Why does the Airbag indicator light up on the instrument panel?

If the airbag light comes on, this means that there is a failure somewhere, and the problem may affect not only the airbags themselves, but also any other element of the on-board safety system.

If there are no breakdowns, when you turn on the ignition, the airbag lamp lights up and flashes six times. If everything is normal with the system and it is working properly, the indicator will go out on its own after that until the next start of the engine. If there are problems, it stays on. The system begins self-diagnosis, detects a fault code and stores it in memory.

After the first testing, after a short period of time the system tests its elements again. If the breakdown was determined incorrectly or the signs of the malfunction disappeared, the diagnostic module erases the previously recorded error code, the lamp goes out and the machine operates in normal mode. The exception is cases where critical breakdowns are detected - the system stores their codes in long-term memory and does not erase them.

What to do after the airbag is triggered?

It is worth knowing that restoring airbags without involving service station specialists is a dangerous undertaking.

And the problem is not even that in the event of a collision the airbags are less likely to open. It's worse if they work spontaneously.

To avoid problems, you should contact an official dealer, who will adjust the system and replace faulty components.

When servicing yourself, there are a number of points to consider:

- In some cars, the airbag and squib are one unit that is purchased as a kit. This is done at a disassembly site or in a store (the first option is cheaper, but the risk of the product not being opened in an accident increases). There are also companies that do not change the airbag, but supply it with a whole squib (such a restoration should be avoided).

When repairing an airbag, the following points are taken into account:

- Removing the negative terminal from the battery is mandatory, after which you should wait until the autonomous power source discharges (7-10 minutes);

- The airbag is positioned with the body facing towards itself.

Often, car enthusiasts do not repair the airbag and limit themselves to restoring the body. In this case, the light bulb on the dashboard is removed or a “fake” is installed instead of a pillow.

This approach is dangerous. It is better to contact an official dealer and restore the system.

As for selling a car with a deployed airbag, this is real, but the new owner should be aware of the problem.

If you repair the panel and turn off the “lamp,” the buyer is unlikely to notice anything without diagnostics, but in the first accident, his death falls on the conscience of the seller.

Burning “Airbag SRS”, “Airbag”, or “SRS” indicator light: causes and solutions

So, for what reasons may the Airbag or SRS indicator appear on the instrument panel:

The integrity of the security guard is compromised - one of the most unpleasant options for a car owner. Due to a violation of integrity, the control unit may no longer receive the appropriate impulses from controllers, belts and other components of the safety system. There is a possibility that the seat belts themselves are equipped with a sensor that detects whether the seat belts are fastened; accordingly, if the driver or passenger is not fastened, the indicator on the dashboard will light up. This is necessary because the operation of the safety guard is relevant and most justified only in the case when the driver moves in a fastened state. In the event that an accident occurs, the PB will fly out at a speed of about 200 kilometers per hour, respectively, if the driver is not wearing a seat belt, this will correspond to hitting a concrete wall at a speed of 25 km/h. Given this factor, most vehicle manufacturers have programmed the PB so that if an accident occurs, it simply will not operate. And this, as you might guess, suggests that there can be no talk of any security. If you try to deceive the system by pulling straps behind the backs of chairs or using all kinds of emulators that will allow you to deceive it, it will be in vain. After all, this way you are only deceiving yourself; if a serious accident occurs, neither the driver nor the passengers will be able to survive because of this. Another problem is the lack of contact or very poor connection of elements in the power supply circuit of the PB. There is a possibility that the connectors are poorly connected. It is necessary to check the quality of the connection, as well as all contacts. Also, the indicator light on the dashboard may appear due to failure or damage to the shock controllers. They may also be poorly connected. We recommend checking the quality of the connections of the elements, as well as the connectors. But if all contacts are working, and the problem indicates a malfunction of the shock sensors, then these devices must be replaced quickly, otherwise there will simply be no point in the fact that the car is equipped with a power supply. One of the most common reasons is a broken door contact. If any repair work is carried out on the doors or they are changed, and the connectors are disconnected, then the contacts must be checked the next time they are connected. It happens that after reconnection the indicator still continues to light, this indicates the need to reset the control unit memory. Another reason is moisture ingress. If moisture gets on the electrical contacts or on the strap lock, it may cause poor contact or a short circuit. If you encounter such a problem, then the places where moisture gets in need to be dried. Failure or incorrect operation of the control unit. Perhaps the contacts on it also came loose. But if the problem lies in the unit’s board itself, then most likely it will have to be replaced. Safety devices. If these elements fail, the corresponding icon will also light up on the instrument panel.

But as practice shows, car owners pay attention to fuses last. Another reason why this problem may occur is when the seats or control panel are replaced. During replacement, the integrity of the wiring could have been damaged, in particular, we are talking about the connection points. In addition, a malfunction may occur as a result of violations when replacing the steering wheel.

If during replacement you damage the contacts, the indicator will always light up. If the safety guards were triggered during a collision, and the indicator continues to light after they were restored, this indicates that information about this remained in the memory of the control unit. Removing the error will solve the problem. The service life of the PB has been completed. On average, the service life of airbags is about 8-10 years; after this period, car manufacturers usually do not guarantee the performance of the airbag. Low voltage in the vehicle's on-board network. First of all, you also need a generator device.

