Reliable and uninterrupted operation of a car is the first and most common desire of any car owner. Starting the engine from half a turn and stable operation of all vehicle systems is a sign of the coordinated operation of all components. But a common problem is the inability to start the engine, which is a clear sign of a faulty starter.

And if we talk about the VAZ-2114, which is produced by the domestic automotive industry, then failure of the starter is a frequent problem. This is due to the lack of high-quality spare parts for VAZ cars. You can solve the problem by purchasing a new spare part.

The cost of a new starter within the territory of the Russian Federation ranges from 3,000 rubles to 7,000 rubles . Here it is worth adding the average amount for service station services for the installation procedure in the amount of another 500-700 rubles.

Reasons for removing the starter

It is worth noting the main malfunctions of the starter, which will require its removal.

The main problems with the starter that will require its removal are:

- When you try to turn on the starter, the traction relay does not work, and accordingly the armature does not rotate.

- When you try to turn on the starter, the traction relay is activated, but the starter does not turn or turns only slowly.

- When you try to turn on the starter, the traction relay is activated and switched off several times.

- When the starter is turned on, the armature rotates, but the engine flywheel does not.

- When the armature rotates, the starter makes extraneous noise.

It is also worth noting, and will save your energy and nerves, that before removing the starter, make sure that the problem does not lie in a dead battery, oxidized terminals, broken electrical circuit, oxidized contacts, etc. To do this, familiarize yourself with the problems that affect the operation of the starter:

Starter repair procedure:

1. First, you need to remove the starter from the car. Now let's start disassembling the part.

2. You need to unscrew the nut.

3. Disconnect the busbar from the contact bolt of the traction relay.

4. Carefully remove the two bolts that hold the traction relay.

5. The traction relay must be removed from the starter.

6. Set aside the starter itself and remove the armature from the traction relay. To do this, lift it up and the armature loop is released from the lever.

7. Now we return to the starter itself. Unscrew the tie rod nuts.

8. The next step is to remove the cover from the drive side with the gearbox and the same part assembled.

9. The cover must also be removed from the side of the commutator with brushes and brush holders.

10. Then remove the gear from the anchor shaft.

11. Pull the armature itself out of the starter.

12. There is a washer installed on the anchor shaft on the drive side (pay special attention to this).

13. Using a screwdriver or other thin object, remove the anchor shaft support.

14. Then use a small screwdriver to remove the two tie rods from the starter cover. In general, it is not necessary to remove them; if you are in a hurry, you can leave them, but it is more convenient to remove the drive and gearbox without these pins.

15. After this, remove the three gears of the gearbox. A starter breakdown may be due to the fact that these gears have damaged, broken teeth or needle bearings embedded in the gears. If this deficiency is present, then replace the parts and the starter will work again.

16. But, if the gears are in order, then continue to disassemble and check the starter for damage further. You need to remove the gearbox with the drive from the cover by first pressing the starter drive gear.

17. The support with the seal must be removed from the lever.

19. Using a hammer, knock the restrictor ring off the retaining ring using a suitable mandrel.

20. Carefully remove the retaining ring first and then the restrictor ring.

21. Remove the drive assembly from the drive shaft.

22. Unscrew the lock ring of the lever.

23. Then remove the lever with the washer and driver.

24. Use a screwdriver to unscrew the lever spring.

25. Now you can remove the lever from the connection and separate the halves of the lever.

26. Remove the internal gear retaining ring.

27. Next, disassemble the internal gear and remove the drive shaft support from the shaft.

28. Carefully remove the O-ring from the pore. Examine it carefully. A damaged, deformed, hardened ring has a bad effect on the operation of the entire starter. It definitely needs to be replaced.

29. The next step is to remove the liner from the support.

30. On the commutator side, remove the two screws and remove the brush holder.

31. Using a screwdriver, pry up the brush clamps.

32. Then remove these retainers and their retainer springs. Again, replace deformed or damaged parts, heavily compressed or bent, or torn springs.

33. Remove the brushes themselves from the brush holder guides.

34. Non-insulated brushes must be removed.

35. Then remove the cardboard insulation pad. If it is damaged, compressed, torn, replace it with a new one.

How to properly remove the starter?

- We put the car in the pit and remove the engine protection by unscrewing the four fasteners.

- Open the hood and remove the negative terminal from the battery.

- Disconnect the wire block from the starter.

- Remove the crankcase protection as shown in the figure.

- Unscrew the fastening nut and remove the wire from the contact bolt of the starter traction relay.

- We climb under the car and unscrew the 2 starter fasteners from below as shown in the figure.

- We go up to the top and unscrew the last, third fastening of the starter.

- Then we climb back into the hole and remove the starter.

How to repair?

