The introduction of Euro-3 environmental standards required automakers to include self-diagnosis algorithms in engine controls for problems associated with gasoline misfires in the cylinders. One of the reasons for the appearance of error 0330 on the VAZ 2114, indicating a misfire, is the desire of manufacturers to increase the service life of an expensive catalytic converter. The fact is that unburned fuel and oxygen enter the catalyst, where the oxidation process continues, increasing the temperature until the honeycombs can sinter, or the gasoline accumulating in the neutralizer at one point explodes and destroys the catalyst. From the article, readers will learn what problems in the car lead to fuel not burning in the cylinders and error code 0330 appearing on the ECU display, as well as what measures should be taken to resolve the problems.

Car self-diagnosis

- First you need to sit in the driver's seat and hold down the odometer button on the speedometer.

- Then insert the key into the ignition and set it to the first position.

- After turning the key, you must release the pressed button. This will cause the needles on the speedometer, tachometer and other gauges to move quickly.

- Then you need to press the odometer key again and release it. An inscription with the firmware version will appear on the device.

- After the third press of the odometer button, the VAZ 2114 error codes will start to light up on the display.

How to reset errors yourself

After self-diagnosis of errors and elimination of their causes on a carburetor or injection engine, a malfunction message may remain on the standard panel. If the problem has been deleted, this means that the code combination remains in memory. We'll look at the description of the faults below, and now we'll tell you how to remove the code from memory. To remove it after testing the device, when VAZ 2114 errors appear, the codes themselves must be written down. After this, the daily mileage reset button is pressed again, this will clear the fault from the control unit’s memory.

Resetting the "Check Engine" error

It often happens that the instrument panel 2114 8 or 16 valves displays a check error - engine malfunction, the orange icon is on. Self-diagnosis does not always allow you to accurately check and determine how to fix such a problem. To fix the problem and find a solution, you should perform more detailed diagnostics of the car using a computer and additional equipment. Perhaps, during diagnostics, an unknown error indicates a malfunction in the microprocessor, on-board network or sensors. After the problem is fixed, the receipt may remain.

The "Check Engine" indicator indicates a problem with the engine.

How to reset the fault code:

- First, turn on the ignition; you do not need to start the car engine.

- Then open the hood. Use a wrench to loosen the bolt on the negative terminal of the battery.

- Wait about one minute, after which the battery terminal must be replaced.

- Close the hood and turn off the ignition.

- After that, turn it on again and start the car engine. If the check remains, it should go out on its own after some time. If the instructions given did not work and the solution did not help, then you need to look for the cause of the problem and fix it.

Troubleshooting

Usually, with P0300 codes on the dashboard, drivers go to car service centers. Our specialists have all the necessary diagnostic and repair equipment to quickly identify the problem and fix it. If the car is equipped with modern “electronic brains”, then identifying the exact location of the problem will not be difficult using the latest devices. The autoscanner connects to the diagnostic connector of the computer and immediately reads all errors in the computer memory.

But if the car has been in operation for over 10 years and no longer corresponds to modern ideas about the operation of an on-board computer, you will have to look for the root cause and eliminate the error at random. Typically, car service specialists begin searching for problems with the ignition system, smoothly switching to adjacent components.

If you have experience working with cars and electronic systems, you can eliminate errors yourself.

Step one

The first step is to check the ignition module itself (that is, the coil and high-voltage wires). Most often, it is because of broken wiring insulation or because the coil is heavily oiled that ignition problems arise. The normal resistance of the wires in the ignition system is 4-10 ohms. There is only one way to identify problems in individual coil units: swap them with the working elements.

All elements of the ignition system must be inspected for wear. It is quite possible that due to natural wear, all the problems with misfires in the cylinders arose.

It is necessary to understand that the work is carried out directly in a system that has high voltage. Therefore, compliance with all safety regulations is necessary!

Step two

After diagnosing the system, they usually move on to spark plugs. The following factors can affect the correct operation of each spark plug:

These factors should be taken into account when checking spark plugs. When measuring compression, low or absent compression indicates a low proportion of compression and, accordingly, problems with ignition of the air-fuel mixture. If spark plugs have been used within the last 30,000 kilometers, they must be replaced with new ones.

It wouldn’t hurt to check the condition of the valves.

Step three

If the problem has not been solved after diagnosing the ignition system and spark plugs, you need to carefully check the operation of the injectors. However, this cannot be done without a stand. Only a service center can identify clogged fuel injectors and clean them.

Step four

If error code p0300 is still displayed on the dashboard, then you will need to check the operation of the fuel filter, pump, and valves. In addition, it won’t hurt to change the fuel in the gas tank - due to low-quality fuel, deviations in the operation of the engine’s dosing systems are possible.

