flat screwdriver with a thin blade.

Without this tubular socket wrench it will be impossible to unscrew the hard-to-reach bolts on the pump mount

Possible problems after replacement

Unfortunately, behind the apparent ease of removing and installing the pump, several problems can be hidden. For example, the pump is very sensitive to tightening - as soon as you twist the bolts a little, the gasket is squeezed out. Many such nuances may arise after replacement.

There was a noise

Noise and whistling sounds from the pump while driving are the most common problem after replacement. There may be several reasons for new sounds:

the bolts are tightened too tightly;

If noise does not affect the performance of the cooling system in any way, that is, fluid circulation is carried out normally, then the part does not need to be changed.

The stove began to heat poorly

If, after replacement, the stove in the cabin began to produce slightly warm air or stopped heating altogether, then there is an air lock in the cooling system. It is necessary to warm up the car to operating temperature and sharply accelerate it - as a rule, these measures are enough for the traffic jam to be overcome and the heater to work as usual.

Also, problems with “heating” can arise due to the fact that the impeller blades on the new part have a slightly different gap. It is impossible to solve this problem, so it is recommended that you initially select a pump from the same manufacturer as the old product, with identical markings.

It is recommended to give it a good throttle to break through the air lock.

Good night! a couple of days ago I changed the pump on the Hunter 409 engine, and the heater at idle began to blow slightly warm air, when you put it on the gas and keep it at rpm it starts blowing hot, the temperature floats from 80 to about 100 when the idle is about 100 at rpm it drops to 80. When the old pump was standing, it was hot in the cabin in the cold, but it rattled, the impeller on the old one was like a textolite round one in the middle with slots like a spiral, and on the new one the impeller was like blades. Due to the difference in the impellers, can the fluid be driven worse? and it seems like they write that since 2007, only impellers have been installed on pumps, or what about blades?

Chink

https://forum.uazbuka.ru/archive/index.php/t-124342.html

The motor gets very hot

Engine overheating can only be associated with poor performance of the cooling system. Consequently, if after replacement the engine begins to get very hot, the pump does not perform its functions or works “at half strength.” Immediate replacement is recommended.

Is it possible to drive if the pump is jammed?

Many car owners are concerned about the question: is it even possible to operate the car if the pump does not work? And if so, what is the best way to drive?

The whole thing comes down to two components:

How necessary is it to use the car?

Of course, if the pump is jammed, the circulation of antifreeze in the system will be disrupted. Accordingly, the engine can only be cooled naturally. Therefore, it is better not to start the car, since overheating of the engine brings certain death to your four-wheeled friend. However, it is allowed to drive a faulty car if it is cold outside. The engine is less susceptible to overheating, but you should avoid traffic lights and forced stops, as the engine heats up faster due to changes in the number of revolutions.

That is, most problems with the pump can be solved on your own. With the affordable cost of this pump, you can change the pump immediately when necessary. However, experienced drivers do not make a replacement until the product begins to act up. Practice shows that the pump's service life is much higher than stated by the manufacturer. Therefore, you don’t have to worry about repairs and replacements if the cooling system is operating normally.

Hi all! I think each of you knows how big a role the engine cooling system plays in any car with an internal combustion engine. In this case, one of the elements of the system is a water pump or simply a pump. The car owner is obliged to know the signs of a pump malfunction in order to diagnose them in time and prevent engine overheating with all the ensuing consequences.

If the pump fails for any reason, the consequences for the engine can be catastrophic. Moreover, capital, that is, major repairs, will not always allow you to get out of the most difficult situation.

The main problem is that the water pump does not immediately indicate the presence of a malfunction. Not in all situations a breakdown can be detected quickly enough. Basically, the driver learns about the problem when thick smoke comes out of the engine compartment. Although this can be avoided. I'll try to tell you exactly how.

Precautions in case of breakdown

Under no circumstances should you start the engine or drive anywhere if the pump is already broken. Otherwise, there is a 90 percent chance that the engine will boil, and this can lead to very serious consequences and enormous costs.

If you have already noticed the above signs and are planning to go to a service center for diagnostics and repairs, but have doubts about the condition of the pump, there is a great way to check whether the engine can be started. Open the hood, remove the drive belt and try to turn the rotating pulley. If it dangles or turns easily, this means that you should under no circumstances go to the service station yourself; it’s better to call a tow truck, it will be cheaper.

Also, if the pump breaks down, you should pay attention to one more detail, this is the condition of the drainage hole.

After all, it often happens that when noticing signs of a pump malfunction, you just have to stick your finger into the very bottom of the mechanism. If you feel droplets of liquid there, it means the seal inside has worn out, and then the situation will only get worse and there will be a risk of failure of the entire engine.

