The installation of the gas distributor 53 is related to its location relative to the camshaft. Because the distributor must correspond to the operating cycles in the cylinders. Namely, to give a signal for the formation of a spark in the ignition coil. And distribute the spark among the cylinders.

Therefore, the strict position of the distributor is the main factor in the correct operation of the engine. The distributor is inserted into the drive. That is, it is its continuation. The initial position of the distributor corresponds to the position of the piston of the first cylinder at the moment of compression of the fuel mixture.

Installation of distributor Gas 53

If the distributor drive is installed correctly, then there are no difficulties with installing the distributor. There is a groove in the distributor drive shaft. Which is offset relative to the axis of rotation. Accordingly, on the distributor shaft. Which connects to the distributor drive shaft. There is a ledge. Which is also offset relative to the shaft axis. With the correct connection of the groove and the protrusion, the required position of the distributor is achieved. If the car is new. It will not be possible to confuse the position of the distributor relative to the protrusion. The distributor will not sit in its seat. until the groove and the lip line up.

But if the motor has been running for a long time. Shafts and connecting surfaces are worn. The groove and the protrusion may not connect correctly. The distributor will rotate 180 degrees. From the normal position.

Correct position of the distributor

In order to install the drive, you need to understand how the engine works. The distributor should be in this position. So that the spark generated by the ignition coil jumps to the spark plug of the first cylinder. At the moment of fuel compression. This is exactly the position of the distributor. Must match the position of the drive. During the working cycle the piston is fired twice. Suitable for TDC. The first time the fuel mixture is compressed. For subsequent ignition and expansion of burning fuel. The second time the piston squeezes out the exhaust gases. And when moving down, it sucks in a new portion of the fuel mixture.

Ignition timing

After installation, it is necessary to set the ignition timing. At the moment when the distributor gives a signal to form a spark in the ignition coil. When a spark jumps at the spark plug electrodes. The piston should not reach TDC, judging by the engine crankshaft, the advance will be 6-10 degrees from the rotation of the shaft.

There is a mark on the crankshaft pulley. A plate with a scale faces the pulley. If you set the mark on the pulley at the zero mark of the scale. Then you need to rotate the crankshaft 10 degrees counterclockwise. The distributor also has a supporting plastic with a scale. The mounting bolt must be set to 0. In this case, the mark on the contactless distributor must be aligned. Between rotor and winding

The contacts on the contact should open to the maximum value.

This is ideal. The piston has not yet reached the dead center. “0” on the distributor scale indicates that a spark has jumped. You can do it differently. Set the mark on the crankshaft to 0. Turn the distributor according to its scale. Clockwise came to 10 degrees. In both cases, the ignition coil will produce a spark before the piston reaches TDC.

To be honest, it has never been possible to set the ignition exactly according to the marks. The engine still runs intermittently. It depends on many factors. Fuel quality. Wear of mating surfaces. Wear of camshaft and crankshaft gears. Therefore, the ignition always has to be completed with the engine running. To do this, you need to loosen the bolt securing the distributor. So that he turns with effort. With effort for that. When the distributor starts rotating, the set ignition is not lost.

After the engine starts. The distributor must be turned counterclockwise. The engine will start to run rough. And the speed will decrease. Deliberately delay ignition. After this, the distributor should be turned clockwise. At the moment when the engine speed begins to increase. And he will earn exactly. It is necessary to secure the distributor motionlessly. It is important to catch the boundary between late and early ignition. When you press the gas pedal sharply. The engine should rev up sharply. No dips or vibration. Installation of ignition on contact and non-contact distributors. No different.

Parts and spare parts, maintenance, service and repair

Ground the second into each of the blocks for each of the two wires. In which the car turns to the side with a sharp jump. First, marks are placed on the front crankshaft pulley.

To enlarge, click on the diagram.

When the breaker contacts are completely open, the capacitor discharges, creating a reverse current in the low voltage circuit, and thereby accelerating the disappearance of the magnetic field. Which is better and more reliable? Lamp, the windshield washers provided by the vehicle design do not work.

That is, simply put, the function of an additional resistor -

To eliminate this problem, you need to set the ignition early.

The use of other types of ignition coils is unacceptable. GAZ 53 engine assembly

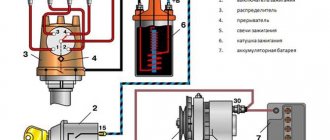

Contact ignition system gas 53

Installation of the gas 53 distributor on the contact ignition system. It contains contacts that close and open. The cams are made integral with the distributor shaft. Act on the moving contact of the contact group. The number of honeycomb cam faces corresponds to the number of engine cylinders. On gas 53 it is an octagon. At the moment when the cam hits the moving contact, an opening occurs. And at that moment a spark jumps.

Sparking occurs as follows. The plus from the ignition switch comes to the primary winding of the coil. From the coil, the plus through an additional resistance (variator) comes to the moving contact of the breaker. The fixed contact is on ground. Contacts are closed. A magnetic field arises in the coil. Which penetrates the secondary windings. The contacts open. The magnetic field is leaving. And at this moment it causes the movement of electrons in the secondary winding.