It is often these mechanisms, not directly related to the ignition system, that cause problems in the operation of the cylinders.

Meaning and interpretation of error codes

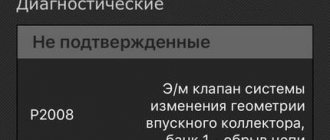

To read the faults, first consider the list with a table of UEr errors that self-diagnosis produces (the author of the video is Ivan Vasilyevich).

| Number | Description |

| 1 | Problems with the functioning of the microprocessor. |

| 2 | Self-diagnosis of the VAZ 2114 detected problems with the electrical wiring of the fuel level indicator controller. The signal level coming from the sensor may be too high or low. It is necessary to test the controller and check the wiring. |

| 4 | Increased voltage in the on-board network. |

| 8 | Low voltage. What to do: in this and in the previous case, the battery and generator must be checked. |

| 12 | There is a problem with the diagnostic indicator circuit on the instrument panel. |

| 13 | The control unit cannot detect the signal coming from the oxygen controller. |

| 14 | An increased signal is received from the refrigerant temperature controller. |

| 15 | The problem is in the operation of the coolant temperature sensor (coolant temperature sensor) - the on-board computer records a reduced signal level. |

| 16 | There is increased voltage in the car wiring. |

| 17 | Reduced voltage in wiring. |

| 19 | Problems have been reported in the operation of the crankshaft position sensor (CPS). An incorrect signal is sent to the control unit. |

| 21 | Problems with the operation of the TPS controller (throttle position sensor). There may be problems with the throttle valve. Check the connection circuit and sensor. |

| 22 | A reduced signal is sent from the TPS. |

| 23 | The intake air temperature controller gives an increased signal. |

| 24 | There are problems with the speed controller. Its failure can be diagnosed by a non-working speedometer. |

| 25 | Reduced signal from the incoming air temperature controller. |

| 27,28 | Incorrect signal coming from the CO sensor. |

| 33,34 | Malfunctions of the mass air flow sensor (mass air flow sensor). Check the flow meter connection circuit and its functionality. |

| 35 | The ECU has detected a deviation in the idle speed values. The sensor may be faulty. |

| 41 | Incorrect pulse coming from the phase controller. |

| 42 | Problems with the electronic ignition wiring. |

| 43 | An incorrect pulse is supplied from the detonation controller. |

| 44,45 | Problems with the composition of the combustible mixture. It can be depleted or over-enriched. |

| 49 | Check for vacuum loss. |

| 51,52 | Problems in the functioning of the PROM or RAM. |

| 53 | There is no CO controller pulse. Open circuit or sensor failure. |

| 54 | No impulse is received from the octane corrector controller. |

| 55 | When the load on the power unit is reduced, the ECU detects depletion. |

| 61 | Problems with the oxygen controller. |

These codes can add up; if you see the number 6, this may indicate errors 2 and 4, or if the number 9 is displayed, errors 1 and 8.

In order to immediately read and decipher problems when diagnosing, it is advisable to download and always carry with you a printout with a description. When diagnosing using a computer, codes on engine 21124 may differ depending on the car model. To read the codes, you need to know how they are supposed to be deciphered. Errors must be reset after they have been deleted (the video was filmed and published by the KV Avtoservis channel).

| Number | Decoding |

| p0102, p0103 | An incorrect pulse is supplied from the mass air flow sensor controller. This means you need to check the wiring. |

| p0112, p0113 | 112 or 113 - the incoming air temperature sensor needs to be replaced. |

| p0115-p0118 | Errors from 0115 to 0118 - the antifreeze controller sends an incorrect impulse. There may be problems with the wiring or the sensor itself. |

| p0122, p0123 | TPDZ. The controller is sending an incorrect signal. If the wiring is damaged, interference may occur. |

| p0130, p0131 | The lambda probe requires diagnostics and replacement. |

| p0135-p0138 | Error 0135 and higher - the lambda probe heating regulator needs to be replaced. |

| p0030 | The ECU reports problems in the electrical circuit in the area from the lambda probe heater to the converter. If error p0030 occurs, you need to test the electrical circuit and the sensors themselves. |

| p0036 | P0036 - a break in the wiring of the heating device DK-2 was detected. |

| p0300, p0302 | When codes 300 and 302 appear, the ECU reports a misfire. |

| p0301 | Gaps were detected in the cylinders of the power unit. Compression needs to be checked. |

| p0325 | The knock sensor is not working correctly. In particular, we are talking about a break in the connection wiring. |