Loading …

What are the indirect reasons why the airbag light is constantly on?

At the same time, even if all parts of the passive safety system function as expected, the light may still come on. This is explained by the fact that the SRS system includes many electronic devices and cables. Therefore, the error may not appear due to problems with the pillows.

The following factors can influence this:

- The battery is old, so the voltage is not enough for the system to work fully.

- The memory of the electronics control unit was damaged as a result of some kind of accident. A collision or impact will one way or another affect the vehicle's systems. Therefore, after an accident, it is better to reset the memory. And sometimes, in order for the airbag indicator to stop lighting, you cannot do without flashing it.

- The squib wears out, just like other basic components of the car. This happens when the vehicle has been actively used for more than a decade.

- Programs crash. Its main causes are chip tuning or incorrect software update.

Where are the airbags in the car and how do they work?

Before checking the presence and condition of protection devices in a particular machine, you need to find out their location. Depending on the make and model of the car, their design and quantity may vary, but in the vast majority of cars the main installation locations can be identified. The most commonly installed safety device is located in the steering wheel - it is intended for the driver. In inexpensive trim levels it may also be the only one. Another common location is at the top of the dashboard, for the front seat passenger. These two devices are combined into the “front-facing” classification.

Next are the location options that are found in more expensive or modern cars. These include side airbags located on the right and left in the cabin - they are called side airbags. Their function is to reduce the risk of injury to the pelvis, abdomen and chest in a collision. This type of protection is usually installed in the backs of the front seats or on the side, on the door side.

The next type of airbag is curtain airbag. They are designed to protect the head during a side impact. They first appeared at the end of the last century. Depending on the manufacturer, the head units (or "curtain airbags") are installed between the pillars at the front and rear of the roof.

Knee airbags are a system that reduces or eliminates injuries to the driver's and front passenger's legs. They are installed in the lower part of the dashboard - under the steering wheel and the glove compartment, respectively.

In the most advanced cars you can also find central airbags. They can be located in one of the armrests of the front row of seats, as well as in the middle part of the rear. The purpose of this system is to reduce the consequences of secondary damage.

In order to find protection systems in a specific car, you need to examine common installation locations. They should be marked Airbag or SRS - these are patented technologies that indicate airbags. This inscription is most clearly visible on the steering wheel. It is this system that is recommended to be inspected first. After unscrewing the cover, you need to check the presence of the system and the integrity of the wiring, as well as the condition of the squib.

Airbags consist of several elements:

- a control system that transmits a signal during a collision and provokes deployment;

- an elastic sheath (most often nylon) that is filled with gas or air;

- gas generator system, which is a squib and a charge for it, ensuring rapid deployment.

Protection systems are divided into 2 types depending on the gas generator. The former are filled with air, the latter with special gas. Most often this is nitrogen or argon. There are also hybrid systems. The opening occurs due to the reaction of the ignited fuel - potassium nitrate, sodium azide or silicon dioxide.

Airbags are disposable devices. Once triggered, they deflate and rupture, needing replacement. That is why it is necessary to monitor their condition in a used car.

How to dress correctly

The entire dressing process can be broken down as follows:

You need to start with the front seats. Carry out dismantling. Remove the headrest from the chair and cover it. First, the seat is put on. It is necessary to carefully straighten the eco-leather, only then place the chair on the side and secure the fasteners

It is important to tighten this part of the chair very well, since this is where the bulk of the load falls. If the tension is weak, wrinkles and folds will form on the chair. If the fastening is made from below, the upper part of the chair is put on like a sweater, but it is necessary to apply force, since the cut of the car cover is made exactly to size

Fasteners on the product made on the back of the seat are less preferred by drivers, as they do not look so elegant. The bottom of the car cover is secured under the seat, and it must be pulled tight. After the covers are put on, you need to install the covers on the previous areas and return the chair to its place. Putting on the eco-leather car seat cover for the front and rear seats is identical.

Before installation, be sure to read the included instructions. This will help avoid mistakes and avoid over-tightening the product.

The factory upholstery of the seats inside the car is subject to wear and tear. Eco-leather car covers will help protect the seats externally and significantly transform the car.

A big role here belongs to the correctness of putting on the cover. If you approach this work thoughtfully, it will take a little time, but the result will please you and your loved ones.

Even after a short period of use of a new car, the standard seat upholstery (especially light colors) loses its neat and attractive appearance. Dust, moisture, food and drinks will certainly leave their “traces” on it, which will then be quite difficult to remove even in specialized services that deal with professional dry cleaning of car interiors. Covers, which are best purchased immediately after purchasing a car, will not only reliably protect the seats from all these troubles, but will also give the vehicle interior an elegant look. How to put covers on car seats: videos, photos and recommendations for installing them are presented in this article.

Restoring the dashboard after the airbag deployed

Repairing the instrument panel after an accident is one of the most labor-intensive tasks in the SRS passive safety system. To replace the airbag and “sew up” the dashboard, you need to completely remove the dashboard. The most difficult thing to do is restore the appearance of the trim on the passenger side - if the plastic is sealed or sheathed with material carelessly, it will be noticeable.