You can rewind the rotor or starter yourself, but this is problematic. In addition, the lamellas on the rotor may be worn out - even installing new brushes will not help. The procedure for repairing a VAZ-2114 starter:

- Remove the solenoid relay by unscrewing 2 or 3 bolts using a screwdriver.

- Remove the back cover by unscrewing two bolts.

- Then unscrew the two nuts with a 10mm wrench to disconnect the three parts of the housing.

- Remove the brushes and disconnect them from the windings.

- Remove the retaining ring from the back of the rotor and remove the cover.

- The retaining ring must also be removed from the front of the rotor. Only after this can the anchor be completely removed.

All elements of the starter have been dismantled, all that remains is to carry out troubleshooting. All faulty parts must be replaced with new ones. Pay attention to the lamellas - if they are worn out, then it is useless to restore them. It will be easier to purchase a new rotor. After repair, all parts must be reassembled in reverse order.

What causes the starter to fail?

Understanding the reasons for the failure of a part, we can say that there are not so many of them:

- Manufacturing defects. Due to the design features of the body, the manufacturer had to reduce the size of the mechanism, so it has insufficient power and often fails;

- Operation of the device with unacceptable overloads. If you have to turn the engine for a long time, the element can overheat;

- Violation of operating rules. For example, a car enthusiast has run out of gas, and in order to move the car to the side of the road, he puts the car in gear and turns the starter, which allows him to move the car. The mechanism is not designed for such a load;

- Natural wear and tear of parts.

The mechanism is a defect of the manufacturer and is considered a “sore” of the VAZ 2114 car, as it often fails.

Symptoms of a VAZ 2114 starter malfunction

Understanding the symptoms of a malfunction, we can highlight several points:

- When turning the ignition key, the mechanism does not move;

- Having started the engine, the bendix does not disengage from the flywheel;

- When you turn the ignition key, only electrical clicks are heard;

- The starter smokes when trying to start the engine;

- The mechanism hums, but does not engage the flywheel.

All the reasons are similar in one thing: the engine does not start rotating during a startup attempt. To determine exactly what the problem is, you will need to remove the mechanism and carry out diagnostics. There are several main reasons for failure:

- It doesn’t turn at all: when the winding is shorted, or the armature shaft on the solenoid relay is stuck;

- Insufficient speed: the armature or stator winding has broken or shorted, or the brushes have worn out;

- Does not transmit speed to the crankshaft: the bendix is faulty;

- Does not turn off even after starting: the spring on the clutch is broken or the traction relay is stuck.

Causes of malfunctions

- Does not turn: short circuit of the winding, jamming of the armature on the solenoid relay, oxidation of the battery contacts.

- Insufficient rotation speed of the bendix: break or short circuit of the armature (stator) winding, wear of the brushes.

- It turns, but does not transmit speed to the flywheel: the bendix is faulty.

- Operation after the engine speed has increased: the traction relay is stuck, the freewheel spring is broken.

Also, the causes of malfunction include wear of the unit, increased loads, violation of operating conditions and defects. Most often, the bendix, armature commutator and solenoid relay fail. Sometimes there is a loose fit of the brushes.

If one of the brushes has failed or the gearbox shaft has become skewed, this is usually a sign of impending destruction of the entire assembly, and it is easier to replace it entirely than to repair it.

In cold weather, the engine does not start well, the starter works at the limit and may fail. If the device is poorly secured or operates in conditions of constant strong vibrations, this also leads to its destruction. Sometimes a factory defect of the unit occurs - incorrect distribution of the lubricant composition in the housing, which leads to failure of the solenoid relay.

You can clean the shaft and add lubricant. The device is installed at an angle with the bendix down, white spirit is drawn into the syringe, and, turning the bendix as it extends, the white spirit is squeezed out onto the exposed section of the shaft, wiping it with a rag. Lubricant is added to the wedge-shaped teeth along which the bendix slides out.

For complete cleaning, the assembly is disassembled and washed in gasoline. Then they put new lubricant in the places from which the old one was removed, and assemble the device.

If the starter does not turn the flywheel, clean the terminals and start the car again.

Sometimes the problem with frequent bendix failure lies in the flywheel bushing. It is necessary to check the condition of the bushing and, if it is unsatisfactory, replace it with a new one.

Gear starter VAZ 2114

Which starter should you choose?

When choosing a new spare part, most car owners give preference to the geared version. Its advantages are that it is smaller in size, turns the engine faster even with a dead battery, and works better in winter.

Of the gearbox options, everyone prefers the following companies:

- KZATE — 3600 rubles

- Eldix — 4500 rubles

- PRAMO – 4400 rubles

Try not to save money when buying a new part. As mentioned earlier, the item from the factory is considered the weak link of the car. If you buy a cheap Chinese analogue, you can return to removing the starter on a VAZ 2114 at the most inopportune moment. Read the reviews in stores in your region, this will help you identify quality brands and not fall for a fake, which will also save time and money.

