Hi all. The thought came to me that before winter, it wouldn’t hurt to sort out the brakes. Lately, there has been a grinding noise when braking. An inspection of the brake system showed that the discs and pads were in good condition.

One of the reasons for grinding and rattling of calipers may be worn guides. Also, worn guides can lead to uneven wear of the pads (when one of the pads wears out faster than the other). This is exactly the wear that was on the old pads when they were last replaced.

Inspection of the guides showed that they are not jammed, but the lubricant has coked and thickened, and there is also noticeable play.

4 guides were purchased along with anthers, the price was 40 rubles per piece. And also a special lubricant for brake systems BOSCH SUPEFIT (5000000151) for 50 rubles. One bag is just enough for four guides.

It is important to know that not any high temperature grease will work for caliper guides. Do not use ceramic grease or copper-based grease. These lubricants coke and cause the guides to jam. They can also be aggressive towards anthers. As it turned out later, BOSCH lubricant is not suitable for guides; the temperature range is only -25°C +130°C, which is naturally not enough for this unit. Although the manufacturer claims that this lubricant is universal and is exactly suitable for guides. I found supporting information in the official brochure about the use of lubricant.

We'll ride it for now, and we'll see.

Before replacing the guides, remove the old grease and thoroughly wash the bracket. To remove the old grease I used 646 solvent.

Its disadvantage is that it is aggressive to the rubber from which the anthers are made, so after the solvent, I washed the staples with a degreaser. New lubricant should be applied in a thin layer.

Major breakdowns

The front caliper of the VAZ-2110 is a structural element that holds the brake pads and is responsible for the level of pressure of these elements on the metal discs. It also helps ensure even pad wear, which guarantees effective braking in any situation. The body is made of aluminum alloy and the piston is made of steel.

Between these elements there is an oil seal that prevents brake fluid from leaking out of the system. The main caliper failures are as follows:

- The appearance of oxidation on the surface of the guide elements.

- Oxidation on the main piston, which leads to deterioration of the mechanism.

Failure can be identified by uneven wear of the pads, as well as by an increased braking distance. If such malfunctions are detected, be sure to change the pads.

Main causes of malfunction

The VAZ 2110 caliper is structurally an element that holds the brake pads and is responsible for the degree of their pressure on the brake discs. It is also responsible for uniform wear of the brake pads and guarantees the driver reliable braking in extreme situations. Thus, the importance of the caliper in the operation of the car is difficult to overestimate.

If by this time you have a completely reasonable question, what can happen to the caliper on a VAZ 2110 (2112), we will be happy to answer you. The main cause of malfunctions is “acidification” of the moving elements, coating them with an oxide film, clogging due to the destruction of protective boots or the use of improper lubricant, namely:

- acidification of the main piston mechanism;

- acidification of guides.

Piston mechanism and caliper guides VAZ 2110

A clear sign of problems that the caliper can cause on VAZ cars is uneven wear of the brake pads and an increased braking distance. In this case, the VAZ pads must be changed, and the caliper mechanism itself must be subjected to comprehensive diagnostics:

- check the condition of the piston, its degree of freedom, the presence of moisture, metal oxide, oxide formations and build-ups, the condition of the protective boots;

- Similarly, check the condition of the guides, make sure that there are no uncharacteristic scuffs, abrasions or deformations of the rod on the surface.

We must also not forget about regularly replacing the brake fluid in the system. This should be done approximately every 40 thousand km. mileage of VAZ-2110.

Since brake fluid is hygroscopic, it easily absorbs moisture, thereby oxidizing the piston mechanism and causing it to fail. The piston stroke becomes difficult and uneven wear of the brake pads and wheel wedge occurs.

Please note that the repair kit offered in stores for self-service of VAZ 2110 (2112) calipers contains special lubricant for both the main piston and the guides. The use of Lithol or graphite lubricant leads to swelling of the protective shock absorbers and further souring of the guides. This kind of repair is unlikely to benefit your car.

Brake fluid

Any brake fluid that is used in automotive systems absorbs moisture very well. It is hygroscopic, therefore it oxidizes the piston mechanism from the inside, which leads to failure of structural elements. This makes the piston stroke more difficult and the brake pads wear unevenly.

The front wheels may become jammed. For these reasons, it is necessary to replace the brake fluid. Its service life is about 90,000 km, but not more than two years. These solutions contain many useful additives that improve cooling and increase braking efficiency.

But over time, under the influence of high temperatures and pressure, these additives evaporate. And the consistency of the brake fluid becomes more like water, and this reduces the efficiency of the system.

What's good about a disc brake?

The main advantages are as follows:

- Compared to a drum, a disc is more reliable, and the braking is “sharper”, due to which the braking distance is reduced;

- The pedal responds faster after pressing;

- The system cools better, which is important when driving in conditions where you need to brake frequently;

- Very convenient to operate and repair, such brakes are easier to dismantle;

- They do not freeze after driving into a puddle of water or after washing.

Repair kits

You can purchase special kits designed for caliper repair. But there is no point in purchasing it. It is much better to replace the VAZ-2110 caliper. In this case, you will increase the life of the entire braking system and also improve its reliability. Such repair kits contain the lubricant that is necessary for the piston and guides.

