Suspension elements, like other car parts, tend to wear out. This is usually accompanied by a knocking noise from the front of the car. Beginners are absolutely unable to immediately determine which part is failing the system. But each driver will be able to carry out diagnostics on his own if he knows all the signs of wear on the ball joint. If the breakdown is related to it, then this often leads to various kinds of problems. As for the wear of other parts (bearings, seals), it is not as dangerous as wear or breakage of a ball.

What is the role of support?

The ball joint is presented in the form of a hinge. At its base there is a ball in the insert, similar to a human joint. It has the ability to move in different directions. The design of the support includes not only the ball with the liner, but also the boot, pin and body. The boot serves to protect the mechanism from various types of contamination. A metal rod is called a pin, which secures the hub to the hinge.

The ball requires careful “care”. Critical wear of the support provokes serious problems for the car and its owner. If a part fails while driving, the support will break and the wheel will turn outward. In the best case scenario, the driver can expect the vehicle to fall onto its wing. At worst, a serious accident.

After separation, the ball hub continues to hold on. But in any case, the wheel becomes uncontrollable. All subsequent events largely depend on how fast the car is moving. The driver must always be on alert to react to a sudden breakdown and avoid an accident.

Fixation on the steering knuckle

If the support is located on the lever, then it can be attached to the steering knuckle. Such features are typical for a ball-on-lever. The design can have three options:

- the threaded pin is connected and secured with a nut, which must be cottered;

- for fastening, a self-locking nut is used, which has an internal locking ring;

- a pinch bolt is installed, which is rare, for example, on the Hyundai Santa Fe since 2006.

The last point is less acceptable, since if it breaks and needs to be replaced, it may turn out that the threads have soured. A negative factor is the need for a special wedge used to release the ends of the knuckle bracket where the ball pin is fixed. Sometimes even in the wonderful suspension designs of German cars, stuck bolts create many difficulties during disassembly. The situation cannot be saved by heating the fist or freezing the bolt. Even a ten-ton force from a hydraulic press does not allow the bolt to be pressed out. Owners of an Audi A6, for example, have to part with amounts equivalent to $400-500. In some cases, engineers move the hinge to the steering knuckle from the lever. Although such a solution does not add maintainability. Then there are several ways to fix it:

- bolting;

- pressing;

- in the knuckle bracket the use of a coupling bolt.

Symptoms of the malfunction and their description

If the driver is completely unaware of how to determine whether a ball joint is faulty, he needs to better study the symptoms indicating a breakdown.

We list the main ones:

There is a knocking noise while driving. The clanging appears at any speed and can be isolated or repeated periodically. It also occurs if the machine is overloaded.

Creaking noise coming from the front wheels when turning. The sounds come from the rack or hydraulic booster.

If the support is damaged, the steering wheel is at an angle (relative to the road). As a result, the tread wears along the inner edge. Uneven tire wear can be immediately seen upon visual inspection.

When braking, the trajectory of movement changes. This usually appears as a slight curling to the side. This is due to the tilt of the wheel.

While driving, the car wobbles. Most often this appears due to play in the ball. The higher the speed, the stronger the wobble. Many drivers do not notice this symptom because they drive on bad roads.

The wheel alignment characteristics have become different. The wheel on which the support has worn out will suffer the most from this. It is difficult to determine changes by eye, so you should contact a service station for help.

If the driver feels the manifestation of at least one of the listed symptoms, he should diagnose the entire system. If the ball fails, then other parts of the system are “at risk.” They should be checked comprehensively.

Ball mechanism for Renault Logan: what and how

The ball joint is an important component of the chassis of almost any modern car. Logan's is non-separable, maintenance-free and is officially supplied only with a lever. It consists of a ball pin, which is pressed into a metal body along with a plastic bushing. Designed to connect the steering wheel hub to the main front suspension arm. If you “run” this unit to a critical state, then the front wheel may spontaneously turn to the side, separately from the other. This situation is dangerous, especially at speeds over 30 km/h.

