The linkage is an important component of the VAZ 2109 gearbox. If it fails or does not work satisfactorily, the linkage can be easily replaced or repaired.

Appearance of the device

There are two types of scenes:

There is no fundamental difference between the two types of units. The advantage of a short-throw is that it provides faster gear changes for a fraction of a second.

Do not believe those who claim that a short walk has a positive effect on dynamics. There is no connection between the rocker and the dynamics of the car. But the short walk has its advantages.

Replacement kit

Reasons for replacement

There are several situations when the owner of a VAZ 2109 has or wants to get into the design of the gearbox and specifically work with the rocker:

- Oil is leaking due to a damaged rocker seal. It must be replaced;

- The old drawstring was out of order;

- I would like to exchange the long-stroke for a short-stroke in view of its advantages.

Now to the question of when replacing or repairing the backstage is a necessary measure.

- The backlash of the gearbox selector has increased significantly.

- Gears change with difficulty, and when changing speed, extraneous sounds appear.

- It is possible to change gears, but with a lot of effort.

- Speeds change incorrectly. Instead of one, a completely different one turns on.

- It is impossible to turn on all or part of the gears at all.

Even if the resulting play is still insignificant, it is advisable to immediately begin repairs or completely change the drawstring.

Replacing the oil seal

If you find that the oil in the gearbox is gradually disappearing, you can suspect the rocker seal. There is nothing else left to do but change the element.

- First, buy a new shift rod seal. It costs about 70-100 rubles.

- Drain the oil from the box, having prepared a clean container in advance. This is in case you refill the same oil. Although this is an excellent reason for you to change the transmission lubricant at the same time.

- To make sure the oil flows out better, first unscrew the filler plug or remove the speedometer gear. After draining the oil, screw the cap back on.

- We climb under the car and disconnect the fasteners of the gearbox lever driveshaft.

- Pull the boot off the cardan, unscrew the bolts securing it to the gearshift rod. Problematic fasteners that you will have to tinker with.

- After removing the cardan shaft, remove the rod boot.

- We remove the damaged oil seal using an awl or suitable available tools. The main thing here is the stock itself.

- We install a new one in place of the old oil seal and press it with a tube of the appropriate diameter.

- Put the boot back in place and rotate the driveshaft.

- Please note that the bolt securing the cardan to the rod is an adjustment bolt. Therefore, screw it in exactly the same way as before dismantling. Otherwise, some speeds may not turn on.

After the work done, do not forget to check the result.

Replacing the cardan

Practice shows that if problems arise with the slide, it is not at all necessary to completely change it.

The instructions for replacing the cardan are as follows.

- Using two 13mm spanners, unscrew the clamp that relates to the speed switch drive rod.

- Pull the boot off with a screwdriver, moving towards the box. If you want, remove it completely. So it definitely won’t interfere with the repair process.

- Using a 10mm wrench, unscrew the fixing bolt on the cardan.

- Apply several gentle, not strong blows with a hammer to knock the cardholder off the shaft. Remove the boot to the side if you have not done so before.

- We replace the old cardan with a part from Kalina. It is more reliable, efficient and durable.

- For reassembly you will need the help of a friend. Do not rush to tighten the clamp immediately at the end.

- The assistant will set the position of the gearshift lever at the optimal points from inside the cabin. First you need to catch the center, then move the lever a little to the right while you tighten the clamps from below.

- Check if the gears engage well. If yes, then we continue assembling the unit and check the updated gearbox under real road conditions.

The experience of VAZ 2109 owners shows that when there are problems with the rocker, the essence often lies in an unsuccessful factory cardan. By replacing it with an analogue from Kalina, you will be able to get rid of discomfort and continue to confidently operate your car. By replacing the cardan shaft, the design of the gearbox will improve significantly.

Adjustment

After changing the link or cardan, you should definitely adjust the operation of the unit.

- Engage reverse gear, loosen the clamp tension.

- Set the gearbox selector to the position in which it should ideally be located when engaging reverse.

- Tighten the clamp back.

- A similar operation is performed with other speeds.

There are situations among VAZ 2109 owners when difficulties arise when engaging reverse gear. This is where adjustment can help.

