Checking the level and adding fluid to the power steering reservoir

The reservoir is located on the left side of the engine compartment, next to the washer fluid reservoir.

Check the fluid level in the power steering pump reservoir.

It should be between the “MAX” and “MIN” marks marked on the tank body.

If the level is significantly lower, add fluid.

2. To do this, unscrew the tank cap.

3. Add working fluid to the required level

4. Wrap the cork

How to check, fill and bleed the Gazelle power steering system

Checking the level and adding fluid to the power steering reservoir

The reservoir is located on the left side of the engine compartment, next to the washer reservoir

Check the fluid level in the power steering pump reservoir.

It should be between the “MAX” and “MIN” marks marked on the tank body.

If the level is significantly lower, add fluid.

2. To do this, unscrew the tank cap.

3. Add working fluid to the required level

List of mechanism breakdowns

Breakdowns are a common occurrence for experienced drivers of such cars. Let us list the main ones that in one way or another will influence the condition of the ZIL-130 power steering:

- drive belt wear or weakening will require replacement of the structural element;

- the appearance of air flows in the system indicates the need to replace the fluid;

- pump failure requires repair or complete replacement of the component;

- An oil level below the required level will require refilling the tank with oil liquid.

Replacing power steering fluid

In the power steering system, the fluid must be replaced when it becomes dirty, and after 6 years of vehicle operation.

1. Hold the nut from turning and unscrew the pressure hose going to the steering mechanism.

2. Drain the fluid from the power steering system. Without starting the engine, turn the steering wheel in both directions from lock to lock until fluid stops flowing out of the hose.

We reconnect the hose to the pump and tighten the fitting to a torque of 44 - 62 Nm (4.4 - 6.2 kgcm).

3. Fill the system with fresh working fluid.

4. Start the engine. In this case, liquid will flow into the system.

Add fluid with the engine running until the level remains constant.

5. Bleed the power steering system.

Bleeding the power steering system

We pump the power steering system when air gets into the system during repair work related to depressurization of the system.

If there is air in the system, the steering becomes jammed when trying to make a sharp turn.

Also, the power steering pump makes increased noise when the steering wheel is turned, and the fluid in the reservoir foams.

1. Pour working fluid into the power steering system

2. Brake with the handbrake and place chocks under the rear wheels of the car.

Raise the front of the car.

3. Set the steering wheel to a straight position and start the engine.

4. Turn the steering wheel to the right until it stops. Air bubbles should appear in the tank.

5. Turn the steering wheel to the left until it stops.

If there is air left in the hydraulic system, air bubbles should appear in the reservoir.

6. Check and, if necessary, add fluid to the maximum mark.

7. Continue pumping until the working fluid enters the tank without air bubbles.

8. We install the car on the wheels and check the operation of the system.

Source

Criteria for normal functioning

A serviceable power steering on a ZIL-130 meets the requirements for uninterrupted operation:

- return of the steering device to the neutral position under the influence of the pressure difference between sections of the hydraulic system;

- the turning moment of the wheel does not exceed certain dimensions;

- works silently;

- the possibility of a maximum angle of rotation of the wheel when turning the steering wheel;

- extinguished points, impacts transmitted from the wheel to the steering wheel while driving on an uneven surface;

- in the event of a breakdown, full control is maintained;

- the rotation of the wheel is proportional to the rotation of the steering wheel;

- the minimum possible time between turning the steering wheel and triggering the system;

- trouble-free long-term operation.

- ease of maintenance.

pumping power steering (can be found in the FAQ

During operation, the hydraulic system is pumped to remove air from the hydraulic system after eliminating faults that led to a leak, and after replacing the tank or oil.

The presence of air in the hydraulic system is characterized by the effect of “wedging” the steering wheel when there is a sharp change in the direction of its rotation, an abrupt change in the force on the steering wheel when turning to the right, cloudy oil and the presence of oil in the tank, as well as increased noise of the hydraulic system.

It is recommended to bleed the hydraulic system with the front wheels hanging.

Before pumping you need to:

— clean the bleeding valve located on the top cover of the steering mechanism from dirt and dust and remove the rubber cap;

— place a transparent plastic tube with an internal diameter of 6.5 mm onto the bleeding valve and immerse the free end of the tube into the oil tank until it touches the filter element.

Bleeding procedure (carried out with the engine not running):

— turn the steering wheel to the extreme left position all the way;

- unscrew the bleeding valve 1/3 - 1/2 turn;

— turn the steering wheel to the extreme right position all the way and, holding it in this position, close the bleeder valve;

- continue performing these four operations in the given sequence until oil flows through the tube without air bubbles;

Signs of malfunctions in the power steering system

There are several signs that the power steering system is airy, in which case it is necessary to bleed it. Among them:

- the appearance of strong noise in the area where the power steering or its pump is installed;

- increased pressure on the steering wheel , difficulty turning it;

- leakage of working fluid from the power steering system.