| p0335, p0336 | P0036 error VAZ 2114 or 10335 - the DPKV has failed or its connection circuit is damaged. If the wiring is intact, then the sensor is replaced. |

| p0340 | Phase sensor malfunction. |

| p0341 | Error VAZ 2114 0341 means a problem with the camshaft controller. |

| p0342, p0343 | Problems with the phase controller. With such an error, detonation of the car engine is possible. Most likely, only replacement will solve the problem. |

| p0346 | P0346 VAZ error - also a problem with the phase regulator. |

| p0363 | P0363 - misfire of the combustible mixture was detected. In cylinders that refuse to work, the fuel supply is cut off. |

| p0422 | Failure to operate the neutralizing device. |

| p0443, p0444, p0445 | Malfunctions 0443, p0444 and 0445 - adsorber regulator, purge is not carried out. |

| p0480 | The engine cooling fan device has failed. The power unit may overheat if it is not replaced in a timely manner. Before replacing, you need to check the connection contacts to the wiring. |

| p0501-p0504 | Error 0501 VAZ 2114 and error code 0504 - the speed controller refuses to work. The device needs to be replaced. |

| p0505, p0506, p0507 | The idle speed sensor does not work or does not work correctly. Its failure can lead to floating idle speed. Possible engine tripping. The controller itself is tested and the wiring is checked. |

| p0607 | The knock controller operates intermittently. |

| p1135 | Error 1135 VAZ 2114 - you need to test the oxygen controller. |

| p6060 | Processor failure. If the fault remains after resetting the code, then the controller must be replaced. |

| p2020 | It is necessary to test the intake flap position sensor. |

| p1617 | Error 1617 - Rough road controller, wiring damage. |

| p1513 | There is a short circuit in the wiring of the idle speed sensor. It is necessary to test the electrical circuit and check the contacts. |

| p1602 | Failures in the voltage supply to the vehicle's electrical network are detected. |

| p0560 | Incorrect voltage level in the on-board network. This parameter can be overestimated or underestimated. The car battery, as well as the generator unit, are subject to testing. |

| p1514, p0511 | The appearance of these errors indicates a problem with a break or short circuit in the IAC (idle speed regulator) wiring. First of all, diagnose the sensor contacts, and then test the circuit, if possible. The sensor itself may also be damaged. |

| p1303 | P1303 - A detected misfire of the air-fuel mixture in the third cylinder is reported. The malfunction must be corrected as quickly as possible, since it can be critical for the neutralizer. |

| p1578 | Throttle valve malfunction. Literally, the problem stands for “zero adaptation parameter is outside the permissible value.” There are several options to solve the problem. The first thing you need to do is clean the throttle valve. If this does not help, then the throttle is adapted. To do this, you need to activate the ignition, and then start the engine after 40 seconds. Alternatively, you can test and tighten the contact terminals on the throttle. |

| p1621 | Malfunction of the RAM, memory problems in the control unit. Detailed testing of the computer is required. |

| p0650 | Problems in the control circuit of the on-board computer error code indicator State. |

| p2135 | P2135 - malfunction of the throttle assembly. If replacing the sensor and cleaning the damper did not help, then the problem may have to be solved by flashing the on-board computer. |

| p2187 | Lean mixture in internal combustion engine cylinders. You need to do a detailed diagnosis of the problem. |

What does error P0030 mean?

Error P0030 occurs in cases where the ECM detects an incorrect formation of the air-fuel mixture or an open circuit of the lambda heater 1 (bank 1) to the converter.

Conditions for fixing error P0030

This error is recorded in the ECU memory only under the following conditions:

- The motor is running.

- The self-diagnosis system detected a lack of reference voltage in the electrical circuit of the oxygen sensor heater.

- This malfunction occurs during 2 drive cycles (sequence: ignition off - ignition on - engine starts - driving, stopping - ignition off).

- On the HO2S heater, the resistance is less than 3 ohms or greater than 35 ohms.

- The temperature of the catalytic converter is above 300°C.

The conditions for recording an error with code p0030 are relevant for almost all cars where two oxygen sensors are installed (control and diagnostic). In particular, it can be found on: VAZ, Ford, Hyundai, Kia, VW, Peugeot, Chevrolet, Subaru, Skoda, Mazda, Citroen and BMW.

Diagnostics using special equipment

The diagnostic process using special equipment consists of checking the car using a laptop. To connect to the diagnostic connector you will need a cable with an adapter. Using this cable, we connect the computer to the connector via USB output. For testing you will also need software; the power of the computer used is not important. There are many versions of different testing programs on the Internet.

