In this article I will share useful information regarding replacing the oxygen sensor, or, as it is also called, the lambda probe, on a Lada Kalina car. The oxygen sensor is a rather complex thing that determines the amount of oxygen in the exhaust gases. Based on this information, the air-fuel mixture is adjusted.

It would be logical to note that if this sensor fails, the mixture in the engine will begin to form incorrectly and the engine will either overflow (rich mixture) or lean (lean mixture). And from this follow the main symptoms of a lambda probe malfunction :

- Unstable engine idle, floating idle. But it should be noted that the reason for this may be the breakdown of other sensors - IAC, TPS, etc.

- Fuel consumption has increased. But I also note that consumption may increase due to clogged injectors and other things.

- The dynamics of the engine have decreased, we press on the gas, but we do not get the proper return. Here, as in previous cases, other sensors may be to blame - DD, DF and others.

Why does the oxygen sensor break down on Kalina cars, for what reasons does it fail?

- Firstly, bad gasoline. Moreover, the quality of gasoline affects the operation of the entire engine as a whole, and not just the DC.

- The second reason is oil getting on the surface of the sensor. This may occur due to worn piston rings or oil seals. Therefore, if the engine is actively “eating” oil, then it is better to wait until replacing the sensor and first remove the oil seal.

- The third reason is overheating of the sensitive element of the probe. This can happen due to pinched exhaust valves or too lean mixture.

Let's move on to the main topic of the article - replacing the oxygen sensor on Kalina. It is installed at the rear of the engine, so to speak, on the exhaust manifold in front of the catalyst. In principle, it won’t be particularly difficult to get there.

Before disconnecting the chip from the sensor, remove the “-” terminal from the battery.

To unscrew the lambda at a service station, they use a special key - like a spanner, only with a small cut for the wire. But at home, regular carob is also suitable. To make it easier to remove the sensor from its place, first spray it with WD-40 and wait a couple of minutes until the liquid penetrates deep into it. Personally, I got it out without any problems at all.

The old oxygen sensor was replaced with a new BOSCH 0258006537, which is what it was. I was pleased with the fact that the purchased sensor was well packaged, and the threads were lubricated with graphite lubricant.

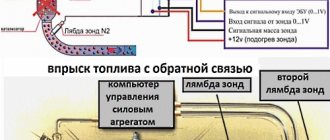

The Kalina oxygen sensor (photo 1), also known as UDC, allows the engine control system to adjust the fuel supply if the oxygen level in the exhaust gases increases, that is, the air-fuel mixture becomes lean. Oxygen creates an electrical potential difference, which amplifies the sensor signal.

Description and device

For the sensor to work normally, it must have a temperature of at least 300°, so after the engine starts, it is heated by the built-in thermal element. Please note that when using leaded gasoline, poisoning of the oxygen sensor may occur. This is also possible when the factory seals the engine with silicone sealants that release volatile substances.

Their presence can damage the device and negatively affect the operation of the motor itself if it enters the combustion chamber. The engine controller reacts to this by writing an error message to the ECU memory. The first oxygen sensors were heated only by exhaust gases. The name “lambda probe” is also found. On automobile forums, many pages have long been written on the topic of what a lambda probe is and what malfunctions it has.

Lambda is exactly the thing that mechanics and diagnosticians encounter most often. The easiest way to diagnose a UDC is to measure the voltage at the signal output. If it does not exceed 0.45 V, this means that the probe is working properly. A particular danger to the normal operation of the oxygen sensor is the soot deposited on it when the engine runs on an over-enriched mixture.

The sensor is located in a special hole in the exhaust manifold on a thread very close to the cylinder block. With a faulty oxygen sensor, you will not be able to legally pass a scheduled technical inspection. The car will be sent for repairs, and the ECU will put it into emergency mode, in which it will not deliver its full power potential.

The frequency of replacing a lambda probe with a new one is on average 50,000 km. That is, after the first 50,000 mileage and beyond. The number of probes on a modern car can reach 4 (on Kalina there are usually two). Based on the number of contacts available, the oxygen sensor can be:

- single-contact;

- two-pin;

- three- and four-pin.

On the Lada Kalina the sensor is a three-pin system. One wire is a signal wire and goes to the engine control unit, the second to the heating element, and the third to ground. Their accuracy is much higher than that of simpler single-contact ones.

The quality of the fuel, namely the presence of organometallic additives in it, directly affects the accuracy of lambda readings. These additives are the most dangerous pollutants for the oxygen sensor when forming exhaust gases.

