The load-bearing part is one of the most important components in the design of a car, because it is thanks to it that it is possible to assemble all the components of the car into a single whole.

Nowadays several types of load-bearing parts are used, each of which has found application on certain types of cars. Initially, all cars were built on the basis of a frame supporting part. But over time, it was replaced by other types, for example, almost all passenger cars use a monocoque body, in which there is no frame, and all its functions are performed by a reinforced body. And yet the frame bearing part continues to be used - on trucks and SUVs.

What is a car frame: purpose, pros and cons

The car frame is a beam structure that acts as the basis for fastening all components and assemblies, such as the power plant, transmission elements, chassis, and so on. The body with this design of the supporting system provides space to accommodate passengers and luggage, and also performs a decorative function.

Car frame

The use of a frame makes it possible to give the load-bearing part high strength. That's why it is used in trucks and SUVs. It also makes it possible to maximize the unification of components and mechanisms between models of different classes.

Previously, car manufacturers produced car chassis with basic parts (frame, engine, transmission, etc.), onto which various types of bodies were “stretched.”

The frame in the car acts as a “skeleton”. It absorbs all external and internal loads when the car is moving and even when it is parked. In view of this, a number of requirements are imposed on the automobile frame:

- sufficient strength and rigidity;

- small weight;

- the correct shape, which will contribute to the rational operation of all elements of the car.

The frame bearing part has a number of advantages. So, thanks to it, assembling the car and repairing it in the future becomes much easier. The main difference between a frame structure and a body structure is that any breakdown can be easily repaired thanks to a good specialist and materials. Another important advantage: driving on bad roads will not be fraught with distortions of the body (door openings, pillars, etc.).

Spar frame

Along with this, there are also disadvantages. The first is a significant increase in the weight of the car due to the presence of a separate frame and body. Accordingly, fuel consumption will also be higher. Another disadvantage is that placing the side members under the body requires additional space, which makes getting into the car difficult and takes up a significant part of the interior.

There is also a decrease in passive safety, since there is a possibility of the frame shifting relative to the body in the event of an impact. Therefore, the load-bearing body is an integral element of a passenger car. At the same time, the frame design copes well with the harsh conditions in which trucks and SUVs drive.

The main advantages of the frame structure

Frame load-bearing frames will not give way to the load-bearing body for a long time, since they have a number of undeniable advantages:

- Simplicity of designs and proven calculation methods.

- Strength. To bend, and even more so, break the frame, a lot of force will be required.

- On passenger cars, the body is attached with elastic fastenings, which increases passenger comfort. To achieve a similar effect in frameless frames, you need to take a number of additional design measures.

- Low torsional resistance. Achieved due to the thickness of the metal of the side members and cross members.

- Increased ground clearance. Bridges are installed on frame structures, allowing for increased cross-country ability.

Truck frame

On one platform you can design different models of cars.

The decisive advantage of the structures is the convenience of major repairs: the frame exists separately, the body is on its own. By removing the top of the car, you gain access to the chassis.

Spar frame

This is the most common type. The frame design includes two power longitudinal beams, which are called spars. They stretch along the body and are connected by crossbars. The beams are made of steel. In order to increase twisting performance, various types of section profiles can be used.

The spars are not necessarily straight - sometimes they have both vertical and horizontal bends. They can be located either parallel to the horizontal plane or at a certain angle, which is typical for SUVs. It is also possible to have different arrangements of the cross members, through which the spars are connected. Today it is the most popular frame design, used in most trucks and SUVs.

This frame is perfect for operating the car on bad roads. It also simplifies the repair and assembly of the car. The disadvantages are that the spars take up a considerable part of the interior and somewhat complicate the landing process.

Types of spar frames

Spar X-shaped

An X-shaped frame is one of the types of spar frames. The peculiarity of its design is that the spars at the front and rear are spread apart, and in the center they are brought together as much as possible. This type is similar in appearance to the “X” beech, which is the reason for its name.