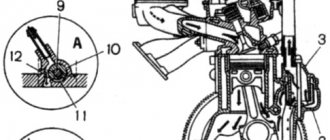

General view of the front suspension structure: 1 — suspension subframe; 2 — suspension arm with silent blocks and ball joint; 3 — steering knuckle with hub and bearing; 4 — shock-absorbing strut; 5 — anti-roll bar

Causes of failure

The supports experience high loads during operation. They can withstand constant impacts when driving over uneven surfaces. There are several main reasons why these parts fail.

Natural wear and tear. One joint can withstand driving for a distance of 20-150 thousand km, but a high-quality part begins to wear out at about 100 thousand km. In addition to quality, wear is influenced by the presence of lubricant, care of the part and other factors.

Torn boot. This element is considered a kind of “consumable material”. For this reason, you need to constantly monitor its condition. If the boot suddenly breaks, particles of dirt and dust will get inside the support. They form an abrasive between themselves, which will “wear out” the insides.

High loads. When a driver travels on rough roads at high speeds, the suspension suffers greatly from shock. This leads to wear of the ball. The same thing happens when the vehicle is heavily overloaded with excess cargo.

Lubrication. The lubricant dries out or evaporates over time. If the boot is damaged, the lubricant will disappear even faster, thereby causing increased wear on the ball. To avoid this, it is necessary to periodically pour lubricant into the ball.

All of the above reasons do not appear overnight. This is only possible if the part was already defective. This can be avoided if, when purchasing, you purchase a higher quality product rather than a cheaper one.

Self-diagnosis

The driver can carry out independent diagnostics of the supports if they are suspected of being faulty. There are several ways to do this. They depend on the suspension design. Today, suspension is divided into single-link and multi-link. Foreign cars, as a rule, are equipped with a multi-link type both in the front and rear of the car.

The easiest way to identify problems is with the upper ball joint in a multi-link suspension. To do this, you need to drive the car into the garage, inviting another person to drive. The car owner must begin to swing the upper part of the wheel and at the same time give signals to the person behind the wheel so that he presses the brake. This technique helps determine the presence of wheel bearing play.

If there are faults in the upper hinge, the play will be felt strongly. You can detect play in the lower support using the same method. But drivers try to rock the wheel not just with their hands, but by first lifting it with a jack. This method only works for multi-link suspension. However, there are instructions that allow you to determine the play on any suspension.

The car owner will not need another person. For diagnostics you need an inspection hole and a mount. Having placed the car over the pit, the driver must lift one side with a jack and install a pry bar between the lever and the steering knuckle. If there is play in the bushing, it will be immediately noticeable when the mount is rocked.

Verification methods

If signs of malfunction appear, it is recommended to carry out diagnostics immediately. To do this, the car is driven onto a viewing hole or lift.

Conventionally, checking the hinge can be divided into several stages:

- Visual inspection. First of all, you need to make sure the visual integrity of the part. The ball must be inspected for a torn boot. If it is damaged, but there is grease inside and no dirt, such a hinge can be saved. It is enough to change only the boot itself. But in most cases, a damaged case is the start of an irreversible breakdown process.

- Checking the condition of the ball pin. The ball pin must be pressed into the steering knuckle eye. Any backlash in this place is unacceptable. You need to grab the wheel vertically and try to shake it.

To make the check more accurate, a partner is placed in the car and presses the brake pedal. If you feel a slight play, then the pin of the part is broken and the ball will need to be replaced.

- Checking the condition of the ball. The ball inside the body should not have any play. But many car owners ignore checking it because they have no idea how to do it. It is necessary to insert a metal mounting between the ball housing and the steering knuckle eye. By rocking the tool, you need to provoke backlash. If it does not occur, then the hinge is considered to be in good condition, but the movement of the ball inside the body indicates a breakdown, which should be repaired as soon as possible.

Diagnostics is performed on a suspended wheel. There should not be any load on the hinge at this moment. Otherwise, the diagnosis will be inaccurate.

May be interesting: The battery light is on - causes and consequences .

