The products of the AvtoVAZ concern, which have long been a reason for ridicule among car enthusiasts, have reached a fundamentally new level after the start of sales of the new Lada Vesta sedan.

After the resounding success, the designers promised to bring to life the concept conceived even before the appearance of Vesta, which at that time was already called Lada Xray. The average consumer expected that a full-fledged crossover would appear on Russian roads, but the new product was “planted” on the B0 platform (we will talk about it later), so it is positioned as a tall hatchback SUV. From the first tests, it became clear that the Xray is a city car with increased ground clearance and, at the same time, good handling. But in the near future, the plant plans to produce all-wheel drive versions of the Lada Xray Cross, filling almost the entire niche of passenger cars with competitive representatives.

Diagnostics of faults in the front suspension of Lada XRAY

During operation of the Lada XRAY, extraneous sounds may appear in the front suspension (something rattles, knocking, creaking or grinding noises are heard).

Let's look at how to determine the source of problems and identify faults in the front suspension of a crossover with your own hands. Checking the car suspension while driving. We evaluate the technical condition of the suspension while driving at low speed on an uneven road. The suspension should work without knocks, squeaks, and other extraneous noise.

How to check shock absorbers. The shock absorber struts should be checked immediately after a long trip, until the working fluid in the shock absorbers has cooled down. We rock the front part of the body in a vertical direction several times. If the body, due to inertia, makes more than two oscillations, then one or both shock absorbers are faulty. The effectiveness of vibration damping is tested on a bench. We check the rear suspension shock absorbers in the same way.

Rock the top of the wheel in the transverse direction.

If you feel play, even barely noticeable, or hear clicks or knocks, you need to more carefully check the condition of the front suspension and hub. We hang the wheels and rock the wheel in the vertical and horizontal plane:

- If play is felt only with the brake pedal released (there is no play when the brake pedal is pressed), then the wheel bearing is most likely worn out.

- If there is play in both cases (with and without the brake pressed), then there is a malfunction in the Vesta suspension.

- If play is felt in the vertical plane, the ball joint is worn out or the strut mount is weak.

- If there is play only in the horizontal plane, the tie rod end is faulty (for the front suspension).

Checking shock absorbers. First, we inspect the shock absorber struts and mounting points for mechanical damage and fluid leaks. Then we apply force with a crowbar to the anti-roll bar and make sure that there is no play in the strut. If there is play, the struts must be replaced.

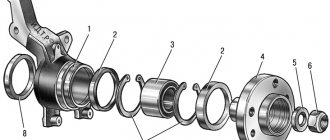

Checking the stabilizer strut cushions (No. 1). We check for any bulging or cracking of the rubber. Replace faulty cushions.

Similarly, we check the condition of the anti-roll bar cushion.

Checking the front silent block of the lever. We shake the front eye of the lower arm with a crowbar. There should be no play, otherwise we change the lever.

Checking the ball joint. First, visually inspect the protective cover; it should be without damage. Then, using a crowbar as a lever, we check that there is no play in the ball joint. If the boot is torn or there is play, replace the lever assembly.

Let us remind you that we described the design and reviews of the front suspension of the new AVTOVAZ model earlier.

Source

Driving sensations

Of course, taking into account all the changes mentioned in the suspension of the Lada X Ray Cross, it drives completely differently.

The car began to hold a straight line on the highway much better, and in the rut it behaves much more obediently. There is a clear “zero” on the steering wheel, and in order to “move” the steering wheel you need to apply a noticeable force, while returning back to “zero” even seems excessive to some. Naturally, there are rolls, given the ground clearance of 215 mm, but they are small and do not interfere with taxiing.

Fans of AvtoVAZ models have always appreciated the energy intensity of the chassis of domestic models. And here the suspension of the Lada X Ray Cross is beyond praise! On a flat surface the car shakes a little. But everything changes on the broken road. Even before serious bumps and swells, you don’t have to slow down!

However, it is worth remembering that the engine protection here is plastic. In fact, it only protects from dirt, small stones and grass. Therefore, if you intend to drive off asphalt at least periodically, it is strongly recommended to install metal protection.

What can rattle in the Lada X-Ray suspension

What I mean is that lubricant is added to the steering tip once for its entire life at the manufacturer's factory. And basically nothing comes there.