Coolant leakage can be detected in another way by placing sheets of paper, preferably white, under the car. Leave the paper overnight, and in the morning if you find wet spots on it, you can be sure that it is time to replace the pump. And in general, according to the rules, this element of the cooling system should be checked, and if possible changed, every 70-80 thousand kilometers, then your car’s engine is not in danger of overheating.

Main reasons

Before talking about the signs of a dying pump that needs replacement or repair, you need to say a few words regarding the reasons for the failure of this device.

In total, there are several main factors that cause this to happen:

- Using low quality antifreeze. About 90% of pumps break down precisely because of this. Such a cooling liquid contributes to the appearance of tarry deposits, which makes the impeller difficult to rotate;

- Corrosion. Again due to low-grade antifreeze;

- Cavitation, that is, the formation of vacuum bubbles that can literally tear out pump particles and destroy the mechanism;

- The result of normal wear and tear. Each device has a limited resource. The best samples last about 200 thousand kilometers;

- Broken fastening. It's simple. The fasteners became loose, the pump became loose and fell apart.

Rust, deposits

Symptoms of failure of the VAZ-2110, 2114 or other car models may be different. Upon external inspection of the pump, rust is visible. The most common corrosion is on the impeller blades. This leads to a decrease in the rate of pumping antifreeze into the system. The cause of rust may be contaminated coolant or a compound that is incompatible with the pump. Mixing different antifreezes can also lead to this problem.

Another cause of rust on the pump is damage to the pump cover. In this case, it will not be able to close hermetically. Due to this, air bubbles appear in the composition, which causes oxidation processes.

In this case, the pump will need to be replaced. The cooling system must be thoroughly flushed and new antifreeze added. It is necessary to check the tightness of the cap. You may need to replace it.

The pump should also be replaced if deposits have formed on the inside of the pump. Such signs of a malfunction of a pump 2114, 2110 or another model can only be determined by visual inspection of the system. Deposits of resin, minerals or other substances appear on the internal surfaces of the pump. They clog the pump, preventing the system from working properly.

The cause of this malfunction is contaminated antifreeze or the use of the wrong composition. The system must be thoroughly rinsed with special mixtures. The pump has been replaced and new high-quality antifreeze is added.

Signs of trouble

I would like to immediately note that in order to determine faults in the water pump, you will need to remove the unit and disassemble it. Only this method provides a real opportunity to see the resulting traces of corrosion, signs of cavitation and contamination.

Practice clearly shows that this happens on a wide variety of machines:

- VAZ 2107;

- Volkswagen Passat;

- FF2, that is, Ford Focus 2nd generation;

- Lada Granta;

- Kia Spectra;

- Chevrolet Aveo;

- Audi A5;

- Nissan Qashqai;

- Mitsubishi Outlander;

- Toyota Camry;

- Skoda Octavia, etc.

Moreover, the situation is approximately the same everywhere. That is, it is impossible to determine whether there are problems without disassembling and looking inside the cooling system water pump.

Therefore, the main emphasis is on indirect signs. With their help, the driver gets the opportunity to diagnose the problem in advance and prevent serious consequences.

The following indirect signs are distinguished:

- A thin whistle appears without interruption during engine operation. Moreover, it comes from the area of the camshaft pulley of the internal combustion engine. A whistle indicates that a higher bearing is failing;

- Coolant leaks. Traces of antifreeze can be seen directly on the power unit, or under the bottom of the car, that is, on the asphalt;

- Pump play. To check for its presence, simply grab the pump pulley with your hand and try to swing the device up and down.

Do not forget about the possible airing of the system, due to which the antifreeze does not fully perform its functions, the engine overheats and a number of resulting breakdowns occur. Here it would be correct to remind you about removing the air lock from the cooling system. Also, be sure to read the material about checking the cap of the expansion tank, which is directly related to the engine cooling system.

I won't talk about how the pump changes. Usually replacement is carried out according to the owner's manual from the car manufacturer. The point is to drain the cooling liquid, disconnect the pipes, first turn off the power to the car, and dismantle the problem unit.

The design and location of all pumps are different, therefore there is no universal instruction. You can find a video online, or simply take the car to a car service center.

Final stage

And at the end of this epic there will be installation of the generator belt and pouring antifreeze into the system. If everything with the belt is extremely clear and simple, then with refueling several questions may arise. One of the main ones is how many liters of antifreeze are in the VAZ 2107, what is the volume of the cooling system?

This question is often of interest to drivers, since they need to know which canister of liquid to buy in the store. Take 10 liters, this will be enough, there will even be a lot left for refilling. The price of a canister of antifreeze of this volume will be about 800 rubles. But the price of a liquid called “antifreeze” (green or red) is one hundred rubles more expensive.

