Owners of 8–16-valve fuel-injected cars produced in Togliatti often encounter engine malfunctions. At the same time, the Check Engine light often lights up. Among the mass of possible malfunctions, diagnostics often reveal a malfunction of the camshaft position sensor (CPS). Error code P0340 is a common problem on VAZ models. Next, we will tell you why the problem occurs, what signs indicate a DPRV failure, and how to change it.

Principle of operation

The DPRV sensor operates on the Hall principle and is capable of determining the position of the camshaft as accurately as possible at different periods of operation by reading pulses. The device transmits the received information to the electronic control unit (ECU). After this, the main controller adjusts the fuel injection for each injector at a certain time. That is, knowing the position of the camshaft, the on-board computer is able to establish a phased supply of gasoline to the cylinders.

Meter design and location

The operating principle of the DPRV is based on the Hall effect - the sensor reacts to the approach of a metal mass by changing the voltage on the signal wire. The design of the device is similar to another element - the crankshaft position detector. Inside the plastic case there is a coil where the 12 V on-board voltage is constantly supplied.

The meter is installed on the engine cylinder head in close proximity to the camshaft. The latter is equipped with a special plate or gear, whose rotation affects the DPRV. The work algorithm looks like this:

- After turning on the ignition and starting the engine, a supply voltage of 12 V is supplied to the sensor. Through the third signal wire, the element supplies the controller with a voltage of 90–95% of the original one.

- When the protrusion on the rotating part of the camshaft passes next to the DPRV housing, the voltage at the signal contact drops to 0.2–0.4 volts, depending on the design of the device and the vehicle model.

- When the voltage drops, the electronic unit clearly “sees” the valve timing, promptly supplies the fuel mixture to the engine cylinders and directs the spark discharge to the desired spark plug.

Note. On cars with 16-valve engines, 2 sensors are installed - one for each camshaft.

When the meter is faulty, the electronics are unable to control the operation of the gas distribution mechanism. In such cases, the control unit goes into error and is guided by the signals of other meters. Spark generation and fuel supply are adjusted according to the programmed program, which affects the operation of the power unit.

Signs of an error

For balanced engine operation, the ECU collects data from all sensors. If there is no signal from one of them or having received incorrect parameters, the computer warns the driver about this. To do this, he lights up the Check Engine icon on the instrument panel. If there is poor communication with the DPRV, the on-board controller also signals a problem in the system. During diagnostics, the scanner will show error P0340 (quite often on VAZ 2114–2115). Over the long years of using “fours” and “tags”, owners have learned to recognize signs of engine malfunction that are directly related to the camshaft position sensor:

- The engine refuses to start.

- The car starts with great difficulty.

- The engine stalls at idle speed.

- Failures appear and former power is lost.

- Fuel consumption increases.

- The engine starts to stall.

- Check Engine light is on.

If the listed symptoms are not observed, and the diagnostic controller shows error P0340, then most likely a failure occurred in the computer itself. On VAZ 2110, 2111, 2112, 21114, 21124 and other models, Bosch M7.9.7 and January 7.2 ECUs were installed. They may become buggy after free firmware updates.

How to get rid of error p0340

Methods for getting rid of malfunctions that caused the formation of error p0340 (malfunction in the camshaft position sensor circuit) depend on the causes of their occurrence, as well as the specific car model - for example, Nissan, Ford, Chevrolet, Opel, Toyota. , VAZ (in particular, VAZ 2114). However, the general verification algorithm will be as follows:

- Using an error scanner, check the ECU memory for errors p0340 and possible others. If only one error is detected (or related ones, for example, p0342, p0343), then you should try to reset, as indicated above. That is, remove them using software or by disconnecting the negative terminal of the battery for 10...20 seconds. If the error disappears after starting the engine, it means that it was a false response of the sensor or ECU. If the error occurs again (you should read the error number again with the scanner), then you need to continue further diagnostics and repairs.

- Check the latch, which ensures rigid contact between the chip and the sensor body. In some situations, it can be broken off, and this leads to loss of contact between all or individual wires and contacts on the sensor.

- Check the quality of installation of the sensor in its mounting location. In particular, check the tightening torque of the nut (usually the sensor is secured using a bolt with a nut with a diameter of 10 mm or similar, depending on the specific engine). Make sure that the engine has the correct sensor for this particular motor. In particular, not only in terms of fastening, but also in model, since sensors may differ in both geometric shape and size, and because of this, the sensitive element of the sensor will not detect the passage of a rapper near it, which will lead to the absence of corresponding signals on the ECU. If the sensor is not suitable, you need to buy a new camshaft sensor and replace it.

- Visually check the condition of the contacts and terminals in the electrical circuit for connecting the camshaft sensor. In some cases, oxidation (rust) occurs on critical terminals, which leads to a decrease in the quality of contact. This is due to exposure to moisture and/or simply old age. If oxides are detected, you must get rid of them by thoroughly wiping the contacts. To clean difficult stains, you can use special electrical contact cleaners.

