“Silent” in translation means “quiet”. This part is a “set” consisting of a bushing and a cylinder, between which polyurethane or rubber is filled. The product is widely used as an “intermediary” between car body parts and suspension elements. Another purpose of silent blocks is to mount engines and gearboxes. The task of rubber-metal bushings is to dampen vibrations, vibrations, and shocks that are inevitable when moving on roads, especially Russian ones. The products help save expensive car components and extend their service life. These parts, provided they are original, last quite a long time: 100 thousand km or more. But it is recommended to check them every 50 thousand km. How to change silent blocks? You can do this yourself or at a car service center in Moscow. It is better not to delay the restoration of normal driving performance of the car.

What happens if the silent blocks are not changed on time?

When the part wears out, a gradually increasing play appears (in the block seat). As a result, the sleeve hole is also developed. This is fraught with:

- pulling the car to the side at high speed;

- increased and uneven tire wear;

- poor handling, especially noticeable when cornering;

- the appearance of a feeling of discomfort when moving, because hitting even small obstacles will bring unpleasant sensations.

Reasons for failure and what breaks in the silent block

It is quite difficult to imagine the metal parts of the silent block breaking. If they say that the silent block has broken, it means that the rubber component of the part has started to tear or has already broken. There are three reasons why silent blocks fail:

- Long service life, as a result of which the rubber dried out, lost elasticity and began to crack and tear

- Chemical attack on the rubber part. For example, too much oil got on the silent block, which corroded it.

- Incorrect installation. Tightening the silent block bolts should only be done when the car is on its wheels, and not suspended. But, alas, many car repair shops do not follow this rule; as a result, the wheel tightened under the canopy is at the extreme point, and when it stands on the wheels, the silent block is strongly twisted and the rubber will tear over time, without even a third of its life. Another subtle point is the installation of a silent block with partitions. Such silent blocks can be installed in a strictly defined position, and if it is installed incorrectly, the silent block will fail very quickly.

What is used to make silent blocks?

Most often it is rubber, but recently polyurethane has begun to be used more and more often. If you have the opportunity to choose, you should give preference to him. The main advantage of polyurethane silent blocks is a longer service life. Such products also dampen vibrations much more effectively and actively “resist” being squeezed out of their sockets.

Which silent block to choose?

Many drivers during the operation of their car are faced with the need to replace silent blocks, which cannot be avoided. Just as there is no perpetual motion machine, there are no parts with an infinite resource. And since the elastic filler is subjected to a large load of compression and straightening, the durability of the silent block depends on a number of factors:

- First of all, this is the quality of the material itself (rubber or polyurethane). Rubber elements give the suspension more softness, while polyurethane products have high wear resistance.

- Much also depends on the reliability of gluing the intermediate insert to the metal bushings. After all, if the integrity of the unit is violated, then its shock-absorbing properties are lost.

- Most car enthusiasts pay attention to the brand of rubber-metal joints and their cost. Moreover, each manufacturer makes its own recommendations regarding the use of parts from certain companies that have been tested and approved. However, it is not always possible to find original spare parts on sale, so drivers opt for silent blocks from other manufacturers. There are many products sold on the automotive market from a variety of companies, but not every product is highly efficient in difficult Russian road conditions.

Recently, polyurethane products have become widespread. But is such a purchase justified or is it still better to give preference to the usual silent blocks with rubber filling?!

How to choose a tool to replace silent blocks

In addition to the traditional set - pry bar, keys, hammer - you will need a special tool. The best option is to purchase a professional puller. This is a hydraulic device that allows you to replace a part in the most gentle way possible, without causing damage to it. Such tools are used in all technical centers. Pullers help to screw (unscrew) a special mechanism into the inside of the part, raising or lowering it. As a result, replacement of spare parts occurs evenly, without distortions, and it is much easier to restore the functionality of the entire lever.

What can result from untimely replacement of silent blocks?

What can happen if the silent blocks are not replaced in time? Most likely, more than one driver asked this question. If this part is very seriously worn out, then this can lead to the car pulling away at speed, or in other words, at speed the car will be thrown from side to side.