- Set the gear lever to first gear;

- Loosen the rocker clamp;

- Turn the rocker drive counterclockwise;

- Turn the drive until the selector is pressed against the plastic stopper for the reverse gear. You will feel this without any problems;

- Resting against the stopper, tighten the clamp under the bottom. That's it, the adjustment is done.

Causes

What could be the reasons why the reverse gear in a VAZ car does not engage? In fact, there can be a lot of them, because the problem with switching gears, one way or another, lies in the transmission system and, in particular, in the gearbox itself.

Gear shift lever in a VAZ 2109 car

- Incomplete release of the clutch. As a rule, if the clutch is not disengaged correctly, all speeds may not engage well, but sometimes this problem affects only the reverse gear.

- The gearbox drive levers or rods are damaged. The fastening may also be loose. To eliminate such a malfunction, it is necessary to conduct a thorough inspection of the unit and transmission system. If necessary, it is recommended to replace all damaged system components.

- The lubricant in the gearbox has run out. In this case, the problem with switching gears will affect all gears without exception. Therefore, the likelihood of such a problem, unless only reverse gear is engaged, is very small. As you understand, you should check the level of consumables in the system and, if necessary, add oil to the gearbox.

- Bad gear oil. The transmission fluid has already lost its properties and cannot fully ensure lubrication of all gearbox components. In this case, the problem will also affect all gears without exception, although in practice there have been cases when problems occurred with engaging the reverse gear. In this case, an oil change will be required.

- Poorly adjusted rocker: the gearbox rocker cardan needs to be adjusted. Due to poor adjustment of the rocker, the reverse gear sometimes not only does not engage, but also falls out. This problem is one of the most common among VAZ 2109 cars, so we will consider fixing it first.

Short walker

Many people are still wondering whether it is worth changing their standard factory long-stroke linkage to a short-stroke one.

Make your decision purely on the basis of individual reflections and do not “be fooled” by statements regarding a significant increase in dynamics with the transition to a short-stroke.

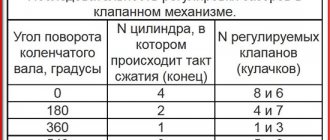

The real difference between short-stroke and long-stroke is shown in the table.

Draw your own conclusions from here - do you need such a drawstring or not. There is nothing complicated in terms of replacement. The only question is the purchase.

Is the shift rod seal leaking? How to replace the rocker seal?

Today we will figure out how to change the oil seal with our own hands and we will be able to save N amount of money. There are only two ways to replace the rocker seal of the VAZ 2108, 2109, 21099, 2113, 2114, 2115. The first is to replace the rocker seal in the inspection hole by knocking out the bushing along with the seal. The second method does not require an inspection hole, but will require you to have a certain manual dexterity, body flexibility and the presence of one (two) long self-tapping screws.

We will need: - two 13mm wrenches, - a 10mm wrench, - a wrench or screwdriver for knocking out the oil seal sleeve, - a small hammer, - a 22mm socket, - silicone sealant.

Spare parts: – gear shift rod oil seal – cardan shaft boot

Let's start replacing!

Using two 13mm wrenches, we loosen the clamp of the transmission control rod (the connection between the rod and the driveshaft can be marked in advance, so as not to have to deal with regulating the gear shift later) and disconnect the rod from the driveshaft. If it doesn’t unscrew well, spray everything with WD-40.

Pull the boot back and use a 10mm wrench to unscrew the bolt securing the cardan to the gearshift rod. Remove the cardan and boot. Using a screwdriver, knock out the bushing from the gearbox.

Using the same screwdriver, we knock the oil seal out of the bushing and with a 22mm head, press the oil seal in until it stops. Lubricate the bushing with sealant and press it into the gearbox with gentle hammer blows.

Advantages and disadvantages

Let's start with the pros, let's figure out why the short-throw rocker on the VAZ 2109 is good:

- The advantages of such a rocker compared to a standard rocker (this, at least, applies to the VAZ 09 and 10 families) is that, solely due to its size, it can significantly reduce the stroke of the lever when shifting gears on and off

- In addition, shifts become even clearer

However, there are disadvantages in any tuning, and this thing also has them:

- High price

- Increases effort to shift gears

Short slide for VAZ 2109: we make it ourselves

A short slide of a VAZ 2109, and under it a long one

The short rocker for the VAZ 2109 is becoming very popular among VAZ car owners who love a variety of tuning and their car. At the same time, many people hate the gear shift lever, which has a long stroke; it simply “wanders” almost throughout the entire interior of the car when changing the desired gear. Therefore, the short-throw rocker for the VAZ 2109 is an excellent solution for them.