Restoring the panel after the airbags are deployed is carried out in the following sequence:

- the negative terminal is disconnected from the battery;

- the glove compartment is removed;

- the instrument panel is dismantled;

- the fastenings of the instrument panel frame are unscrewed;

- the panel is dismantled and completely disassembled.

In this case, it is necessary to disconnect all the wires from the dashboard that interfere with removal, remove buttons, deflectors, etc. from the panel. Complete restoration of the dashboard with the installation of new airbags sometimes costs more than tens of thousands of rubles, so car owners are often offered to only restore the casing, without repairs and installation of airbags. But even such work is not cheap; many car owners try, if possible, to find a used instrument panel at car dismantling yards. As a rule, installing second-hand parts is cheaper than a complete repair, and besides, the original panel looks more natural - if the dashboard is restored, it is still noticeable upon careful examination. The restoration of the instrument panel after an accident is carried out by tuning studios; the work is divided into several stages:

- dismantling the dashboard;

- preliminary cleaning and treatment of the dashboard;

- sealing damaged areas using special adhesives;

- making patterns from material chosen by the customer;

- installation of covers on the restored instrument panel;

- Installation of dashboard, electrical connection.

At the request of the car owner, the instrument panel is decorated with decorative chrome elements or natural wood inserts, and an additional acoustic system is installed. The tuned panel looks very impressive, while all the defects that were previously present on the dashboard are hidden.

Why is the control unit reflashed?

There is such a thing as an SRS control unit, that is, a unit responsible for the operation of the safety glitch.

This block contains a program that automatically changes after the impact sensors are triggered and the airbags are activated. When restoring a car as a result of an accident, this unit must be reflashed or replaced.

Without doing this, the airbag error light on the dashboard will constantly light up. Even if the airbags are physically present, they will not work. The essence of flashing is to reset the data and return it to its original state.

Not all SRS units can be reflashed, and they must be replaced at the same time as installing a new set of airbags.

Reflashing, like replacing a block, is not a cheap procedure. It is almost impossible to do it yourself in a garage.

Airbag control structure

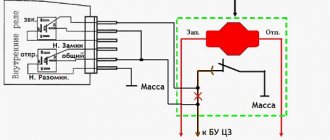

Modern airbag control systems are structurally simple and consist of the following elements:

- ECU (electronic control unit). Its main element is a three-dimensional accelerometer, which calculates the deceleration of the car when impacted on different axes. It must be borne in mind that the command for airbag squibs is issued only during sharp deceleration in a moving car, so complaints about allegedly faulty airbags that do not work at low speed are actually groundless. The control unit also reads information from a number of additional sensors described below.

- Shock sensors are an element of outdated Airbag systems that did not have an accelerometer built into the ECU. Such sensors were attached either in the bumper area, and responded to critical deformation, or in the front part of the cabin, and gave a signal about a sharp deceleration. They only made it possible to determine the fact of an impact in the direction where they were located, which is why they are not applicable on modern cars with many airbags that are triggered depending on the direction of the impact.

- Airbags. They consist of an elastic shell that is filled with gas when the squib is detonated by an electrical signal. The only airbag malfunction that the ECU can track is a significant change in the resistance of the squib ignition circuit relative to the specified one, that is, a short circuit or break. If the reason for the airbag warning light to come on is a detected open circuit, you can turn it off on a number of vehicles by removing this airbag or another element from the system configuration menu using a diagnostic scanner.

- Auxiliary actuators. The most common are seat belt pretensioners. They are squibs that, before the airbag deploys, press the person to the back of the seat. In this case, the pretensioner will work only in one case - if the seat belt is extended to a sufficient length (determined by the sensor located on the belt reel) and is latched into the buckle. A malfunction of any of these sensors will not only cause the warning light to come on, but also block the corresponding pretensioner.

- Additional sensors. These include seat belt sensors, the front passenger's front airbag switch, and so on. Their malfunction also leads to the registration of a corresponding error and the turning on of a warning lamp on the instrument panel.

- Wiring and connectors. The most common problems associated with them are mechanical damage. The most common malfunction of safety systems lies in a break in the connecting cable of the driver's airbag.

Replacing the gearbox cushion on a Kalina: when and how to change it

The Kalina is equipped with rubber-metal gearbox support cushions. This is a simple design consisting of two plates (metal), with rubber located between them.

The low price of the Lada Kalina caused a stir among car enthusiasts who need a car for every day. The budget suggests that it will need repairs soon. Replacing the Kalina gearbox cushion is not the easiest task.

Removing the airbag

To prevent the airbag from triggering, you must remove the terminals from the battery and then wait until the activator capacitor is completely discharged (at least 1 minute). During work, do not allow the airbag module to fall, get liquids on it, or heat above 95°C.

- Insert two rods (nails or screwdrivers with a diameter of 5 mm) into the special holes on the sides of the steering wheel, and then simultaneously compress the spring clamps of the airbag with them (for clarity, the photo shows two rods without the driver’s airbag). When the pillow module rises, the assistant should pull it towards him with his hands.

- Disconnect the two horn wires and the yellow block with the wires in the center by prying them up with a flat-head screwdriver.

- The photo shows the steering wheel and airbag of the Lada Granta.