Another significant sign of wear on rubber-metal joints is considered to be uneven wear on the tires of the car. There is no need to start replacing silent blocks, as there may not be very good consequences. For example: the landing zones for attaching the hinges may be destroyed, which will result in a complete replacement of the front suspension arm assembly.

How to make a device with your own hands

The simplest option is to use a “27” head, which will serve as a mandrel for pressing. A small hydraulic jack or vice will also work. In the first case, you can try to squeeze out or press in the silent block right in place. When using a vice, the part will have to be removed. Other options for homemade “pullers”:

- bolt M20;

- a pair of tightening cups with washers;

- threaded rod;

- a piece of pipe whose diameter exceeds the diameter of the silent blocks.

Such “tools” work simply. Take a bushing and place it on the side where the silent block will be pressed out. A threaded bolt is installed in the hole. Next, they begin to tighten the nuts and the washers are gradually brought together: one of them presses the product out of the seat. Still, it is worth noting: the replaced spare part will last longer if the operation was carried out in a car service center.

How to remove the silent block

Selecting the right hinge is half the battle; you should replace it. To do this, you can visit a service station, but since the operation is not so complicated, you can do the work yourself. But first you need to remove the worn part and for this you do not need to have a special tool; it will be needed at the stage of installing the silent block.

Pressing out can be done using improvised means. To do this, first cut off the protruding rubber filler on one side, and then knock it out with a hammer using a metal attachment.

The silent block can be removed from the lever using another method. Take a bolt onto which a washer of smaller diameter than the eye of the lever is put. Then the bolt is inserted into the bushing of the worn part, a piece of pipe with a washer is placed on the other side (its diameter must correspond to the size of the pipe) and the nut is screwed on. Then, using one wrench, the bolt itself is held in place, and the nut is screwed in with the other. At the same time, it will begin to push the silent block out of the eye into a piece of pipe.

For some products, another method is suitable - soldering with an open fire. But it is better not to use it, since prolonged exposure to high temperatures can only cause harm, negatively affecting the structure of the metal. Over time, it will begin to quickly lose its properties, and the suspension unit will become unusable. In this regard, only the mechanical method should be used.

Replacement of silent blocks of front levers

If you have a puller, no matter whether professional or homemade, replacement occurs relatively quickly. The progress of the operation can be seen in the video, which is easy to find on the Internet. It is much more interesting to consider the method of dismantling and installing parts without special tools on a front-wheel drive car. How to replace silent blocks? To do this you need:

- Drive the car onto an overpass or inspection hole (you can also use a jack). The engine crankcase protection will have to be removed.

- Unscrew the bolts securing the arms.

- Using a “17” wrench, unscrew the nut securing the stabilizer (strut) to the lever;

- The bolt will have to be knocked out of the stabilizer.

- Remove the wheel.

- To unscrew the extension nut, you will need a “24” wrench. If things get tough, use a wire brush, WD

- To remove the lever, remove the ball joint bolts. If problems arise, remove the lever directly with the crab by unscrewing the 3 bolts securing it to the body. The nut can then be unscrewed using a chisel or by heating.

- Now you can change the silent block of the extension, for which a good old chisel will do.

- You can press silent blocks in a vice. If they do not go in completely, place the lever on a level place and finish the job with a hammer.

- When the stretching is done, you can move on to the lever. A puller will do here (the process is described above).

- The new part is installed using a pressing tool. Pre-lubricate the silent block with liquid soap.

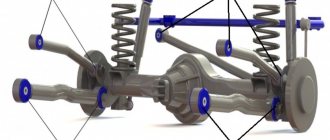

Why do you need a silent block?

The silent block is otherwise called a rubber-metal hinge. Externally, the part resembles a cylinder and consists of three main components:

- The outer part - steel is used for its manufacture; it also has seating elements: stiffeners and a shell.

- The core is a solid metal sleeve.

- Clearance - this space between two metal elements is filled with an elastic material (rubber or polyurethane).

The operation of the silent block is as follows. The inner sleeve is clamped on all sides by elastic material, which prevents its rotation. The outer bushing is in the same conditions and does not rotate relative to the rubber or polyurethane insert.

