Defects that appeared after replacing the clutch

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

What makes the gearbox on the Kalina noisy, what to do if the gearbox lever on the Lada Kalina 1 and 2 rings

The noise of the Kalina gearbox usually starts from the factory. This problem is caused by insufficiently precise machining of the gears - with a tolerance of 0.2 mm. In this case, noise or howling is heard only in a certain gear. Therefore, it is impossible to completely make the box silent; you can only reduce sound vibrations.

Lada Kalina of the 1st and 2nd generations has both manual and automatic transmissions. The box model depends on the engine size and the number of its valves. A common problem is that the gearbox on the Kalina (as well as on many other VAZ cars) is noisy.

If after replacing the clutch the car jerks

For example, before the repair, the car did not pick up speed well, it was slipping, and the clutch pedal was activated at the very top. All the signs of a worn driven disc were present. After replacing the disk, the car began to jerk. What could happen after the repairs were carried out?

- The issue may be a defective part. This is not so rare when it comes to non-original spare parts. In Russian-made cars (VAZ, GAZ, AZLK, IZH), defects also occur in factory parts. That is, the driven disk is simply curved. On the clutch basket (drive disc), the pressure petals may be at different levels, then the release occurs unevenly and the car jerks.

- The car may jerk due to clutch adjustment. More precisely, it was not performed after replacing the disk. The linings of the new part are much thicker; in this case, the clutch pedal “takes at the very end”. When starting off, the car moves jerkily, and the gear shifts into gear with a crunch.

- The car jerks due to the replacement of not all the parts that needed it. In particular, the cause of jerking is the worn surface of the flywheel under the driven disk. If the flywheel has not been replaced, there may be jerking when driving, and the car may also slip.

Signs of clutch problems

Often drivers, especially new car owners, when problems arise with the clutch, realize that the car has begun to behave differently, but continue to drive without making any attempts to find out what the reason is. As a result, this leads to serious damage and the car completely fails. Knowing the main symptoms of a clutch malfunction, you can take timely measures - carry out repairs yourself or contact service center technicians or service stations.

Below are the main symptoms of clutch malfunctions and which unit is responsible for this or that atypical behavior.

Incomplete clutch release

Among motorists - “the car is driving.” In other words, when the clutch lever is pressed, the driven disc is partially disconnected from the motor wire shaft. This leads to the fact that the car begins to twitch at the beginning of the movement at the moment of changing gear, even though the pedal is depressed smoothly, as usual.

What causes this problem to occur:

- Small pedal free play. It may be different for each car; you should look for information in the technical data sheet.

- The drive is poorly adjusted. On mechanical and hydraulic drives, the defect is eliminated in different ways.

- Clutch disc deformation. This happens more often when the axial runout value is greater than 0.5 mm. Under such circumstances, the friction lining of the disk bends and presses it against the flywheel of the internal combustion engine.

- Clutch disc wedge in shaft grooves. A common reason is parking the car for long periods of time, especially outdoors.

That is, it is not so easy to determine exactly what led to the clutch failure, because one defect may be the result of damage to one or more elements.

If after adjustment the defect has not been eliminated, the only option is to replace the clutch with a kit. Always change the clutch as a set (disc, basket, release) since saving on spare parts usually leads to repeated disassembly, loss of time and money.

If there is a noise or whistle after replacing the clutch

Many car owners often complain that after replacement, a noise or whistle appears that was not there before. What could be the reasons for the extraneous sound and why does this happen? » alt=»»>

- The new release bearing turned out to be of poor quality or does not contain enough factory lubricant. A whistling or noise appears when you press the clutch pedal. Many people mistakenly believe that the bearing makes noise when the clutch is disengaged. But this is even illogical, in this state the part does not bear the load, and accordingly the noise (whistle) in this state is minimal.