- Using a multimeter in continuity mode or measuring insulation resistance, you need to verify the integrity of the wires coming from the computer to the camshaft sensor.

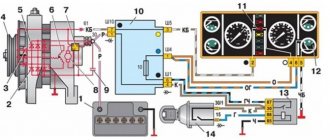

Usually there are three wires. In addition to checking the integrity of the wires, it is also necessary to check the insulation resistance value in pairs between them, as well as between each of the wires and the machine body (“ground”). However, in the latter case, the ground wire will “ring” with the body. Moreover, in the process of the described test, the multimeter probes must be placed on the contacts of the corresponding connectors. Scheme for checking the PRV sensor - When checking the insulation resistance value, you need to clearly know which connector on the “chip” is responsible for what. For example, on the already mentioned VAZ-2114 (and on other front-wheel drive VAZs) two types of camshaft sensors are used - 21110-3706040 and 21120-3706040. They differ in contacts. The first sensor has contact “A” - ground, “B” - signal wire, “C” - power (plus). The second sensor has contact “A” - ground, “B” - power, “C” - signal wire. Usually the second end of the power wire (plus) comes from the control relay. As for similar sensors on other machines, you must additionally look at their documentation (sensor connection diagrams).

- If checking the wires shows that they have defects (breakage, damage to insulation), then it is necessary to perform a visual inspection of them in order to determine the location of their damage. First of all, you need to pay attention to the places of bends and fractures, where the wires change their shape and can simply fray as a result of vibration. You also need to inspect whether the wires pass through places where moisture or process fluids (for example, lubricant) accumulate. Over time, the insulation in these areas may become compromised. If the location of the damage cannot be found, it means that the entire wiring of the camshaft position sensor needs to be replaced. In this case, it is necessary to use special flexible automotive wires with the appropriate core cross-section.

- If everything is fine with the wires and the chip, then you should check the condition of the sensor itself. You can read how to do this at the link above. If the situation allows, you can replace the sensor with a known working one. Please note that there are many sensors on the market today that are of frankly poor quality. Accordingly, it is better to choose original sensors in accordance with the documentation for the car, and order them from official representatives of the automaker. This is expensive, but can pay for itself, since low-quality sensors will have to be purchased again and time and effort spent on installing them.

- If there are no problems with the camshaft sensor, you need to check the normal operation of the electronic control unit. However, it is not recommended to do this yourself, since this is a complex and important part of the car. Therefore, for help, you need to contact a car service center, where there are specialists and additional diagnostic equipment.

Finally, it is worth noting that when identifying malfunctions of the camshaft sensor, it makes sense to check the operation of the crankshaft sensor, since these shafts work synchronously, and if there is no signal from the camshaft sensor, then the ECU uses signals from the crankshaft sensor. It is necessary to check if there are any errors in the memory of the electronic engine control unit regarding the DPKV, for example P0335, and also, if possible, inspect its mechanical condition and wiring (similar to the DPKV).

Conclusion

Error p0340 is not a critical error, and if it is formed in the memory of the electronic engine control system, the car can be used. However, this leads to loss of engine power, “floating” idle speed, and increased fuel consumption. This is especially true for cars equipped with gas equipment and using gas as fuel.

Therefore, it is better not to drive for a long time with such an error, as it will cause a lot of inconvenience to the driver. Accordingly, it is advisable to carry out diagnostics and carry out repair work as early as possible, especially since they are simple and most car enthusiasts can handle them.

Reasons for failure

Quite often, the cause of error P0340 on VAZ models is the sensor itself (DPRV). Over time, its internal contacts are destroyed. But sometimes a failure occurs due to other reasons, such as:

- Wear of camshaft pulleys (appearance of backlash).

- The timing belt jumped 1-2 teeth.

- The wires on the power supply have oxidized.

- Broken wire or short circuit.

- The plug came loose randomly.

Very often error P0340 appears on VAZ Kalina models. The car simply refuses to drive without changing the throttle. Here, the fault is often the controller itself, located under the heating radiator, where it is simply filled with coolant (antifreeze, antifreeze) when depressurized. The experts already know: if the “brains” are washed and dried, the fault disappears and Kalina will drive again.

CMP Camshaft Position Sensor Error Codes

| Common CMP Trouble Codes | Cause of camshaft sensor error |

| P0340 CMP | No signal from camshaft sensor |

| P0341 CMP | Incorrect valve timing |

| P0342 CMP | Camshaft sensor circuit low |

| P0343 CMP | Camshaft sensor circuit high |

| p0344 CMP | Unstable signal from the camshaft sensor (intermittent signal) |

On which engines does p0340 pop up more often?

According to the observations of service workshop specialists, failure of the air flow control valve occurs more often on 16-valve engines. But engines with 8 valves also suffer from error P0340, especially after installing gas equipment (LPG). Moreover, the malfunction is repeated regularly, so the technicians have to adjust the gas equipment to the optimal fuel supply mode again and again. As a result, such cars have chronic problems with engine starting and loss of power.