Lada Granta 2013, l. With. - with your own hands

Voronezh

Lada Granta, 2012

255 000 ₽

Tyumen

Lada Granta, 2013

110 000 ₽

Chita

Lada Granta, 2013

300 000 ₽

Krasnodar

Lada Granta, 2013

345 000 ₽

See more cars on Drome

Participate in the discussion can only registered users.

Login Register

Search

Lada Kalina

VAZ-1117, 1118, 1119

- 1st memory

- CDS key

- How does CDS work?

- Electronic anti-theft device

- Doors and seats

- Protective bag

- Salon

- control

- Dashboard

- onboard

- Lighting

- Light and wiper switches

- Ignition lock

- Internal heater

- Konyuk

- Circuit breakers

- Tire sizes

- Technical properties

- Passport details

- What's under the hood

- How to drive with air conditioning

- Replacing low beam

- Install racks and gears

- Firmware for viburnum brain

- Reviews after 2.4 years of operation

- What they fixed in 4 years

Steering column

Safety cushion (Airbag) Lada Kalina

Lada Kalina has a front airbag

driver (Airbeg) and in an embodiment. front passenger airbag and front seat belts with drawstring and load limiter.

When the airbag deploys, the front seat belts are tightened for a few milliseconds (to securely secure the driver and front passenger), and the airbags are filled with a special gas that opens and reduces the risk of injury to the upper body and head.

Aviation copes with frontal impacts.

Composition of the airbag accounting system:

- an airbag module, which is installed in the control column;

- airbag module for front passenger safety, located on the instrument panel above the glove compartment;

- seat belts with pre-tensioner and load limiter;

- a rotating device mounted on the steering column switch connector for connecting the horn switch and the airbag module to the on-board vehicle;

- Airbeg control and diagnostic unit, located in the floor tunnel of the housing under the device panel console;

- Airbag warning device on the device panel.

Kalina 2

I saw how a young man in the potassium water group was contacting how to remove

a mat with torpedoes, unfamiliar to the passenger.

Air power is making a big push forward. But you install airbags in some other situations:

- collision with a stationary converted obstacle at low speed (hitting the curb, edge of the sidewalk.);

- collision with a moving deformed obstacle at high speed (head-on collision with another car);

- which is expected to create quite a strong impact on the car in front (in other words, dropping the truck onto the deepest potholes, landing hard on yet another car drop off the ledge).

Airbeg does not work if:

- turning off the ignition;

- there was a minor head-on collision;

- automatic rollover is disabled;

- was the side of the car or the back.

MAIN!

The Airbeg only provides the best protection if the seat, backrest and headrest are positioned correctly, in which case the driver's (passenger's) entire back rests on the backrest and the seatback is pressed down so that the upright driver's seat bends slightly. Hands at elbows. you could hold the steering wheel.

Incorrect seating position when opening the airbag may result in injury due to other death as the airbag requires some space when filling with gas.

Airbeg is a separate, disposable device and does not even require maintenance while the vehicle is in use. After airbag

control module and airbags, belts with tensioners were replaced with special service stations.

Inflatable chamber pillow

The seat belt does not replace the seat belt, but only complements it, working with it in pairs. With seat belts removed during airbag deployment, the risk of serious injury at the other fatal end is high.

Never place any objects on the control wheel on the panel of another device as they may cause serious injury if the airbags deploy.

While driving a car, it is strictly forbidden to attach your forearm (palm) to the place where the airbag is installed. In addition, the front seat passenger should not stand on the panel of the device while driving.

Top of page

Source

Post Views: 22

Removing the Kalina steering wheel

We decided to replace the Kalina steering wheel with a sports one, then first learn how to remove it yourself. The steering wheel is also removed if the dashboard (panel), slip ring or steering column is removed.

First, disconnect the negative terminal of the battery. Required tool: 24mm socket.

- Press out the horn switch trim using your fingers.

- Remove the steering wheel cover.

- Disconnect the wires from the horn switch.

Before removing the Kalina steering wheel, its position must be marked with a marker relative to the shaft.

- Unscrew the steering wheel mounting nut (not all the way to avoid injury during removal) using a 24mm socket.

- While rocking, pull the steering wheel towards you. We remove it from the shaft splines.

- Completely unscrew the steering wheel nut. Remove the Kalina steering wheel.

Installation of the Kalina steering wheel is carried out in the reverse order, guided by the marks made during removal.

Similar materials

How to check a car before buying

You can check the car's history before purchasing using online services. For example, through the all-Russian Internet service “Autocode”. Here you can get information in 5 minutes about whether the vehicle you are interested in was involved in an accident or not. If the car has been in a serious accident, it means that the safety devices have already been activated. But they replaced them with new ones or installed a dummy - it’s up to the potential buyer to check.

To become the owner of information about road accidents in which the car was involved, enter the VIN or state registration number. vehicle number in the search form on the main page of the Autocode website. Within five minutes you will receive information about the type and date of the traffic accident. In addition, the diagram will indicate the location of the most significant damage to the body.

In addition, a detailed report contains information about the former owners of the car, the history of registration actions, the actual mileage of the car, the dates of technical inspections, information about the presence of traffic police restrictions and other useful information about the vehicle.

To be completely sure of the desired swallow, you should inspect it for any technical problems. However, if you do not have enough experience, or you are in another city, an auto expert will do it for you! To do this, just leave a request for an on-site inspection service on the Autocode website.