You cannot use graphite lubricant such as CV joint or Litol-24, as this will cause the protective shock absorbers to swell and the guides to simply oxidize. As a result, repairs will not bring the desired effect for a long time.

When lubrication is not effective and replacement is required

Sometimes owners try to “cure” the knocking noise of worn guides with lubricant, but if the wear on them is high and the caliper is literally hanging on its fingers, the paste will not help - only repairs. By the way, on some cars, parts of the brake system begin to make themselves known by knocking during the warranty period. For example, a similar thing was noted in the case of Chevrolet models, in which the problem manifested itself at runs of up to 30 thousand kilometers and was associated with a “disease” of the guides.

If the “fingers” are worn out, it is recommended to purchase a repair kit that includes guides, boots and fasteners. The main thing is not to get into parts that are defective or made from low quality material. Unfortunately, this happens. Caliper rattling is also possible when the guide seats are worn out. This can be treated by installing special rubber bands on the pins.

Calipers for VAZ 2110: repair and maintenance

Have you ever wondered what exactly your safety on the road depends on? You can, of course, refer to other road users or the condition of the roads. But it will be much more relevant to talk about the technical side of the issue. The hero of our today's article on the VAZ 2110 is the caliper.

Front brake cylinder VAZ 2110

An incredibly simple mechanism in design and operation, at the same time it is an extremely important part of your VAZ car. A properly functioning caliper can give you those precious few meters of braking distance in reserve, which can protect you from a terrible disaster or damage to your vehicle.

Not every motorist knows how to properly monitor and maintain the brake mechanism, has a vague idea of how to dismantle it and, perhaps, will generally look at his interlocutor with a blank look when mentioning a certain VAZ caliper. But servicing this element of the brake system is quite simple and does not require much effort.

VAZ 2110 caliper maintenance

On the road you should not rely on the Almighty. Therefore, if you feel that something is wrong with the braking distance of the car, it is better to take the initiative into your own hands. Arm yourself with a modest arsenal of locksmith tools, consisting of a small number of open-end and socket wrenches, as well as a certain amount of theoretical knowledge - get down to business.

Symptoms of mechanism malfunction

The design of this mechanism is very simple, but it is the most important component of the braking system. If the brake caliper of the VAZ-2110 is in good working order and operates in normal mode, then this directly affects the braking distance of the car. In case of sudden braking, you have a chance to win several “golden” meters, which can protect you from a fatal outcome.

Among the main symptoms of breakdowns of this mechanism are the presence of smudges near the front wheel, as well as an increase in braking distance. But similar symptoms can also appear when tubes, hoses are destroyed, or the fluid level in the system decreases. Therefore, before repairing the caliper, you need to make sure that it is faulty.

Do-it-yourself dismantling of the caliper on a VAZ-2110

The very simple design of the product and the triviality of the process of dismantling it allow even a novice motorist to carry out repairs and maintenance. If you carefully follow the recommendations below, you are unlikely to encounter difficulties at any stage of the process. You will save a lot of money spent on a trip to a service station, and a considerable amount of time, because the service time is comparable to the time required to travel to the workshop.

Dismantling VAZ caliper

The sequence for dismantling the product is as follows:

- The first step is to jack up the car and remove the wheel. To be on the safe side, it can then be placed under the bottom of the car in case the jack fails;

- On a VAZ 2112, the caliper is attached to the bracket using two M17 bolts, which you should unscrew. Penetrating lubricant may be needed to strip the bolts;

- If you need to replace the VAZ caliper or carry out a comprehensive repair, unscrew the product from the brake hose. You seal the hose tip and you can begin further disassembling the product.

Diagnostics

To check the front brake caliper of the VAZ-2110, you will need to perform the following steps:

- Assess the condition of the metal piston and the ease of its movement inside the cylinder.

- Check for metal oxidation, oxide formations or build-ups, or moisture on the elements.

- Assess the condition of all rubber boots.

- Check the condition of the VAZ-2110 caliper guides. You must make sure that there is no abrasion, deformation or scuffing on their surface.

Any damage to the caliper body and its and other elements should alert the driver. In this case, it is necessary to change the mechanism.

What kind of lubricant should be used for calipers?

To choose the right lubricant for pins (guides), pistons in caliper cylinders and other elements, you need to focus on the requirements described below:

- The lubricant must be non-aggressive to rubber, elastomeric and plastic parts.

- It must remain resistant to brake fluid, water and other aggressive substances that can dissolve and wash it away.

- The lubricant must be high-temperature and withstand heat of 180°C or more. It should not melt under increased thermal loads and should not leak.

- It must also be frost-resistant and not lose its properties at sub-zero temperatures, which can reach –35°C and below.

Therefore, do not listen to garage craftsmen who say that you can use lithol and other similar lubricants to lubricate the calipers. This can lead not only to breakdowns of this unit, but also to more serious losses, for example, in the event of an accident.