- The clutch basket has unevenness and roughness at the tips of the pressure petals. Typically, spare parts from Russian manufacturers have such a defect. It should be noted that as the parts are ground in, the whistle that appeared initially disappears. You can temporarily eliminate the noise by lubricating the petals with lithol. But this can be done without disassembly on GAZ cars; on front-wheel drive cars, to perform a similar procedure it is necessary to dismantle the gearbox.

- It is possible that before replacing parts, the car owner did not pay attention to extraneous noises such as whistling, as he was expecting repairs. But after replacing the clutch, extraneous sounds remained, which the owner of the car did not expect. Noises are often caused by the gearbox. If, when the clutch is depressed, the unpleasant sound disappears or noticeably subsides, then most likely this indicates wear on the gearbox input shaft bearing.

- The driven disc linings have roughness. A rustling noise occurs when changing gears. There is no need to worry too much ahead of time - the new parts will get used to it, and the defect will disappear during the operation of the car quite quickly.

- The input shaft bearing in the crankshaft may also make noise. When disassembling the car, you should do an external inspection of the bearing. If it is very dry, it must be lubricated with lithol or other suitable lubricant. It is better to replace a clearly worn part immediately.

Where does noise come from when a car's clutch operates?

Noise, manifested in the form of buzzing sounds of different tones when the clutch is operating (it is turned on, off and when the engine is idling), indicates the occurrence of quite serious problems that require a quick solution.

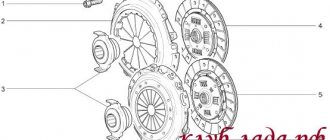

Clutch design of VAZ 2108, 2109, 21099 cars and their modifications

Using the example of the clutch of VAZ 2108, 2109, 21099 cars, let’s try to figure out where the noise came from when the clutch was operating and what ways to solve this problem.

Where did the noise come from when the car clutch operates?

Clutch noise when engine is idling

If you listen, from the clutch and gearbox side, while the car engine is idling, you can hear a continuous, distinct noise. When you depress the clutch pedal, the noise disappears or noticeably decreases.

Such signs may indicate a failure of the gearbox input shaft bearing on which the clutch basket and driven disc are “mounted”. The shaft begins to “dangle” together with the broken bearing, making noise, and when the clutch is disengaged, the load on it is reduced and the noise disappears. This malfunction is often accompanied by oil leakage from the gearbox under the input shaft oil seal. In the early stages, the malfunction is practically unnoticeable, but as the bearing deteriorates, it makes itself known.

The release bearing can also make noise and even howl at idle, since its working surface is always pressed against the leaf pressure spring of the basket and rotates with it (the clutch on the VAZ 2108, 2109, 21099 is backlash-free). A bearing malfunction may be a consequence of lubricant leaking out of it, after which a play appears and it will begin to make sounds when its moving part rotates. See photo at the beginning of the article.

To determine what exactly is noisy at idle - the releaser or the shaft bearing, we will do the following.

Disconnect the cable from the clutch release fork. We start the engine and leave it idling. Then turn the fork slightly clockwise. The release bearing will come out of contact with the clutch pressure diaphragm spring and the sound should disappear. The howling has disappeared - the release valve is faulty and needs to be replaced. If it does not disappear, you will have to remove the box and replace the input shaft bearing, or replace the oil in it with a better or thicker one.

Checking the serviceability of the clutch release bearing on VAZ 2108, 2109, 21099 cars

Noise when disengaging the clutch

If a howling sound is heard from the clutch housing when you press the pedal, then the release bearing has most likely failed. We release the pedal, the noise disappears or decreases. If the bearing jams or is completely jammed, then it will not be possible to press (disengage) the clutch normally. The engine will stall, and it will become almost impossible to “stick” the gear.

Also, when you press the pedal, the clutch may make noise if its drive is not adjusted correctly. It “drives” - the driven disk does not completely move away from the flywheel when turned off, it rubs against it and makes noise. The malfunction can be eliminated by adjusting the drive.

Noise when engaging clutch

When the driver releases the clutch pedal, turning it on, a distinct noise or even rattling, metallic ringing and knocking is heard from the gearbox and clutch.