There are options with injecting through a tavodnitsa. But with my hands

Thanks to a forum participant, I found out what exactly they changed for me. Thank him very much for this!!

"Hello. Replaced the tie rod end. Text: “During diagnostics, a knock was detected in the right steering tip. It is necessary to replace the tip and adjust the wheel alignment angles.”

| View Options |

| Linear view |

| Combined view |

| Tree view |

Project of the Official Lada Club

Copyrights © 2014-2020 LADA Xray Club | Lada Xray Club

Our forum is dedicated to the new LADA Xray and Lada Xray Cross. Anyone can communicate with like-minded people; to do this, spend less than a minute and register. We discuss Lada Xray, X-ray photos, videos and prices of LADA Xray Cross.

The LADA Xray forum was created for fans and those interested in the new Lada Xray and LADA Xray Cross. Read reviews from X Ray owners and independent test drives of the Lada Xray.

Price Lada Xray - from 430,000 rubles. Price LADA Xray Cross - from 500,000 rubles.

Source

Dynamics and acceleration up to 100 km

At the moment, the main line of engines for the Lada X Rey consists of 2 gasoline units with a volume of 1.6 and 1.8 liters. The engines have different power ratings: 106 and 122 l/s. At the same time, the more powerful version has a torque of 170 N*m already at 3750 rpm. In combination with correctly selected gear ratios in the box, the car is able to reach 100 km/h in 10.9 seconds.

The maximum speed (according to the manufacturer) is 183 km/h, but in practice for domestic car owners, the figure of 200 km is more realistic. However, the tall hatchback was not originally designed for high speeds.

Although the car has good dynamics, it is more suitable for economical movement around the city. After all, even the version with the 1.8 engine has a mixed consumption of up to 8.6 l/100 km. Read a more detailed review about which engine is installed on the x ray.

In terms of choosing a gearbox, the manufacturer is ready to offer automatic and manual transmissions in 5 speeds. Fans of classic “mechanics” can choose one box from 3 available (JR5 512, JR5 518 and domestic VAZ 21809).

The main difference is the gear ratios. In general, the engine + gearbox pair was chosen quite well and the car turned out to be quite dynamic.

As for the shortcomings of factory engines, according to information from owners of internal combustion engines, after 25-35 thousand they can consume oil. This problem does not affect everyone.

Also, Lada X Ray is characterized by problems with wiring. The most vulnerable point is considered to be the braid of wires to the engine control unit and sensors. Even at low mileage, problems often occur.

Diagnostics of faults in the front suspension of Lada XRAY

During operation of the Lada XRAY, extraneous sounds may appear in the front suspension (something rattles, knocking, creaking or grinding noises are heard). Let's look at how to determine the source of problems and identify faults in the front suspension of a crossover with your own hands.

Checking the car suspension while driving. We evaluate the technical condition of the suspension while driving at low speed on an uneven road. The suspension should work without knocks, squeaks, and other extraneous noise.

How to check Lada XRAY shock absorbers

The shock absorber struts should be checked immediately after a long trip, until the working fluid in the shock absorbers has cooled down. We rock the front part of the body in a vertical direction several times. If the body, due to inertia, makes more than two oscillations, then one or both shock absorbers are faulty. The effectiveness of vibration damping is tested on a bench. We check the rear suspension shock absorbers in the same way.

We rock the upper part of the Lada XRAY wheel in the transverse direction.

If you feel play, even barely noticeable, or hear clicks or knocks, you need to more carefully check the condition of the front suspension and hub. We hang the wheels and rock the wheel in the vertical and horizontal plane:

- If play is felt only with the brake pedal released (there is no play when the brake pedal is pressed), then the wheel bearing is most likely worn out.

- If there is play in both cases (with and without the brake pressed), then there is a malfunction in the Vesta suspension.

- If play is felt in the vertical plane, the ball joint is worn out or the strut mount is weak.

- If there is play only in the horizontal plane, the tie rod end is faulty (for the front suspension).

Other interesting articles on maintenance and repair Lada Xray

Checking shock absorbers. First, we inspect the shock absorber struts and mounting points for mechanical damage and fluid leaks. Then we apply force with a crowbar to the anti-roll bar and make sure that there is no play in the strut. If there is play, the struts must be replaced.