And now let’s talk about how to properly fill fluid into a VAZ 2107. In particular, this guide will help you if you are having an emergency or scheduled fluid change. So, it is advisable to install the car correctly - the front part is slightly raised.

This is done so that the heater radiator is lower than all other elements of the system. Disconnect the thin tube from the carburetor or throttle body (if you have an injector). It comes from the pump and is necessary to warm up the throttle assembly or carburetor body.

Open the cap on the radiator and expansion tank, making sure that the drain plugs are in place and tightened. That's it, you can start pouring antifreeze into the radiator. If it's uncomfortable, use a watering can. How many liters of antifreeze a VAZ 2107 will fit at this stage is impossible to say for sure. But three to five liters should definitely fit.

Take your time, let the liquid drain slowly. Squeeze the pipes with your hands to expel as much air as possible. When the liquid stops leaving, you need to close the filler neck, pour antifreeze into the expansion tank and start the engine.

Warm up the engine to operating temperature and, if necessary, add antifreeze to the expansion tank. Put on a thick cloth glove and carefully crimp the pipes. Air should escape into the tank. When the antifreeze comes out of the tube that you disconnected from the throttle, you need to put it back in place.

This indicates that the liquid has entered all corners of the system. Only traffic jams remain relevant. You can get rid of them if you carefully tighten the pipes with the engine running and warm.

That's all, now the VAZ 2107 pump does not leak, the system is pumped and free of air pockets. Now not only will the cooling be ideal, but the heater will also start working at maximum efficiency. And for winter this is the most important factor.

Replacement cost

Not everyone takes on a water pump with their own hands if it must be replaced. They prefer to go to service centers or just some garage-type workshops, where prices are usually lower.

It is important to note that the cost of replacement directly depends on the car make, model and availability of the spare part itself. In some cases, replacement is carried out in literally 20 minutes. In other situations, craftsmen spend several hours. Moreover, most of the time is spent on getting to the pump and removing it.

All this has led to the fact that price tags vary greatly, depending on certain conditions and circumstances. In one case, you will pay about 1000 rubles. In another you will have to pay 5-6 thousand. And this does not take into account the cost of the newest pump for your car.

Should I change antifreeze after replacing the pump?

A question for those who want to save money everywhere and on everything. If I answer this briefly, I can confidently say that yes, the coolant needs to be changed. Please also pay attention to the question regarding mixing antifreeze in the cooling system. It will be useful and important to know all the nuances.

If we talk about the necessity of replacement, then everything is extremely simple. To begin with, in the vast majority of cases it is impossible to replace and remove the pump without first draining the antifreeze from the system. But some people want to save money; they drain the coolant into a clean container, install a new pump, and then pour the old antifreeze back in.

A big mistake, since any water pumps for cooling systems are characterized by increased demands on the quality and purity of the liquid. Therefore, you should absolutely not use previously drained antifreeze, even if you just recently changed it, even before the pump failed. Do not attempt to filter or strain the coolant. Just buy a new can of quality antifreeze that is suitable for your car and fill it up. There simply cannot be any other options. Remember this. Otherwise, you will soon have to spend money on a new pump again.

To ensure that the water pump lasts as long and reliably as possible, make it a rule to use only high-quality compounds. As you remember, 90% of pump failures are related precisely to the quality of the coolant used. I think it will not be difficult to draw the appropriate conclusions.

Have you encountered a water pump failure and how early were you able to identify the presence of malfunctions?

Thanks to everyone who reads us! Don't forget to leave comments, ask questions and invite your friends to join us!

( 1 ratings, average: 5.00 out of 5)

Did you like the article?

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

Fluid leaking from the drain hole or from under the seating surface

There may be various symptoms of pump failure for VAZ-2109, 2107, 2114 and other car models. So if the coolant was of poor quality, there may be a leak in the drain hole area. In this case, leakage occurs, the formation of drops after the car is broken in. This can be determined by looking at the surface of the drain hole. Please note that a small leak in a new pump is normal. This happens during the first 10 minutes of engine operation. This is because the mechanical seal moves to the correct position.

If a new pump has a break-in period. If the pump is not operating properly but fluid continues to flow from the drain port, the pump is damaged. It is necessary to thoroughly flush the cooling system and install a new pump. Then you need to fill in the required amount of new antifreeze of acceptable quality.

If there is leakage from under the seating surface, this also indicates a malfunction. In this case, a sign of failure of the VAZ-2107, 2110, 2109 or other models is humidity, the appearance of drops, drops on the body or around a certain area. The cause of such a breakdown is incorrect installation of the pump or incorrect use of sealants and gaskets.

If the pump is new, remove it and check that it is installed correctly. It is especially important to pay attention to the tightening torques. If the pump is already old, it needs to be replaced.