Operating principle and manufacturing method

The VAZ 2109 short-throw gearbox came from professionals in motor racing; you will agree what kind of sport it is if a lot of time is spent shifting gears. What does such a scene give:

- Thanks exclusively to it, switching becomes much more pleasant for you, and the lever stroke is significantly reduced by almost half, the result obtained from the installation is simply incredible

- Therefore, smart people picked up this “theme” and launched it into the “masses”

- It turns out that today the VAZ 2109 short-stroke rocker is sold in almost every auto parts store

- Of course, the price is significantly inflated, but this is not an obstacle for most motorists

- There is nothing surprising here, because the rocker is worth it, I myself, like many car owners, was ready to buy it, I liked the short rocker of the VAZ 21093 gearbox so much.

- However, as soon as I saw its design and understood the main point of tuning, I changed my mind about paying for it, because it is possible to make one with your own hands in just half an hour of work

- What I got - see for yourself. Now I’ll tell you in a few words about how the whole mechanism works, also see the photo

The diagram I have given will allow you to understand how the short-throw rocker on the VAZ 2109 works:

- The "O" - "F" line represents the low and high points of your standard lever set to neutral.

- In order for you to engage the gear, you will need to move the rod connected to the lever (point “B” is the point of their connection) to point “A”

- The handle of the gear shift lever will move to point “E”

- You understand that our task is to reduce the “E”-“F” switching distance that the handle travels

- And for this we need to increase the length of the lever to point “H”, which will allow us to raise the rod by the same distance (the segment “C”-“D” is equal to the segment “A”-“B”)

- It turns out that the lever that changes gears will have to travel a shorter distance; in this case, you won’t have to stretch or “search throughout the cabin” for the desired gear and its lever

Let's get down to business

The short-stroke rocker for the VAZ 2109 requires the following tools for manufacturing:

- Grinder and cutting wheel for metal or, at worst, a hacksaw for metal

- A piece of pipe and a piece of flat metal

- Welding (welding machine)

- be sure to purchase a lever drive from Lada Kalina

- The photo shows the places where you will need to make an incision.

- Everything is quite simple: you will need to remove the rocker from the car

- Moreover, it is not necessary to remove everything (I admit, I did just that and regretted it a little - it’s a chore, it turns out) it will be enough to disassemble your ball joint (to do this, unclench the locking metal ring so that the plastic fastening tabs separate and the ball is released)

- Then loosen the clamp near the gearbox and turn off the traction

- After this, carefully pull the rod through the dirt cover and get out of the car.

- Now you need a grinder with a cutting wheel for metal, a familiar welder with a welding machine, or someone who has access to one (you have the machine and know how to weld yourself - generally a test)

- Next, use a grinder to cut the parts according to the marks in the top photo. Then we weld a piece of pipe (with a wall thickness of 2 - 3 millimeters) into the rod and a piece of sheet metal with a thickness of 5 - 6 millimeters

- These pieces must certainly have the same length, otherwise you will have an unpleasant distortion, which is not at all desirable and the drive will only work worse

- For myself, I lengthened it by only 2 centimeters

- However, the space in the cabin allows you to lengthen it by 3 - 5 centimeters

- At first two centimeters was quite enough for me, but then I got used to them and it seems not enough again

- By the way, regarding the pieces, welders have nowhere to put them; as a rule, finding a suitable one does not cause any problems

- The VAZ 2109 short-stroke rocker is installed in the reverse order of removal

- However, among other things, the hinge with a hook, which serves to prevent erroneous engagement of reverse gear, rises automatically and no longer fits into a special slot on the blocking plate

- In order to avoid this, either remove this plate completely (this is for the especially lazy) you can ride without it, or you should move it upstairs to the height to which the hinge has risen

When you have installed the rocker on the VAZ 21093 gearbox, all that remains is to replace the drive shaft to eliminate play in the lever

Why change the driveshaft?