Diagnostics is performed as follows:

- It is recommended to inspect the vehicle before starting the inspection. Check the volume of consumables - engine oil, brake fluid, coolant.

- Find the diagnostic connector and connect your laptop to it. If you have a special scanner, then that's even better. But since finding a scanner is not so easy, and buying one is not cheap, you can use a laptop. Before testing can begin, the ignition must be activated. There is no need to start the power unit.

- After connection, the testing utility starts. The software interface may vary. When you launch the software, graphs or a list of parameters with numbers may appear. This information will allow you to draw conclusions about the operation of the power unit.

- The scan starts. Fault codes will appear on the laptop screen. To decrypt, use the information provided in this article. We could not describe all the codes, but we deciphered those that occur most often. Usually, when downloading a program to a computer, users are provided with a separate file describing the faults.

- After decryption, the problem is repaired.

How to find a fault

Checking the positive contact of the oxygen sensor heater

First of all, it is worth checking the voltage in the connecting block of the first lambda and the presence of oxides; it happens that after cleaning the contact with a special product, the problem goes away. It is also worth checking the performance of the sensor itself by measuring the resistance.

To check the lambda probe wire, you need to disconnect two parts of the connecting block. We do not touch the part that goes down to the “female” sensor, but take measurements on the “male” block, the wires of which lead to the ECU.

With the ignition on, use a multimeter to check what voltage is supplied through the wires from the computer to the sensor heating element. To do this, select the voltage measurement mode of 20 V on the device and take readings on the contacts one by one. We attach the black probe to ground to the body, and connect the red probe to the upper right contact (if the block is not twisted, this will be the positive contact of the sensor heater). It should show a little more than 12 V. The diagonally opposite, lower left contact also goes to the heater and it should show a voltage of no more than 3.27 V.

When connected to the upper left contact, the multimeter will show a very small value - 0.02 V. After this, connect the probe to the opposite, lower right contact - there the voltage should be about 0.45 V. This is the contact of the oxygen sensor, which analyzes the level of oxygen in the exhaust gases and transmits the reference voltage directly to the ECU. After this, the system adjusts the fuel-air mixture based on the data received.

The oxygen sensor reference voltage should always be checked with the engine warm!

You can also check the male block by selecting the ringing mode on the multimeter. If all contacts ring, then the wire is in normal condition, and the problem most likely lies in the oxygen sensor itself.

To check the lambda probe itself, select the resistance measurement mode of 200 Ohms on the multimeter. We connect the red probe to the upper right contact, and the black one to the lower left , both go to the lambda heater (on most cars these wires are white). Normally, the resistance of the working sensor should be 3.3-3.5 Ohms. More details about checking the lambda probe can be found using the example of Ford Mondeo 1 here.

Decoding the error codes of the ECU (on-board computer) of the VAZ of the tenth family

| If the check engine light comes on or problems are noticed in the operation of the car’s systems, then you can find out the cause as quickly as possible using the on-board computer, or high-quality diagnostics of the car at a service station. The article provides explanations of error codes. |