This indicates wear or breakage of the driven disk (wear, deformation, loosening of its linings, breakage of damper springs) or loosening of the gearbox to the engine.

Notes and additions

— On VAZ 2108, 2109, 21099 cars, the clutch is constantly engaged, that is, the input shaft of the gearbox rotates together with the clutch basket and driven disk. See “Design and principle of operation of the clutch of VAZ 2108, 2109, 21099 cars.” When you press the pedal, the release bearing comes into operation, which presses on the pressure spring of the basket, forcing its drive disk to move away from the driven one.

— The operation and serviceability of the clutch can be fully assessed by carrying out a comprehensive check. See “Checking the clutch on VAZ 2108, 2109, 21099”.

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. » alt=»»> Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.

Troubleshooting methods

Data-lazy-type=”image” data-src=”https://vazremont.com/wp-content/uploads/2017/11/foto-7-1.jpg” alt=”Gearbox repair” width=” 496″ height=”280″ class=”lazy lazy-hidden size-full wp-image-4366″ srcset=”” data-srcset=”https://vazremont.com/wp-content/uploads/2017/11/ foto-7-1..jpg 300w" sizes="(max-width: 496px) 100vw, 496px">

- If all the gears in the VAZ 2114 gearbox are lost, this means that the problem lies in the bearings. If the breakdown is not repaired in time, repairs will cost even more.

- Noise after starting the engine. The cause of the malfunction also lies in the bearing (drive shaft) or lack of transmission oil.

- The noise disappears after changing gears. The trouble lies in the synchronizer clutch. It is possible that there are problems with the locking mechanism.

- It is not possible to disengage the clutch completely. The “culprit” is the same drive shaft bearing.

Good for those carefree drivers who belong to the category of “riders”. They don't care what happens in the car. It makes noise, crackles, howls, whines - the main thing for riders is that the car is moving. And they ride on their “victims” until death.

But a normal vehicle owner pays attention to every squeak in their favorite vehicle. Therefore, upon hearing the noise that the gearbox makes, the driver begins to get nervous and look for the cause.

If he himself is not a professional, he naturally turns to a car service center. There they console him: “It’s okay. Let’s change the release bearing and everything will be back to normal!” Well, you can understand the repairmen too. Drivers are dummies, and according to service technicians, they exist so that the profession of an auto repairman will be prestigious. (In the monetary sense.) But, if you look at it soberly...

Even if you are a person of a humanitarian mindset, you should have enough sense to try to determine for yourself whether it is worth going to the mercy of prestigious auto repair shops or whether it will be a waste of money.

To begin with, you can try to disconnect the cable that goes from the pedal to the clutch fork, and move the fork itself towards the generator. Start the engine. If the noise persists, then most likely it is produced by the support bearings located at the rear of the primary and secondary shafts. If you change regular engine oil to a thicker one - such as GL-4 or GL-4/GL-5 - the extraneous sound may well disappear. And if it hasn’t disappeared, but you are confident that the diagnosis was made correctly, you can spit on this noise. In the sense that it does not affect anything other than your hearing.

Another reason for the sound that irritates the driver may be the clutch disc itself - if there is play in the central clutch of the disc, with which it sits on the input shaft. The damper springs of the driven disk can also play.

The release bearing, by the way, can indeed also make noise due to play coupled with the clutch release guide sleeve.

If the rubbing teeth of the gears and the input shaft in your car have worn out - this could be due to natural old age, or from your manner of jumping off a la a Hollywood stuntman - here you go, another reason for the noise of the gearbox.

It often happens that this extraneous noise appears for a very simple reason - the inattention or negligence of the driver. It is necessary to regularly check the oil level in the box. If the oil is “driving” somewhere, then noises may arise – and very quickly – for all of the above reasons.