On all VAZ 2108-2110 cars without exception, there is a strong play in the gearbox linkage, as a result of which we get unclear gear shifting:

- We can say with confidence that this is a disease or a deficiency of all cars of this brand

- The cause of this “illness” is the original gearbox driveshaft

- If you want to eliminate such a drawback, then our instructions will help you reduce the backlash of the rocker and increase comfortable gear shifting (especially since you achieved this by replacing the rocker)

- First you need to get to the car market and purchase there (or at a spare parts store) a short-stroke universal joint from a Lada Kalina car

- You should take it complete with a boot, because the boot does not fit on a standard cardan

repair of the gear shift lever on VAZ 2108, VAZ 2109, VAZ 21099 cars

1. Remove the protective cover of the gear shift lever (Fig. 5.14) from the floor tunnel lining.

2. Remove the floor tunnel lining.

3. Remove the screw securing the floor tunnel lining at the rear.

4. Remove the floor tunnel lining by sliding the floor tunnel lining back.

5. Remove the nut securing the shift lever shaft, and then the five bolts securing the shift lever base to the floor.

6. Remove the gear shift lever with the base, while removing the rubber protective cover from the base.

7. Remove the gear shift lever shaft with two plastic bushings. If the axle dangles freely in the bushings installed in the gear shift lever, then the bushings are worn out and the bushings need to be replaced. When installing the bushings, lubricate the bushings with grease.

8. To replace the plastic support for the gear shift lever, remove it from the spherical pin of the lever, put grease into the hole of the new support and put the support on the pin.

9. To replace the leather cover, remove the handle by pulling it off the gear shift lever. 10. Install the gear shift lever in the reverse order. Tighten all threaded connections to a torque of 16-26 Nm (1.6-2.6 kgf-m).

11. To replace the gear shift rod from the bottom of a VAZ 2108, VAZ 2109, VAZ 21099, loosen the clamp and disconnect the gear shift rod from the joint tip.

12. Unscrew the nut securing the gear shift lever axis and remove the rod into the interior of the VAZ 2108, VAZ 2109, VAZ 21099.

Rice. 5.14. Details of the gear shift lever for the VAZ 2108, VAZ 2109, VAZ 21099:

1 — gear shift lever; 2 - bushing; 3 — lever axis; 4 — lever support; 5 - base; 6 — leather case; 7 - handle

Types of mechanisms

Despite the different design models, only two types can be distinguished:

- Long-stroke (standard, previously installed on cars of model 2109 and similar).

- Short-wheel drive (installed on Kalina cars).

Structurally they are very similar, only different in size. The advantage of short-throw ones is that with their help, gears are engaged easier and faster.

True, many myths have formed around the gear shift: some claim that the dynamic characteristics of the car are significantly improved. This is all wrong; there is no connection between the dynamics of the car and the view of the backstage. But still, the short-stroke one has advantages over the standard one.

Installation of a short-stroke rocker on a VAZ 2109

The linkage is an important component of the VAZ 2109 gearbox. If it fails or does not work satisfactorily, the linkage can be easily replaced or repaired.

Appearance of the device

There are two types of scenes:

There is no fundamental difference between the two types of units. The advantage of a short-throw is that it provides faster gear changes for a fraction of a second.

Do not believe those who claim that a short walk has a positive effect on dynamics. There is no connection between the rocker and the dynamics of the car. But the short walk has its advantages.

Replacement kit

Why change the backstage?

There are situations when it is necessary to intervene in the gear shift mechanism due to the failure of a component. But there are times when an extreme measure is required - replacing the VAZ-2109 rocker. In these cases, replacement is required:

- An oil leak appeared due to damage to the oil seal. Only the oil seal can be replaced.

- Complete failure of the scenes.

- You have realized the advantages of a short-stroke design and you have the funds for this kind of tuning.

Symptoms of gear shift mechanism failure:

- Increased gearshift lever play. Please note that this behavior may also be caused by a loose cardan. Sometimes the bolt securing it gets screwed out, so to reduce the backlash it is enough to tighten it, and first apply a drop of thread locker.

- Difficult to shift into gear. Sometimes extraneous sounds are heard.

- Gear shifting is not possible.

- Inconsistency between the position of the lever and the selected speed. For example, the back one disappears, and the first one is in its place.

If a slight play appears, it is advisable to carry out diagnostics and identify the breakdown of the unit. Make repairs immediately, otherwise one or more speeds will disappear at the most inopportune moment.