Removing and disassembling the gearbox control drive

We carry out the work on an inspection ditch or overpass. Below the car..

. Using a 13mm spanner, loosen the tightening of the nut of the coupling bolt of the clamp securing the control rod to the shank of the gear selector rod hinge.

Using a slotted screwdriver, we open the clamp and move it along the rod.

Remove the transmission control rod from the shaft of the gear selector rod hinge. Remove the clamp from the rod.

Using a 13mm spanner, unscrew the two bolts securing the torque rod to the base of the gear shift lever.

. and disconnect it from the base. In the cabin, remove the floor tunnel lining (see “Removing the floor tunnel lining”). Having unscrewed the fastening nuts, disconnect the air ducts for blowing the feet of rear seat passengers from the heater (see “Removing the instrument panel assembly with the heater”) and lift the air ducts. Squeezing the clamps of the wire block..

. disconnect it from the reverse gear lock solenoid switch block.

Use a 13mm socket to unscrew the three bolts securing the base of the gear shift lever, and unscrew the fourth bolt under the air duct with a 13mm wrench.

We remove the gear shift lever with its base, bringing the control rod into the cabin through a hole in the floor. Use an awl or a thin slotted screwdriver to pry it off.

. and remove the gear shift knob plug. Using a 13mm socket, unscrew the locknut securing the handle.

Unscrew and remove the handle from the lever. Turning the decorative cover inside out, loosen the plastic clamp securing the cover or cut the clamp.

Remove the cover from the lever. By loosening the plastic clamp securing the solenoid switch wires.

. remove the switch. If it is necessary to replace only the reverse gear lock solenoid switch, then these operations can be performed on the vehicle without removing the entire transmission control drive.

Using a 13mm spanner, unscrew the nut of the control rod axle bolt, holding the bolt axle from turning with a wrench of the same size. We take out the bolt-axle.

. and remove the metal washers, plastic bushings and spacer bushing.

Using circlip pliers, remove the circlip on the ball joint of the lever.

We remove the gear shift lever with the ball joint from the base. Removing the gear shift lever can be done on the vehicle without removing the entire drive assembly. To replace the upper rubber sealing ring (round section) of the ball joint, use a screwdriver to pry off the ring.

Remove the ball joint from the lever. Remove the lower sealing ring (rectangular section) from the ball joint.

Remove the transmission control rod from the case. The cover on the pull rod fits tightly. Therefore, to make removal easier, we moisten the rod with soapy water. If you only need to remove the drive rod.

. then using a 13mm spanner we loosen the tightening of the nut of the coupling bolt of the clamp securing the jet thrust to the tip. We unscrew the two bolts securing the torque rod to the base of the gear shift lever (see above).

Using a 13mm spanner, unscrew the nut securing the torque rod end to the gearbox bracket.

. and remove the jet rod assembly with the tip.

We remove two plastic bushings from the torque rod tip.

. and a rubber damper. Unclenching the clamp.

. remove the tip from the rod. We assemble and install the gearbox control drive in the reverse order. Before assembly, put LSC-15 lubricant into the ball joint of the lever. An assistant will be required to adjust the drive. Make sure that the switch rod in the gearbox is in the neutral position. Do not tighten the clamp bolt nut. We check the ease of axial movement and rotation of the box control rod relative to the shank of the switch rod hinge. In case of jamming, it is necessary to release the groove of the rod with a slotted screwdriver. We install the gear shift lever so that its lower part is perpendicular to the floor of the body, and the handle is located from the front passenger seat at a distance equal to 1/3 of the distance between the seats. Having installed the control rod clamp at a distance of 2-3 mm from the end of the rod, tighten the nut of the clamp coupling bolt. We check that the drive is adjusted correctly - nothing should interfere with the movement of the lever, the gears should engage easily and without jamming. Otherwise, repeat the adjustment.

Installing and removing airbags on a Lada Granta car

Of course, quite a large number of people are trying to compare two models of domestic vehicles. Firstly, this is a car with the beautiful name “Lada Kalina”. Secondly, this is also a domestic vehicle under an equally beautiful name - “Lada Granta”. It would seem that the models were produced at the same factory, and the elements are similar, but according to experts and the creators of the car, they are the complete opposite of each other. Actually, their internal structure speaks about the same thing.

In addition, it is worth noting that if we touch on the topic of safety on the country’s roads, then the second model is tens of times superior to the first. Perhaps this is why the popularity of the Lada Granta is so great. For example, let's look at the safety level regarding your vehicle's airbags. The model called “Lada Granta” was equipped at the factory with nothing more than airbags that inflate during a collision. In addition, there is a side airbag inside the cabin.

Of course, no one really cares about the airbag; it doesn't need to be cleaned, removed or changed unnecessarily. But you must admit that situations may arise that the driver or owner of the vehicle will have to remove the steering wheel, or simply disassemble it. What to do with the airbag in this situation?

Remember that before you start removing the steering wheel, and therefore disassembling the airbag, which was installed and mounted in it according to technical standards. First, you need to turn off your vehicle's engine ignition.