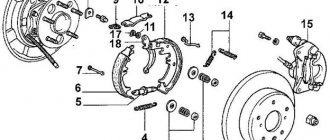

Detailing

Assembly elements on the front brake mechanism:

- Dustproof cover;

- Pad holder;

- Noise protection gasket and spring;

- Two pads: internal, with a wear indicator, and external;

- Fastening plates;

- Cylinder cover and piston;

- Caliper;

- Bracket;

- Air release valve;

- Gasket, bushing, pin, seal.

For the tenth to twelfth VAZ models, these units are structurally the same, only the VAZ 2110 caliper bracket is different. Therefore, it becomes possible to install not only the “native” unit, but also from “related” models. Naturally, this requires replacing the bracket itself.

It plays a vital role in securing the caliper and brake mechanism, and also forms the front clamping mechanism along with the caliper, piston and caliper.

Thus, the bracket is not only a holding element, but also a guiding element of the front wheel locking mechanism.

Front caliper parts

Naturally, when it fails, the entire assembly is often replaced, but individual elements can be repaired, for which there are special repair kits.

The price of a repair kit averages about 500 rubles and includes:

- 1 hose fitting with cap;

- 2 protective covers for guides;

- 1 O-ring;

- 1 caliper protective ring.

The price of a new left or right front caliper fluctuates around 1000-1500 rubles.

VAZ-2110 caliper maintenance and repairs

It is mandatory to service the VAZ caliper after each replacement of brake pads, as well as in the event of a forced inspection due to its malfunction, for which it is first necessary to check the condition of all rubber elements, shock absorbers and anthers. It is also imperative to replace the grease for the caliper guides. You need a good synthetic based silicone lubricant that can withstand high temperatures.

To remove the piston from its seat, it is necessary to create the appropriate force using an air compressor (pistons are repaired one at a time, the stroke of the second is blocked, for example, by a wooden block). With the same success, when removing the product from the car, you can press the brake pedal without disconnecting the VAZ 2112 caliper from the brake hose. It is advisable to use a rubber adapter in order to absorb the sharp impact of the freely moving piston and its “shot”.

VAZ 2110 caliper repair

The piston is pushed back using a special clamp. In this case, the boot should be bent to compensate for excess air pressure. The hole for the piston and for the guides are cleaned and washed with carburetor cleaning fluid, all gaskets, boots and seats are also thoroughly lubricated.

Which caliper lubricant is better?

The answer to this question is both simple and complex: of course, it is best to use high-quality materials, but chosen correctly. Remember that low-temperature materials dry out or wash out quite quickly, leading to completely disappointing results such as soured and jammed guides and pistons, as well as squeaking pads.

The main thing is to know what you are choosing. For example, for fingers you should use a grease based on a thickener and synthetic oils that can withstand high temperatures - it will not “leak” or coke. At the same time, anti-squeak compounds for the back of brake pads are harmful in the case of fingers.

The procedure for removing the caliper and video instructions using the example of a VAZ 2110

So, let's look at the order of actions that need to be performed.

- Raise the car with a jack

- Remove the front wheel

- Disconnect the brake hose from the front strut.

- Unscrew the two caliper mounting bolts from the inside

See the step-by-step instructions using the example of the VAZ 2110, which was made specifically for this article:

As you can see, this process can be completed in 5 minutes, the name of the necessary tool is at hand and an idea of all the necessary actions. A new caliper complete with brake pads has a price of 2,000 rubles for original AvtoVAZ products. If we consider cheaper analogues, then you can buy a caliper for 1,500 rubles - a piece.

Of course, in most cases it is necessary to change only the necessary spare parts of this entire structure, because the cylinder, bracket and pads are sold separately. And for many car owners it simply doesn’t make sense to buy the whole thing assembled.

Checking the caliper and restoring it

The caliper is installed on the front and rear brakes. Its verification and restoration can be carried out independently, but, in the absence of the necessary practical skills and theoretical knowledge, it is best to turn to professional specialists. Let's consider in theory a method for checking and restoring a caliper on a VAZ 2110, the price of which is one of the lowest on the market.

The main task comes down to properly disassembling the caliper, cleaning it of old grease residues, applying a new special compound and checking the integrity of the rubber seals. First you need to gain free access to the front brake mechanism, which is located directly behind the wheel. For these purposes, supports are installed that help to easily and quickly remove the wheel.

After this, they begin the process of replacing the brake pads on the front caliper of the VAZ 2110. To do this, you need to remove the lower bolt, which is responsible for fastening the caliper, using a screwdriver, the body of which can easily be tilted up. When replacing old brake pads, you should remember their location, since the installation of new parts should be carried out in the same place.

If the VAZ 2110 caliper body was folded up and the brake pads were removed, then you can proceed to the next stage. In this process, you will need to unscrew the upper bolt responsible for fastening the caliper. It is worth noting that the line and brake fluid must remain connected.

Next, the bolts that serve to connect the knuckle and caliper bracket are unscrewed. After removing the bolts, you can remove the bracket (along with the brake pad clamps and guides). Subsequently, the piston is removed from the caliper body. It can be quite difficult to do this yourself, so you can use the services of professional auto repairmen working at service stations.