Removing the gear shift drive VAZ 2108-2109

One of the reasons why it is necessary to remove the gear shift drive may be an increase in the free play of the gear shift lever, or difficulties in engaging them. Over time, the drive's hinge mechanism wears out, so the solution to the problem may be to completely replace it or repair it using repair kits.

Description of removing the gear shift drive VAZ 2108, 2109

Take a screwdriver and spread the ends of the clamp, sliding it back along the rod.

Pull the drive rod off the splined tip of the gear shift rod hinge.

How to replace the oil seal

If you detect an oil leak from the gearbox, carefully inspect the crankcase.

The leak will reveal itself. Lubricant usually leaks out through the CV joint seals and rocker panels. In the latter case, to replace you will need to perform a number of actions:

- Purchase a new VAZ-2109 gearbox seal. Its price is about 100 rubles.

- Drain the oil completely from the gearbox by unscrewing the plug from the bottom using the key “17”. If necessary, you can replace the lubricant later. It is recommended to pull out the upper dipstick to facilitate oil drainage.

- Disconnect the cardan from the rocker arm.

- Remove the boot, use a 10mm wrench to unscrew the bolt securing it to the gearbox rod.

- Using an awl or a thin screwdriver, remove the old oil seal. Inspect it for damage.

- Install the new oil seal using a pipe or large washer to press in.

After replacement, install the boot. Assess the condition of the cardan: if it has too much play, it will need replacement. After carrying out all the work, be sure to check that the speeds are turned on correctly.

VAZ 2109 - removing and replacing the gear shift lever

In most cases, the main reason for removing the gear shift lever on a VAZ 2109 car is its mechanical damage, as a result of which it is impossible to adjust the quality of gear switching, or the lever has become completely unusable and needs to be replaced.

If the base and the lever itself are in good condition, then there is no need to change them; it is enough to just replace the broken bushings or plastic support. It may also be necessary to replace the gear shift rod located under the car. To remove the gear shift knob, do the following:

- Remove the decorative leather cover from the lever.

- Next, remove the decorative plastic tunnel. To do this, remove the hatch and unscrew the fastening screws and remove it from the car interior.

- Now you can remove the lever by first unscrewing the nut and removing the bolt from the axle. Then unscrew the five bolts securing the base to the car body.

- Having unscrewed the bolts, carefully turn it over and remove it by removing the rubber cover from the base.

Actually, now that the lever has been removed, you can begin to replace the failed elements.

- First of all, we disassemble and remove the axle. To do this, remove the two plastic bushings on both sides. The axle must be replaced if it dangles in its socket, that is, in the bushing, which is installed in the lever itself. Replace faulty elements and lubricate them with grease before assembly.

- Next, remove the plastic lever support. To remove it, simply pull it towards you. Lubricate the new one with grease and install it back.

- Replace the leather cover if necessary.

Next, if you need to replace the gear shift rod, to do this we climb under the car and unscrew the nut of the clamp mounting bolt. Then, inside the car, disconnect it from the shift lever. Pull the rod into the cabin. At this point, the repair work on removing and replacing the VAZ 2109 gear shift lever has been completed. Reassemble in reverse order.

How to replace the universal joint

In most cases, it is not the rocker itself that fails, but the cardan. Due to its displacement, even a small one, a failure occurs in the gear shift mechanism.

Standard VAZ-2109 scenes are rarely installed during repairs; similar parts from Lada Kalina are used. The replacement looks like this:

- Using two keys set to “13”, unscrew the clamp securing the cardan to the rod.

- Using a screwdriver, pull the boot towards the box housing. If desired, you can remove it completely, and if it has cuts or other damage, replace it with a new one.

- Unscrew the fixing bolt with a “10” key.

- Knock down the cardan with a hammer, strike carefully so as not to damage anything.

- The Kalinovsky universal joint is much more durable and reliable, so install it instead of the standard one.

- Reassemble the entire structure in reverse order. But do not rush to tighten the bolt on the clamp - adjustment is necessary.

Removing and installing the gear shift lever VAZ 2108, VAZ 2109, VAZ 21099, Lada Samara

Gear shift lever:

1 —

gear shift lever

2 -

bushing

3 -

lever axis

4 -

lever support

5 -

base

6 -

leather case

7 -

handle

1.

Remove the protective cover of the Lada Samara gear shift lever from the floor tunnel lining.

2.

Remove the floor tunnel lining.

3.