Error Interpretation of the error code: 0102 Low signal level of the mass air flow sensor 0103 High signal level of the mass air flow sensor 0112 Low level of the intake air temperature sensor 0113 High level of the intake air temperature sensor 0115 Incorrect signal of the coolant temperature sensor 0116 Incorrect signal of the coolant temperature sensor 0117 Low level of the coolant temperature sensor fluid0118 Coolant temperature sensor signal high0122 Throttle position sensor signal low0123 Throttle position sensor signal high0130 Oxygen sensor signal incorrect 10131 Oxygen sensor signal low 10132 Crankshaft sensor signal high 10133 Oxygen sensor slow response 10134 Oxygen sensor signal missing 10135 Oxygen sensor heater fault 10136 Oxygen sensor ground short 20137 Oxygen sensor signal low 20138 Oxygen sensor signal high 20140 Oxygen sensor open 20141 Oxygen sensor heater fault 20171 Composition too lean0172 Composition too rich0201 Injector control circuit open 10202 Control circuit open injector 20203 Open circuit injector control 30204 Open injector control circuit 40261 Short to ground in the injector circuit 10264 Short to ground in the injector circuit 20267 Short to ground in the injector circuit 30270 Short to ground in the injector circuit 40262 Short to +12V in the injector circuit 10265 Short to +12V injector circuit 20268 Short to +12V injector circuit 30271 Short to +12V injector circuit 40300 Many misfires 0301 Misfire in cylinder 1 0302 Misfire in cylinder 2 0303 Misfire in cylinder 3 0304 Misfire in cylinder 4 0325 Open circuit of knock sensor 0327 Low sensor signal level detonation 0328 High signal level of the knock sensor 0335 Incorrect sensor signal crankshaft position sensor signal error0340 Phase sensor error0342 Phase sensor signal low0343 Phase sensor signal high0422 Low converter efficiency0443 Canister purge valve circuit malfunction0444 Canister purge valve shorted or broken0445 Canister purge valve short to ground04 80 Cooling Fan Circuit Malfunction 10500 Speed Sensor Signal Invalid 0501 Invalid speed sensor signal0503 Interruption of the speed sensor signal0505 Idle speed controller error0506 Low idle speed0507 High idle speed0560 Incorrect on-board network voltage0562 Low on-board network voltage0563 High on-board network voltage0601 ROM error0603 External RAM error0604 Internal RAM error060 7 Knock channel malfunction 1102 Oxygen sensor heater resistance low 1115 Faulty heating circuit O2 Sensor1123 Idle Rich1124 Idle Lean1127 Part Load Rich1128 Part Load Lean1135 O2 Sensor Heater Circuit 1 open, short1136 Light Load Rich1137 Light Load Lean1140 Measured load is different from calculation1171 Low level of CO potentiometer1172 High level of CO potentiometer1386 Detonation channel test error1410 Control circuit of the canister purge valve short circuit to +12V1425 Control circuit of the canister purge valve short circuit to ground1426 Control circuit of the canister purge valve open1500 Open fuel pump relay control circuit 1501 Short circuit to ground relay control circuit fuel pump 1502 Short circuit to +12V of the fuel pump relay control circuit 1509 Overload of the idle speed regulator control circuit 1513 Idle speed regulator circuit short circuit to ground 1514 Idle speed regulator circuit short circuit to + 12V, open 1541 Fuel pump relay control circuit open 1570 Incorrect APS signal 1600 No connection with APS1602 On-board voltage failure network on ECU1603 Error EEPROM1606 Rough road sensor incorrect signal1616 Rough road sensor low signal1612 Reset error ECU1617 Rough road sensor high signal1620 EPROM error1621 RAM error1622 EPROM error1640 Test error EEPROM1689 Incorrect error codes 0337 Crankshaft position sensor, short to ground 0338 Crankshaft position sensor, open circuit 0441 Air flow through the valve is incorrect 0481 Cooling fan circuit malfunction 20615 Starter relay circuit open 0616 Starter relay circuit short circuit to ground 0617 Starter relay circuit short circuit to +12V 1141 Oxygen sensor 1 heater malfunction after the neutralizer 230 Fuel pump relay circuit malfunction 263 Injector driver malfunction 1266 Injector driver fault 2269 Injector driver fault 3272 4650 Injector Driver Malfunction CheckEngine Lamp Circuit Malfunction

P0300 - misfire error. Causes, consequences, elimination

Almost every car owner who has some problems during the operation of his car, throughout the entire time, independently eliminates minor breakdowns, or makes the necessary replacements of any parts. But, unfortunately, sometimes the help of a specialist from a car service is necessary, since car enthusiasts do not have enough skills, experience or knowledge in any of the areas regarding the repair of their vehicle. But don’t worry, because our instructions will help you figure it out and do everything yourself.

The error code P0300 indicates an incorrect ignition order, which means random multiple misfires in the cylinders; in English, the diagnostic device will display: “Random cylinder misfire detection system.” If gaps are found in a certain cylinder, then the outermost number P030x will change from 1 to 4 and so on up to 6, or maybe up to 12, it all depends on which specific “pot” the transmission is in. Therefore, error p0300 is the original one from such errors as P0301, P0302, P0303, P0304. They often happen due to the fact that there is no spark, the supply of the fuel mixture is disrupted, or there are problems with the release of exhaust gases.

We will talk in more detail about all the probable causes of misfire and errors p0301, p0302, p0303, p0304, what the consequences are and how to eliminate them.

What causes the P0300 code to appear?

If a misfire occurs in the engine, the level of intoxication of exhaust gases in the exhaust pipe increases, which also leads to an increase in degrees in the catalyst device, because of this it is damaged (the cells will melt, since the degrees are more than 800). On a few cars, to reduce the burnout of the fuel mixture in the catalyst and, of course, the level of toxicity, the ECM detects the frequency of misfires using a crankshaft sensor, a camshaft sensor and, in addition, registers error p0300, indicating this with a check-in lamp. In addition, the unit is able to turn off the injectors of a specific cylinder where leakage was found. It should be noted that drivers of cars such as Lacheti, Matiz, Priora and other VAZs with an injector, as well as Opel, Nissan, and Kia models, are often interested in the appearance of this error.