If you decided to check and restore the VAZ 2110 caliper yourself from start to finish, then you can try to carry out the following steps:

- conveniently position the caliper body without disconnecting it from the brake line.

- press the brake pedal and release it only when the piston is pressed out of the cylinder by the pressure.

Do not be alarmed if liquid suddenly leaks from the cylinder, as this is quite normal for removing the piston using the above method. Next, you need to interrupt the brake line connection and also plug it (to prevent further fluid leakage). Once the so-called “blockage” has been established, the process of disassembling the “tens” caliper can be considered successfully completed.

It is worth considering the fact that the above steps do not cover the replacement and reassembly of the brake system. But, based on their complexity in describing the initial stage, one can understand how complex a part the caliper is.

How and when to lubricate

Indeed, how often should caliper guides and other components be treated with special pastes? Experts believe that this should be done at least during scheduled maintenance of the brake system - when replacing pads, or in case of unpleasant and irritating “acoustic effects”. As for the process itself, it is not necessary to coat the guides in three layers - it is enough to apply a couple of grams. The main thing then is to make sure that the guides are mobile.

For general clarity, here are some recommendations from the official Liqui Moly website on servicing the brake system after replacing the pads. First, clean the caliper guide pins and their seats from old grease and degrease using a quick cleaner. Then the pistons of the brake cylinders are recessed with a special tool or clamp. If there is binding or excessive force, remove the rubber cylinder boots, remove any dirt, and spray Silicon-Spray under them. “Rock” the caliper piston, sequentially squeezing it out of the cylinder using the brake pedal and pushing it back in with a clamp. After checking that the piston moves easily, re-spray the boot with silicone spray and put the rubber seal back on. If it is impossible to restore the operation of the brake cylinder, replace it or repair it with obligatory polishing (or replacement) of the piston and replacement of the brake cuff with boot.

Do-it-yourself dismantling of the caliper on a VAZ-2110

The very simple design of the product and the triviality of the process of dismantling it allow even a novice motorist to carry out repairs and maintenance. If you carefully follow the recommendations below, you are unlikely to encounter difficulties at any stage of the process. You will save a lot of money spent on a trip to a service station, and a considerable amount of time, because the service time is comparable to the time required to travel to the workshop.

Dismantling VAZ caliper

The sequence for dismantling the product is as follows:

- The first step is to jack up the car and remove the wheel. To be on the safe side, it can then be placed under the bottom of the car in case the jack fails;

- On a VAZ 2112, the caliper is attached to the bracket using two M17 bolts, which you should unscrew. Penetrating lubricant may be needed to strip the bolts;

- If you need to replace the VAZ caliper or carry out a comprehensive repair, unscrew the product from the brake hose. You seal the hose tip and you can begin further disassembling the product.

how to remove the caliper on a VAZ 2110 video Video

Video instructions on how to independently replace the front wheel brake caliper on a VAZ 2108-2109,…

Diary of an Auto Mechanic - A kit for brake calipers can be purchased here▻ https://ali.pub/oxsvd This video shows...

In this video I'll show you how to replace the brake caliper and bleed the brakes. To replace you will need a special...

The procedure for replacing front brake pads on VAZ 2108-099, VAZ 2110-2115, Lada Kalina, Priora, Granta. Lada repair...

High-quality used spare parts for Daewoo - https://avtolanos.com.ua.

Video review of replacing the front brake cylinder on a VAZ 2110-2112, Kalina, Granta, Priora.

Lubricating caliper guide pins, replacing pins and boots, video review of repairs. For all cars...

Trialli repair school: the video used brake discs https://www.trialli.ru/catalogue/tormoznaya-sistema/diski-tormoznye/df-142/ and brakes…

Trialli repair school: brake pads were used in the video https://www.trialli.ru/catalogue/tormoznaya-sistema/kolodki-tormoznye/pf-965/

How to replace brake discs and pads on a fret.

Repairing a stuck caliper. What happens when the brake caliper is stuck (the brakes get hot and the brake sticks...

Video guide for replacing front wheel brake discs on VAZ 2110-2112, 2114-2115, Kalina and Granta, Priora,…

We remove the brake caliper to replace the cylinder of a VAZ classic car. Tips on how to allow less air…

REPLACEMENT OF FRONT PADS FOR VAZ 2110,2111,2112.

Quick caliper repair. Detailed description of how to do it and in what order.

Do-it-yourself lubrication and repair of a brake caliper using the example of the front caliper of a VAZ 2112. Repair and maintenance…

Replacing a boot with a caliper For many car enthusiasts who are faced with repairing brake calipers...

A surefire way to press in the front brake piston yourself when replacing old pads with new ones without any...

Video guide on replacing the rear brake cylinder on VAZ front-wheel drive vehicles!

Source

Where and how to buy?

You can buy a caliper at any auto store that specializes in selling components for domestically produced cars. As a rule, in such stores all goods are in stock. You can select a suitable caliper either by writing out its markings, or rather the final index of the last 5 digits, or by providing the seller with a faulty caliper (the weight of the product is only 2.17 kg ). Approximately once every 3 years, the suspension of cars of the 2109-2115 family was updated, therefore, the location of the mating threaded seats (mounting bolts) may vary slightly.