However, when a torsional force of a certain intensity occurs, the bushings can rotate relative to each other at a small angle, due to the elasticity of the filler. This limits the turning radius of the lever, but for the full functioning of the suspension this radius is quite enough. This rubber-metal part can also be called a dry hinge, since it performs its duties without lubrication. Its operation is ensured precisely due to the elasticity of the insert between the metal bushings.

In other words, the task of silent blocks comes down to dampening vibrations that inevitably arise when the car is moving. In addition, they prevent their spread between suspension units.

The car suspension on each side is connected to the body at 2 or 3 points. In the first case, it is attached to the lever and the strut, and in the second - to two levers and a shock absorber. That is, the number of parts depends on how many mounting points exist in the vehicle. It is these parts that bear the heaviest load.

Techniques for replacing silent blocks of the rear suspension using the example of a VAZ2109

If there is no lift, jack up the wheel by first loosening its mounting bolts. But first, place safety supports under the beam. Prepare keys for “19”, puller, hammer, WD40, new parts. At the following stages:

- Disconnect the brake pipes, unscrew the nut, which will loosen the bolt connecting the body and the beam.

- Remove the bolt using a metal rod of smaller diameter and a hammer.

- Lower the beam down.

- To remove the old part, use special tools or simply crumble the rubber.

- Clean the freed area and lubricate it with liquid soap or other similar household product.

- To install a new product, use a homemade device if you do not have special tools. Insert a long bolt into the hole in the bushing and the eye of the beam. Now place the washers and gradually tighten the nut until it is in place.

- Now you can install the beam by tightening the fasteners in the reverse order.

What is a silent block of a suspension arm and its functions

In car structures where there are vibrations, displacements, radial and axial loads, there must be softening special rubber parts. They perform an important function, so they need to be changed frequently. Rubber parts that are subjected to compression, stretching, and displacement wear out quickly.

A silent block is a rubber-metal hinge (RMH) in the design of a car suspension. The salent block device includes:

- two metal tubes;

- rubber connection between these tubes.

This part is made by vulcanization, which is why it has excellent vibration insulation properties. Salent blocks are capable of absorbing all types of loads that appear during vehicle operation.

If the silent blocks are heavily worn, then driving the car will be uncomfortable, noise will appear and the joints of the parts will begin to wear out faster.

Silent blocks are installed on the front and rear suspensions. They are installed on levers. In addition to levers, silent blocks connect the mounting points of the gearbox, engines and shock absorbers.

To increase reliability, it is necessary to change vibration isolation pads on time.

Features of replacing front silent blocks on a VAZ “classic”

First, the silent blocks of the upper arm are changed. It is better to do all operations in the inspection pit. To do this, jack up the car and remove the wheel, loosening the wheel nuts in advance. Then:

- turn the steering wheel in a convenient direction to unscrew the ball joint nut using an open-end wrench set to “22”;

- the support must be dismantled with a puller;

- remove the long bolt securing the lever to the body;

- pull out the lever and remove the old bushings from it: this can be done using special tools or simply by breaking the worn parts;

- You can install new silent blocks using a socket of a suitable size and a hammer.

As for the lower lever, everything is more complicated. First you will have to remove the shock absorber. Then you need to tighten the spring with a special device. Then:

- remove the shock absorber;

- Unscrew the nut securing the ball joint and pull it out using a puller;

- unscrew the mount (a couple of nuts) of the anti-roll bar: be careful not to break the studs;

- remove the spring;

- now an important point: you need to unscrew the two nuts securing the lever to the body: the most important thing here is not to confuse or lose the gaskets by which the camber of the front wheels is adjusted;

- pull out the lower arm.

If you do not have a special puller to press out old silent blocks, it is better to burn out the old parts using a can of gas (they are inexpensive and are sold in hardware stores). It is better to insert new parts using a special tool or using crimping in the form of the same head of the required diameter and a hammer.

Bottom line

In no case should you ignore any extraneous sounds, otherwise everything may end in an unfavorable outcome - expensive repairs. Faulty silent blocks lead to increased load on the suspension components. And this in turn affects ride comfort.