Remove the screw securing the floor tunnel lining at the rear.

4.

Remove the floor tunnel lining by sliding it backwards.

5.

Unscrew the nut securing the lever axis of the VAZ 21099, and then the five bolts securing the base of the lever to the floor.

6.

Remove the lever with the base, while removing the rubber protective cover from the base.

7.

Remove the lever axis with two plastic bushings. If the axle dangles freely in the bushings installed in the lever, then the bushings are worn out and need to be replaced. When installing the bushings, lubricate them with grease.

8.

To replace the plastic lever support, remove it from the spherical pin of the lever of the VAZ 2108, VAZ 2109, VAZ 21099, put grease into the hole of the new support and put the support on the pin.

9.

To replace the leather cover, remove the handle by pulling it off the lever.

10.

Install the VAZ 2108 gear shift lever in the reverse order. Tighten all threaded connections to a torque of 16-26 Nm (1.6-2.6 kgfm).

A bent gear shift rod needs to be replaced or straightened.

12.

Unscrew the nut securing the gear shift lever axis of the VAZ 2109 and remove the rod into the passenger compartment.

Backstage adjustment

There is nothing complicated in the procedure; you can do it yourself, but you will have to run from the pit to the salon.

Yes, it is advisable to do this work in a pit or overpass. You need to act approximately according to this principle:

- Loosen the nut on the clamp.

- Set the gearshift lever to the reverse gear position.

- Set the box rod to the reverse speed position. This is difficult to achieve, so adjustments will have to be made.

- Check how the gears shift. If the rear one is too far to the left, loosen the clamp and turn the cardan counterclockwise. If the fifth speed (including reverse) has gone too far to the right, then the cardan rotates clockwise.

By adjusting the position of the gearshift rocker, you will notice that when the lever is installed in the middle, neutral speed will be engaged. When turning on the fifth gear, the lever should not catch the passenger seat, and when moving in reverse, the driver's seat should not interfere with the movement of the lever.

Short-throw slides for "nine"

Such designs were developed exclusively for sports models, but are widely used in production ones. Advantages of the VAZ-2109 short-stroke rocker over the standard one:

- Easier gear shifting.

- The backlash of the gearshift lever is reduced, especially when using a cardan from Kalina.

- You need to either buy it or make it yourself.

- It takes a lot of force to change gears. Despite the smaller stroke, this type of backstage is more suitable for people who are not only strong in spirit.

But you don’t have to buy a VAZ-2109 rocker in stores; you can make a short-shifter from a regular one with little welding skills.

To do this, cut the old rocker in two places and weld pieces of a metal plate to lengthen the arms. The main thing is for the new drawstring to fit into place, so first carefully study the drawing, which shows the locations of the cuts.

The VAZ 2109 is known as the most successful car of the Volga Automobile Plant after the collapse of the Soviet Union. It is still widely popular among domestic drivers. At the moment, production of the VAZ 2109 and its modifications has been suspended. In addition to 2109, its direct successor 2114 is often found on the roads of our country, as well as the successor to the “eight” 2113, and the “tens” - 2115.

Tuning the VAZ 2109 transmission

The classic transmission of all VAZs is manual. It is quite reliable, cheap to maintain and well suited for use on domestic roads.

Upgraded car

There are several popular types of tuning for manual transmissions. They appeared as a banal need to improve the performance of the car. The main work packages include:

- Replacing the backstage.

- Conversion from 4-speed to 5-speed.

- Installation of a sports row.

- Modernization of the pedal unit.

- Replacement of the main pair and differential.

Let's take a closer look at one of the tuning options. Replacing the rocker with a short-throw one is a useful tuning that will significantly simplify gear shifting. We all know that the lever of the “nine” and most other VAZ cars is absolutely inconvenient. It has a huge backlash, which simply has a terrible effect on the accuracy of gear shifting. If men with long hands can still cope with it without any critical effort, then women will have a very difficult time with it.

The easiest way out of the situation is to install a short-stroke cardan from the Lada Kalina on the 2109. Such tuning will cost you approximately 1,500 rubles. Along with the cardan, you will have to get a boot from the same model, because it won’t be original with it.

The necessary tools for work are a set of keys, a slotted screwdriver and a hammer. It will also be very good to have an assistant.