New ventilated brake discs are compatible with all mentioned calipers for VAZ 2109, 2110, 2114, 2115. The installation is fully consistent with original components.

Sources

- skolkos.ru/skolko-stoit-support-na-vaz-2109-2110-2114-2115/

- drive2.ru/l/510984286187290783/

Replacing brake caliper guides for VAZ 2110, 2111, 2112

Lately, there has been a grinding noise when braking. An inspection of the brake system showed that the discs and pads were in good condition.

One of the reasons for grinding and rattling of calipers may be worn guides. Also, worn guides can lead to uneven wear of the pads (when one of the pads wears out faster than the other). This is exactly the wear that was on the old pads when they were last replaced.

Inspection of the guides showed that they are not jammed, but the lubricant has coked and thickened, and there is also noticeable play.

4 guides were purchased along with anthers, the price was 40 rubles per piece. And also a special lubricant for brake systems BOSCH SUPEFIT (5000000151) for 50 rubles. One bag is just enough for four guides.

It is important to know that not any high temperature grease will work for caliper guides. Do not use ceramic grease or copper-based grease. These lubricants coke and cause the guides to jam.

They can also be aggressive towards anthers. As it turned out later, BOSCH lubricant is not suitable for guides; the temperature range is only -25°C +130°C, which is naturally not enough for this unit. Although the manufacturer claims that this lubricant is universal and is exactly suitable for guides. I found supporting information in the official brochure about the use of lubricant

These lubricants coke and cause the guides to jam. They can also be aggressive towards anthers. As it turned out later, BOSCH lubricant is not suitable for guides; the temperature range is only -25°C +130°C, which is naturally not enough for this unit. Although the manufacturer claims that this lubricant is universal and is exactly suitable for guides. I found supporting information in the official brochure about the use of lubricant.

We'll ride it for now, and we'll see.

Before replacing the guides, remove old grease and thoroughly wash the bracket. To remove the old grease I used 646 solvent.

Its disadvantage is that it is aggressive to the rubber from which the anthers are made, so after using the solvent, I washed the staples with a degreaser. New lubricant should be applied in a thin layer.

The boots on the new guides turned out to be complete crap, several tore at once, so I had to install the old ones, which turned out to be in good condition. By the way, when assembling, you should first put the boot on the bracket, and then on the guide. This makes it much easier and less likely to tear the boot.

After replacing the guides, the grinding noise when braking no longer bothers me.

What types of lubricants are there?

Caliper lubricants can be divided into several different types, each of which contains several lubricants that correspond in their characteristics to the operating conditions of various elements of the disc brake caliper.

Synthetic or mineral pastes with added metals

In the first group, it is worth considering high-temperature lubricating pastes with Anti-Seize properties. These lubricants contain a fully or semi-synthetic and mineral base. With the addition of synthetic thickeners, submicron particles of metals such as molybdenum or copper. Instead of metals, solid substances of lubricants can be used, which work successfully at super-temperature values. This group includes:

- Complex lubricating paste products.

- Metal-free pastes.

- Lubricants containing copper or molybdenum disulfide.

They can be used to cover anti-squeak plates, pressure springs, and the back side of the pads.

These are pastes from such brands as Huskey, Loctite, Wurth, LIQUI MOLY, Textar, Mannol Kupfer, Valvoline Cooper, Motip Koperspray, Bosch SUPERFIT.

Installation of calipers from Volga on VAZ 2110

| There are never too many 'brakes', so many are trying to improve their efficiency by replacing the original brake discs and pads with alternative, imported ones. There are also more advanced modifications to the brakes, for example, installing GAZ 3110 brakes on a VAZ 2110. |

Brakes GAZ 3110 and VAZ 2110, what is the difference?

The negative aspect of switching to more massive calipers from the Volga is in weight. For example, the weight of a VAZ caliper with pads is 3.2 kg, and the weight of a Volga caliper with pads and adapter is 5 kg. That is, by replacing the standard 'tens' calipers with Volgov calipers, we increase the amount of unsprung mass of the car.

The positive aspect of the Volga brakes is that the large pad area allows for better heat dissipation. Car enthusiasts also note their better efficiency compared to standard VAZ 2110 brakes.

Adapter for GAZ 3110 caliper for VAZ with front-wheel drive

Drawing of an adapter for the Volga caliper for VAZ 2108/2110/1118/2170 (AutoCAD format)

In the archive there is an adapter for brake discs R14 and R15, archive password: lada2111rf

Gas 3110 from storage. Automobile equipment surplus, used sale.nelikvidi.com

Installation of calipers from GAZ 3110 to VAZ 2110 (R15)

You will need: Volga calipers along with pads, an adapter for Volga calipers on a front-wheel drive VAZ (2 pcs), caliper hoses from a Chevrolet Niva (short).

