The behavior of a car while driving is influenced by many conditions. These are the features of the depreciation system and the standard size of tires. But the main thing is the parameters of the installation angle of the rear and front wheels. The vehicle's stability on the road, handling, tire wear and even fuel consumption depend on them. Ideally, the wheels should be positioned strictly perpendicular to the road surface, but achieving such indicators is almost impossible. The position can change when turning, with a redistributing load, so the designers of the manufacturing plant immediately set several optimal geometry values for each car brand.

Types of tilt

In order for the car to be stable, controllable and safe when moving, the wheels (both front and rear) are installed according to certain parameters. The basis on which installers focus when making adjustments is the direction of movement, body parts and road surface.

Camber (Camber)

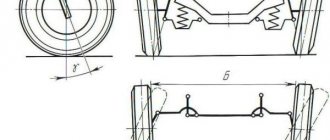

Represents the angle between the vertical vector and the wheel plane. Correctly aligned, it guarantees the correct position of the car wheels. When their upper area is inclined inward (towards the center of the machine), this indicates a negative value. If the car wheel is directed in the opposite direction (outward), it is positive. The photo below clearly shows the difference between the indicators.

When setting up, it is important to take into account that both tires need to be set as equally as possible. The deviation cannot be more than 30°.

When collecting information about what the camber angle of the front wheels should be, you should learn about other nuances.

- When a vehicle moves along a curved path, longitudinal tilt contributes to better stabilization. Under its influence, the car wheels try to take the desired position, which corresponds to moving in a straight line.

- Designers carry out calculations based on the characteristics of the vehicle body. In the factory configuration, the value is stable, but often when modifying the suspension (tuning), motorists independently adjust the values set by the manufacturer. This leads to the formation of collapse.

- Camber also forms when the vehicle roll changes, this is especially noticeable on trucks. When the truck is not loaded, camber is positive. Vehicles literally move on external tires. With a zero indicator, it is possible to achieve the least tire wear, which can significantly extend their service life. Negative characteristics also impart stability.

Toe-in (TOE)

The easiest way to study the wheel alignment angle is from photos and pictures: TOE is the inclination between the plane of the car wheel and the longitudinal axis of the vehicle. With proper adjustment of the indicator, it is possible to set the optimal wheel arrangement necessary for a comfortable ride.

The values are:

- positive (when mixing);

- negative (when diluted).

TOE ensures the correct position of the steered pair of wheels at different speeds and vehicle turns. Thanks to the toe-in, it is possible to compensate for small gaps and ensure the elasticity of the suspension. The indicators that are set by the manufacturer imply a parallel arrangement of the lines of the car wheels.

When the components of the suspension and vehicle control systems wear out, adjustment of the RS is necessary to increase the descent parameters. The main purpose of setting the tilt is to stabilize the rotation of the wheels while driving. As a result, TOE affects the car's handling and ability to drive straight. When the values differ from the specified ones, the vehicle begins to “wobble” along the road, the driver is forced to constantly correct the direction using the steering wheel.

When dealing with wheel alignment geometry, you should remember that exceeding the established values leads to rapid wear of the tires.

Signs of deviation from the norm:

- sawtooth damage on rubber;

- characteristic squeal when making a turn;

- excessive fuel consumption.

Our production

Truck tires

Tires for special equipment

Tires for agricultural machinery

Cross slope (King pin)

This is the angle between the vertical line and the projection of the kingpin across the plane of the vehicle. If you set the wrong values, the car will become unstable and unstable on the road. Due to the constant change in the position of the wheels, it will not be easy to drive such a vehicle. And if there is a large difference between the indicators of the angle of inclination of the axis of rotation (TAA) of the left and right sides, the car will drift.

The LOP is formed between the imaginary vertical and the MacPherson suspension, which is directed inward (when viewed from the front). Typically this level is set by the manufacturer and cannot be adjusted. However, some manufacturers use a change in the NOP angle to simplify camber correction. This angle is always positive.

By adjusting the LOP, you can minimize the impact of surface impacts and reduce the risk of loss of steering control after hard braking.

Setting incorrect values can also lead to:

- reduced steering stabilization;

- premature wear of components of the suspension unit;

- inability to move straight over rough terrain.