And if the driver stops paying attention to the noise of the gearbox, then such a ride can end very badly - the gearbox will simply jam. It’s good if this happens without consequences - such as a traffic accident - and in the city

Imagine that you put your entire blessed family in the car - right down to the cat and mother-in-law - and drove out of town for a picnic with barbecue and badmintons. And already at a considerable distance from civilization, the above-predicted blunder will occur with the gearbox. It will be a sad story...

Let's start with the fact that one of the most common transmission-related problems is. This problem is well known to many owners of cars with, and quite often a vehicle with a humming gearbox is quite suitable for further use.

In other words, if a manual transmission is humming, but the unit itself is working normally, the gearbox is often used for quite a long time without repair. As for, in this case the appearance of automatic transmission hum and noise is a more serious problem.

Read in this article

Clutch slipping after replacing all its parts

After replacing all elements, adjustment is required, but many car owners ignore this point. The cause is slipping, the car accelerates slowly, the engine speed does not correspond to the speed of the car. The engine just roars, and the car is driving quite slowly, as they say, slipping.

In cars with a mechanical clutch cable, adjustment is made by the cable itself. In hydraulically driven machines, this process is carried out using a clutch rod. In modern cars, you often come across rods that do not have adjustments. But this does not mean at all that it cannot be produced. In such cases, adjustment of the clutch pedal itself is provided, but not everyone knows about this possibility. » alt=»»>

The noise of the Lada Granta gearbox as a feature of the car

The mechanical transmission box of the VAZ-2181, introduced in 2012, uses a cable rather than a rigid traction drive. The cable drive provides easier gear shifting (especially 1st and 2nd gears). The disadvantage of the design is the occurrence of extraneous sounds.

Gearbox noise "Lada Granta"

According to the manufacturer, the hum appears due to poor quality processing of manual transmission gears. In 2014, plant representatives issued a statement that the problem had been fixed. The noise was reduced, but did not disappear completely. The outdated equipment used when processing gear teeth does not allow obtaining the required degrees of accuracy. To eliminate the whine of the gearbox on the Grant, a significant amount of production will need to be modernized. So far, AvtoVAZ cannot afford this.

In 2022, the transmission can be found on Grants in the body:

- sedan, hatchback, station wagon with a VAZ-11186 engine (16 valve, volume 1.6 liters);

- liftback with VAZ-21127 engine (16 valves, 1.6 l);

Also, the VAZ-2181 is installed on the “Cross” modification with the VAZ-11186 and VAZ-21127 engines and the “Drive Active” with the VAZ-21127 engine.

It is rarely possible to defeat the howl of a manual transmission on a Grant. If the driver and passengers are noisy in the cabin with a manual transmission, it is better to buy a Lada Granta with an automatic transmission or a robot. A sudden noise should alert you. The howling of the box may indicate failure of individual elements. It will be cheaper to pay for a transmission overhaul than to buy a new unit later.

Vibration that occurs after replacing clutch elements

There are few reasons why vibration occurs after replacing a clutch. Vibration usually appears in two forms:

- The pressure plate (clutch basket) is not balanced;

- During assembly, the driveshaft was installed in a different position from the original installation (but this only applies to rear-wheel drive or all-wheel drive vehicles).

By and large, on cars with front-wheel drive, you can inaccurately secure the wheel drive (CV joint), and the movement of the car will be accompanied by vibration and knocking, but this does not happen often.

If the clutch basket creates vibration, you can try moving it to a different position. As a rule, the pressure plate mounts are symmetrical. On many models, the basket is attached to the flywheel with six bolts, and the basket can be placed in three positions. In one position the vibration may disappear completely or be minimal. But it is better to exchange the warranty part immediately for another one. This will be less hassle for the car owner.

The clutch system is the main mechanism of the car, through which torque is transmitted from the power unit to the transmission. The smooth operation of the gearbox and, accordingly, the proper functioning of the gearbox depend on the correct, proper operation of the system. It consists of: a pressure plate, a clutch basket, a drive mechanism and a release bearing. When you press the clutch pedal, a mechanical (using rods) or hydraulic (using liquid) drive acts on the release bearing, which presses with the help of a damper spring, in common parlance: the clutch basket, the friction disc to the flywheel.