Remove the caliper along with the bracket, and then disconnect the hose from the tube. Drill out the hole in the bracket on the body that holds the connection between the hose and the tube. This is done in order to thread the hose fitting. Connect one end of the hose to the tube. The other end is with a caliper.

Next, screw the adapter to the guide of the GAZ 3110 pads using M12x25 bolts with a pitch of 1.25 (it is advisable to use bolts with the letter 'X') and M12 bolts. Then screw the adapter with the guide to the steering knuckle using standard M10x25 bolts, pitch 1.25. Install the Volga pads, having previously cut off the wear sensor wires from them. Install the caliper. The bleeding fitting must be at the top, otherwise it is impossible to bleed the brakes. All that remains is to bleed the brakes, and here it is worth considering that with GAS calipers, more brake fluid is poured into the system.

Installation of calipers from GAZ 3110 to VAZ 2110 (R14)

In general, the installation is similar, but there are a number of points that are worth paying attention to: 1. Due to the fact that when installing R14 brake discs, the guide will move towards the steering knuckle, so we saw off the edges of the boot using a grinder. 2

The adapter is used for R14 brake discs. Bolts should be used 5mm shorter, M10x20 pitch 1.25 with an M10 lock washer. Otherwise, the bolt will press the adapter to the brake disc and the disc will not turn

2. The adapter is used for R14 brake discs. Bolts should be used 5mm shorter, M10x20 pitch 1.25 with an M10 lock washer. Otherwise, the bolt will press the adapter against the brake disc and the disc will not turn.

3. The Volga’s caliper is larger than that of the “ten”, so you have to install a disc with a different offset, in this case the ET35 offset. An 11mm spacer for the wheel rim is also used. When installing disks, the seat may cling to the disk guide; in this case, you can grind the guide or use a spacer of the required thickness.

Conclusion

The negative point, which is the large weight, in practice does not affect the behavior of the machine. And the performance of brakes with GAZ calipers is significantly better.

By the way, this is not the only way to tune the brakes; rear disc brakes are very popular, as well as simply replacing brake discs from R14 to R15.

Replacing the front brake cylinder on a VAZ 2113, VAZ 2114, VAZ 2115

Welcome! Front brake cylinders - there are only two of them, each of their cylinders is located in a brake caliper, their real name is: “Working brake cylinders”, their operating principle is as follows: when you press the brake pedal, the liquid presses on the pistons, which are located in the brake cylinders, and the pistons in the meantime, the pads are pressed against the brake disc, when the foot is removed from the brake pedal, the fluid returns and the pistons stop applying pressure to the brake pads (Braking stops).

Note! To carry out the work, stock up on: Wrenches, copper O-rings for brake hoses (take about 4), as well as brake fluid, something to plug the brake hose with, hex heads, different types of screwdrivers, and spanners and of course, the tools needed to remove wheels from a car!

Where is the brake cylinder located in the caliper? The easiest way to see the cylinder is when the caliper is removed from the car, but by simply pulling out the brake pads, the cylinder can be fully seen, the cylinder itself is sold and replaced as an assembly, it consists of several but very important things, firstly, the piston is located inside the cylinder and walking back and forth, thereby pressing and moving the brake pads away from the disc and of course the cylinder has a bleeder fitting, it is closed with a cap in the small photo with a blue arrow and the last element is indicated, this is the boot at the piston of the brake cylinder, it is indicated with a green arrow, thanks to it, the brake fluid is not squeezed out and into the cylinder, dirt, sand and moisture do not get in, they are very destructive for the cylinder and if they get inside, they will wash out all the lubricant (If it is water) or the lubricant will mix with sand (If sand gets in into the cylinder), and as a result the piston will barely move (braking efficiency will therefore drop).

Caliper repair

If you decide not to replace, but to repair the mechanism, then you can purchase a special kit for this purpose. It consists of the following components:

- Gaskets.

- New piston.

- Guide elements.

The cost of the repair kit is about 500 rubles. And a new caliper for a car of the tenth family, depending on the greed of the seller, may cost 2-3 times higher.

But before installing the new elements that are included in the kit, it is necessary to completely disassemble the VAZ-2110 caliper. To do this you will need to use an air compressor. Connect it to the hole for the brake pipe, and then gradually supply air. It is advisable to install a rubber spacer or a wooden block under the piston. This will avoid a shot, since the piston moves freely.

A similar action can be performed immediately before removing the mechanism. To do this, you do not need to disconnect the caliper from the system; instead of the brake pads, install a small wooden block. Gently press the brake pedal to build up pressure in the system. In this case, you will lose some amount of liquid, but if you were planning to fill in a new one anyway, then this is not a problem.

Installation of a new piston is done using a clamp. Be sure to bend back the boot to avoid damaging it. Before installing the piston, it is necessary to remove contaminants on the internal surfaces with non-aggressive liquids. It is not recommended to use liquid to clean the carburetor, as it can damage rubber and plastic products.

Installing a new caliper

Installation of the device is carried out in the reverse order. To do this you need to do the following:

- Install the brake caliper housing and tighten the mounting bolts.

- Tighten the bolts using a 17mm wrench.

- Push back the locking plate and unscrew the bolt with a 13mm wrench to remove half of the caliper.