Kingpin caster (CASTER)

When studying methods for installing alignment and camber, you should remember that Caster is measured in degrees. The indicator is presented as an angle in the axial plane of the vehicle, located between the vertical and the line connecting the central turning zones. The straight line passes through the ball joints along the suspension arms located above and below, if you have a standard double-wishbone system in front of you. Or along the upper and lower mounting points of the shock absorber strut, in the case of a MacPherson unit or the longitudinal axis of the vehicle. The Caster value can be negative or positive.

When driving in a straight line, correct adjustment of the front wheels allows them to maintain their established position. If the parameters are violated, the car will be pulled to the side, a characteristic squeal will appear when the car turns, and additional efforts will have to be made when performing maneuvers to the right and left.

When making adjustments, it is important to know that body defects usually cause the CASTER to change unevenly. Such a difference between the tilt of the kingpin on the right and on the left most often entails the vehicle moving off the trajectory, even if the other angles are adjusted as necessary.

It is Caster that allows the steering system to self-center. The correct setting directly affects the ability to turn easily when coasting, accelerating or braking. So, for sports cars on slippery and uneven road surfaces, a steeper longitudinal slope (vertical) would be optimal. On smooth roads with good grip, a gentle (smooth) angle is more suitable.

Running shoulder (SCRUB RADIUS)

It is the gap between the point where the support and the central plane of rotation of the wheel intersect, and the place where the axis of rotation coincides with it. The value can be positive, negative or zero. SR is determined by the transverse angle, camber and offset of the disk.

If there is a negative indicator, the wheel tries to move in the direction opposite to the turn, and the steering wheel pulls to the starting position. Zero ensures that there is no extraneous influence of forces on the control system if tire damage occurs or the car has to brake sharply.

The parameters depend not only on the design features of the suspension, but also on the tires themselves. When the value is other than zero, the settings act as a lever, affecting the components of the suspension assembly and steering.

A positive shoulder can lead to disruption of the course and stability of the vehicle due to an increase in the drag force of any of the wheels.

When setting the characteristics to zero (or a value close to it), remember that in this situation the plane of rotation shifts to the outer part of the treads, which leads to problems with driving the car. At the slightest unevenness of the road surface, the steering wheel will be torn out of your hands. In addition, wheel bearing damage will seriously increase.

How is this implemented in reality?

It’s easier for racing car designers: here the suspensions have high angular rigidity and a short stroke. In this case, the static and dynamic indicators are approximately the same.

But on ordinary cars there are soft, elastic, comfortable suspensions with long travel. And the greater the suspension travel, the more the dives, lateral rolls, and bumps into obstacles are reflected on it and, accordingly, the camber changes.

Therefore, in order to achieve maximum controllability combined with comfort, designers of consumer cars have to conjure up the suspension kinematics.

Convergence

This is the position of the wheels relative to the longitudinal axis of the car when viewed from above. It can also be positive (the front parts of the wheels “look” at each other), negative (the front parts of the wheels tend to move apart) and zero (the wheels are parallel to each other).

Wheel alignment

What is toe-in responsible for?

There is a theory (in quite authoritative sources, too, by the way) that toe-in is needed to compensate for the side effects of camber and keep the wheels in the desired position. They say that broken wheels inevitably tend to roll to the sides, while knocked down wheels tend to fall on top of each other. This theory assumes an unambiguous connection between camber and toe: with negative camber, the wheels should diverge, and with positive camber, they should converge.

The reality is, of course, different.

The camber traction helps keep wheels with negative camber from falling into a heap when moving. There is no point in compensating for it with toe-in. With positive camber, the thrust also tends to increase toe-in - this is due to the design of the controlled suspension.

Front axle wheel alignment adjustment parameters: changing values

The values may change when system components wear out and old parts are replaced with new ones. All tips and rods that act as a connecting link between the steering column, the mechanism itself and the wheels have a threaded connection. It is this that makes it possible to reduce or increase the length of messages to correct the toe angle.

The toe-in of the front and rear wheels is adjustable on all types of units. The exception is the axle or rear beam. Camber adjustment is more often found on axial suspension units with lower and upper link centers.

In addition, it is not possible to adjust the parameters of both axes on all brands of cars. This will not be possible on models with independent MacPherson strut suspension (with a number of exceptions).