Oxygen sensor for Lada Kalina: original, analogues, price, catalog numbers

| Catalog article/marking | Price in rubles |

| BOSCH 0 258 006 537, 0 258 986 602 (original) | From 2100 – 2400 |

| BREMI 30223 (8 valves) | From 1900 - 2000 |

| ERA 570023 (8 and 16 valves) | From 1900 - 2000 |

| FENOX SD10100O7 | From 1900 - 2000 |

| DENSO DOX-0150 | From 1900 - 2000 |

| PIERBURG 7.22701.08.0 | From 1900 - 2000 |

| NGK 95801 | From 1900 - 2000 |

| FENOX AM28116C3 | From 1900 - 2000 |

| Metal spacer | From 1900 - 2000 |

| Electronic emulator | From 1350 |

| *prices are as of May 2022 | |

Considering the high cost of original parts, many car owners prefer to buy cheaper analogues. The price difference is 20 – 25%.

There are also those who completely remove the catalytic filler from the exhaust system, weld in the exhaust pipe, and install a blende under the DCC.

After 80 thousand km. The Lada Kalina catalyst becomes unusable, as evidenced by a number of signs. At the request of the client, the service station technicians remove (cut out) the standard catalyst and replace it with a “dummy”.

“Empties” are made according to the following scheme: 4-2-2 or 4-2. Popularly called spiders. This is a one-piece design together with the exhaust manifold coupling and exhaust pipe.

To prevent the electronic control unit from identifying a system error, the lambda probe is replaced with one of the following types of decoys:

Features of the lambda probe

It is not always necessary to change the sensor when an error message associated with the UDC appears. What should I do if the probe signals a lean mixture and the signal output voltage is below normal? It’s best to start by increasing the fuel supply (injecting a little into the intake manifold with a syringe) and monitoring the lambda readings. If the sensor detects an enriched mixture, it means that the problem is not in it, but in the fuel supply system. Perhaps the fuel pump is not pumping or the hose is damaged.

Sometimes the diametrically opposite happens: a message about a rich mixture when there is no apparent reason for this. In this case, an artificial leak is made and the lambda reaction is checked in the same way. If the sensor is normal, the signal output voltage will return to normal. The UDC must immediately respond to any changes; this is the main criterion for its normal operation. If the sensor has a slow response, then you really need to change it urgently.

The degree of lambda wear can be determined without much experience in diagnostics. A probe that reacts slowly to the transition from a lean mixture to a rich one and back again definitely needs to be replaced. Sometimes the reason for the strange behavior of the lambda is misfire, that is, the mixture ignites too late. Replacing the sensor will get you nowhere. But it would be wise to check the spark plugs in such a situation.

It must be taken into account that air is sucked into the exhaust system and cannot pass past the oxygen sensor. Therefore, a lambda reaction may occur that will correspond to a lean mixture, although in fact it may be too rich, which will be confirmed by checking with a gas analyzer. Therefore, when diagnosing, it is the gas analyzer readings that you should pay attention to first.

Conclusion: it is necessary to diagnose a lambda by monitoring the voltage of its signal output using a scanner or motor tester. By playing with the quality of the mixture, artificially enriching or depleting it, you can simultaneously track changes in the readings of the oxygen sensor, which will prompt a diagnosis of the serviceability or malfunction of the latter. But the errors that the ECU shows may turn out to be a hoax. Sometimes electronics make mistakes.

Errors and malfunctions, sensor maintenance

A common problem is the failure of the UDC heating element. The oxygen sensor itself can be damaged by grease, dirt, water, or damage to the integrity of the housing, contacts or wires. That is, the reason may be either damage to the heater circuit or the lambda probe itself.

To check the heater circuit, you need to turn off the ignition, disconnect the harness connector from the controller and check contact X1/C4 by connecting it to the vehicle's on-board network. If a short circuit does not occur, then the controller is faulty. If there is, you need to disconnect the UDC block and check the closure of its contact D. If present, you need to check the wiring harness; if not, the UDC has failed.

If this happens, it will not necessarily cause engine problems. True, fuel consumption will increase, and the efficiency of the catalytic converter will decrease. That is, the opposite of what the lambda probe is made for will happen: an increase in harmful emissions into the atmosphere.

When the harness, block or plug of the lambda probe is damaged, the only solution is to replace it. The oxygen sensor must be in contact with ambient air. For this purpose, special gaps are made between the probe wires, which can be easily damaged if repairs are undertaken.