When does error code P0300 appear?

It is worth noting that the P0300 error code is recorded by the controlled unit only when some cylinders have misfires at the same time, since a misfire in one of them can only be recorded after 2 repetitions at once; the frequency of rotational movements of the CV is important here. At idle, the error will be entered into memory after three and a half minutes of engine activity, and at revs of more than two thousand km - a little more than 1 minute. The extreme rate of DTC in the ECM memory is more than 3.25 percent, missed flashes per thousand revolutions. When misfires are found only in a specific cylinder, then it is not error p0300 that is generated, but another one, with the order number of the combustion chamber of the internal combustion engine.

Method for determining cylinder misfires

It will be easy to find out that the yellow check lamp is on due to a disturbed flammability order, since, due to the ignition being started, the engine begins to “sausage” at low speeds, there are jerks and jerks during acceleration, and there is still no traction, and the consumption of the fuel mixture increases.

Error p0300, p0301, p0302, p0303 and p0304 causes of occurrence

Unfortunately, the diagnostic device is not able to find a specific cause of the malfunction and with regard to misfire in the engine cylinder, but more possible breakdowns occur in 2 cases - either there is no fuel, or there is nothing to burn it with. But, do not rush to experience the joy of quickly finding the cause of error p0300, as this may also become:

Cylinder misfires. Method for diagnosing the cause.

The main causes of error P0300

3. In the intake and exhaust mechanism:

4. In the controllability electronics system:

Not a common problem of multiple misfires lies in the ignition system

Tips for checking and troubleshooting

First, let's check the ignition wires and ignition coils (module) if the ignition misfires. Often they come with knocked out insulation, torn or with an oily surface. We measure the wiring using a multimeter (good resistance is about 4-10 kOhm), in resistance mode. To check individual ignition coils, you just need to swap places with the exact working cylinder and clear the error again. If the code designation has changed to the license plate of a different cylinder, the coil turns out to be broken. With the ignition module, everything is not so simple; you need to check it with a tester.

All elements of the ignition mechanism must be checked with great care for signs of wear or damage.

Afterwards, we go to the spark plugs - the electrode is damaged, the gap is incorrect or there is oil deposits, a failure occurs or the spark plugs are unstable.

The spark plug insulation should be white, without any yellow marks from spark holes. Having taken out the spark plug to inspect it, we measure the compression in the cylinder. If it is low or absent, this will lead to incomplete compression and will also create problems with the mixture ignition.

Fuel injectors are clogged , which leads to interruptions in the supply of the fuel mixture to the combustion chamber, but, unfortunately, without a stand it will not be possible to quickly check. In this case, we can only recommend adding a fuel mixture with a high octane number and driving the car a little at higher rpm (4-5 thousand rpm).

If the fuel filter has not been changed for a long time or bad gasoline has been used, this often leads to improper operation of the injector. Therefore, you need to remember when you changed the filter and where you filled the fuel mixture.

EGR valve is stuck or there is a leak through the intake manifold gasket - something that also often becomes the reason for detecting random misfires. It is unlikely that you will be able to determine this on your own, so when diagnosing with a computer, you need to pay attention to the indicator of long-term correction of the fuel mixture. It will indicate how much the ECU will compensate for the imbalance in the air/fuel mixture. If this parameter in a certain cylinder differs by ten percent, then this indicates a vacuum leakage and air mass being sucked in.

A good adjustment will not exceed one to three percent or one side. It also happens, but rarely, that the cause of a disrupted ignition order is disrupted gas distribution phases or disrupted exhaust gas outlets; they are controlled by the controlled unit and, in addition to the P030X code designation, there are other errors that relate to the catalyst device, oxygen sensor, camshafts.

See all photo news >>

VAZ error codes - the most common problems and their reflection

Almost all modern cars are equipped with excellent on-board computers that can fully diagnose important systems and technical components of the vehicle. When a breakdown known to the computer occurs, the driver receives on the screen a certain set of numbers and letters, which is called an error code. The first computers installed on domestic cars of the VAZ corporation simply produced general errors, illuminating the Check Engine light even in cases of minor problems. Today, computers are smarter and can accurately describe the problem that has arisen.

Unfortunately, VAZ error codes are far from ideal. Sometimes a problem with the battery or generator is displayed as a serious engine failure. Therefore, you should not immediately pick up a calculator and start calculating the amount of repair costs. First you need to diagnose the problem and get more information about what is happening under the hood of your car. Today we will talk about some specific error codes and discuss the features of various problems.