What is toe-in, standard indicators (numbers), how is it regulated?

Toe is a parameter that reflects the angle between the plane where the wheel rotates and the direction of movement. In other words, this is the ratio of two parameters - the distance between the front and rear edge of the wheel.

If installed correctly and there are no deviations, it is considered that the toe is equal to “zero”, i.e. correct.

The toe-in parameter for each car is individual and there is no single standard. Measured in millimeters or degrees/minutes.

Incorrect adjustment leads to the following problems:

- Rapid tire wear. If the toe-in is 5 mm or more, then after 1000 kilometers the pattern on the tire will be “eaten up”.

- Deterioration in controllability (increasing tendency to skid) and stability.

As mentioned, the convergence parameter comes in two types:

- Negative - in this case, the tires wear out on the inside.

- Positive - the tire pattern is worn out on the outside.

New vehicles equipped with independent suspension often have adjusters that allow the toe angle of the rear wheels to be adjusted.

At the same time, the consequences of toe deviation on the front and rear wheels equally affect the operation and controllability of the machine.

When to adjust and is it worth it?

Wear of parts is a natural process that cannot be prevented. When components are deformed, the angle values change, which is why they have to be adjusted and the correct wheel alignment must be installed.

Typically, the need for unscheduled intervention arises after a vehicle hits various obstacles, or gets a wheel into a hole or an open hatch. The same thing happens after accidents in which the body part was damaged.

If after the incident the car’s behavior on the road has changed (it begins to pull to the side, while driving the steering wheel is not in the central position, when exiting a turn it does not return to its original position, the tires wear unevenly, a characteristic squeal is heard, etc.), do not hesitate - contact service station specialists for help. Their assistance will also be needed after replacing components of the suspension and steering system.

Ways to adjust wheel geometry

Wheel alignment adjustment has long ceased to be a problem for car enthusiasts. Almost every service station has equipment installed that performs the required amount of work to adjust wheel geometry.

Modern stands at which work is carried out come in several types:

- Laser;

- Computer;

- Optical.

The equipment provides quick and accurate adjustment of wheel geometry with the delivery of results to the car enthusiast (what happened before the repair and what happened after). In this case, the total setup time takes no more than a few minutes.

The main thing is to find a service station that employs experienced specialists who know how to handle specialized equipment.

Often, car service owners purchase equipment to install wheel alignment, but there are no competent technicians to service it.

Many car enthusiasts adjust wheel geometry with their own hands.

One of the following methods can be used here:

- Using a laser pointer;

- Using a telescopic ruler.

The most common option is using a telescopic ruler and plumb line.

To complete the work, you also need a regular ruler, chalk and a set of wrenches.

First, the wheel camber is adjusted, and then the toe-in.

All operations are carried out in a garage, which saves money and nerves. The disadvantage is the high measurement error - 1 mm in one direction or the other.

Read more on this topic here.

On VAZ 2101, 2103 cars, these works are performed as follows.

Where is the best place to set up?

We advise you to trust the care of your car to trusted salons or familiar specialists. When choosing a company, rely on personal recommendations, online reviews and service station ratings to find a really good place.

To diagnose the general condition of a vehicle, a competent technician will only need a lift and a measuring device. If you wish and have knowledge in the field of truck maintenance, you can evaluate the scope of work yourself. But if you decide to delegate this responsibility to a specialist, he will cope with the task more efficiently and will be able to not only diagnose the problem, but also fix the problem.

When it comes to a thorough inspection and elimination of serious problems, it’s definitely not worth saving on visiting a service station. Salon technicians have appropriate equipment (such as a 3D stand), consumables and assistants, which helps them deal with breakdowns faster than amateur motorists.

Where to do it and what to do it on

The first rule is to look for a smart, conscientious craftsman, and not a “sophisticated” stand. Second, choose a service based on your needs. If, for example, the car is in good working order and you just want to check and adjust the toe-in, you do not need a 3D stand for this. A good specialist can do this with a lift and a measuring rod. With the same result, the difference in price will be very noticeable. But if you need a thorough check of the entire “geometry”, you cannot do without the appropriate equipment. Stands for monitoring and adjusting wheel alignment angles can be divided into two large groups: optical and computer.

