Vehicle weights

The actual weight of the car is 1045 kilograms. The main units of the “six” have the following weight:

- 140 kilograms - engine with equipment (starter, generator, carburetor, etc.);

- 26 kilograms - gearbox;

- 10 kilograms - square shaft;

- 52 kilograms - rear gearbox;

- 7 kilograms - radiator grille;

- 280 kilograms - car body.

It is noticeable that the body is the heaviest structural unit of the car. It weighs as much as two engines with all the components. The remaining mass of 530 kilograms is scattered between interior trim parts, wheels, fuel lines, brake lines and other things, the discrepancy in mass of which does not reach such large values.

An interesting fact is that according to all the norms and standards of the Soviet economy, the “six”, having an actual weight of 1045 kilograms, fell into the category of small class vehicles, but at the same time, thanks to the engine capacity of the VAZ 2106, it was a full member of group number three.

Main characteristics of the “six”

VAZ 2106 is considered a Soviet and Russian car, produced in the period 1975-2005. The car was manufactured and produced at VAZ, but already in 1998 some production facilities were moved to Syzran and Kherson. In 2002, the “six” was assembled at IzhAvto, where the last model of the legendary car was left on the assembly line.

It will be interesting to know: in total, over 4,300 million VAZ 2106 units have been produced in the entire history of the automotive industry at various factories.

The “Six” was also produced in several modifications. Regarding the body, the following noteworthy points can be made:

- The modification of the VAZ 21061, intended for sale in Canada, had a completely different body installed. This one had special aluminum bumpers and fangs. The bumper also had trims and ends made of black plastic;

- The VAZ 21063 body was equipped with “five” bumpers;

- The body of 21065 was also equipped with aluminum bumpers, and some of the cars going for export were generally modified;

- The VAZ 2121 was equipped with a body with the same bumpers as on the export 21061, only without sidelights.

Symptoms of a problem

As soon as the driver notices any changes in the operation of the rear axle (for example, extraneous sounds appear that were not there before), he must respond to these changes as quickly as possible so as not to aggravate the possible malfunction. The most typical sign of such problems may be increased noise levels:

- coming from the rear wheels;

- during operation of the rear axle;

- when accelerating the car;

- when braking with the engine;

- during engine acceleration and braking;

- while the vehicle is turning.

In addition, a knocking sound when the car starts moving and an oil leak may indicate a malfunction of the rear axle.

Oil leakage indicates a malfunction of the rear axle of the VAZ 2107

Grinding noise when moving

The causes of a grinding noise from the rear axle when the vehicle is moving can be:

- wear or destruction of axle or differential bearings;

- deformation of the beam or axle shafts;

- incorrect adjustment, damage or wear of gears or bearings of the gearbox and differential;

- wear of the spline connection with the semi-axial gears;

- incorrect adjustment of the gear teeth of the main gear;

- insufficient amount of oil.

The cardan spins, but the car does not move

If the driveshaft rotates while the vehicle is stationary, the cause may be a failed axle spline or wear on the teeth of the differential or final drive gears. In any case, if the cardan spins, but the car does not move, this indicates a fairly serious breakdown and, most likely, replacement of the axle shafts, bearings or gears will be required.

Oil leakage from the housing and from the shank side

The most likely causes of oil leakage from the rear axle housing:

- wear or damage to the drive gear seal;

- wear of the axle shaft seal, determined by oiling of the brake shields, drums and pads;

- loosening the bolts securing the rear axle gearbox housing;

- damage to sealing gaskets;

- axial play of the shank;

- breather jamming.

Wheels are stuck and won't rotate

If the rear wheels are jammed, but the drum and pads are in order, the cause of this malfunction may be failure of the bearings or the axle shaft itself. Most likely, in this case, the bearings have crumbled or the axle shaft has become deformed (for example, due to an impact) and the parts need to be replaced.

Important nuances in work

- When driving the oil seal using a mandrel, do not overdo it. Apply gentle blows and control the depth of the oil seal. If you hit it hard, you can easily damage the oil seal;

- Before installing the oil seal, lubricate the rim and sealing edge with fresh oil;

- Before installation, inspect the flange for wear in the area where the sealing lip of the oil seal meets. If there is a “groove,” the flange must be replaced.

As you can see, the process of replacing the VAZ 2107 gearbox seal is quite simple and does not take much time. The most important thing in this job is to properly tighten the rear axle flange nut.