Basics of error codes on VAZ cars - diagnosable components

Today, cars from domestic manufacturers across the entire model range are equipped with the necessary computer diagnostic systems. But these systems are far from ideal, and even the designers of the plant itself admit this. General sensors are used as the basis for identifying problems; these systems do not provide any specific data in the event of a breakdown.

Demonstration of problems with your car is based on some functions, so the codes cannot show the exact problem. For example, there are several sensors on the engine air supply system. Oxygen and its consumption can indeed indicate problems with the unit, but this is not always accurate. The most serious error codes that you should pay special attention to are the following:

- problems with the on-board electrical network - codes P0562 and P0563 indicate low and high voltage levels, respectively;

- codes P0506 and P0507 indicate incorrect idle speed settings - too low and too high;

- four codes indicate a malfunction in one of the cylinders - P1301, P1302, P1303, P1304;

- also four codes are responsible for malfunctions of the injectors on each cylinder - P0201, P0202, P0203, P0204;

- an extremely important code, after which it is better to stop operation - an indicator of increased engine temperature P0217;

- The P0300 code is often a harbinger of the need for major repairs, because it means random fuel misfires.

Most codes are related to the operation of sensors, because this is the easiest way to build a car diagnostic system. Nevertheless, this approach has proven to be effective for owners of domestic cars, because now you can know for sure that some kind of problem has occurred with the car. It no longer makes sense to fix the problem yourself; the car system has become much more complicated.

Therefore, after receiving information about a malfunction, it is best to visit a car service center and carry out diagnostics. Service stations never rely solely on on-board computer data. Often, an independent check of all systems is carried out and the presence of problems is determined by the behavior of the car, the owner’s testimony and other important criteria.

Causes of errors

It is not enough to identify a problem in a timely manner; it is much more important to understand the reason for its occurrence. Experienced drivers know only a few reasons for these errors. Most often this happens due to interruptions in the spark plugs or when the fuel supply is interrupted. However, these errors can appear for a variety of and sometimes unexpected reasons.

Even the most modern diagnostic device will not be able to identify the original source of the problem. However, at their core, errors p0300, p0301, p0302 pop up in cases where there is either no combustible mixture in the cylinder (nothing to ignite) or there is no possibility of ignition (no spark). Thus, the causes of error p0300 may be hidden in the following systems and components of the car:

Also, the possibility of a malfunction of one or more cylinders cannot be ruled out. If during operation the gap between the piston and the cylinder decreases, this will inevitably lead to a lack of ignition. In rare cases, problems may arise due to mechanical damage to the power unit itself.

However, if an error code is displayed on the instrument panel indicating the exact cylinder number (for example, p0302 or p0306), then we can talk about problems in the ignition system.

How does a mechanic diagnose a P0030 code?

First, the mechanic reads all the stored data and error codes using an OBD-II scanner. He will then clear the error codes from the computer's memory and test drive the vehicle to see if P0030 appears again. If the error code appears again, the mechanic will visually inspect the heated oxygen sensor for damage, as well as check the ground and measure the voltage at the sensor.

The mechanic will then carefully check any associated electrical wires that may have been damaged due to excessive heat due to high exhaust temperatures.

Diagnosis and problem solving

Trouble P0030 can only be caused by the oxygen sensor heater circuit or the oxygen sensor itself. Diagnostics usually begins with checking the sensor wiring. Typically the heated oxygen sensor comes with four wires.

Two wires go directly to the heater circuit, and the other two are for powering and grounding the sensor. You may need a wiring diagram for your car. To be sure you are testing the correct set of wires.

Wiring check

Test the heater circuit using a digital multimeter or volt-ohmmeter. Consult your vehicle's wiring diagram to determine the exact pinout of the ground connector.

The reading should be close to the battery voltage. If this is not the case, then there is most likely a problem with the sensor's power supply.

It is also necessary to check the grounding. To do this, you need to connect the positive terminal of the battery to the red wire of the multimeter. And the black wire to ground to check the grounding of the circuit. The result should be 12V, if not then this indicates a grounding problem at the sensor.

Sensor check

If the power and ground are ok, then the next option is to check the sensor heating element. To determine if it has an open circuit or high resistance.

Set the volt-ohm meter to Ohm scale, check the resistance of the heater circuit using the electrical diagram as a reference.

Make sure you have disconnected the O₂ sensor. The heater circuit inside the sensor should have little resistance. Exceeding the limit value indicates a break in the heating part. Therefore, the oxygen sensor will have to be replaced.

On which cars is this problem most common?