Optical stands can be beam or laser. In beam light, the light source is an incandescent lamp. Two such sources (collimators) are attached to the wheels, and measuring screens (targets) are placed in front and on the sides of the car, onto which a beam of light is projected. When adjusting toe, the beams are directed to a measuring rod located in front of the machine. Laser stands are more accurate and easier to work with. Measuring screens are installed on the sides of the pit or lift. There are holes made in their centers through which laser beams are directed strictly towards each other. Mirrors are attached to the wheels of the car, from which the rays are reflected onto the screens. The advantages of optical stands include simplicity and the resulting reliability. They also differ in their low price. But the disadvantages are much more significant - relatively low accuracy, the ability to work with only one axle of the car at a time, the lack of a database on models and the inability to measure some parameters (for example, the rotation of the rear axle) that characterize the overall “geometry” of the car. If the car has a multi-link suspension, optical stands are contraindicated for it.

Computer stands are divided into sensor (CCD) and 3D. In the first, interconnected measuring heads are mounted on each wheel, the information from which is processed by a computer. According to the method of connection between the heads, the stands are corded (a rubber band is stretched between the heads, and the connection with the computer is via a cable), infrared wired (communication between the heads is provided via infrared rays, and with the computer via a cable) and infrared wireless (the heads are connected to the computer via radio channel). The last type of stands is by far the most common. When choosing, keep in mind that there are still open-loop computer stands (with two measuring heads), the functionality of which is much lower than closed-loop stands (with four heads).

The advantages of computer stands are obvious: high accuracy, the ability to work with two axes at once and measure many more parameters, the presence of a constantly updated database (about 40 thousand models), a program that tells the mechanic the sequence of actions. But CCD stands are not without their drawbacks - fragile sensors, dependence on temperature conditions and lighting. They require periodic checking and adjustment (twice a year).

Many experts call the emergence of computer 3D stands a revolution in the field of control and adjustment of wheel alignment angles. As they say, genius is always simple. Video cameras are mounted on the rack in front of the car, which with the highest accuracy record the position of plastic reflective targets attached to the wheels. To measure angles, just roll the car 20-30 cm back and forth and turn the steering wheel left and right. Data from video cameras is processed by a computer and produces all conceivable geometric parameters in real time. This technology is called “machine vision”. To carry out measurements, 3D stands, unlike all others, do not require placing the car on a perfectly flat surface. The disadvantage is the price.

Adjustment features

Wheel alignment can only be done if the chassis and control system are in good working order. Before repairing, the technician must make sure of this. Namely: place the vehicle on a lift, inspect the tires, supports, springs, steering wheel, etc. At the same moment, the tire pressure is checked.

If serious damage or play is detected, the technician must refuse to adjust the tilt parameters. All existing defects must first be eliminated.

If there are no deviations, the machine is placed on a horizontal platform and loaded, following the manufacturer’s recommendations, since it is he who usually indicates the optimal settings taking into account the load. Therefore, making adjustments on an “empty” car is already a violation. In order for the suspension elements to fall into place (assume working condition), apply forceful pressure to the front and rear of the vehicle.

Regardless of the stand at which the adjustment is carried out, the craftsmen compensate for the disc runout in order to avoid serious violations in the measurements.

How to choose a service station

Many service stations can assure you that they provide high-quality wheel alignment adjustments. However, if the technician immediately puts the newly driven car on the stand and begins tuning, you can freely interrupt the procedure and look for another service station.

The fact is that the correct angle of inclination of the wheels cannot be established if the car’s suspension is faulty. For this reason, a professional will first make sure that this system in the car is working properly. As a result of diagnostics, hidden problems are often revealed that will subsequently affect the position of the wheels.

Only after the technician diagnoses the suspension and chassis does he begin adjusting the wheel alignment. Serviceable parts have minimal play (and in some it should be completely absent). Otherwise, the angle of the wheels will be set incorrectly (if the technician manages to do this on a faulty chassis).

For these reasons, before allowing specialists to begin setting up the machine, you should clarify whether they do diagnostics of the chassis or not.

And one more nuance. If a driver has driven a car for a long time with a damaged camber, then the tires on it have already worn out. It happens that after high-quality tuning, the machine still behaves unstable. In this case, you should pay attention to the quality of the rubber, and ideally, replace it with a new one.