Secondly, it is completely natural to stop your vehicle. Thirdly, you need to open the hood of your car, and in our case, it is a Lada Granta, and pull out the negative terminal of the car battery. Why, you ask? All for the same thing, that no short circuit occurred. If you do not do this and a short circuit still occurs, then most likely you will need to completely change the on-board computer, which will lead to large financial costs.

Please pay attention to one more important point in this procedure. Look carefully at the position in which the wheels of your vehicle are standing (which means they have already stopped)

Remember that they must be located in a straight position.

Now you can proceed to the next stage of working the steering wheel of your vehicle. It is necessary to unscrew several bolts that are located on the side of the car's steering wheel. Remember that they are the ones that serve as fastenings for the gas generator module, which together with the steering wheel represent a single picture, or, to be more precise, a single structure. In the event that the module does not work, it must be placed on a flat surface, so that its cover is positioned in the upward direction.

After this, you need to unscrew those screws that are responsible for fastening the steering shaft, and using a Phillips screwdriver you can perform this procedure. Remember that you must remove the O-ring along with the switch. And only after this it is necessary to carry out work that is associated with the process of disconnecting the harnesses and wires of the on-board computer network.

The final stage of the disassembly technique will be to remove the steering wheel shaft; this can be done using a flat-head screwdriver. You can then remove the airbag and, if necessary, replace it with a new airbag. Then install it in its “native” place

Now note that the wheels of your vehicle are level and the negative terminal of the car battery has been removed, the first thing you need to do is install the steering shaft and connect it to the “original” device. Then it is fashionable to dismantle the red transport key

After this, you need to install the washer system levers, as well as the alarm system of your vehicle. Once everything is done as described above, all you have to do is thread the two wires through the hub at the front of the steering wheel and carry out the final process of assembling the steering wheel in the reverse order of how we disassembled it.

Got to the passenger airbag. — logbook Lada Kalina Station Wagon 2011 on DRIVE2

In a previous entry I talked about the fact that the heater was leaking. The Internet offers a couple of ways to replace the radiator without removing the panel. One method is to saw the heater body, and the second is to shorten the heater radiator pipes. But it’s not that interesting, and besides, I’ve long wanted to do Shumka, because it’s terrible there, everything rattles there. Therefore, it was decided to remove the panel. There will be a lot of unflattering words addressed to those four people who signed the drawings of the viburnum panel =) But this is all in the future, but for now observations about the passenger airbag, because of which some of the nerves are wasted. More precisely, in my opinion, because of the structural defect in its connection with the panel.

Unscrewing five nuts with three different tools

Nuts M5

And having removed the connector with the fourth tool, take out the pillow with the fifth tool

Removed pillow

And we see such a picture

Passenger airbag space

And here the questions begin, to which you can hardly get answers. And the most important thing: why the hell?! Why the hell is this edging needed, because of which all the fuss is a waste? Because of unification? But damn, according to the catalog for the viburnum there are 22 (TWENTY TWO) different panels assembled. And there is only one plastic. Why the hell then twenty-two panels? Why the hell are there three panel frames (iron tube with brackets)? And there's only one piece of plastic. Why the hell does the pillow cover snap onto this edging when it is snapped onto the pillow body and secured with staples, and only some unknown crap can rip it off from there? So that it sits straight, because crooked hands cannot mold the plastic correctly so that it doesn’t move? In short, one hell of a thing =(

Now, if it weren’t for this edging, then there would be no need to remove this pillow. It could be twisted later if necessary. In short, as soon as I remove the panel lining, I’ll carefully feel everything again, and, probably, I’ll cut the hell out of this edging in order to save myself in the future from unnecessary work.

What to do with worn seat belts?

The seat belt squib often deploys along with the airbag. There are two options here - turn to specialists or do the work yourself.

In the second case, the sequence is as follows:

Move the front seat forward as far as possible; Unscrew the blind edge of the belt from the body part; Disassemble the lower edge of the rack trim (the mechanism is located there); Pick out the plug on the adjustment mechanism; Remove the rack trim to check the level of wear; Carefully unscrew the belt and push it away from the adjuster; Remove the device and discard the system connectors; Remove the cover and locking assembly; Under the steel plate there is a mechanism with a return spring. The latter, when the squib operates, is triggered, jumps out of its place and fixes the belt; Compress the springs and put everything back in place.

Driver airbag repair procedure

Using the driver's side airbag as an example, you can briefly learn how restoration is performed. Buying new airbags is quite expensive. Therefore, most often, motorists give preference to the restoration option, when the squib is changed and the control unit is reflashed.

To complete this task you need:

- remove the panel from the airbag where the airbag inscription or icon is located;

- disconnect the fired airbag from the steering wheel;

- remove the decorative plastic cover;

- disconnect the squib by unscrewing the required number of nuts;

- install new components;

- connect to the on-board system and reflash the control unit.

Returning the airbag to full operational status is not so easy. This is a popular service in specialized workshops, which simply cannot be cheap.

What you definitely shouldn’t do is drive with empty airbags, using a dummy, and try to sell the car in this form.

Source

Remove the steering wheel of a Lada Granta with an airbag

The work is shown on a car equipped with an airbag. On a car without an airbag, the work is easier; you only need to remove the steering wheel pad.

To complete the work, you will need a special puller to remove the airbag and a new steering wheel nut. If you don’t have a puller, you can make one from an old slotted screwdriver with a blade width of 5-6 mm. To do this, you need to make a small groove in the middle of the blade.