Checking the stabilizer strut cushions (No. 1). We check for any bulging or cracking of the rubber. Replace faulty cushions.

Similarly, we check the condition of the anti-roll bar cushion.

Checking the front silent block of the lever. We shake the front eye of the lower arm with a crowbar. There should be no play, otherwise we change the lever.

Checking the ball joint. First, visually inspect the protective cover; it should be without damage. Then, using a crowbar as a lever, we check that there is no play in the ball joint. If the boot is torn or there is play, replace the lever assembly.

Source

MacPherson struts

Many people know this type as a “swinging candle.” The main difference is the presence of a shock-absorbing strut, which performs several functions at once. In this case, all functions are performed simultaneously. The design involves:

- shock absorber;

- spring.

The element is attached to the wheel hub from below, and to the body from above. In the second case, additional supports are also used. Thanks to this type of fastening, it is possible to ensure reliable fixation of the wheel with the body when rocking. There is also a guiding system. Its role is played by levers having a transverse direction.

The stand is the most popular and in demand type. Its purpose is to ensure comfortable movement on the road. The suspension is valued for its reliability and durability.

Knock from behind

Various components and parts can knock in the rear of the car, so it is important to be attentive to such manifestations:

- Bolts. To cause annoying knocking noises to appear, simply loosen the wheel fasteners slightly. In addition, under such circumstances, vibration may occur in the rear of the vehicle while driving at speed.

- Wheel disks. Many people believe that installing disks of larger diameter and width is quite justified. This has a positive effect on handling, cross-country ability, and directional stability. On the other hand, too much width and mismatched offset lead to friction against the wheel arch and the appearance of unpleasant beating sounds.

- Plastic rear fenders. Many car owners install such protection on wheel arches. Some of them make mistakes during installation. As a result, the part may simply move away from the fastening. As a result, the plastic may begin to rub against the tire.

- Wheel bearings. Such worn parts begin to hum and knock more and more. In an unfavorable scenario, the hub race may break, jamming the wheel while the car is moving. If the wheel wobbles, then this clearly indicates a problem.

- Shock absorbers. A worn element can be identified by oil leaks on the body. The service life of shock absorbers is on average 60,000 kilometers, after which they need to be replaced with new ones.

- Silent blocks. These elements in the rear suspension wear out over time. This leads to backlash, which causes knocking noises when moving. At the same time, when driving on uneven roads they will only intensify.

- Springs. Due to a broken shock absorber bushing and destruction of the rubber gaskets, very strong knocking sounds appear along the edges of the spring. This is especially true when driving over bumps. In addition, the machine may tilt to one side.

- Brake system. The beating of the brake pads on the disc is also accompanied by loud knocking noises. In drum structures, such manifestations arise due to deformation of the drum cover, which begins to come into contact with the brake pads.

Type diversity

Any of the car suspensions must provide the necessary smoothness, have kinematic characteristics that meet the requirements for stability and controllability of the car.

In a car with a dependent suspension, a rigid connection of opposite wheels is implied, the movement of one of which in the transverse plane facilitates the movement of the second. Cars with independent suspension are characterized by a more complex design in which the wheel displacement does not depend on each other. This type of independent car suspensions are divided into lever and spark plug. The most common types are:

- with swinging axle shafts;

- on trailing arms (spring, torsion bar);

- with oblique levers;

- with longitudinal and transverse arms;

- with double longitudinal and transverse arms (spring, torsion, spring);

- torsion-lever;

- "MacPherson";

- hydropneumatic and pneumatic suspensions;

- adaptive.

Dependent type

On a car of this type of suspension, a rigid connection between the wheels is implied. Dependent type units are among the first inventions of mankind, which did not go very far from the design of carts, when two wheels were connected to each other by an axle.

Modern analogues are divided into spring and spring. The first option provides a spring as an elastic element, the fastening of which is carried out to the bridge beam, with its ends to the frame or body of the car. The second suspension option involves the use of a spring.

Dependent suspension

Although this type is considered obsolete due to the age of its invention, it is still widely used among trucks and SUVs. Disadvantages that are indifferent on a bad road become obvious on the highway:

- handling remains much to be desired due to the decent sprung masses when driving at high speed;

- poor directional stability;

- The level of comfort for passenger cars is very low.