To learn how you can do wheel alignment at home, watch the following video:

Camber - Toe. The old-fashioned way with your own hands. Wheel alignment without service station

When and how to adjust the toe angle of the front wheels

During operation, the tilt parameters change. The UCC should be checked and configured:

- after repair work, replacement of suspension parts;

- when installing (dismantling) gaskets to increase ground clearance;

- when excessive or uneven tire wear appears;

- The steering wheel stops returning to its original position when driving straight or when turning.

Motorists adjust wheel alignment at service stations or in the garage. When planning to make the adjustment yourself, it is important to understand that this requires not only special tools and suitable space, but also the appropriate skills. Therefore, in their absence, it is better to seek help from specialists.

When can you change the acceptable value?

When setting the zero deflection, the service life of the tires will be maximum. It should be installed if:

- the car is used primarily for driving in a straight line;

- by car they transport cargo two (or more) times lighter than the maximum norm;

- the vehicle has new springs, tie rods, and silent blocks;

- the motorist drives at an acceptable speed, operates the vehicle calmly and carefully;

- mostly you have to drive on good, smooth roads;

- the car is operated on a dirt or sandy surface;

- It is possible to check and configure the UCM at any time.

What is wheel geometry?

Wheel geometry is a common term that in everyday life among car enthusiasts and at service stations is called “wheel alignment”.

This setting affects the following machine parameters:

- Controllability;

- Tire wear rate;

- Sustainability.

Adjusting the wheel alignment angle is mandatory for all cars, and the work itself must be performed by specialists using special equipment.

What are the dangers of incorrectly setting wheel toe and camber angles?

If the tilt parameters are set incorrectly, the car owner will face a lot of unpleasant moments. Among them:

- rapid tire wear;

- systematic damage to oil seals, bearings, steering fingers;

- increased fatigue on the road, when the car has to be leveled every now and then.

In addition, a car with inadequate performance may skid when turning, it will lose stability and change direction when braking. As a result, not only will your truck break down more often, but your risk of getting into an accident will also increase.

CAMBER camber

The angle of inclination of the wheel in the vertical plane relative to the road. If the upper part of the wheel is tilted towards the center of the car, then the camber is negative, if outward - positive, if without angles of deviation - zero. The camber of the left and right wheels should be as equal as possible to each other. For example, the camber of the right wheel = + 36 minutes, and the left wheel = + 33 minutes. Both indicators are within the tolerance range. The difference between them should not be more than 30 minutes; deviation from this norm will lead to the car moving away from straight-line motion and one-sided wear of the tread. Negative camber will have a beneficial effect on cornering stability, and zero camber will ensure minimal tire wear and, as a result, significantly increase tire service life.

How installation angles affect handling

In order to consider the characteristics of the vehicle depending on toe-in and camber, relevant research and tests were carried out with the participation of the VAZ-2114.

Negative Caster

Caster was set to the maximum minus value. The position of the front pair of wheels is shifted back. This picture can most often be seen on a very old car.

After making adjustments, the vehicle began to respond well to steering inputs. But at the same time it turned out to be too easy, the car began to “drive”, and instability appeared. To drive the VAZ-2114, the driver had to make a lot of effort and steer while turning. It is almost impossible to control the behavior of vehicles at high speed.

Correct installation

When the caster angle is set to normal-plus, the wheel alignment is set to zero. In this situation, the VAZ-2114 behaved completely differently: the vehicle demonstrated good stability when driving straight. Management has become easy and comfortable.

Custer

Caster is the angle between the steering axis of the wheel and the vertical. If the stance is tilted back, the caster is positive; if it is tilted forward, the caster is negative. If it stands strictly vertical, zero.

Custer

Positive caster makes the car more stable when driving at medium and high speeds. The car wobbles less, reacts less sensitively to bumps, and self-levels at speed.

In addition to all of the above, caster directly affects the camber and toe angles. Therefore, the angle adjustment begins with it (if it is adjustable), then the camber is adjusted, then the toe-in.

Consequences of incorrect wheel alignment angles

After what work is it not necessary to do a wheel alignment?