- The piston must be completely pressed inside the mechanism and new brake pads must be installed.

- Reinstall the caliper half and tighten the nut. Bend the locking plate using a chisel.

- Screw on the brake hose.

- Bleed the entire system to get rid of any air in it.

After bleeding the system, it is imperative to put rubber plugs on the fittings. With their help, these elements are protected from moisture and dust. And the next time you pump, unscrewing the fittings will be much easier.

Repair

The first rule: if you don’t want further troubles, especially when one of the wheels jams, never repair only one caliper, always both together!

To sort through, repair or replace individual parts, and possibly completely change the unit if it turns out that there is nothing left to repair, you need to follow the following algorithm:

Remove the ring securing the cover, and then the cover itself; To avoid damaging anything, place a piece of wood or a rag between the caliper and the piston, then remove the piston

Also watch your fingers - parts of the mechanism can press them; After removal, pay attention to the piston and cylinder. If you find any damage on them, then the entire assembly needs to be replaced; If everything is fine, using a wooden or possibly a plastic tool, remove the piston seal from the caliper cylinder; If you have a PD51 model, you need to squeeze out the bushing, remove the covers protecting from dust on both sides; All elements should be washed with a liquid intended specifically for cleaning brake mechanisms; You probably purchased a repair kit

From this, “push” a new seal onto the piston, then place it in the cylinder. This must be done without using brute force, otherwise the brake mechanism may subsequently jam; Install the piston dust cover - a new one, from the repair kit; The bushings must be lubricated with silicone grease, which is also included in the repair kit, then installed in the corresponding holes; Install the dust covers in their proper places; Before installing the caliper on the car, replace the copper gaskets on the hose connection.

The front brakes can now be completely reassembled. A prerequisite after repair is to bleed the brakes.

All that remains is to check whether the wheels lock properly when you press the brake pedal, and whether the caliper is sticking. Everything is fine? So, you can hit the road.

Source

VAZ 2110 | Front brake caliper

9.4. Front brake caliper

| GENERAL INFORMATION |

| 1. Dust cover 2. Pad holder 3. Anti-noise pad 4. Inner brake pad (with wear indicator) 5. Pad mounting plates 6. Outer brake pad 7. Anti-noise pad 8. Anti-noise spring 9. Pad mounting plates | 10. Mounting ring 11. Cylinder boot 12. Piston 13. Seal 14. Brake caliper 15. Gasket 16. Air release valve 17. Bushing 18. Pin |

| 1. Brake disc 2. Pad holder 3. Brake pad wear indicator 4. Mounting plates 5. Outer brake pad 6. Internal anti-noise pad 7. Anti-noise pad 8. Brake pad mounting plates 9. Inner brake pad 10. Anti-noise pad | 11. Cylinder boot 12. Retaining ring 13. Seal 14. Piston 15. Bushing 16. Dust cover 17. Gasket 18. Air release valve 19. Brake caliper 20. Dust cover |

Dust resulting from brake pad wear contains asbestos, which is hazardous to health. Do not blow it out with compressed air or inhale it.

If it is necessary to rebuild the caliper (usually due to a brake fluid leak), first find out the price of spare parts or the cost of an already rebuilt or new caliper. Before you start rebuilding, purchase a repair kit. Always repair both calipers together - never repair just one of them.

| EXECUTION ORDER |

| 1. Unscrew the wheel nuts, lift the front of the car and place it on supports. Remove the wheel. |

| 2. Unscrew the bolt (indicated by the lower arrow) and disconnect the brake hose (indicated by the upper arrow) from the caliper. |

| 3. Using a piece of rubber hose of the appropriate diameter, cover the hole in the hose to prevent dirt or moisture from getting inside and to reduce the loss of brake fluid. |

| 4. Following the instructions given in subsection 9.3, remove the caliper (removing the caliper is part of the operation to replace the brake pads). |

Bulkhead

| EXECUTION ORDER |

| 1. To rebuild the caliper, remove the boot mounting ring and boot. Before removing the piston, place a block of wood or some rags between the piston and the caliper to protect against damage during removal. |

| 2. To remove the piston from the caliper, connect an air hose to the brake hose connection to the caliper and press out the piston using compressed air. Do not apply too much pressure, just enough to push the piston slightly out of the cylinder. |

| Warning Be careful that your fingers are not between the caliper and the piston, as the piston may press them. |

| 3. Inspect the surface of the piston and the walls of the caliper cylinder. If they are scratched or show signs of corrosion or wear, replace the caliper along with the piston. |

| 4. If these items are in good condition, remove the piston seal from the caliper cylinder using a wooden or plastic tool. Metal tools may damage the surface of the cylinder. |

| 5. On the PD51 caliper, press the bushing out of the caliper and remove the dust covers on both sides. |

| 6. Clean all components using brake cleaning fluid. |

| 7. To assemble the caliper, you need to purchase a repair kit suitable for your car model. |

| 8. Dip the new piston seal and piston into brake fluid and install them into the caliper cylinder. Do not force the piston into the cylinder, check that it is installed correctly and push it firmly into the cylinder (do not use too much force). |

| 9. Install a new piston dust cover and mounting ring. |

| 10. Lubricate the bushings with silicone grease (included in the repair kit) and insert them into the caliper holes. Install dust covers. |