Peripheral

It is a type of spar frames. This type began to be actively used on large European-made passenger cars and “dreadnoughts” from the USA in the 60s. In such frames, the spars are located so widely that during the installation of the body they are located at the sills. This allows the floor level to be significantly lowered, while at the same time reducing the immediate height of the machine.

An important advantage of such a machine is its maximum adaptability to side impacts. However, there is a significant drawback - the frame cannot withstand significant loads, so the car body must have the necessary strength and rigidity.

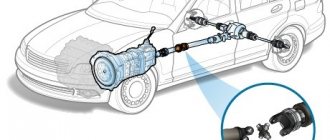

Spinal frame

This type of frame was developed by representatives and was mainly used for machines produced by it. The main supporting element is a pipe connecting the engine at the front with the transmission elements that are located inside it. Essentially, the pipe acts as a single housing for the gearbox, transfer case and drive shafts. Torque from the engine to the transmission is supplied through a shaft placed in the pipe. Moreover, this shaft is not a cardan shaft, which ensures greater reliability.

Spinal frame

This frame design, combined with independent wheel suspension, provides very long travel, which makes it indispensable in special-purpose vehicles.

The advantage of the backbone frame is also that it has very high torsional rigidity, and the transmission elements are reliably protected from external influences. But due to the fact that certain mechanisms are located inside the frame structure, repair work becomes noticeably more complicated.

Fork-ridge

The fork-spine type of frames is also a Tatra development. In this version, the engine is not mounted to the transmission pipe, but on a special spar fork. This is done in order to reduce the level of transmitted vibrations from the operating internal combustion engine to the frame and, consequently, to the car body. However, today fork-spine frames are no longer used in the automotive industry.

Fork-spine frame

Recommendations

- Rajput, R. (2007). Textbook of automotive technology

. Lakshmi Publications. item 410. ISBN 9788170089919. Retrieved February 28, 2015. - "Kenworth Heavy Duty Body Builder Manual - 2012" (PDF). Kenworth Truck Company

. PACCAR. August 2012. p. 203. Retrieved April 14, 2022. - "International HX Series" (PDF). International trucks

. Navistar, Inc. 2022. Retrieved April 14, 2022. - "unit body". engineering-dictionary.org

. Retrieved March 28, 2016. - Visnich, Bill (September 1, 2008). "Moving to single body layup without dunking." Wards Auto

. Retrieved March 28, 2016. - ^ a b

Genta, Giancarlo;

Morello, Lorenzo; Cavallino, Francesco; Filtry, Luigi (2014). The Past, Present and Future of Automobiles

. Springer. pp. 23–26. ISBN 9789400785519. Retrieved March 28, 2016. - ^ a b c d e

Simanaitis, Dennis (October 5, 2011). “From carts to carbon fiber. All about the car body/chassis.” Road and track. Retrieved August 10, 2016. - "Joseph Ledwinka." Hagley Museum and Library. May 29, 2013. Retrieved August 10, 2016.

- "20 Cars That Changed the Automotive Industry Forever." Magic Online. October 13, 2014. Retrieved August 10, 2016.

- "John Tjaard's designs—the result of the 1936 Lincoln Zephyr." Old motor. December 27, 2014. Retrieved March 28, 2016.

- Consumer Guide

Auto Editors (1985).

Great Cars of the Forties

. Louis Weber. paragraph 54. ISBN 9780881762808. Retrieved March 28, 2016. - Ted, Tidious (July 8, 2014). "Great American Cars of the Forties - 1941 Nash 600." Retrorambling

. Retrieved March 28, 2016. - "My Mother's Compact Car: Twenty Years of the Rambler." Car Quarterly

.

33

(2):33. 1994. Retrieved March 28, 2016. - ^ a b

Narus, Donald J. (2012).