Recommended Tools to Troubleshoot P0340

- Reading error codes and engine parameters - LAUNCH X431.

- Car charger - this or similar.

- To measure wiring use a digital multimeter.

- Electrical contact cleaner.

- Advanced diagnostics - oscilloscope.

Previous post Error P0562 - what it means, symptoms, causes, diagnosis, solution

Next entry Error P0137 - what it means, symptoms, causes, diagnosis, solution

Replacing the DPRV

If there is no wire break, and the power supply is not in place, then most likely the problem is in the DPRV itself. It needs to be changed. To work, you will need a 10 mm socket wrench (head). The sensor is located in a visible place, on the right side of the head. Attached with only 2 bolts. But despite the close and convenient location, getting to the distant bolt is very inconvenient. There have been cases in practice when owners removed the intake manifold and the ramp with injectors. Other owners simply broke the sensor housing and then removed the bolt. In general, the process of replacing the DPRV looks like this:

- Disconnect the negative terminal from the battery.

- Disconnect the DPRV plug.

- Unscrew the 2 sensor mounting bolts.

- Install a new DPRV.

- Connect the power plug.

- Place the negative terminal on the battery.

There is no need to start the car right away. First, turn the ignition on and off 2-3 times. Let the ECU see the working sensor. Then you can start the car and check the quality of the engine. If the Check Engine icon is still on, you need to connect the controller and erase error P0340.

Diagnosis and problem solving

First of all, you need to read all stored error codes using an OBD-II scanner. If there are no other faults, proceed to solving the problem.

It is necessary to check the wires, connectors and other electrical components of the system. If any defects are found, eliminate them. After this, you need to clear the error codes from the PCM memory again and recheck the system.

If the error code appears again, check the battery charge and also inspect the starter motor. Troubleshoot, then clear the PCM memory again and check the system to see if P0342 appears again.

This procedure must be performed every time after repair work is performed. This will help determine if the problem is resolved.

Check the camshaft sensor itself if you need to replace it. In most cases, these steps will help fix your vehicle's problem.

Replacing the phase sensor on a Lada Kalina with your own hands

First of all, a little about the tools that will be needed to perform this type of repair. Fortunately, here you can get by with just a 10mm wrench. But it is best to use a socket with a crank, or even more conveniently, a ratchet. It will just be quite inconvenient to do this with a regular key.

First, it’s worth showing clearly where all this is located:

So, first you will need to disconnect the power plug, after first squeezing the plastic latch and lifting it up a little:

Then use a ratchet to unscrew the bolt securing the Kalina phase sensor:

And now you can freely remove it by pulling it towards the windshield:

And this is what this part looks like when removed from the car:

After this, we replace the camshaft sensor and put the new one in its original place. There are absolutely no difficulties during the work process.

Its retail price ranges from 250 to 300 rubles, depending on where you buy it. Of course, this part fails quite rarely on Kalina, but still, these instructions will not hurt anyone.

About the so-called phase sensor on Kalina with 8 cells. 1.6 liter engine. Mileage 180 thousand. The engine is in perfect order. The signal indicating a malfunction of this particular sensor came on (the tester did not detect any more problems). First, CHECK went out after 10-15-20 minutes. drive. Then this time extended to half an hour, an hour. But still - it went out. Now it doesn't go out at all. I've been driving like this for about two to three months. I just did the diagnostics yesterday. Why ? The car has moved! The dynamics have clearly improved in all (.) modes. Fuel consumption decreased from 8.3 to 8.0 liters. The driving mode is standard and does not change from year to year. It is clear that it is now closer to summer, and consumption should decrease. But according to the physics of the matter, if the dynamics can improve, it is really due to an increase in fuel consumption. Reference: the average (multi-month) consumption has never fallen below 8 liters. What kind of standby modes are these that, in fact, seem to be better than the standard one? A friend, an excellent motor mechanic, albeit on marine diesel engines, suggested that due to the lack of afterburning (or whatever) exhaust in the cat. neutralizer - because the standard one has fallen apart, and naturally there is an empty collector in its place - the engine is well fed, everything is good, and everything that it doesn’t need goes straight into the atmosphere, without any extra hassle. Diagnostics does not show a malfunction of the lambda probe. He is the only one in the state, naturally on site. Straight up, miracles. Or would you say, replace this sensor? Should I go even better? But I repeat, the driving mode is absolutely standard and less than 8 liters. Over the 10 years of operation, the display showed very rarely, and not for long.

DPRV error. Incorrect timing

This is one of the most common problems that leads to errors in the camshaft sensor.

As I wrote above, the engine control unit monitors the synchronization of the DPRV and DPKV signals. Therefore, if an error was made when installing the timing belt, then there will be no normal synchronization and the ECU may throw an error based on an incorrect DPRV signal.

And if, along with an incorrect DPRV signal, high pressure in the intake manifold or large negative fuel corrections are detected during diagnostics, then it is imperative to check the timing marks.

You can see how to do this on the page