The VAZ 2107 has an overhead valve gas distribution mechanism. This means that the camshaft is located at the top of the engine, in the cylinder head. The timing belt is designed to regulate the supply of gas-fuel mixture to the cylinders and organize the removal of exhaust gases. To operate the timing gear, a sprocket gear is installed, the drive of which on the VAZ 2107 injection engine is a chain with special devices.

Timing chain for VAZ 2107

When is stretching necessary?

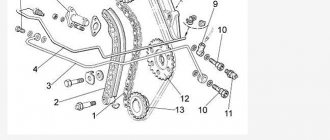

The gas distribution mechanism on the VAZ 2107 injector consists of the following elements:

- intermediate and crankshaft gears;

- camshaft and intermediate shaft;

- rocker;

- sedative;

- intake and exhaust valve;

- tensioner;

- shoe;

- timing chain drive.

The photo shows timing parts.

Components of the gas distribution mechanism

Thanks to the timing belt, the air-fuel mixture is supplied and exhaust gases are removed. Its operation is carried out using a chain drive or belt. They transmit torque from the crankshaft to the camshaft.

The shafts must be in a certain position. To do this, special marks are placed on the crankshaft pulley and the camshaft sprocket, which must be set correctly. If the marks do not match, serious problems with the engine may occur, including major engine repairs.

During operation, the chain drive and belt are under constant tension, so after a while the chain gradually stretches - its pitch increases. In this case, the engine begins to idle unstably, the speed begins to fluctuate, and the engine may stall.

If metallic sounds appear when increasing or decreasing speed, this is a sure sign of stretching of the chain drive or wear of the damper. To eliminate these sounds, you need to tighten the chain or replace the damper. Chain drive tensioning should also be done after replacing any timing parts, including the guide rail and shoe.

The chain drive on the VAZ 2107 injector is adjusted using a tensioner, which can be a mechanical, automatic or hydraulic tensioner. To install a hydraulic tensioner on a VAZ 2107, you need to redo the timing belt. Instead of the standard one, an automatic tensioner is often installed; it is more reliable.

Diagram of the gas distribution mechanism

How often does tension need to be applied?

During operation, the chain is subjected to heavy loads, so its service life is 60-80 thousand km. Adjustment should be carried out every 15 thousand km, but if the driver discovers earlier that something has begun to rattle when the engine is running, then it should be diagnosed. Before tensioning, you need to check its serviceability.

It is also necessary to check the tension in the case when the timing belt repair on the VAZ 2107 was carried out or in the case when, after tensioning, knocking of the product is still observed. The knock, or more precisely, the rustling of the chain, will not be difficult to distinguish even for an inexperienced driver. This rustling noise can be clearly heard if you lift the hood and listen to the engine at idle speed. If you add gas, the rustling disappears, which actually means that it’s time to tighten the timing chain. For this, a timing chain tensioner is used, which come in different types: automatic and mechanical.

Step-by-step instructions for stretching

Now let’s pay attention to the question of how to properly tension the timing chain on a VAZ 2107. Initially, it is worth noting that the timing mechanism on VAZ 2107 cars with an injector and carburetor fuel supply system are absolutely identical. The tension on the VAZ 2107 is performed in the following sequence:

- The car is placed on a flat surface, the “neutral” is turned on, and the wheels are fixed.

- The tensioner cap is loosened (using a 13 key), which is located near the pump.

- The crankshaft is turned 2 turns clockwise, for which a special key is used (pictured).

- After this, the tensioner is tightened to failure.

- Next, we start the engine and listen to see if the clanging remains.

- If it disappears, then the chain is tight. If there is any left, we recommend repeating the procedure from point No. 2.

If the actions taken are not successful and the noise remains, you will have to resort to a visual inspection of the timing mechanism, and for this you will have to disassemble the engine.

The chain tension must be adjusted by rotating the crankshaft. If you don’t have a special key to rotate the crankshaft, you can hang up the rear of the car or one of the wheels, then engage 5th gear and rotate the wheel.

Tension check

The VAZ 2107 chain is located in the front part of the engine. It is not visible, since it is covered by the cylinder head cover and the block itself. Before you start disassembling the VAZ 2107 engine, you need to understand the features of visual inspection and checking its tension. It is rational to check the chain tension only in cases where regular tensioning does not help solve the problem.

To visually check the tension of the VAZ-2107 timing chain, you must first remove the air filter housing, then the cylinder head cover. To do this, you will need a “10” wrench, with which you need to unscrew 8 fastening nuts.

When removing the cylinder head cover, special attention must be paid to the integrity of the gasket. If necessary, it is better to replace it, since in most cases an engine oil leak may occur.