Nash, 1939-1954

. New Albany Books. paragraph 27. ISBN 9781467521246. Retrieved March 28, 2016. - "Chrysler Goes Unibody: 1960." allpar.com

. Retrieved March 28, 2016. - Bruzek, Joe (October 22, 2008). “What is a one-piece design?” Ask.Cars.com

. Retrieved February 28, 2015. - Foster, Patrick R. (2014). Jeep: The Story of America's Greatest Car

. Motorcycles. paragraph 124. ISBN 9781627882187. Retrieved March 28, 2016. - Niedermeyer, Paul (January 19, 2012). "Automotive History: An X-Ray Look at GM's X-Frame (1957-1970)." Curb Classic

. Retrieved February 28, 2015. - Underkoffler, David (26 June 2022). “Body on frame and unibody: pros and cons.” Car news. Retrieved October 13, 2020.

- "Subject: Mercedes Benz 190SL," Teutonic T-bird "born, 1954..." vwvortex.com. Retrieved February 28, 2015.

- Ludvigsen, Karl (2010). Colin Chapman: Inside the Innovator

. Haynes Publishing. pp. 150–164. ISBN 978-1-84425-413-2. - Burger, Jerry; Hendrickson, Steve (2000). The Hot Rodder's Bible

. MBI Publishing. pp. 123–124. ISBN 9780760307670. Retrieved February 28, 2015. - "AMC Pacer station wagon." Car and driver

. Vol. 22. 1977. p. 24. Retrieved February 28, 2015.

Space frame

The most complex type of frame structure used for sports cars. This design is a frame based on thin alloy pipes and has very high rigidity and strength. In the automotive industry, these frames were supplanted by monocoques, however, similar designs are used to create buses.

Space frame

Axle weight distribution

The characteristic “weight distribution along the axles” (“chassis load distribution”) is responsible for how much vehicle weight falls on the wheels of the front and rear axles.

This characteristic is directly related to the vehicle's fuel efficiency and turning ability. The ability of a vehicle to maneuver – turn at a given angle and maintain stability – depends on the distribution of weight along the axes.

The ideal option for sports cars is a weight distribution of 50/50 (equal - not the front and rear axle).

For front-wheel drive cars, the weight distribution along the axles is 70/30 (70% load on the front axle and 30% on the rear axle). This is important for optimizing traction on the drive wheels.

Load-bearing base

The load-bearing base is something between a body and a frame structure. Spars are also used here, but they are united by a bottom rather than cross members. The most widespread and popular owner of a load-bearing bottom is the Volkswagen Beetle, in which the body is attached to a flat floor panel using bolts. Another mass-produced car, the Renault 4CV, has a similar design.

Load-bearing base

The load-bearing bottom is highly technological and is used in large-scale production. This design makes it possible to make the floor and center of gravity of the car quite low.

The frame load-bearing part of the car has a number of advantages and features that make it indispensable for trucks and SUVs. And although the frame is used purely for specific types of cars, some elements of its design are used extremely widely, as they make it possible to make the load-bearing bodies more rigid. Almost every passenger car is equipped with reinforcing side members or subframes.

Chassis curb weight

Very often you can come across the concepts “curb weight of the chassis”, curb weight of the vehicle.” What is it?

The curb weight of a car is the total weight of the car with all operating materials (full tank of gasoline, coolant, oil). The weight of the driver and passengers is not taken into account. Their mass is taken into account when we are talking about the total mass of the vehicle.

The curb weight of each type of car is different:

- Pickups and SUVs. Weight reaches 2.5 tons.

- Full-size cars, minivans. Weight - about two tons.

- Compact cars. Curb weight – no more than 1360 kg.

- Microcars, microcars. Curb weight is about a ton.

Very often, the curb weight of a vehicle in the characteristics is indicated precisely as the curb weight of the chassis. As a rule, both “Curb chassis weight”, sometimes it indicates “Gross vehicle weight” and “Curb vehicle weight”.