Repair

There are several ways to repair a ball, but most often it is simply replaced with a new one. As for foreign cars, replacing the support and lever is an expensive procedure. That is why repair (restoration) services have become the most in demand.

Restoration will cost the driver less than completely replacing the part. Various technologies are used to restore supports. The simplest of them is conversion into a collapsible one. Here the plastic inserts are changed and the finger is polished.

A more complex technology involves filling the body with liquid polymer. The substance hardens, after which the supports are removed and replaced with non-original elements.

Such savings will sooner or later create an emergency situation on the road. To avoid this, we recommend replacing the ball joints with new ones if they fail. Restoration is allowed only if the driver does not have the opportunity to change elements every second.

Design features

If you disassemble an old, worn ball joint, you can see several elements:

- a rod protruding from the body with a thread and a transverse hole at the end - a finger. It is made of high-strength steel, the thread pitch is very fine;

- The finger is wearing rubber protection - a boot, which has a metal ring at the bottom for a tight fit to the base. It protects the hinge from foreign objects, water, dirt, and road dust;

- the finger is connected to the ball, this is one integral part;

- There are plastic inserts around the ball. They fix its position, eliminate gaps, provide the necessary movement and rotation;

- the ball is inserted into the ball joint housing. There are three holes for attaching to the lever. If the model is serviceable, then an oiler is screwed into it from below to add lubricant.

To Contents...

Selection rules

Choosing ball parts on your own is not so easy, especially when there is a wide variety of parts on the product market. Products from the following manufacturers have the highest quality characteristics:

Sidem is a European manufacturer that produces high-quality products. The products have a durable boot without a retaining ring. This design prevents moisture and dust from getting inside. In addition, polyurea-based lubricants are excellent at repelling water.

TRW is an American company that sells its products internationally. Over time, the concern was bought by a German company. The new management has tightened quality control over products. As a result, ball joints began to cover more than 90% of automobile models, incl. for VAZ.

Delphi is an American company that produces high-quality ball joints for middle-class cars. The manufacturer has assumed warranty obligations during the first year of operation. But despite this, drivers report accident-free runs.

Lemforder is a German company that supplies products for most automobile brands. The catalog has a huge assortment of ball joints, which are considered the best for chassis repairs.

Ball joints are also manufactured by domestic manufacturers. These include the companies BZAK, Belmag, Trek and Kedr.

Recommendations for extending the service life of supports

Signs of bad ball joints include a variety of “symptoms.” The main reason for their appearance is natural wear and tear. The service life of the part varies from 15 thousand km to 120 thousand km, but experts say that it can be extended.

You can avoid damage if you follow simple rules:

Do not allow high speed when driving over uneven surfaces.

Regularly check the integrity of the boot.

Periodically carry out diagnostics of the mechanism, especially during long-term operation.

Do not allow the lubricant in the joint to evaporate.

The rate of wear also depends on how much the driver loads the car and on what roads he drives. The height of the rubber profile plays an important role. For example, a vehicle with a low profile has a ball lifespan that is half as long as a vehicle with a medium and high profile.

Is it possible to drive with a broken ball joint?

Having learned which ball joints are better and their causes of malfunction, the driver involuntarily wonders whether he can now drive the car. All this largely depends on the wear and damage of the unit. It is allowed to move around if there are “early” signs. These include rare knocking, lack of “wobble” on the road, etc.

If the driver still decides to drive with a broken ball joint, he needs to avoid high speeds and bumps on the road. But it is best to think about repairs and replacement of parts. Ignoring the problem will result in a serious accident.

Necessary tool

- The jack (hydraulic or pneumatic to choose from) is designed to raise the machine to the desired level to simplify the process of checking and further replacing the VAZ 2114 ball joint if necessary.

- A set of wrenches allows you to loosen the tightening on the desired part and unscrew the bolts and nuts.

- A ball joint remover will be needed to remove them.

- Wheel chocks are used to be placed under the rear of the car. Sometimes a brick base is used here to simplify the task.

- Supports under the car to improve interaction with the jack, to ensure safety during the operation. In addition, sometimes a block of wood is also used.