Installation

| EXECUTION ORDER |

| 1. Installation of the caliper is carried out in the reverse order of removal. Be sure to replace the copper sealing washers (gaskets) at the brake hose connection (new washers are usually included in the repair kit). |

| 2. Bleed the brake system circuit, following the instructions (see subsection 9.12). Check that the brake hose connections are not leaking. Check the operation of the brakes before normal operation of the vehicle. |

VAZ-2110 caliper maintenance and repairs

It is mandatory to service the VAZ caliper after each replacement of brake pads, as well as in the event of a forced inspection due to its malfunction, for which it is first necessary to check the condition of all rubber elements, shock absorbers and anthers. It is also imperative to replace the grease for the caliper guides. You need a good synthetic based silicone lubricant that can withstand high temperatures.

If you had to buy a repair kit, it contains such lubricant, all the necessary gaskets, new guides and a piston. The price of such pleasure will cost you about 500 rubles. Buying a new VAZ-2110 (2112) caliper, depending on the store and region of Russia, will cost from 1000 to 1500 rubles.

To remove the piston from its seat, it is necessary to create the appropriate force using an air compressor (pistons are repaired one at a time, the stroke of the second is blocked, for example, by a wooden block). With the same success, when removing the product from the car, you can press the brake pedal without disconnecting the VAZ 2112 caliper from the brake hose. It is advisable to use a rubber adapter in order to absorb the sharp impact of the freely moving piston and its “shot”.

VAZ 2110 caliper repair

The piston is pushed back using a special clamp. In this case, the boot should be bent to compensate for excess air pressure. The hole for the piston and for the guides are cleaned and washed with carburetor cleaning fluid, all gaskets, boots and seats are also thoroughly lubricated.

Types of brake caliper lubricants

Compositions can be highly specialized and universal. The first include pastes, the use of which is allowed only on individual parts (for example, in guides). The latter are generalists who can be used on various caliper components. So to speak, everywhere.

The variety of targeted compositions can be judged by the palette of the Liqui Moly company. Thus, its arsenal includes embedded silicone grease under the brake cylinder boot, paste to eliminate squeaking and jamming of brakes, lubricant for the backs of pads and surfaces of anti-squeak plates, not to mention branded brake fluid, a cleaner and a rust solvent.

By the way, lubricants for guides with corresponding catalog numbers are produced by many automakers, including Toyota, Nissan, Volvo, BMW, Ford, Land Rover, Mazda, Honda and Volkswagen.

As an example of a universal composition suitable for different parts of the caliper (guides, pistons and the back of the pads), we mention the expensive American Slipkote 220-R DBC or MS-1600 from the domestic brand VMPAUTO with a humane price, which retains properties and characteristics over a wide temperature range – the manual for it indicates a “fork” from -50 to +1000 degrees – and does not negatively affect rubber parts.

It is especially worth noting that some domestic car owners to this day use what they find in the trunk or garage - for example, lithol, grease, graphite lubricant and other compounds based on mineral oils. Experts consider the use of such materials to be an absolutely erroneous and unacceptable action, despite the calls of “experienced” people who talk on various forums about the benefits of “real, good” lithol. Let us repeat, their use leads to the demise of rubber guide boots. As for graphite, it also cannot withstand high temperatures - it can burn out or liquefy. It cannot be used due to unsuitable characteristics.

Removing the caliper

The mechanism is of a very simple design; dismantling can be done without much difficulty. Even a novice motorist can cope with such work. In order to remove the VAZ-2110 caliper, you will need to perform the following steps:

- Loosen the wheel bolts on the side being repaired.

- Raise the side to be repaired using a jack and remove the wheel completely. Install it under the bottom of the car. This will protect you in case the car suddenly falls off the jack.

- Cars of the tenth family have the caliper attached to the bracket using two M17 bolts. They need to be unscrewed. If you can't strip the threads, use a penetrating lubricant.

- Unscrew the brake hose, which is located at the top of the caliper.

When dismantling, evaluate the condition of all rubber tubes. If there is damage on them, even small cracks, it is imperative to install new elements. Such breakdowns can lead to the brake system depressurizing while driving.

Requirements for caliper lubrication

Let's start with the fact that the compositions are subject to very specific requirements, dictated by the specifics of the caliper design and the operating conditions of its components. One of the first is the ability to withstand high temperatures of hundreds of degrees, to which parts of the brake system can heat up. In such conditions, unsuitable lubricants may harden or leak. Attention should also be paid to “frost resistance” - the composition should not lose its properties at temperatures of -15-20 C degrees.

An important point is that the lubricant should not have an aggressive effect on rubber and plastic elements. Otherwise, the guide anthers, which protect against the ingress of water and dirt, will begin to deform, swell and simply stop fulfilling their intended purpose. Pastes must also have high adhesion, that is, they must be resistant to washing out by both precipitation and road reagents.