1. Prepare the car for work, remove the terminal from the negative terminal of the battery.

On a vehicle equipped with an airbag, to prevent the airbag from deploying, wait at least five minutes after disconnecting the battery before continuing to operate. Place the removed airbag module with the actuator down and away from the workplace.

2. Set the front wheels of the car to the straight-line position.

3. Using a homemade puller through a hole in the steering wheel upholstery. . first on one side and then on the other, squeezing the outer tendrils of the spring clips (for clarity, the airbag has been removed).

. release the two airbag module holders.

4. Moving the airbag module away from the steering wheel, disconnect the ends of the two wires.

5. Use a slotted screwdriver with a thin blade to release the wire block retainer.

6. Disconnect the wire connector from the airbag module.

7. To avoid injury in the event of inadvertent deployment of the airbag, place the removed module away from the workplace with the decorative trim facing up.

8. If necessary, install the steering wheel in the previous position. Using any available method (marker, felt-tip pen, thin chisel) we make installation marks on the shaft and steering wheel.

When removing the steering wheel, the moving part of the slip ring is not automatically locked against rotation. As a result, the central position of the moving part of the ring may be disrupted during assembly. In this case, there is a high probability of damage to the contact ring when turning the steering wheel to one of the extreme positions. To secure the ring, the steering wheel is equipped with a special stopper.

And on the slip ring there is a special hole. By inserting a stopper into this hole, you can fix the moving part of the slip ring in a certain position.

When disassembling, it is necessary to lock the slip ring and not remove the lock until the steering wheel is installed on the steering shaft.

9. Insert the stopper into a special hole to fix the slip ring.

10. Using a 24 mm socket wrench with an extension, unscrew the nut

fasten the steering wheel and leave the nut on several turns of the shaft thread.

11. Using successive palms on the rim of the steering wheel on the right and left sides, we knock it off the shaft splines.

12. Having unscrewed the nut, remove the steering wheel from the shaft, while pulling out the slip ring wires along with the pads from the hole in the steering wheel hub.

We install the steering wheel in the reverse order, aligning the previously made marks and installing a new self-locking nut. Steering wheel fastening nut with a torque of 32-51 N m (3.2-5.2 kgf-m).

If it is necessary to install the steering wheel in a new position (for example, if the spokes are inclined when the car is moving in a straight line), put the wheel on the shaft and secure it with a nut without tightening it completely. After driving straight a few meters, make sure it is in the correct position. If necessary, move the steering wheel to the required number of splines and tighten the nut.

1. Prepare the car for work

2. Use a Phillips screwdriver to unscrew two screws on both sides of the steering column.

Using the same screwdriver, unscrew the two screws securing the linings to each other 2 and the three screws I securing the lower lining to the steering column.

3. Move the steering column locking lever down until it stops and lower the steering column. Remove the ignition switch trim.

4. Remove the bottom trim by pulling the lever through the hole.

5. Remove the upper steering column trim.

Install the covers in reverse order.

The driver's airbag (gas generator module assembly) is dismantled when the steering wheel is removed, or to replace the airbag contact ring or sound signal. If this is the first time this process is performed, it is recommended to invite an assistant. On Lada Granta, Lada Priora and Lada Kalina 2, the driver's airbag has a different shape, but the removal process is no different.

How to put covers on Kalina

The interior of a Lada Kalina car can be made prettier and more comfortable using fairly primitive methods. One of the most famous is the installation of seat covers. They prevent rapid wear of the seat covering and improve the appearance of the interior.

You will need

- – covers;

- – vinyl-braided wire;

- - nylon cord.

Instructions

1. Buy seat covers that specifically match your car's interior. On average, good-quality covers for Kalina cost from 2,500 rubles. It is better to choose models made of dense fabric, resistant to abrasion and nice to the touch. If funds allow, choose more expensive heated covers. In addition to providing greater comfort, they are more durable due to the internal frame.

2. Lay out the covers, remove their ties, which, as usual, are made of unsatisfactorily strong materials. Insert a vinyl braided wire of a suitable size into the holes, one that is highly durable and can be easily tightened if necessary. Braid made of similar materials helps in evenly dividing the force on the tightening. This way you will be able to protect them from possible breakage.

3. Replace the ribbons located at the edges of the covers and prepared for tensioning them with a nylon cord about 3 mm in diameter. It is quite strong, and with its help you will be able to stretch the cover much better. Sew it on to replace the old puffs. You can buy especially strong nylon cords in fishing stores.

4. Remove the seats. To do this, unscrew the mounting bolts or nuts that attach them to the floor. Put on the new covers and tighten them as tightly as possible using new ties so that they do not wrinkle or slip. Check the tightening points carefully. Reinstall the seats by tightening the bolts or nuts.

Replacing the Kalina gearbox lever cushion

Societies › VAZ: Repair and Modification › Blog › Replacing the ball

lever Kalina car 1.6 8kl

There is a joke that AvtoVAZ engineers will not die by their own death. More and more, when I take on repairs, this joke becomes that it remains to make our client a stronger former.