Wheel alignment is not a cheap procedure, and often unscrupulous services assure drivers that after carrying out this or that work, it must be done. Below are the most common situations where a driver may feel like they need to perform a wheel alignment, but in reality they don't.

Tire replacement

The most common misconception is that when replacing winter tires with summer tires and vice versa, a wheel alignment is required. This is not so, since replacing tires performed in a standard manner does not affect the toe-in and divergence parameters of the wheels. If, after replacing the tires, the car begins to pull spontaneously to the side when driving in a straight line, you should first check the tires for even wear.

Replacing shock absorbers

We recommend reading: How to bleed shock absorbers before installation

After replacing the shock absorbers, there is no need to perform a wheel alignment, since the steering rods and ball joints practically do not depend on them. When replacing shock absorbers, these steering elements are not affected; they do not even need to be unscrewed.

Replacing stabilizers

The situation with stabilizers is identical to shock absorbers. After replacing them, there is no need to perform a wheel alignment, since the work does not affect the key elements of the suspension and steering.

Maximum steering angle

It characterizes the maximum angle at which a car wheel will turn when the steering wheel is fully turned. And the smaller this angle, the greater the accuracy and smoothness of control. After all, to turn even at a small angle, only a small movement of the steering wheel is required. But do not forget that the smaller the maximum turning angle, the smaller the turning radius of the car. Those. It will be very difficult to turn around in a confined space. So manufacturers have to look for some kind of “golden mean”, maneuvering between a large turning radius and control accuracy.

Measuring the longitudinal and transverse angle of inclination of the axis of rotation

Of greatest interest is the measurement of the tilt parameters of the rotary axes. Their position is determined by two key characteristics: lateral inclination and longitudinal (caster).

A short video (2 min) about what a caster is

If the wheels of a car could turn 90 degrees and stand across the body, these parameters could be easily calculated using an inclinometer. But in real conditions this is impossible to do, so you need to limit yourself to a rotation of 20 degrees in both directions relative to the zero position. The difference in the obtained angles must be multiplied by an additional factor of 1.5 - this is necessary to compensate for errors that are allowed during the measurement process.

To measure caster, the bubble level bulb must be mounted perpendicular to the plane of the wheel.

To determine caster, you first need to turn each wheel 20 degrees in front of the steering axis: right to left, and left to right. In this case, you need to set the inclinometer to zero or write down the results. Next, the wheels are turned behind the turning axis: right to the right, left to the left. If the angle measured behind the steering axis is greater than the angle measured in front of the steering axis, then the caster is positive. If it's the other way around, then the caster is negative. The protractor should show a slight difference of a few degrees. This difference should be multiplied by the same factor of 1.5. For example, if the protractor showed a value of +2 degrees, then the caster value should be taken as +3 degrees.

The transverse inclination is calculated in a similar way, but the protractor is installed in a slightly different position. For additional convenience, you can use a smartphone, on which you should install in advance an application that simulates two mutually perpendicular bubble levels. An ordinary building level, preferably with a rotating bubble, will also work for these purposes.

To measure the lateral inclination of the steering axis, the bubble level flask must be fixed parallel to the plane of the wheel.

Measuring the level of lateral inclination of the axis of rotation.

If the task is not to measure specific numerical values of slopes, but only to compare them (they are not adjustable on most cars anyway), then the results do not need to be multiplied by a correction factor of 1.5. The main thing is to make sure that the angles are equal on both axes (right and left).

In the process of self-measurements, it is not necessary to strictly observe the rotation of the wheels exactly 20 degrees, especially when there are no appropriate tools to determine these angles (for example, graduated turntables). You can turn the steering wheel about 3/4 of a turn. It is necessary to ensure that when turning left and right, the steering wheel is locked in symmetrical positions. To do this, you can put some marks on the bottom of the steering wheel. When the steering wheel is in zero position, the line connecting the marks must run strictly horizontally.

Another way to get accurate results is to draw corners on the asphalt near the wheels using a protractor. If you don't have this tool, you can use a square sheet of paper with equal sides. Folding it diagonally, we get an angle of 45 degrees. Then one corner is folded in half again, resulting in an angle of about 22.5 degrees, which is close to the standard 20. Next, you need to attach the sheet to the wheel and outline its edge with chalk, thereby creating the necessary marks on the asphalt.

Marking the corners for turning the wheel