Replacing the rear axle of a VAZ 2106

When it is necessary to replace the rear axle of a vehicle such as a VAZ 2106, you will need to acquire special tools for working with this unit. A standard driver kit is provided for this. In this case, you cannot do without a liquid intended for degreasing surfaces. So, experts recommend using white spirit and gasoline.

In order to dismantle the rear axle, you must:

- install the car using a pneumatic lift (repairs can also be performed on an overpass or by driving the vehicle into a deep pit intended for inspection);

- drain the engine fluid into a container and disconnect the universal joint with a part such as the flange mount of the shank;

- dismantle the axle shaft of the humming rear axle, unscrew the fastening element, align the rear axle gearbox with its beam;

- replace the unit, make adjustments if necessary, check the unit for operability;

- clean the structural elements of the unit, degrease the oil seal and bearings, fastening components;

- connect the gearbox to the rear beam of the vehicle and, using the cross technique, tighten the fasteners.

- pour motor fluid into the unit.

Oil seal replacement process

First you will need to arm yourself with the necessary tools. In particular, you need to prepare:

- flat screwdriver;

- calipers;

- a regular mount or some convenient strong metal rod;

- keys for 13 and 24;

- torque wrench;

- dynamometer;

- durable cord.

On a VAZ 2106, the rear axle oil seal is replaced after the oil is drained from the crankcase. In this case, you must not forget about the oil drain cap, which should be screwed into place.

Removing the axle shafts

Let's get started:

both rear axle shafts will need to be removed from the rear axle beam.

To do everything correctly, you need to strictly follow the instructions. So:

- dismantle the wheel;

- remove the brake drum;

- we see four nuts that will need to be unscrewed (to avoid problems, you will need to turn the axle shaft until the large diameter holes coincide with the two brake shield locking nuts):

- unscrew the nuts;

- remove the spring washers;

- turn the axle flange 90 degrees so that the large-diameter holes and the brake shield mounting nuts coincide;

- We secure the brake drum with two wheel bolts (you can tighten them by hand).

Note. These wheel bolts do not need to be tightened, leaving approximately 5 mm to ensure acceleration of the drum. But you need to be extremely careful not to damage the brake drum.

The axle shaft is abruptly removed from the rear axle beam.

Advice. There is a special impact puller that will allow you to remove the axle shaft much faster.

Special impact puller for removing axle shafts

Removing the old cuff

After both axle shafts have come out, you need to do the following:

- holding the cardan from turning with a pry bar (see Repairing the cardan on your own) from turning, unscrew the four nuts securing the hinge flange;

- remove the bolts;

Replacing the rear axle oil seal on a VAZ 2106

- disconnect the flanges using a flat-head screwdriver;

- now you need to wind a strong cord, which was stored in advance, onto the flange of the drive gear (when winding it, you need to make several turns and wind it);

- We use a dynamometer to check the moment of resistance to turning or the RPM of the drive gear (this value must be remembered or written down).

Note. MSP is the product of the dynamometer readings, expressed in kgf, and the force application lever, expressed in cm.

- Now you will need to unscrew the flange mounting nut, holding the drive gear with a special wrench;

- remove the flat washer.

Advice. There is a special wrench to hold the pinion flange. You can even make it yourself from a piece of metal pipe of the required size and two bolts and nuts.

Homemade key for holding the pinion flange

Replacement of the oil seal in the rear axle of the VAZ 2106 continues:

- the drive gear flange is removed;

- we find the drive gear oil seal and remove it from the neck using a screwdriver;

- install a new cuff.

Installation

Note. Before installing a new oil seal, you need to lubricate its working edge with Litol-24.

Light blows with a hammer through a special frame will help to correctly install the oil seal in place.

It is recommended to watch this video, where everything is described in detail.

https://youtube.com/watch?v=_MHYhEGwT84

Note. It must be remembered that the new oil seal should be pressed into the gearbox housing to a depth of 2 mm, counting from the end of the gearbox housing. As a mandrel, you can use some old bearing, or rather its ring, or even a piece of pipe of a suitable size and diameter.

- put the drive gear flange in place;

- put the required washer;

- tighten the flange mounting nut, while holding the drive gear with a special wrench.