It started for our client with an iron dull knock in the engine area on bumps. At first I thought maybe there was something to do with the protection. However, that was not the case here. I drove into the pit. And there p?ts. The gearshift lever rod rests on the muffler. Oh how! It turns out the lever

The gearbox is held on a holder, which is rubber and in two places is very narrow for such loads. Pull the gearshift lever up and pull out the entire mechanism. There is a boot between the iron platform and the holder. Because my clip fell into two parts, it wasn’t particularly difficult for me to disassemble the entire assembly. Do not remove the boot from the wing, it will not come off. HOW?! I have no idea how it came out in his image. My shift took about 2 hours.

Let's start the substitution. We will need: A new ball joint lever (570 rubles) A key for 10, 13. A Phillips screwdriver. Pliers with thin ends, or tweezers. If, of course, there is a ratchet, it will make the work much easier. Have some patience. The absence of minors nearby, because the repair of viburnum greatly develops the imagination in the direction of obscenity.

The car must be driven into a pit or onto a lift. Some of the work happens from underneath the car. You need to remove the muffler, unfortunately not all of it. For this purpose, we remove the clamp near the rear wheel. Be careful when the muffler is disassembled, a lot of rust and dirt spills out. Next, remove the muffler from the rubber bands and move it in any direction. Next, unscrew the two 13mm bolts that the cage to the rod. Below is what remains for our client to do. Alas, I needed to tighten the handbrake again. We remove the protection and tighten it. There's basically nothing complicated there. To pull up, you need two 13mm wrenches. There is no photo below, I was very busy with the process.

Next we go to the salon. The bestseller begins with this question. I don’t know how, but VAZ engineers manage to make everything possible very awkward for analysis.

Many owners of VAZ 2109, VAZ 2110, VAZ 2111, VAZ 2112, Lada Kalina cars had to encounter unpleasant rattling , vibration, and movement of the gear shift knob. Today we will look at how to eliminate vibration of the gearshift mechanism of a VAZ 2109, VAZ 2110, VAZ 2111, VAZ 2112, Lada Kalina by resorting to car repairs with our own hands. So, in this article we will look at how to replace the gearshift pad of a VAZ 2109, VAZ 2110, VAZ 2111, VAZ 2112, Lada Kalina

Before we begin to consider the sequence of replacing the gearshift pad of a VAZ 2109, VAZ 2110, VAZ 2111, VAZ 2112, Lada Kalina, let's decide what tools we need to acquire and what spare parts we should buy.

I definitely recommend buying a gearshift pad for VAZ 2110, 2111, 2112 produced by Balakovo.

Tools for replacing the gearshift pad of a VAZ 2109, VAZ 2110, VAZ 2111, VAZ 2112, Lada Kalina:

- Socket and socket wrench size 13.

- Combination key for 10.

- Pliers.

- A screwdriver and a small ratchet with a Phillips head.

Replacement of the gearbox rocker pad should be done on an overpass, inspection pit or lift. You can just crawl under the car, but you will waste a lot of time and be tortured.

The content of the article:

Elimination of chattering of the gearbox lever 2110

We continue to fight for silence in the car.

I tried to defeat the cause of the vibrations, and not the consequence in the form of lever rattling. I changed the engine mounts, installed an additional gearbox mount, and changed the gearbox ball race. In terms of rattling, all this did not bring any significant results, it only calmed down a little.

Well, let's treat not the cause, but the consequence of vibration. There were three options for solving the problem:

1. Purchase of repairs. set of scenes.

2. I washed down a couple of millimeters of the cylinder.

3. Installation of plastic washers.

The first option seemed untenable to me. I wanted to solve the problem once and for all, and the bushings were visually in good condition.

I decided to use the second and third options at the same time.

I sawed it down using sandpaper and made a 2mm cylinder.

Then I leveled it with a file.

I cut out washers from the lid of a 3L jar.

Finally, success! There is silence in the cabin. Naturally, the vibration on the handle has not gone away, but it has stopped cracking completely. The lever began to move a little tighter, but this does not cause discomfort, rather the opposite. Previously, after 3000 rpm, the engine sound was almost inaudible due to the terrible rattling of the lever. The engine sound is now clearly audible and just great. The zero impedance filter gives a special charm to the sound. This was really unheard of before.

The next item in the plan to eliminate the itching of the gearshift lever will be replacing the ball joint race of the gearbox lever, or, in simple terms, the “butterfly”.

I bought such a thing, cost 320 rubles, manufacturer Balakovo.

To replace the “butterfly” you need a hole, because In order to remove it, you need to unscrew the 4 bolts from the bottom. This is a little problematic to do, as the exhaust system gets in the way.

Then you should remove the gearshift lever. To do this, unscrew one nut and one screw.

In order to unscrew the screw, insert a screwdriver into the joint of the tunnel.

Some people prefer to drill a hole in the tunnel or remove the top completely. I don't see the point in this, because... The tunnel is quite flexible, after a screwdriver there are practically no marks left.

The old "butterfly" was in disgusting condition. It just fell apart in my hands.

When assembling the lever, all moving parts should be generously lubricated. I used silicone grease with fluoroplastic.

I'm not happy with the result; replacing the butterfly gave practically nothing. The vibrations decreased slightly and the timbre of the chatter changed slightly. The next step will be to cut down the cylinder and place a plastic washer.