In addition, there are several other signs that indicate the system is becoming airy - the appearance of foam on the surface of the working fluid in the expansion tank, spontaneous turns of the steering wheel to one side. If you encounter at least one of the described symptoms, it means you need to bleed your power steering.

Lots of details

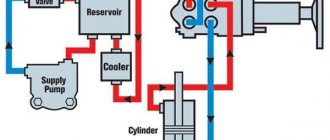

Power steering is a whole complex of individual units and elements such as:

- Power steering pump

- Steering rack combined with a hydraulic cylinder (there are rack models with an external hydraulic cylinder)

- Working fluid control device (spool mechanism)

- High and low pressure connecting hoses

- Expansion barrel

- Working fluid

The pump is a metal casing, inside of which a drum with blades rotates. As the blades rotate, they capture the working fluid and supply it under pressure to the steering rack. The pump is driven by an engine via a belt drive. In electric boosters, the pump rotates using an electric motor.

The steering rack is made in the form of a cylinder, inside of which there is a gear rack, which is also a hydraulic cylinder rod, a hydraulic cylinder piston and a control mechanism. Steering rods are screwed into the ends of the rack, which are connected to the rotary hub. The steering rod is movably connected to a gear rack through cardan joints.

The spool mechanism is a pressure distributor of the working fluid in the cylinder cavity, depending on the rotation of the steering wheel. It is redirected through channels to the power steering piston, or in the “straight” position, it simply circulates around the ring without doing any work.

The expansion tank is located above the pump level in the engine compartment. It is usually made of durable plastic. Inside it has a filter element and a liquid pressure divider.

Special oils of a certain viscosity and operating temperature are used as the working fluid of the power steering. Usually the manufacturer indicates the specification of power steering oil, but for the average person they also indicate its color, which coincides with the color of the expansion tank cap. For example, the Volkswagen concern uses green. Filling liquids of different specifications is unacceptable; we’ll talk about what this will lead to below.

How to pump power steering

How to fill oil and bleed power steering

The procedure for replacing fluid and pumping power steering is carried out in strict accordance with the existing algorithm. Some automakers may add their own features to it. If you have a manual for your car, we recommend that you read the relevant section. In general terms, the steps must be performed in the following sequence:

- Raise the vehicle completely on a lift or with the front wheels off the ground.

- If necessary, drain the old fluid from the expansion tank. To do this, remove the return hose (going to the power steering system) from the expansion tank and put a plug on it so that liquid does not spill out of the hose. A hose leading to an empty bottle is connected to the released tap on the tank, where the old hydraulic fluid is supposed to be drained.

- It is most convenient to pump out the main volume of liquid with a syringe and pour it into a separate bottle. When there is very little liquid left, move on to the next point.

- Fill the expansion tank with working fluid to the top.

- Next, you should turn the steering wheel from side to side (from lock to lock) several times so that the old fluid remaining in the system flows out through the hose. Since the new fluid displaces the old, do not forget to monitor the oil level in the tank so that air does not get into the hose.

- If the fluid level drops, add it again.

- Start the engine for 2-3 seconds and turn it off. This is done so that the liquid begins to spread throughout the system.

- Next, add working fluid to the tank to the MAX level and repeat the procedure by starting the engine. Repeat this cycle 3-5 times.

- The signal to stop pumping is the fact that air from the return hose stops entering the drain bottle. This means that there is no more air left in the hydraulic system and fresh, clean fluid enters the reservoir.

- After this, you need to reinstall the return hose (connect it to the expansion tank where it was originally installed).

- Refill the reservoir to the MAX level, then start the engine.

- To pump the hydraulic booster, you need to slowly turn the steering wheel 4-5 times from the left to the right stop. At the stop points, pause for 2-3 seconds. If there is any air left, it should escape into the expansion tank. During the inspection process, we make sure that the pump does not make any extraneous noise.

- An indicator that pumping has ended will be the absence of air bubbles on the surface of the liquid in the tank.

- After this, close the expansion tank tightly.

Problem solving

Getting rid of air in the system

Now we will take a closer look at several ways to remove air from the power steering. First of all, inspect the system for damage; if none are detected with the naked eye, we will change the search method. You need to ask a friend to help. Turn on the car engine and ask your friend to move the steering wheel from side to side. Bubbles may have appeared on the rubber tubes or pipes. If you find such a place, then this part needs to be replaced with a new one.

If the reason lay in an open cap on the liquid tank, be sure to close it. After this, you can try to expel the air from the system yourself. Turn on your vehicle's engine and let it idle for about 5 minutes. After this, start turning the steering wheel to the right all the way, hold in this position for 10 seconds, then turn to the left and hold this position again.

After several such cycles of turning the steering wheel, the air should come out of the system. You can check this by looking at the technical fluid; there should be no foam in it.

If the oil in the power steering is still foaming, disconnect the return hose and plug it with an improvised plug. Immerse the disconnected end of the hose in a clean container, which can be a glass jar. Turn on the engine and turn the steering wheel all the way from side to side until liquid flows from the hose. We turn off the engine, return the fluid to the reservoir and repeat the manipulation. This should be done until oil begins to flow out without bubbles.