A bearing made of high-alloy steel is a fairly reliable part, but frequent connection of the clutch (driving a car in a big city), improper operation of the mechanism: holding the car for a long time with the clutch pedal depressed (a mistake by inexperienced drivers) leads to overheating and destruction of the bearing race. Replacing the clutch release bearing is described in the step-by-step instructions below.

How does a clutch work in a car?

The main purpose of the clutch is to smoothly connect the engine flywheel to the input shaft of the gearbox when the car starts moving, as well as when changing gears. Another important task of the unit is to protect the transmission from mechanical overloads during sudden braking, thus preventing the possibility of breakdown and costly repairs.

There are several classifications of clutches. Depending on the number of slave disks, they can be multi-disk or single-disk (this is the most common type).

Depending on the environment in which the mechanism operates, it can be “dry” or “wet”. Currently, automakers prefer the first option, which does not require a special oil bath for operation.

The classification of clutches in accordance with the drive allows us to distinguish between hydraulic, mechanical, electrical or combined mechanisms. Depending on the design features on the pressure disk, the springs can be arranged in a circle or have a central diaphragm.

The clutch consists of:

- clutch disc (called “driven”);

- pressure plate;

- release bearing and its drive fork;

- drive system and clutch switch (release pedal).

The operating principle of a single-plate automobile clutch is that the working surfaces of the flywheel, disc linings and the pressure surface of the “basket” are tightly attached to each other. Under the influence of the release springs on the pressure plate of the “basket”, the latter is pressed tightly against the clutch disc, causing it to adhere to the flywheel.

The input shaft, entering the splined coupling, receives torque from the clutch disc. When the pedal is depressed, the drive system is activated; under the pressure of the release bearing, the release springs move the working surface of the “basket” away from the disc. The freed disk stops causing the transmission input shaft to rotate, while the engine continues to run.

We recommend

Double-disc clutches consist of two discs and a “basket” that has two working surfaces. The mechanism is supplemented with limiting bushings and a system for adjusting synchronous pressing. The principle of operation itself is similar to that previously described.

Signs of a faulty mechanism

The only sign of a faulty release bearing is an unusual sound (noise, whistling, knocking) when the clutch pedal is depressed, which disappears when the pedal is returned to its place. In winter, in severe frosts, noise is often heard when the clutch is engaged, but you should not pay much attention to this, since the materials from which the mechanism parts are made react differently to temperature changes, and the sounds disappear during the warming up process. There are no external, visible malfunctions of the unit, since the bearing is located in the clutch housing. The regular appearance of noise with each press of the clutch pedal indicates an imminent replacement of the release bearing. Unusual sounds occurring when the clutch is depressed indicate a malfunction in the gearbox.

Noise additives in the box

Transmission noise reduction additives can temporarily reduce the noise during operation. However, the cause of the hum will not be eliminated. Therefore, it makes sense to use additives only for preventive purposes or during pre-sale preparation of a car in order to get rid of it as quickly as possible.

Different types of additives are suitable for different problems, so when choosing one it is important to determine exactly what is humming in the box. The most popular attachments for reducing noise in manual transmissions are:

- Liqui Moly Getriebeoil-Additiv . Forms a protective film on the surface of parts due to molybdenum disulfide, and also fills microcracks. It effectively reduces noise in manual transmissions and extends the service life of the transmission.

- RVS Master TR3 and TR5 are designed for optimal heat removal during constant overheating of the unit. Which also helps reduce noise in the box.

- XADO 1Stage . This additive can be used in any transmission - mechanical, automatic and robotic. Contains boron nitride. Removes noise and vibration in the gearbox. Allows you to get to the workshop in the event of a critical loss of oil in the gearbox.