You should purchase original parts, cheap Chinese fakes, although they do not require large investments, break at the most inopportune moment, and then what kind of savings can we talk about?! Only with serviceable and original parts can you experience full comfort from driving your car.

How to check functionality

There are two ways to check the good condition of the silent blocks in the front suspension:

- visually and audibly - the condition of the inserts is inspected for swelling of the rubber inserts and the integrity of the hinges. When hitting a nervous surface, friction and squeaks are heard.

- Diagnostics are carried out by specialists at the service station.

In the event of any malfunction, an urgent replacement of the silent blocks of the front levers is necessary.

If this is not done in time, the unit may cause destruction of the hinge mounting seats.

Particular attention should be paid to the play in the shafts and if they are excessive, they should be replaced immediately.

How to understand when it's time to replace

Before you set out to press in these parts, you should first of all inspect them thoroughly to make sure that they really require replacement.

Check for holes and any deformations, for swollen rubber on the hinges and for cracks. Manipulate the components, determining the presence of backlashes. If the permissible norm is exceeded, then replacement of parts is inevitable. It is not recommended to delay the pressing procedure. Over time, this problem will only get worse and can lead to suspension arm failure. The main indicators that indicate the failure of one part or several:

- Driving the car has become much more difficult.

- When overcoming bumps, the suspension begins to knock loudly. Tires wear unevenly, which has not been observed before.

- It has become much more difficult to adjust wheel alignment.

Advantages and disadvantages

The main advantages arise from the purpose of rubber-metal hinges:

- maximum quiet and comfortable operation of the unit;

- no maintenance requirements;

- there is no need to use lubricant, which deteriorates and develops over time;

- simplicity and low cost of design;

- diagnostic clarity that does not require qualified personnel;

- easy replacement at the end of its service life;

- the ability to set properties by selecting the material of the elastic element.

RMS competitors include all kinds of ball and cylindrical joints, which do not have the disadvantages inherent in silent blocks:

- Excessive freedom of movement in the hinge, characteristic of the RMS, is not always useful;

- cheap materials quickly age and deteriorate;

- rubber bushings do not work well at too high and low temperatures;

- strength under load is strongly related to the rigidity of the unit, and attempts to implement a compromise lead to an increase in weight, dimensions and cost;

- operating angles and the ability for relative movement of the clips over a wide range are limited.

On cars where control accuracy is more important than comfort and low price of the suspension, RMS have limited use. They are often replaced with ball joints (BJ) during sports car tuning.

POLYURETHANE OR RUBBER BUSHING BLOCKS, WHICH IS BETTER?

If the car has rubber bushings and silent blocks in the suspension, which can be replaced with polyurethane parts, then you will only improve the characteristics of the suspension and its operation. Polyurethane silent blocks will last at least 5 times longer than rubber parts.

Polyurethane silent blocks improve the car's behavior on the road, reducing unwanted deformations in the suspension and eliminating the “squeezing” effect typical of rubber parts. This means that the suspension always operates in the mode intended by the designers.

If you want to improve handling, polyurethane silent blocks are what you need. If you calmly move from one point to another, then choose ordinary silent blocks.

When to change

Silent block chamomile

The main symptoms that indicate the need to replace rubber-metal hinges:

- Poor vehicle handling when cornering.

- Uneven wear of the tread of car tires.

- Extraneous noises and squeaks in the suspension that occur while driving on a bumpy road.

Pressing tools and methods

At the factory, the silent block is pressed into the beam seat and is held there solely by friction. Therefore, you won’t be able to simply knock it out and get it out. It would be best to press out and press the part with a special puller. In the absence of one, you can resort to drilling out the rubber damper, which will loosen the tension a little, and cutting the outer ring with a hand hacksaw. On the Internet you can find methods in which the outer ring is bent with a chisel or a screwdriver is driven under it, and then the silent tape is knocked out of its seat. We do not recommend using such barbaric methods, as there is a risk of damaging the seat in the beam.