Note. The tightening torque of the nut must be equal to a certain value depending on the resistance torque of the drive gear. When tightening the nut, you should start with a smaller torque and periodically check the resistance torque. If, at the moment of tightening the nut, it is discovered that the moment of resistance is too excessive, then this indicates unacceptable deformation. You will have to replace the bushing by disassembling the gearbox and then adjusting the engagement of the main gears. It will be difficult to carry out such work on your own; a highly qualified specialist is needed.

We assemble all the components and parts in reverse order.

The oil seal replacement process is complete. During the process, you should try to compare the methods for dismantling and installing a new oil seal with photos and diagrams. It is not difficult to carry out this operation with your own hands; it will be enough to follow the advice and notes given in the instructions. Replacing it yourself will help you avoid unnecessary expenses and save a lot of time, because at good car services there is now a long queue and the price of services is high.

Rear gear ratios of other cars

The gearboxes of VAZ cars are more or less clear. What about other cars? For example, the Gorky Automobile Plant has a large number of modern models of both medium-duty and passenger trucks. The most popular GAZ models are the Gazelle GAZ-3302 and Sobol GAZ-2752. If we do not consider all-wheel drive modifications of these cars, then the rear gear ratio will be either 5.125, or 4.556, or 4.3.

The highest-torque gearbox went to GAZ vehicles with ZMZ406 and ZMZ402 engines. It has the best power characteristics and is recommended for car owners transporting heavy loads and working in harsh conditions. A gearbox with a lower number will give greater dynamics, like a faster one. In this case, a relatively shorter service life should be noted.

To complete the picture, let’s consider foreign versions of gearboxes and their numbers. A good option for comparison would be the rear-wheel drive models of the German auto giant BMW. BMW gear ratios range from 3.07 to 4.1. Moreover, the number of unit models exceeds ten. Just from this indicator you can understand how often foreign designers make changes to car components.

The most dynamic gearbox with a number of 3.07 is found in models of the E90, E91 and E92 series. If we look at powerful options, we can highlight the BMW X5 with a 3-liter engine, which has a rear gear ratio of 4.1.

Rear suspension device for VAZ 2101, 2102

1 – spacer sleeve; 2 – rubber bushing; 3 – lower longitudinal rod; 4 – lower insulating gasket of the spring; 5 – lower spring support cup; 6 – suspension compression stroke buffer; 7 – bolt for fastening the upper longitudinal rod; 8 – bracket for fastening the upper longitudinal rod; 9 – suspension spring; 10 – upper spring cup; 11 – upper insulating gasket of the spring; 12 – spring support cup; 13 – rod of the rear brake pressure regulator drive lever; 14 – rubber bushing of the shock absorber eye; 15 – shock absorber mounting bracket; 16 – additional buffer for suspension compression travel; 17 – upper longitudinal rod; 18 – bracket for fastening the lower longitudinal rod; 19 – bracket for fastening the transverse rod to the body; 20 – rear brake pressure regulator; 21 – shock absorber; 22 – transverse rod; 23 – pressure regulator drive lever; 24 – holder of the lever support sleeve; 25 – lever support sleeve; 26 – washer; 27 – spacer bushing The rear suspension of the VAZ 2101, 2102 car is dependent, includes a guide device, elastic elements and devices that dampen vibrations.

A little anatomy

In the last years of its life on the AvtoVAZ assembly line, the classic Zhiguli remained perhaps the only passenger car in the world with a rigid drive axle. This design is simple and technologically advanced in production, but has serious disadvantages in operation:

- large unsprung mass of the bridge, which negatively affects the smoothness of the vehicle;

- tendency to steer when one of the wheels hits an obstacle - at this time, due to the misalignment of the bridge, both wheels tilt from the vertical and tend to roll in the direction of the tilt;

- reduction in the useful volume of the trunk, because there must be free space between the axle and the car body for the axle to move during the compression of the suspension.

The advantage of a rigid axle, in addition to manufacturability, is its better adaptability to bad roads: the ground clearance under the axle practically does not change depending on the load, and the wheel drive is reliably protected from external influences by the axle housing.

The Zhiguli bridge consists of a stamped-welded bridge beam (such beams are called “Banjo” for their characteristic shape), a main gearbox with a differential, and axle shafts. The gearbox is made in a separate open housing, the flange of which is bolted to the crankcase. A drive gear with a driveshaft mounting flange and a differential with a driven wheel are mounted in the housing on bevel bearings. The main gears are hypoid, that is, their axes are located at an angle of 90 degrees to each other, but do not intersect (they are crossed). The amount by which the axis of the drive gear is offset relative to the axis of the driven gear is called hypoid offset. Such a transmission, if it is precisely manufactured and well adjusted, operates smoothly and with the least noise, but due to the intense sliding of the curved teeth, it is very sensitive to the quality and quantity of oil in the bridge.