After removing the valve covers, access to the upper part of the product becomes available. Here you need to inspect the tensioner shoe and damper for integrity, and then check the chain mechanism with your hands, and if that doesn’t work, you can use a pry bar or a large screwdriver.

The mount must be installed so that it stands between the chain mechanism and the block body. As a result, we get a lever that is used to check the chain tension on a VAZ 2107 car. If it bends easily, then its tension needs to be adjusted or replaced. The ideal tension is one at which the product does not bend and is taut like a string.

Step-by-step instruction

Before starting work on tensioning the chain, the car must be placed in a comfortable position. Place the gearshift knob in the neutral position and secure the wheels so that the car does not roll during the procedure.

Tools

To carry out the work, the following tools are required:

- set of socket wrenches;

- set of heads;

- pliers;

- screwdriver;

- hammer.

Before starting work, you should make a visual inspection of the chain drive. If mechanical damage is found to the tension roller, shoe, guide, sprockets or chain, the defective parts must be replaced.

Stages

The sequence of work when tensioning the chain both in an engine with an injector and with a carburetor consists of the following steps:

Video “Chain Knocking on a Classic”

This video examines the cause of engine knocking and demonstrates chain drive tension.

Chain that needs tightening

It is necessary to tighten the chain on a VAZ 2107 in the following cases:

Why is this so important to do?

During operation, the chain is subjected to significant loads. After all, it interacts with two shafts - the crankshaft and the camshaft. Over time, the part stretches out. The chain pitch changes and the engine begins to operate unstably. As a result, the revolutions fluctuate, and the mechanism itself jumps one or more teeth. If the circuit begins to make noise, this is the first sign for diagnosis.

The tensioner may have failed. But in most cases, simple adjustments save the day.

Experts recommend tightening the chain every 15 thousand kilometers. Its resource itself is about 100 thousand. By this time the part must be replaced. The sedative also changes. Before tensioning the chain on the VAZ-2107, check its condition. All the necessary elements can be found in the VAZ-2107 timing belt repair kit.

Main Causes of Circuit Failure

As the engine speeds up, the chain begins to rattle. In this case, the metallic ringing goes away as the speed decreases. A stretched timing chain contributes to a gradual shift in the valve timing, which leads to engine malfunctions.

All owners of cars of this brand should know how to tighten a chain on a VAZ 2107. This work is performed using a “13” wrench and a hammer. The chain is adjusted as follows.

- The tensioner is discharged. When performing this procedure, the shoe should snap off. If this does not happen, it means that the timing chain tensioner plunger is stuck. The problem is eliminated by tapping the unit body with a hammer.

- Using a key set to “13”, the cap nut is unscrewed.

- Using a special crankshaft wrench, the pulley is turned a couple of turns.

- The crankshaft stops at the moment of maximum rotational resistance. In this position, tension is applied.

- While holding the crankshaft from turning in the opposite direction, tighten the cap nut.

- The cylinder head cover is being installed.

Signs of stretching

The symptoms of this problem are specific. And it will be very difficult to confuse them with something else.

So, the main signs of a stretched gas distribution element chain are:

- Increased engine noise. Yes, the chain itself is very noisy. But in this case, the sound will be accompanied by a characteristic clattering sound, even at idle speed. As you press the pedal, the clunking sound will increase in intensity.

- Unstable engine speed. Since we now have shifted valve timing, the engine will adjust. Excessive vibrations occur and are transmitted to the body.

In some cases, the damper breaks. In this case, only replacing it will help. How to tension a chain on a VAZ-2107 (injector)? Photos of the process are in our article.

By the way, on a VAZ-2107 with a carburetor power system, unlike injection engines, to turn the crankshaft it is enough to turn the ratchet. But let’s not get ahead of ourselves and consider several ways to tighten the motor chain on a VAZ-2107.

Automatic tensioner system

Some car owners of classic VAZs replace the standard chain tensioner with an automatic one of the “Pilot” type. The automatic tensioner does not require maintenance after installation and, without the intervention of a technician, ensures that the chain is tightened as it stretches. The advantages of the Pilot device include:

- no need to supply an oil line, which eliminates chafing of the VAZ 2107 injector timing chain and loss of oil pressure;

- the absence of plunger elements, which is why the automatic chain tensioner “Pilot” does not jam;

- the movement step is 1 mm, which allows you to regularly monitor the degree of tension;

- no shoe wear;

- reduction of motor noise;

- increasing the service life of all timing components;

- long service life - about 25 years.

The “Pilot” chain tensioner improves the performance of the VAZ 2107 injector engine due to the precise execution of valve timing. The process associated with how to tension the chain is carried out regardless of the operation of the car engine.

This article will discuss how to tighten the chain on a VAZ 2107 yourself. The procedure is quite simple and you can do it yourself, although it is better together.