The process of replacing the gearbox rocker

Dismantling the old rod

First you need to loosen the clamp on the main rod and remove the hinge from it. To do this, use a 13mm wrench. Next, remove the boot and, using a 10mm wrench, unscrew the bolt on the desired cardan. Usually it is fixed almost tightly, so here you will need a hammer to loosen it a little with gentle blows. By the way, you can immediately check the condition of the oil seal and, in case of any defects, replace it with a new one.

New drawstring and cord from Kalina

Installation of a modified backstage

Having removed the old cardan, you can begin installing the new one. To do this, you must first put on the boot. Next, we place a new cardan on the gear selector rod and secure it with a fixing bolt. Be sure to make sure that the bolt fits into the special recess on the rod. Also, do not forget to apply thread locker to the bot so that it does not unscrew due to vibration.

The next step is to put the drive rod on the rod. For some models, the stem from Kalina will have to be shortened by about 1.5 cm.

Adjustment

Next, you must carefully adjust the position of the lever so that it is centered with a slight offset to the right. Here we will need an assistant who will have to monitor the placement of the lever in the cabin. After installation is complete, tighten the clamp, while an assistant must hold the lever from moving.

And, of course, you yourself should try how conveniently the lever is adjusted and, if something happens, reconfigure it.

By the way, some craftsmen cope with shortening the scenes without buying a new one. To do this, you need to disassemble the slide, as in the previous paragraph, and trim the necessary parts using a grinder. Next, weld a piece of pipe and sheet metal into the rod. If you yourself are not very knowledgeable about this, you can ask any welder. This process can be studied more clearly using a visual video.

Gear shift drive VAZ-2109

The gear shift drive is mechanical. It consists of a gear shift lever 38 (Fig. 62), a ball joint 36, a rod 34, a gear selection rod 19 and gear selection and shift mechanisms.

Rice. 62. Gear shift drive:

Content

1 - secondary shaft; shift fork for 1st and 2nd gears; 3 — turn of switching between III and IV gears; 4 — 5th gear shift fork; 5 — rod for turning on 5th gear; 6 — retainer ball; 7 — clamp spring; 8 — clamp cover; 9 — guide axis of locking brackets; 10 — reverse light switch; 11 — three-arm gear selection lever; 12 — plug of the reverse gear lock; 13 — reverse gear turn; 14 — gearbox housing; 15 — blocking brackets; 16 — housing of the gear selection mechanism; 17 — axis of the gear selector lever; 13 — spring of the gear selector lever; 19 — gear selection rod; 20 — gear selection rod lever; 21 — fork rod for shifting III and IV gears; 22 — shift fork rod for 1st and 11th gears; 23 — clutch housing; 24 - bushing; 25 — rod seal; 20 — conical screw for fastening the hinge; 27 — sewn-in hinge cover; 28 — housing of the gear shift drive rod hinge; 29 — hinge bushing; 30 — hinge axis; 31 — hinge tip; 32 — gear shift drive rod clamp; 33 — gear lever housing; 34 — gear shift drive rod; 35 — protective cover of traction; 36 — ball joint of the lever; 37 — spherical lever finger; 38 — gear shift lever; 39 — lever finger; 40 — lever axis bushing; 41 — locking bracket.

The gear shift lever with its ball pin 37 rests on a plastic ball joint 36, which is located in the lever housing 33, fixed to the floor of the body. Two plastic bushings 40 are pressed into the lever sleeve 38, through which a pin 39 passes, connecting the lever to the rod 34. The pin is locked with a bracket 41. The other end of the rod 34, using splines and a clamp 32, is connected to a hinge consisting of a body 28 and a tip 31, hingedly connected to each other by an axis 30. The axis is pressed into the hole of the tip 31, and plastic bushings 29 are installed in the holes of the hinge housing. The hinge parts are covered with a rubber protective cover 27. The hinge housing is mounted on the gear selection rod 19 with a conical screw 26.

The gear selection rod 19 is installed in the holes of the clutch housing and its outer end rests on the bushing 24. At the exit from the clutch housing, the rod is sealed with an oil seal 25. At the inner end of the rod, the gear selection lever 20 is secured with a conical screw. It interacts with the three-arm lever 11 of the gear selection mechanism. This mechanism is made as a separate unit and is attached with three bolts to the clutch housing 23. There are two axes installed in housing 3 (Fig. 63) of the gear selection mechanism. Axle 6 is equipped with a three-arm gear selector lever 4 and two locking brackets 5, and axis 7 passes through brackets 5, securing them from turning. One arm of the gear selection lever 4 is used to engage forward gears, the other is used to engage reverse gear, and the third arm is used by lever 2 of the gear selection rod.