It is necessary that the sensor remains at least relatively clean, that is, water and dirt should not come into contact with the contacts and wiring harnesses. This may interfere with the operation of the lambda probe. It is also necessary to monitor the integrity of the insulation of the wires extending from the UDC. Do not bend or twist the oxygen sensor wiring harness and the associated fuel injection system wiring, otherwise the probe will not be able to properly monitor the air-fuel mixture.

Monitor the condition of the sealing pad on the outer surface of the sensor and prevent it from being damaged. To remove the lambda, turn off the ignition, disconnect the wiring harness from the probe, and carefully unscrew the device itself using a 22mm wrench. The procedure for installing a new sensor is described in the next section. The new lambda requires careful handling during installation to avoid contamination and damage.

Replacing the device

You can buy an oxygen sensor in auto stores, directly from a car dealer and on the Internet. But in order to correctly carry out the replacement, you need to know a number of important parameters:

- heater resistance value;

- probe electrical circuit diagram;

- catalog number of your sensor.

There are also many replacement options, but among them there are fakes. Typically, car enthusiasts replace a failed lambda probe with the same one, but from a different manufacturer. A wide selection of sensors is provided by the American company Walker, which has a branch in Russia. Lambda probes manufactured by Bosch are interchangeable with zirconium sensors of similar structure.

Please note that a non-heated sensor can be replaced with a heated sensor. Not the other way around. Before installing a new oxygen sensor, it is necessary to remove the terminals from the battery and apply graphite lubricant to the device itself (that is, to its threads). We install the lambda in its original place, start the engine and wait until the sensor warms up to operating temperature. As it warms up, we monitor the signal output voltage with a voltmeter.

Sometimes, when tuning the exhaust system, it becomes necessary to disable or remove the second lambda (in front of the catalyst). Moreover, the composition of the mixture does not depend on its operation, since it is controlled by the first sensor located in the intake manifold. There are different ways to do this. You can do the so-called decoy. To do this, the first lambda is removed and its wires are extended. The second sensor is also removed, the wires are exposed and they are connected.

In one of the wires the voltage will be about 4 W; it is to this wire that you need to solder a resistor with a resistance of 1 Ohm. It is also necessary to solder a capacitor with a capacity of 2.2 F, after which the 1st sensor is connected to the converted exhaust, and the second one simply remains dangling in its original place. This method usually saves money because it eliminates the need to reflash the ECU, which is expensive.

However, some drivers still advise reflashing. But since replacing the exhaust does not make it possible to leave the catalyst, there are few options in this situation. There is another way - installing an oxygen sensor emulator. Either reprogram the Euro-3 engine to Euro-2 for a lot of money, or solder the blende yourself for a long and painful time.

The emulator is a device precisely designed to be compatible with the brains of the engine. Using it, you will not damage the lambda in the intake manifold and will not make things worse for your iron horse. Otherwise, the ECU simply will not allow the engine to operate normally, since it will stop receiving data from the catalyst and diagnostic sensor (the probe has been removed). This is how the oxygen sensor on a Lada Kalina is repaired. Good luck!

The Kalina oxygen sensor breaks down quite often. This is due not only to the operating conditions typical of Russian roads, but also to the design features of the Lada Kalina car.

In this regard, many car owners repair it themselves, because if you often contact a service station about this, you can spend a lot of money.

How to replace the speedometer cable on a VAZ 2101-VAZ 2107?

Note! Before buying this sensor in a car store, take exactly the same one that you had (you need to look at the markings for this on the old sensor, but for this, of course, you will have to remove the sensor), if you neglect this, the engine will most likely not work as expected should, we also categorically do not recommend that you take oxygen sensors without heating, (Even if your car was equipped with one), such sensors may not always give correct readings until they warm up, due to which the engine will again not work correctly, so before When purchasing a new sensor, be sure to take all these nuances into account!

1. The sensor is removed very easily, first remove the negative terminal from the battery (How to do this, read “in this article”, point 1) and then disconnect the deck and wire connectors, as soon as this is done, unscrew the sensor itself by the thread that is on applied to it and thereby remove it from the hole in the exhaust manifold and that’s it, you can install a new one.

Additional video: Watch the video that talks about the oxygen sensor, which is located below:

Oxygen sensor device

The diagnostic oxygen sensor also has a second name - lambda probe. This is always worth remembering when reading technical literature or when purchasing it for replacement. In addition, it should be noted that such a sensor is a vital part of the power unit control system of the Lada Kalina.