The design of the puller is a prefabricated mechanism consisting of mandrels, a pin and two nuts. The outer diameter of one mandrel, for which a thick washer is best suited, should match (preferably even a little smaller) with the diameter of the outer metal holder of the silent block on the press-out side. The second attachment will serve as a stop and a cavity into which the silent will go when pressed out. Its diameter must be greater than the internal diameter of the seat in the beam. As mandrels you can use large washers, bearing races, pieces of pipes of suitable diameter. There are universal wheel bearing puller kits on the market that may be suitable for repairing the rear beam.

What other tools are needed besides a puller? You need spanners and sockets for unscrewing the beam mounting brackets and the silent block itself. When completely removing the rear beam, you will need to unscrew the lower shock absorber mount and the brake hose, and you will also need keys to bleed the brake system. It is most convenient to carry out work from the inspection hole.

Reason for replacement

The photo shows the approximate condition of the silent block, which needs to be replaced. Typical signs of wear:

- deep cracks;

- peeling of rubber from the inner or outer race.

Symptoms of breakdown that appear during vehicle operation include the appearance of knocks, impacts when driving over uneven surfaces, or asphalt joints. Diagnostic methods:

- visual inspection for the defects described above;

- place a lever between the bracket for attaching the beam to the body and the silent block, which will allow you to move the silent block in different directions. If there is a strong tear or detachment, a large play will be noticeable in the place where the silent block is pressed in relative to the mounting bracket (read more about diagnosing the vehicle chassis).

Design Features

Orientation of the Daewoo Lanos rear beam silent block

There is no fundamental difference in the silent blocks of the rear beam of different car models. A distinctive feature of a particular model can only be the requirement for the position of the silent block relative to the beam. In the photo you can see a buffer element from an Audi 80. It is recommended to press the part into the beam so that the axis of the slots is horizontal with respect to the vehicle body.

This does not apply to parts that have an all-rubber buffer, and the silent block body does not have characteristic protrusions for fastening to the bracket. They can be installed in any direction. But in any case, you should monitor the depth of pressing. Most products are pressed flush, but in some design options the silent blocks will stick out more in a certain direction (for example, on the Renault Trafic). Therefore, even during the disassembly process, you should measure the location of the part. If the buffer is not solid rubber, during disassembly, paint or scratch a mark on the silent block body and on the beam seat. This will allow you to install the silent block during assembly in exactly the same way as it was done by the manufacturer (provided that the products have not been changed before you and were installed correctly).

Signs of silent block failure

The poor condition of roads during active use of the car creates additional stress on the suspension. As a result, the silent blocks that take the first blow begin to experience additional stress.

The greatest load falls on the elements of the levers and suspension rods. For preventive purposes, experts recommend checking the performance of silent blocks every 50 thousand kilometers.

This will make it possible to identify possible problems in the suspension at an early stage and correctly replace the silent blocks. Often, if a car has not been subjected to preventive inspection for a long time, critical malfunctions may appear that have a serious impact on the safety of driving the car.

Today, the following signs of silent block failure can be identified:

- When driving, the car “pulls” in one direction;

- Lateral tire wear;

- Violation of the vehicle's directional stability when braking;

- Body vibration when the car moves;

- External changes in the integrity of silent blocks;

- Suspension creaks when the vehicle moves;

- Increasing the “stiffness” of the suspension.

Each of these signs or they together indicate a possible problem in the operation of the silent block. There is no need to ignore them and continue to operate the machine.

Such a disregard for one's own safety can end very badly for the driver and passengers.

Silent blocks service life

Silent blocks on smooth roads can last about 100,000 km. However, on a road surface with a large number of holes and potholes, the durability of the part is reduced by about half. As a rule, a visual inspection of the product must be carried out after 50 thousand km. The block is checked for cracks and peeling in the rubber seal, as well as for the presence of play.

To most clearly determine the block defect, it is necessary to remove the wheels so that the arms hang to the side under the load of the shock absorber. As a rule, all problems with tires will be immediately visible. In the same position, the lever should be moved from side to side; if it is movable, then, therefore, an unacceptable backlash has formed. If these defects are found, the part should be replaced.