There are similar additives in automatic transmissions. Examples for automatic transmissions include:

- Liqui Moly ATF Additive . Complex additive. Removes noise and vibrations, eliminates shocks when shifting gears, restores rubber and plastic transmission parts. Can be used with ATF Dexron II and ATF Dexron III fluids.

- Tribotechnical composition Suprotek . Can be used with both automatic transmissions and CVTs. The additive is restorative, including removing vibration and noise in automatic transmissions.

- XADO Revitalizant EX120 . This is a revitalizant for the restoration of automatic transmissions and transmission oil. Eliminates shocks when shifting gears, eliminates vibration and noise.

The additive market is constantly being replenished with new compounds to replace old ones. Therefore, the lists in this case are far from complete.

Conclusion

Most often, a manual transmission is noisy because the oil level in it is low, or the oil is of the wrong viscosity or is old. In second place is bearing wear. Less commonly, wear of gears and couplings. As for automatic transmissions, similarly, most often the cause of the hum is low oil level, wear of gears and bearings, and malfunctions of hydraulic system elements. Therefore, the first thing to do when a howling or noise of a different nature appears is to check the oil level, and then look at the situation, under what conditions it occurs, how big the noise is, and so on.

In any case, it is not recommended to operate any transmission that makes a hum or shows other signs of malfunction. In this case, the box will wear out even more and its repair will cost more. The exact cause can only be found out by disassembling and troubleshooting the unit.

Bearing replacement

Spare parts and tools

We recommend watching this video:

Without a pit, a lift and the help of a friend, it will be very difficult to complete the task. So if you decide to replace the release bearing yourself, you should provide as much space as possible under the bottom of the car for removing and installing the gearbox. The tool set is very simple: wrenches of various sizes, a container for draining oil, molybdenum high-consistency lubricant.

Algorithm for performing repair work on a unified unit

The work of dismantling the unit is labor-intensive, but does not require special mechanical skills; the main thing is to follow the sequence of actions:

- disconnect the battery;

- disconnect the cable or hydraulic clutch. On some cars, for example: Nissan, this requires removing the air filter and the battery mounting plate;

- disconnect the gear selector;

- dismantle the engine compartment protection;

- on cars with front-wheel drive or all-wheel drive, it is necessary to drain the oil from the gearbox, after which we disconnect and remove the front drives;

- on cars with rear-wheel drive and all-wheel drive, remove the driveshaft;

- disconnect all sensors and wires leading to the gearbox;

- Having installed the stops under the gearbox, unscrew the bolts connecting the gearbox to the power unit and mounting it to the car body, and carefully, without damaging the input shaft, remove the assembled mechanism;

- release the spring fastenings of the clutch release clutch and disconnect it from the drive;

- remove the clutch from the gear selection shaft;

- remove the bearing from the coupling;

- apply a thin layer of high-consistency lubricant to the surface of the gearbox input shaft (excess lubricant in the clutch mechanism leads to slipping of the clutches);

- install a new release bearing;

- install the transmission in the reverse order;

- connect all sensors, actuators and connectors;

- fill in the transmission fluid recommended by the manufacturer;

- pump the hydraulic clutch drive;

- adjust the mechanical drive of the system;

- install and connect the battery.

For proper use of fasteners, it is worth putting them, when dismantling, into labeled containers.

Features of the clutch system of some cars

Car manufacturers have taken different approaches to the design of the clutch mechanism; in cars of the French concern PEUGEOT, the release bearing, when you press the pedal, does not press, but pushes out the damper.

On some cars, for example: Volkswagen, equipped with a 020 gearbox, the release bearing is replaced without removing the gearbox. This part is located in the rear part of the gearbox. To replace it, you need to remove the left front wheel, disconnect the clutch drive, remove the box housing plug, move the pusher aside and replace the bearing.