Types of chain drive

The VAZ “Seven”, like other “classics”, is equipped with a double-row timing chain. However, there is a single-row chain that, if desired, can be installed on a Zhiguli.

Single row chain

A chain drive with one row has less noise when the engine is running compared to two rows. This factor is one of the main factors in favor of choosing single-row chains. Therefore, some VAZ 2107 owners decide to replace the timing drive. The lower noise level is due to the fact that fewer links are driven. Plus, it is easier for the entire engine to rotate such a chain, which has a positive effect on the increase in power. However, due to the low noise level when such a chain is stretched, it is not always clear that the part needs tension.

Single row timing chain has lower noise levels

Double row chain

Despite the advantages of a single-row chain, a chain drive with two rows is the most common, since it is characterized by high reliability and if a link breaks, the entire chain does not break. In addition, the load on the timing drive parts is distributed evenly, as a result of which the chain and gears wear out more slowly. The life of the part in question exceeds 100 thousand km. Although recently, in order to reduce the weight of power units, automakers have been installing chains with one row.

The double-row chain, despite its higher noise level, has a long service life

Replacing a double-row chain with a single-row one

If you are thinking about replacing a double-row chain drive with a single-row one, you will need to purchase the following parts:

- crankshaft, camshaft and oil pump gears for single row chain;

- sedative;

- shoe;

- single-row chain;

- automatic tensioner.

To install a single row chain, you will need to replace the gears, chain, guide and timing chain tensioner

All of the listed parts are taken, as a rule, from the VAZ 21214. Replacing the chain should not cause difficulties. The only thing that is required is to replace the sprockets, for which you unscrew the corresponding fasteners. Otherwise, the steps are similar to the procedure for replacing a conventional double-row chain.

Preparation for adjustment, tools

Before starting work, it is better to place the car on a flat surface and put it on the handbrake. The gearbox knob is placed in neutral position.

You will need a number of tools, namely:

- socket wrench 10;

- carob at 38;

- carob at 13.

If the listed keys are available, you can proceed directly to tensioning the chain.

For a carburetor (performed if it is necessary to determine the integrity of the damper): remove the air filter housing from the carburetor and disconnect the “gas” draft from the roller;

Disconnect the traction lever;

Disconnect the bracket hose;

For injection (performed if necessary): remove the throttle cable and breather hose.

Using a 10 mm tubular wrench, remove the cover from the cylinder block;

Removing the mechanism

The car is placed on a level surface and immobilized with the handbrake.

To partially replace the tensioning mechanism, you do not need to remove anything from the engine. It is enough to unscrew the two nuts securing this element and remove it.

You need to pull it out carefully so as not to damage the gasket located under it.

But if this one came complete with a new tensioner, then it is not necessary to monitor the safety of the old one.

We stretch the chain on the VAZ

Using a 13mm wrench, unscrew the tensioner nut.

Using a 38 key, we begin to turn the crankshaft clockwise, usually 2 turns are enough. You can not only turn it with a key, but simply push the car, 2 - 3 meters is enough.

Important! Do not allow the engine to crank backward when cranking forward. Otherwise, the procedure is repeated.

When the engine rotates, the chain is tensioned on the damper side and loosened on the tensioner side, at which time the tensioner is activated. This happens with a characteristic click. If this does not happen, tap it lightly.

If you have removed the head cover, you can check the tension; there should be no deflection. If everything is fine, tighten the tensioner nut.

Reinstall the cylinder block cover.

We check the operation by starting the engine. The correct tension is determined by ear: the metallic ringing should completely disappear.

Nowadays there are automatic tensioners on sale; they are both praised and criticized.

This is a regular chain tensioner for VAZ 2101-2106, 2107

The video shows the procedure for a carburetor engine, but the process is identical for both engines.

Useful notes

If you have a “seven” with a carburetor, then after replacing the timing chain you need to adjust the ignition, because the drive sprocket of the ignition distributor-distributor (in common parlance, distributor) was also removed from its seat. Injection models do not require such adjustment.

Soviet and early Russian cars of the classic family were traditionally equipped with double-row timing chains. This provided increased reliability due to the fact that the break of one link did not provoke an instant collision of the piston with the valve in the open position. The disadvantage was the increased weight. In order to save money and simplify the design, the chain began to be made single-row. The resource of a double chain reaches 100 - 120 thousand kilometers, while a single chain is half as much. Some car owners are returning a double-row chain to their power units. True, for this you will also have to replace all the gears that mesh with the chain. Today, a set of such parts is quite difficult to find, so get ready for search work if you want to increase the reliability of the timing mechanism.

A double-row timing chain has a much longer life, but choosing a set of parts for its installation is much more difficult