Choosing a new starter

According to statistics, when answering the question “Which starter is better for a VAZ 2114?”, most car enthusiasts are advised to choose a geared version. It is smaller in size than the standard one, provides a quick start even with a weak battery, and spins the flywheel better in winter. It is easier and faster to install. The engine of such a device weighs less and experiences less mechanical stress.

Of the gearbox options, KZATE (KATEK) has the most positive reviews. Eldix and PRAMO brands are also popular.

The disadvantage of geared devices is that there may be problems with waterproofing, which cause short circuits and anchor breakages.

Starter KZATE

There are machines with the device fastened not with three, but with two bolts. In this case, a starter from ten is suitable, but you need to replace its Bendix with a gearbox from nine.

Replacing the starter on a VAZ 2114

Before removing the starter, you need to clear the engine compartment by removing the air filter housing. This will give us more access to the element's location. How to remove the starter on a VAZ 2114 without a pit? Access to the bolts is also open through the engine compartment; the only thing you have to do is tinker a little with the bottom bolt. Afterwards you can start repairing:

- Remove the positive terminal from the battery. This must be done so as not to short-circuit the wiring and remove the voltage from it.

- Then disconnect the plug of the red wire that pulls in the relay.

- We take the key for 13 and disconnect the second wire from the body.

- Now you can start removing the part itself. We unscrew the three 13mm bolts that secure the part to the box.

The starter no longer holds anything and you can remove it from its seat and pull it out.

When installing a new part, try to tighten the bolts firmly, but do not overdo it so as not to bend the threads or studs.

Starter replacement

The work does not require a pit or a lift. When you don’t have time to travel to a car service center, you can replace the device yourself.

Sequencing:

- Open the hood.

- Remove the terminals from the battery.

- Remove the air filter pipe.

- Remove the air filter.

- Find the starter between the radiator and the manual transmission.

- Unscrew the three nuts securing the device. To do this, use a key of 13.

- Remove wiring.

- Moving to the right and removing from the engine guides, remove the device.

- After dismantling, the condition of the flywheel shaft (bushing) is usually checked.

- The mechanism is installed in the reverse order.

Starter Eldix

When installing, apply lubricant to the surface in contact with the flywheel bushing.

Bendix replacement

- The plug at the point of its attachment to the body is bent with a flat screwdriver.

- The ring is removed. You may have to knock it down with a hammer.

- The retaining ring is removed. It is enough to pry it off with a flat screwdriver.

- The part is pulled out from the body.

If there is no visible damage on the bendix, this does not mean that it is working. If indirect signs of malfunction appear, it must be changed.

Starter PRAMO

The new part is installed in the reverse order.

By installing a VAZ 2114 gear starter, car enthusiasts solve most problems with starting the engine and constantly replacing Bendix and other spare parts.

Replacing the solenoid relay

It is not always necessary to replace the starter; sometimes simply servicing it is enough.

You can replace the solenoid relay without removing it, but then you will have to work a little, as this is quite inconvenient.

You can learn how to replace the relay correctly from the video:

Following the instructions from the article, replacing the starter on a VAZ 2114 with an 8-valve engine will not be so difficult. The starter is one of the most complex mechanisms in a car because it consists of many parts that wear out and fail over time. Although the system is only concerned with starting the car, there are many processes going on inside the case that must work in time and pass enough current to start the engine. It is impossible to monitor the condition of the internal parts, the only thing is that if you notice that the starter turns weakly and sometimes does not work, it is better to immediately remove it and take it for repairs or fix it yourself. This will save money on the subsequent purchase of a completely new element.

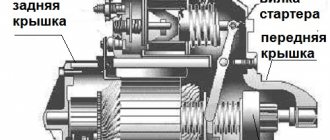

Design

Where the starter is installed on the VAZ-2114, there are several more elements - an air filter, a thermostat, etc. Therefore, in order to gain free access to all components of the launch system, you will have to remove some parts. The starter design consists of the following components:

- Back cover.

- Bronze bushings.

- Copper-graphite brushes.

- Armature with winding (rotor).

- Stator with windings.

- Bendix - overrunning clutch, fork and gear.

- Gear starters have a planetary mechanism.

- Front cover.

- Solenoid relay.

Next, we proceed to describe the operation of the mechanism.

VAZ 2114 starter device

A car starter is designed to start an internal combustion engine by driving the engine crankshaft. The movement from the starter to the crankshaft is transmitted through the flywheel.

The VAZ 2114 car began to be produced by the Tolyatti Automobile Plant in 2000; it adopted many components and parts from its predecessor - the VAZ 2108-09 series. Accordingly, the design of the VAZ 2114 mechanism is very similar to its predecessor from the “nine”. The parts have external design differences, but the parts themselves are completely interchangeable with each other.