The problem with code P0030 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Acura

- Audi (Audi a4, Audi q5)

- BMW (BMW X5, E90)

- Chery (Chery Tiggo, Fora)

- Chevrolet (Chevrolet Aveo, Captiva, Cruz, Lacetti, Malibu, Trailblazer)

- Citroen (Citroen Berlingo)

- Daewoo (Daewoo Matiz)

- Dodge

- Ford (Ford Mondeo, Fiesta, Focus, Fusion)

- Geely

- Honda

- Hyundai (Hyundai Solaris, Elantra)

- Kia (Kia Picanto, Rio, Sid, Spectra, Sportage, Cerato)

- Mazda (Mazda 3, Mazda 6, Mazda cx7)

- Mercedes

- Nissan (Nissan Pathfinder)

- Opel (Opel Antara, Astra, Vectra, Corsa)

- Peugeot (Peugeot 308, Partner)

- Porsche (Porsche Cayenne)

- Saturn

- Skoda (Skoda Octavia, Superb, Fabia)

- Subaru (Subaru Outback, Impreza, Legacy, Forester)

- Suzuki (Suzuki Grand Vitara)

- Toyota

- Volkswagen (Volkswagen Golf, Jetta, Passat, Polo Sedan, Touareg, Tiguan)

- Volvo (Volvo s80, xc90)

- VAZ 2107, 2112, 2113, 2114, 2115

- Lada Granta, Kalina, Niva, Priora

- UAZ Bukhanka, Patriot, 409

With fault code P0030, you can sometimes encounter other errors. The most common ones are: P0031, P0036, P0037, P0050, P0057, P0102, P0130, P0134, P0135, P0141, P0341, P0343, P2101, P2118, P2251, P2626.

3 years ago AutoTime 0

Deciphering the code P0030

P0030 – HO2S Heater Control Circuit Error

What does error code P0030 mean?

For normal operation of a Ford engine, it is necessary that the exhaust gases have an air-to-fuel ratio of 14.7 to 1. It is this parameter that is determined using oxygen sensors (HO2S), which measure the amount of oxygen in the exhaust gases. This information is then sent to the engine control module (ECM) to regulate the fuel supplied to the engine. The error indicates improper operation of the oxygen sensor (lambda probe).

An oxygen sensor heater is necessary for the lambda probe to respond very quickly to changes in parameters. Helps reduce harmful emissions, especially during startup and when the Ford engine is not warmed up.

What Causes Code P0030

If the error code is cleared and reset, but returns after starting the engine, it means that the HO2S sensor is not sending the appropriate signals to the ECM (engine control module).

The cause may be defective wiring, sensor or control unit (rare).

What are the symptoms of code P0030 Ford

The Check Engine light is on.

In the case of a malfunctioning heater circuit, the oxygen sensor will not correctly measure oxygen in the exhaust gases during the first 3-5 minutes of engine operation.

The lack of data from the lambda probe affects the ECM's ability to control the fuel mixture; it will be calculated using fixed parameters (usually overestimated) until the problem is corrected.

How to diagnose error code P0030

Error P0030 Ford is diagnosed by an OBD-II scanner. The mechanic resets the OBD-II error code and then drives the vehicle to see if the error returns. If the error comes on again, you need to check both the power and ground on the sensor, and also make sure that the wiring is intact.

Many lambda probe wiring problems are related to high exhaust gas temperatures.

Common mistakes when diagnosing code P0030

There is no need to immediately think that the oxygen sensor is faulty. Before replacing it, you need to make sure that the wiring and connectors are in good condition. Make sure there is 12 volt power. And only after that change the sensor.

How serious is the error?

If the ECM receives a P0030 error, the Check Engine light on the instrument panel will illuminate. With this error, a Ford car can drive safely, but it is necessary to go for diagnostics as soon as possible to make sure that there are no problems other than increased fuel consumption. If you constantly use a car with such a malfunction, the catalyst may fail in the near future. The engine will run on a super-enriched mixture, the unburned residues of which, when entering the catalyst, disable it.

Additional comments about P0030

Many Ford vehicles with more than 100,000 km on them have immediate problems with oxygen sensors, which usually occur during engine starting or during prolonged use. If the Check Engine light comes on and the vehicle is running normally, the OBD-II system can be reset using a scan tool and the problem may not reoccur. That's why it's important to clear errors and test the car before starting repairs.

Trouble code P0030 indicates that there is a problem with the oxygen sensor heater circuit. In the English version, the description of the problem will be as follows: Oxygen O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1). The problem may be related to both the lambda itself and its connection wire, or even to the control unit or its firmware. To find the real reason, you should carefully analyze the symptoms and check each component in turn.