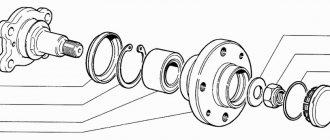

The design of the bridge is relatively simple and technologically advanced, although it is not without its drawbacks

Signs of gearbox problems

The rear gearbox is one of the reliable mechanisms of classic Zhiguli cars and breakdowns rarely occur with it. However, like any other unit, it may have its own malfunctions, which are determined by characteristic symptoms. They are worth dwelling on in more detail.

Noise when accelerating

If during acceleration there is an extraneous sound from the gearbox installation site, then it can be caused by:

- worn out or incorrectly adjusted differential bearings. It will require dismantling, disassembling and diagnosing parts with subsequent adjustment;

- Incorrect meshing of the teeth of the main pair gears. Eliminated by proper adjustment;

- lack of lubrication in the gearbox. The lack of oil in the crankcase is restored, after which it is checked for leaks at the places where the sealing elements are installed.

Noise when accelerating and braking the engine

If noise occurs both during acceleration and during braking by the power unit, there may not be many reasons:

- deterioration or failure of the bevel gear bearings of the main pair. Eliminated by replacing failed elements;

- Incorrect adjustment of the gap between the tip and the planetary gear. The mechanism needs to be diagnosed and replaced with damaged parts, as well as setting the required gap between the gear teeth.

Video: how to determine the source of noise in the rear axle

Knocking, crunching noise when moving

If the gearbox begins to make sounds uncharacteristic of its normal operation, then it will be possible to accurately diagnose the breakdown only after disassembling the unit. The most likely causes of a crunching or knocking sound may be:

- tooth breakage on the gears of the main pair;

- great wear of the main pair;

- Problems or incorrect adjustment of the bevel gear bearings.

Noises when turning

Noise in the gearbox is also possible when turning the car. The main reasons for this phenomenon may be:

- tight rotation of the satellites or the appearance of scratches on their surface. Eliminated by replacing damaged parts or treating roughness with sandpaper. If the defect cannot be removed, the failed parts must be replaced;

- jamming of side gears. If the gears have barely noticeable damage, clean them with sandpaper. Elements with signs of heavy wear are replaced with new ones;

- The gap between the differential gears is set incorrectly. It is necessary to set the correct gap between the gears;

- defective semi-axial bearings. The ball bearings need to be replaced with new ones.

Knock when starting to move

The appearance of a knock in the rear gearbox of a VAZ 2106 at the beginning of movement may be accompanied by:

- large gap between the splines of the bevel gear shaft and the flange. It is necessary to inspect the condition of both parts. If significant wear is detected on the splines, the elements are replaced;

- increased gap between the teeth of the main pair gears. The problem is “cured” by adjusting the gap;

- large amount of space for the pinion axle in the differential box. The box needs replacing;

- The fastening of the reaction rods of the rear beam has become loose. It is necessary to inspect and tighten the fastening.

Gearbox jammed

Sometimes the REM may jam, i.e. torque will not be transmitted to the drive wheels. The reasons that can lead to such a malfunction are as follows:

- lack of lubricant in the mechanism, which could leak due to leakage of the unit;

- failure of satellites;

- damage to the bearing on the bevel gear of the main pair.

Lack of lubrication in the gearbox leads to increased production and jamming of the mechanism

Oil leakage can be determined without disassembling the gearbox, but other faults cannot be identified without this procedure. If, after disassembly, scuffs, broken teeth or visible damage to the bearing are found on the gears, then the parts need to be replaced.

Oil leak

Lubricant leakage from the “six” gearbox is possible for two reasons:

- failure of the shank oil seal;

- damage to the gasket between the gearbox and the rear axle stocking.

To accurately determine where the oil is leaking from, you need to wipe off the lubricant with a rag and after a while inspect the gearbox: the location of the leak will be noticeable. After this, you can take further actions - remove the entire gearbox to replace the gasket, or dismantle only the cardan and flange to replace the lip seal.

An oil leak is indicated by a wet gearbox in the lower part.

Recommendations

Comments 52

Will you build a flying ship? — I’ll buy