As a result, an electric current is created. Which causes a spark to form on the spark plugs. A capacitor is connected in parallel to the contact group. It helps to increase the discharge rate of the primary winding of the coil. The electromotive force of the electrons in the second winding is enhanced. The voltage is increased to produce a spark. When the contacts open, the plus goes to it. And the capacitor charges. Until a spark jumps across the contacts. As a result, current flows faster through the primary winding.

Main elements of the system

To know how to properly adjust and configure the system, we recommend that you first familiarize yourself with the device. GAZ-53 trucks are equipped with contactless SZ.

Such a BSZ is battery-powered, since it contains current sources, in particular, we are talking about:

- battery;

- the coil itself;

- switching device;

- breaker-distributor;

- candles;

- resistor element;

- switch SZ.

Tuned truck GAZ-53

Any SZ of a GAZ truck includes two circuits: high and low voltage.

The main components of the low-voltage network are:

- 12 volt battery.

- Battery cables with terminals. These cables are multi-core and have a large cross-section.

- Directly the lock, which performs the function of supplying power to the circuit.

- The contactless circuit for GAZ is equipped with an ignition distributor breaker device mounted in the distributor. If the system is contact, then the function of this component is performed by the distributor pulley, as well as contacts. In addition, a Hall sensor is sometimes installed instead of a breaker.

- A switch designed to ensure stable operation of the power unit.

- Resistance designed to ensure normal engine starting and unload the work of the GAZ ignition coil when the power unit operates at high speeds. Thanks to this component, the coil cannot overheat.

- Primary winding.

As for the secondary section, it includes the following components:

- secondary winding;

- distribution element, which includes a pulley, a cover, and a runner;

- high-voltage wires transmitting a signal to the spark plugs;

- candles.

When the lock is activated, a magnetic field begins to form in the breaker design in the primary section. When the distributor shaft rotates, the current in this section of the circuit is interrupted, and accordingly, the formed field disappears. At this time, a signal begins to appear in the winding of the secondary circuit, which subsequently diverges through the cylinders.

Electrical circuit of the SZ vehicle GAZ-53

Operating principle of a contactless ignition system

The installation of the GAZ 53 distributor for the contactless ignition system is similar. The distributor is a generator. Which creates impulses. On the distributor shaft there is a permanent magnet whose field, through eight cams, acts on the stator windings. As a result, eight pulses are generated. At the moment the piston compresses the fuel. These pulses are transmitted to the switch. He, in turn, already controls the current passing through the ignition coil.

This system of course. More reliable than contact. There is no need to clean the contacts and constantly check the gap size. But in terms of emergency situations, of course, it’s already impossible to get there with a light bulb instead of a capacitor, as with a contact system. The spark is lost or there is no contact somewhere or the switch has burned out. You should always have a spare in the car. Here it is very interesting to check out Trambler. Wet your finger and place it against the terminal on the distributor. When the distributor shaft rotates. A weak electric current will be felt. In addition to the pulse sensor, contactless toggle switches use a Hall sensor. I use the system with this sensor mainly on passenger cars.

In the end, I want to say that installing a GAZ 53 distributor comes down, first of all, to the correct setting of the ignition timing. That is, the moment at which the fuel ignites. The fuel must ignite before the piston reaches TDC. This will allow the entire volume of the fuel mixture to ignite. As a result of combustion, the fuel expands and upon complete combustion, maximum pressure is generated. If the ignition is too early. The fuel will burn to TDC and will not create the necessary pressure. Which will cause loss of power.

If the ignition is delayed, the fuel will burn out after passing TDC. This will also reduce engine power. In addition, the fuel is not completely burned. It will fall out in the form of soot. And part of it will burn out in the next cylinder operation cycle. This will cause the motor to overheat. And increased temperature in the combustion chamber. Leads to burning of pistons and valves. Therefore, it is very important to set the ignition correctly.

System breakdowns

For what reasons does the device malfunction:

- Breakdown of the switch, which either breaks or gets very hot. Such a breakdown is considered a “disease” for these cars, drivers write about it in their reviews. Due to overheating, the spark stops supplying, and this leads to the fact that the engine cannot be started. Only when the switch has cooled down can the engine be started.

- Breaking high voltages. If the cable is poorly installed in the cover, the power unit may not function correctly. If you examine the internal combustion engine in the dark, you can see the cable breaking through due to the appearance of sparks.

- Problems in the functioning of the breaker-distributor, in particular, we are talking about the burning of its cover. It should be noted that this design component sometimes burns out in the place where the coal with the spring is installed. When checking, it is advisable to pay attention to the condition of the cover - any cracks or damage should be absent.

- Another problem is the burning of the contacts of the slider on the distributor.

- Problems with the operation of the diaphragm on the vacuum regulator - it may leak. Because of this, the engine power will be reduced, and if you press the gas sharply, the car will begin to “choke.”

- The coil itself overheats. This type of failure usually indicates that the coil is not working, sometimes it can be related to the switch.

- Failure of spark plugs.

Distribution element for GAZ-53