The VAZ 2114 starter consists of the following main parts:

- Stator, which is made in the form of windings located in the housing;

- Rotor (or armature), moving part;

- Bendix, transmits motion from the rotor to the engine flywheel;

- Solenoid relay is a device that drives the rotor by turning the ignition key.

What usually goes wrong?

On a VAZ 2114 car, you can repair the starter with your own hands in an hour, no more. Provided that all components are replaced with new ones. Most often, starter brushes fail; they rub against the lamellas and wear out. As a result, the rotor does not move when voltage is applied to it. Sometimes even when you turn the ignition key, sparks appear. On new injection cars, which include the VAZ 2114, a gear starter is installed. Its advantage is that its rotor rotates at a higher speed, which makes starting the engine easier.

Its disassembly is practically no different from the procedures that are carried out with a conventional starter. Another typical failure is the destruction of bronze bushings. On a VAZ 2114 car they are located:

- One is in the rear starter cover; partial disassembly will be required to replace it.

- The second is in the engine block. It will have to be replaced through a small window in the clutch housing.

If the bushing breaks, then there is no power to the motor armature. The minus voltage is not transmitted from the battery, or the voltage decreases due to resistance. The result is that the rotor rotates much more slowly, and from the outside it may seem as if the battery is dead. These symptoms are typical not only for VAZ cars, but also for cars of other series and even brands - UAZ, Chevrolet, etc.

The pull-in relay allows power to be supplied to the motor windings. But it has two functions, the second is to extend the bendix so that its gear engages with the teeth on the flywheel ring. Bendix is an element that transmits torque to the engine crankshaft from the rotor.

It is based on an overrunning clutch and a gear, with spiral-shaped splines inside. A frequent breakdown is the destruction of the overrunning clutch. As a result, the gear moves both clockwise and counterclockwise. Although it should rotate freely in one direction.

And practically “incurable” breakdowns are complete or partial destruction of the rotor, stator, or their windings. These are the kind of breakdowns in which repairs are not much cheaper than the entire starter assembly.

The main reasons for the failure of the VAZ 2114 starter

There are not many reasons why a starter may fail. It could be:

- Manufacturing defects;

- Operation of the device with unacceptable overloads;

- Violation of operating rules;

- Natural wear and tear of parts.

It should be noted that in pursuit of compactness of all parts of the engine compartment, the manufacturer slightly did not calculate the power of the starting mechanism. The starter often fails due to its low power, which is a design flaw, a “disease” of the VAZ 2114. Often the starting mechanism breaks down in cold weather, when the engine has to be turned for a long time to start. It can fail prematurely if it is not secured properly. Wear of the bushing in the gearbox, which supports the starter armature, also contributes to breakdown (the bushing is shown with an arrow in the picture below).

Another typical factory defect is that the solenoid relay stops working the first time after a certain time. The factory apparently saves lubricant. Often, when disassembling an almost new solenoid relay, you can observe a completely dry core and the housing in which the core moves.

What needs to be changed?

In order to carry out repairs, you need to purchase a set of spare parts. In particular, you will need the following components:

- Brushes.

- Bushings.

- Bendix.

As a rule, these elements most often fail. If there is a breakdown of the windings or part of the housing, then it will be much easier (and more efficient) to install a new starter or a used one, but working.

Signs of a faulty VAZ 2114 starter

- When you turn the ignition key, the engine does not start;

- When starting, the engine continues to spin, the bendix does not disengage from the flywheel. You can stop the movement only by removing any terminal from the battery;

- When you turn the ignition key, “dry” clicks occur and the engine does not turn over;

- When you try to start the engine, smoke comes out of the starter and smells like burnt wire windings;

- When starting the engine, the starter buzzes and does not engage the flywheel. The launch does not happen the first time.

Tips that may be useful when replacing a starter

- Before removing the starter, you need to make sure it is faulty. First of all, you need to check the reliability of the terminals on the battery. Oxidized terminals should be cleaned of deposits and re-secured. The reason for the failure may also be poor weight of the engine and the body. You should also check whether the solenoid relay wire has come loose from the connector and whether the positive terminal nut on the starter is tightly tightened;

- When removing a part, you can disconnect the positive wire of the terminal last. In this version, it is more convenient to unscrew the nut of the positive wire. By pulling the starter closer to you, it will be easier to get to the desired nut;

- You need to install the solenoid relay wire in place until it stops. The connector must be fixed, and in this case the wire will not fly off during movement due to shaking;

- Do not forget to first remove the terminals from the battery and turn off the ignition - this will save you from additional problems.

That’s basically all that can be said about how to change the starter on a VAZ 2114.

Source