Cleaning the fitting

To get to the fittings, you need to remove the car wheels and unscrew the protective cap using an eight key. After this, we connect a hose with a diameter of about 6.5 millimeters to the fitting. This hose will drain oil from the hydraulic system. Important point! Please note that when draining the fluid from the fitting, you must add oil to the tank so that its level does not fall below the minimum! We carry out the process until clean oil begins to flow out without foam and dirt. We put the system back together and pump fluid through the system by turning the steering wheel with the engine running.

Typical power steering malfunctions

Malfunctions in the operation of the hydraulic booster can be easily identified by characteristic signs. Among them:

- The steering wheel turns hard . Probable causes are failure of the power steering pump, use of unsuitable working fluid, sticking of the spool mechanism channels.

- , a high-frequency sound (similar to a whistle) is heard while driving The probable cause is a loose drive belt.

- The steering wheel turns jerkily . Probable causes of the malfunction are the working fluid not meeting the specifications declared by the manufacturer, a malfunction of the fluid distributing mechanism, or a pump malfunction.

- The presence of intense foaming in the expansion tank. Probable causes are mixing of different types of fluids, failure of the power steering pump.

- When the engine is running, the steering wheel spontaneously turns in any direction . The probable cause is malfunction of the spool mechanism, most often, clogging of its working channels, incorrect assembly (for example, after installing a repair kit).

Recommendations for operation and maintenance of power steering

In order for the power steering and its system to operate normally, as well as to extend their service life, you must adhere to several simple rules:

- use working fluids recommended by the automaker , and also replace them in a timely manner (most automakers recommend replacing power steering fluid every 60.120 thousand kilometers, or once every 2 years, it depends on the driving style and intensity of use of the car);

- carry out bleeding of the power steering system in strict accordance with the algorithm described above (or observing individual requirements, if any are set by the car manufacturer);

- monitor the condition of the steering rack boot , because if it is torn, dust and dirt will enter the system, which leads to the power steering pump exiting. A sign of a problem that has already occurred is the hum of the power steering, which is not eliminated even by replacing the fluid.

Cost of replacing fluid and pumping power steering

If you plan to carry out work on replacing the fluid and pumping the power steering yourself, then you will only need to buy oil in a volume of 1 to 3 liters (including flushing, while the volume of the power steering system of a passenger car is up to 1 liter). The price of the liquid depends on the brand and store. It is within $4.15 per liter. If you do not want or cannot carry out such work yourself, contact a service station for help. Approximate prices for January 2022 are:

- fluid replacement work - 1200 rubles;

- power steering pumping - 600 rubles.

Operation and Maintenance

To achieve productive operation of the hydraulic booster and increase service life, you should adhere to the following rules:

- Bleed the power steering according to the sequence described above.

- Fill only with working mixtures tested by the manufacturer, replace them at the recommended frequency, and also if the hydraulic booster is overloaded during operation.

- Keep an eye on the steering rack boot. If the element is torn, then dirt and dust will get inside. This will cause the power steering to exit the pump. Then there is a hum from the power steering.

Where is the power steering bleeder valve located?

I have been looking for a long time how to pump the power steering, but some people advise this.

others like that. But nothing helped me. For a long time I was looking for information on how correctly and finally found it in one smart book!

I decided to write it here, in case it might come in handy for someone. The presence of air in the hydraulic system is characterized by the effect of “wedging” the steering wheel when there is a sharp change in its rotation, an abrupt change in the force on the steering wheel, cloudy oil, as well as increased noise of the hydraulic system.

It is recommended to bleed the hydraulic system with the front wheels hanging. Before pumping you need to:

- Clean the bleeding valve located on the top cover of the steering mechanism from dirt and dust and remove the rubber cap;

- Place a transparent plastic tube with an internal diameter of 6.5 mm onto the bleeder valve and immerse the free end of the tube into the oil tank until it touches the filter element.

Bleeding procedure (carried out with the engine not running):

- Turn the steering wheel to the extreme left position until it stops;

- Unscrew the bleeding valve 1/3 - 1/2 turn;

- Turn the steering wheel to the extreme right position all the way and, holding it in this position, close the bleeder valve;

- Continue performing these four operations in the given sequence until oil flows through the tube without air bubbles;

- At the end of pumping, close the valve and remove the tube;

- Add oil to the tank to the required level, screw the oil tank cap into the neck;

- Place the car on the front wheels;

- Start the engine and turn the steering wheel 2-3 times from one extreme position to the other;

- turn off the engines and open the bleeding valve slightly by 1/3 - 1/2 turn;

- After the remaining air escapes through the bleeder valve with a characteristic “spike” and oil appears in it, immediately close and finally tighten the bleeder valve.

During the pumping process, you should add oil to the tank in a timely manner, avoiding exposing the end of the tube immersed in oil, and upon completion, restore the required oil level in the tank.