Because of this circumstance, any breakdown can cause the vehicle to stop or create conditions under which the operation of its engine becomes impossible.

The oxygen sensor itself is usually mounted in the exhaust manifold, which gives it the ability to monitor the level of oxygen in the exhaust gases while the engine is running. As a result, the lambda probe can send a signal with which the Lada Kalina fuel system controls the quality and quantity of the fuel mixture necessary for high-quality engine operation.

Installation of the "blende"

For high-quality installation, welding equipment is required. Experts recommend installing the blende only in certified service centers.

- Welding machine;

- Sander;

- Metal pipe;

- Flange connections;

- Flashlight to improve visibility and visibility.

- Disable the existing oxygen concentration sensor;

- Use a welding machine to cut out the catalyst in the exhaust pipe section;

- Weld the metal insert;

- Screw in the spacer together with the DKK controller.

If the owner of a Lada Kalina wants to install electronic decoy, then this will require flashing the ECU with a portable scanner.

Source

Oxygen sensor life

According to the recommendations of the manufacturer of the Lada Kalina, replacing the oxygen sensor on this car must be carried out after 80,000 - 160,000 km. However, in the case when obvious signs of a malfunction appear, this procedure can be carried out earlier, without waiting for the deadline set by the manufacturer.

So, similar signs of probe malfunction include:

- increased unmotivated fuel consumption;

- Unstable engine operation at idle;

- change in dynamic and speed characteristics.

It is worth noting that the rapid output of the lambda probe is facilitated by the poor quality of the fuel used by the car owner. Therefore, for preventive purposes, it is worth checking the quality of the gasoline you purchase.

In order to make it easier for the car owner to replace the oxygen sensor, the manufacturer has developed an entire diagnostic system. For this purpose, for example, a special scanner is used. In addition, if an on-board computer is installed on the car, all types of sensor errors can be detected in the diagnostic mode on its screen.

So, in particular, error PO130 indicates an incorrect sensor signal, and error PO135 indicates a malfunction of the sensor heating element. A complete list of all error codes and their interpretation can be found in the instructions supplied with the car.

Replacing the oxygen sensor and choosing fuel

Since the lambda probe cannot be repaired, if it fails, it is simply replaced, and it costs around 1,500 rubles, which is not such a large amount. To replace, you will need a multimeter or voltmeter, an inspection hole and a special key. The replacement procedure begins with the sensor being disconnected from the on-board computer.

Next, use a voltmeter to measure the voltage level at the sensor by turning on the ignition. The normal voltage value is considered to be 0.45 V. If it is absent or differs by 0.02 in one direction or another, this may indicate a malfunction of the oxygen sensor.

Having determined that the sensor is faulty, they begin to replace it. To do this, remove the sensor wire holder from the hole in its protective screen. Next, use a 22 key to unscrew the sensor from the catalytic manifold.

Directly to dismantle it you will need a special key of a special configuration. At the same time, some experienced car enthusiasts unscrew the sensor with a regular 22 open-end wrench.

Installing the new sensor in place is done in the reverse order.

Do-it-yourself diagnostics of the oxygen concentration sensor on Lada Kalina

To check the equipment we use a multimeter. The sequence of actions is as follows:

- We place the car above the inspection hole;

- Remove the limit switches from the controller;

- Connect the multimeter terminals;

- We activate the device to the “Resistance” position;

- We analyze the received data.

If the arrow tends to infinity, the lambda probe is working; if the arrow drops to zero, the part is damaged. Remember that the controller is non-separable and cannot be prevented.

How to choose high-quality fuel for a car?

Since all failures of the oxygen sensor occur due to low-quality fuel, it is worth paying special attention to its selection. For example, you should not purchase gasoline from an unknown manufacturer, second-hand. Typically, such “gray” gasoline is of very poor quality and contains harmful impurities.

Also, do not replace the brand of gasoline with another one not recommended by the manufacturer. The fact is that the entire fuel system and power unit are assembled at the factory for a certain type of gasoline, and if you replace it, you can significantly reduce the service life of both the engine and the entire car as a whole.

The same effect can be achieved by independently altering the fuel system, carried out by the car owner in order to switch to cheaper gasoline.

Another way to prevent fuel sensor breakdowns is timely maintenance. The fact is that a fully operational fuel system produces the cleanest exhaust mixture, which, in turn, has a gentle effect on the sensor without causing damage to it.

If the lambda probe begins to give incorrect readings, it must be replaced to prevent serious damage to the power unit.