(malfunctions and their causes)

The frequency of clutch problems can be very different, even for cars of the same model and the same year of manufacture. It all depends on the conditions in which the car is primarily used, for example, when driving around the city, you have to use the clutch much more often than on the highway, and this causes it to wear out quickly. Driving style affects the durability of the clutch in a similar way - active driving accelerates wear. In addition, for the service life of a clutch that has already been repaired, it is important what quality of spare parts were used during the rebuild.

A working clutch should disengage completely when you press its pedal, and when engaged, it should not slip, and the on-off process itself should be silent. If the car owner cannot answer affirmatively to at least one of the listed points, then it’s time to start diagnosing the clutch.

Let's start with noise

If pressing the clutch pedal is accompanied by noise, then the release bearing is most likely to blame. Before changing the bearing, you need to make sure that the position of the clutch release fork is adjusted correctly, otherwise the new release valve will not last long either.

It occasionally happens that the clutch makes noise when disengaged due to heavy wear and even collapse of the splines in the driven disc hub. Wear and breaking of splines can be observed on driven disks on which worn friction linings have been repeatedly replaced. A faulty gearbox input shaft bearing or misaligned engine and gearbox installation also cause wear on the clutch disc splines.

By the way, the clutch is also responsible for the noise that accompanies its activation due to wear and broken splines. In addition, the culprits of the noise when switching on can be: a clutch fork return spring that has lost its elasticity or has completely jumped out of place; worn or broken parts of the torsional vibration damper in the driven disk.

The clutch "drives"

When the clutch does not disengage completely, gear shifting problems occur. In addition, this process is accompanied by grinding noise.

There are many reasons for this abnormal clutch behavior. For example, the rivets on the driven disk could have become loose, or its friction linings could have broken due to poor-quality repairs in handicraft conditions. Deformation of the pressure or driven disk cannot be ruled out due to overheating due to slipping of oily friction linings. The pretext for incomplete disengagement of the clutch may be worn out or even broken blades of the diaphragm spring. Finally, if there has been a long break in the operation of the car, the driven disk may simply rust to the flywheel.

However, the cause of the malfunction should be sought primarily in the drive. If it is mechanical, then you should carefully inspect the clutch cable - is it laminated? In a hydraulic drive, air may enter the system, leakage of working fluid, or, for example, clogging of the hole in the lid of the feed tank.

The clutch is slipping

In this case, the “norm” of the clutch manifests itself in the fact that it simply does not keep up with the increasing engine speed. The car accelerates slowly and climbs hills as if it had lost some of its power. If the process is accompanied by the appearance of a specific smell of burning linings, then we can definitely say: the clutch driven disc is completely worn out and needs to be replaced.

Other, less common causes of clutch slippage include heavy oiling of the surfaces of the flywheel, driven and pressure disks; incorrect adjustment or jamming in the drive mechanism; warping of the driven disk, due to which it does not adhere to the flywheel with its entire surface, but only with its edges. By the way, these same defects can manifest themselves in the fact that the car will move away jerkily, despite the smooth engagement of the clutch.

Clutch repair is a labor-intensive and expensive operation, because it requires removing the gearbox and purchasing far from cheap spare parts. Even garage workers charge at least $50 for work, and as for replacing parts, it is recommended to change the entire set - the driven disk, release bearing, basket assembly. If today you only need to change the driven disk, then no one can guarantee that the day after tomorrow the clutch will not fall apart, therefore, you will have to dismantle the gearbox again.

Main problems after replacing the clutch

What does the concept of replacing a clutch include? Clutch replacement means complete replacement of the clutch disc. Quite often, after such manipulations, previously non-existent side effects appear.

If you think about this problem, then there are not very many special prerequisites for the emergence of such negative aspects. As practice shows this:

- illiterate work of non-professional craftsmen;

- factory defect of a new spare part;

- incorrect diagnosis of the problem, due to which the wrong elements or not all components requiring repair were replaced. As a rule, after this, hidden defects reveal themselves fully.

In general, the problem of the emergence of new problems and defects in the operation of a car is very complex and individual in each specific case. But there are still common characteristics.