Independent type

This version of car suspensions is completely different and has nothing in common with the one discussed earlier. This design does not have a rigid connection between the wheels. In practice, such a suspension implies autonomous fastening of each wheel to the car body, and when one of them oscillates, these changes are not transmitted to the others. Thanks to this factor, body roll is reduced, resulting in increased stability. The practical implementation of independent car suspensions is varied, which is divided into two main types: lever and spark plug. Types of the first: double-lever, transverse-lever, oblique-lever and longitudinal-lever. The latter include MacPherson suspension.

Among passenger cars, MacPherson and wishbone suspensions are widespread. The reasons that give a car a number of advantages explain the popularity factor of suspensions, among them:

- decent level of comfort;

- high degree of controllability;

- good feedback when steering;

- rolls are minimal;

- high speed.

Independent suspension

Combined type

This is a combination of the two car suspensions described earlier. Their design includes an independent suspension at the front and an axle at the rear. The developers' compromise solution allows for comfortable movement on asphalt and free overcoming of minor off-road conditions.

This combination of passenger cars will fit perfectly into crossovers and SUVs. The ability to move freely around the city, go to the forest for a picnic, or drive along country roads becomes an embodied task. Even if it turns out to be something average, in most cases it will provide acceptable driving conditions.

Combinations Worth Considering

The types of pendants described above do not exhaust their diversity. There are some other types of units that deserve attention:

- Torsion bar. It is based on the work of a special element - a torsion bar, which is a metal shaft. Its function is represented by twisting when a load occurs.

- Active. For passenger cars with this suspension, the term “active” implies the possibility of fluctuations in parameters during operation of the unit.

- Pneumatic. Responsible for changes in the height of cars relative to the road, in other words, fluctuations in ground clearance. The design of the air suspension provides for the use of air stops on each wheel. A separate air suspension for passenger cars is not a separate type, but serves as a kind of addition to the standard one.

Sounds under the bottom

In cars with all-wheel drive or rear-wheel drive, characteristic knocking noises may appear under the bottom while driving, the cause of which is the driveshaft crosspiece. The sounds are especially clear when starting to move, sharply accelerating or changing gears.

Knocks are often accompanied by vibrations. It should be borne in mind that this problem cannot be ignored, since when driving a car with a bad spider, the driveshaft can simply come off. This may cause the car to roll over. The rear crosspiece is loaded more, so it fails faster.

If it's knocking from the front

Determining the cause of front suspension knocks is not always easy, even at a service station, since in order to detect malfunctions of some parts, they need to be disassembled.

The most common elements that produce noise are:

- Steering rack. The beginning of wear on this device can be detected by simply jerking the steering wheel left and right. Here, when driving, a distinct feedback will be felt against the background of knocks. Most often, this problem affects domestic cars older than 10 years.

- Silent blocks. These elements of the front suspension arms are most often affected. Due to the rupture of the rubber elements, the metal parts come into contact with each other, producing metallic sounds. They are often quite difficult to diagnose. If you place your foot on the floor, the knocks should be felt in the foot.

- CV joint Before they fail, these elements begin to crunch when turning. External elements fail more often, so they may be the cause of knocking.

- Spherical bearing. This part begins to knock when driving even on small uneven roads. Due to wear of the mechanism and rupture of the protective rubber, the efficiency of this part is noticeably reduced. She starts knocking unexpectedly, increasing in volume and intensity. To diagnose the ball joint, you will need to dismantle it, so it is better to seek professional help from a repair shop. Visually you can determine the integrity of the rubber boot.

- After prolonged use, even high-quality racks begin to knock. In this case, the knock will be dissipated throughout the entire suspension. Often this device fails after the support bearing breaks.

The difficulty of diagnosing the chassis is explained by the fact that all its elements are interconnected. Even after disassembling the suspension, it is not always possible to immediately detect the source of the problem.

Source

General assessment and conclusions

X-Ray, despite numerous criticisms, is one of the best domestically produced cars. For little money, the buyer is provided with a large range of different options. At the same time, the presence of specific functions is not considered a marketing detail, but is a completely justified necessity.

In addition to various options, the manufacturer offers the most prepared vehicle, which is adapted to domestic operating conditions.

The model has a processed bottom, energy-intensive suspension, engine protection, high ground clearance, large tire profile, high-quality filters, good lighting, as well as reinforced body components. All this can be obtained already in the basic version.