Rice. 63. Parts of the gear selection mechanism:

1 — gear selection rod; 2 — gear selection rod lever; 3 — housing of the gear selection mechanism; 4 — three-arm gear selection lever; 5 — blocking brackets; 6 — axis of the gear selector lever; 7 — guide axis of locking brackets; 8 — reverse fork; 9 — gear selector lever lock; 10 — thrust washer of the gear selector lever; 11 — lever spring.

Under the action of spring 4 (Fig. 64, II), lever 7 and locking brackets 6 move on their axes until ball 2 stops against the step on axis 5. In this position, the brackets lock one end of the reverse fork 1, entering its groove, and the other the end locks the fork of the first and second gears (as well as the fifth gear of a five-speed gearbox); The forward gear selector lever is set to the 3rd and 4th gear position.

Rice. 64. Gear selection scheme:

I - reverse; II - forward travel; 1 — reverse fork; 2 — locking ball; 3 — clamp spring; 4 — spring of the gear selector lever; 5 — axis of the gear selector lever; 6 — blocking brackets; 7 — three-arm gear selection lever; 8 — rod for shifting 1st and 2nd gears: 9 — rod for shifting 3rd and 4th gears; 10 — rod of the 5th gear shift fork.

When the gear shift lever is moved transversely towards reverse, the force through the rod 34 (see Fig. 62) is transmitted to the gear selection rod 19, which, turning on its supports, through the lever 20 moves the gear selection lever II and the locking brackets on their axes. In this case, spring 4 (see Fig. 64, I) is compressed, and bracket 6 comes out of the groove of the reverse fork 1. Instead of a bracket, the arm of lever 7 for selecting reverse gear fits into the groove of fork 1, and when lever 7 is turned on its axis, reverse gear is engaged. Thus, when moving the gear selector lever along its axis, gears are selected, and when turning on the axis, gears are engaged.

The gear shift drive also includes rods 5 (see Fig. 62), 21 and 22 with forks attached to them. The position of the rods is fixed by ball clamps 6. Fork 4 fits into the groove of the 5th gear synchronizer clutch, fork 3 into the groove of the clutch of 3rd and 4th gears, fork 2 into the groove of the 1st, 2nd gear and reverse clutch, and fork 13 into the groove of the intermediate gear. reverse.

Automatic transmission for VAZ 2109

The first model that served as a springboard for the installation of automatic transmission among VAZ cars was 2115. Now automatic transmission is occasionally found on cars 2109, 2110, 2113, 2114, 2115 and 99. VAZ models released in the 00s, Lada Kalina and Lada Granta, became the first domestic passenger cars with factory equipment including an automatic transmission.

Option #1

At the moment, anyone who wants to install an automatic transmission on a “nine”, 2113 or 2114 has two options. The first is to install a contract automatic transmission from Toyota Corona. The undoubted advantages of such modernization:

- A used automatic transmission option is easy to find in almost any car market;

- It has a reasonable price;

- The Toyota Corona transmission does not require special firmware during installation.

Option No. 2

Naturally, the second option for installing an automatic transmission is to contact an official VAZ dealer in your area. Seeing the interest of drivers in such tuning, they also took up its implementation. Peculiarities:

- Licensed gearbox with a 1.5 year warranty;

- The automatic transmission is completely Japanese assembled, produced by Nissan.

It should be immediately noted that the option of ordering an automatic transmission installation from an official dealer is more reliable, but the price is approximately twice as high.

Is the game worth the candle?

With all their advantages, to be honest, automatic transmissions on 2113, 2114, and even more so on 2109 are very rare. On such cars, an automatic transmission can be considered simply an expensive extravagance. Not only does the automatic transmission itself somewhat worsen the car’s performance, it eliminates the main advantage of domestic cars – efficiency. So you will not only lose on the purchase, but your gas mileage will probably increase.

You will learn where to start your auto tuning in our article.

Which acoustics are suitable for your car - read the link https://avtopolza.ru/tyuning/podbiraem-akustiku-v-mashinu/.