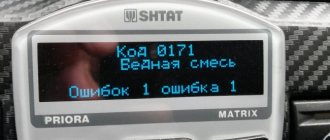

Error Code P0171 occurs when the mixture is too lean, when there is not enough fuel and too much air. This mixture occurs when the engine is taking in too much air from the environment and/or the fuel system is not injecting enough fuel.

This state of the mixture entails misfires, delays in the car's response to the accelerator, jerking during acceleration, idle failures, and unstable engine operation. In engine management systems Euro 2 and higher, the lambda probe controls the quality of the mixture in which there should be 14.7 parts of air per part of fuel. When the permissible range for the increased presence of air, which is 20-30% of the norm, is exceeded, error P0171 .

Causes of error P0171

The most common causes of P0171 are:

- Fuel pressure regulator malfunction

- Damage to the fuel pump

- Fuel filter clogged

- PCM (Powertrain control module) malfunction

- Vacuum leak

- Malfunction of one or more fuel injectors

- Malfunction of one or more oxygen sensors

- Malfunction of the mass air flow sensor

How to find and fix problem areas in a car

At this stage, it is advisable to first conduct a visual inspection of all the above components and devices. It often happens that the problem of this type of error may be associated with a violation of the integrity of the supply wires or loosening of the fastening.

If a visual inspection does not reveal a malfunction, it is necessary to conduct a comprehensive check of the functionality of each of the presented devices.

First, let's evaluate the condition of the flow meter . After dismantling it, you should pay attention to the presence of deposits and contamination. The sensor should be washed using special washes, which are available in a wide range of auto stores.

If there is no spray nearby, you can wash the flow meter with alcohol or a solution of gasoline and kerosene in equal parts. It is worth noting that this sensor cannot be blown out with compressed air using a compressor. Such a procedure can simply disable it.

This is interesting: What is a diesel intercooler: principle of operation and causes of device failure

If the warning lamp still indicates an error, you need to check the functionality of another component. Next up is the EGR valve . An external inspection of this device includes checking the tightness of the underwater pipes of the valve and its body for mechanical damage.

In order to ensure that the valve is working properly, you must adhere to the following sequence of actions:

- Remove the valve underwater pipes;

- Blow out the valve cavity with compressed air;

- Remove underwater contacts;

- Apply current to the valve from the battery;

- Purge the valve again.

If the valve is in good working order, at the time of the first purge, the valve should not be purged, but the second time, vice versa.

At the next stage, we will evaluate the condition of the fuel pump . First of all, you need to make sure whether it shows signs of life at all, which is expressed in the characteristic “rumbling”. The overwhelming majority of modern cars are equipped with submersible fuel pumps.

The operating pressure of such pumps ranges from 3 to 4.5 bar. Therefore, it is enough to connect a pressure gauge to the fuel line and see for yourself that it is working.

It's time to look at the injectors . Of course, visual control of their condition is exclusively subjective, but, nevertheless, it does not hurt to look at them, especially if you only had to remember about their existence just now. If the working part of the nozzle with calibrated holes is covered with soot, then there is no need to talk about its effective operation.

the fuel pressure regulator is working properly . This procedure will not take much time if you have a multimeter at hand.

The verification algorithm looks like this:

- remove the chip from the pressure regulator;

- We attach the negative wire to the “-” terminal of the battery;

- positive wire to the signal terminal of the regulator (the one in the middle);

- start the engine;

- gradually increase the speed up to the maximum value.

When the engine is running at idle, a working regulator consumes about 1.5 V. As the speed increases, the operating voltage should increase to 4.8 - 5 V. If the multimeter needle remains stationary, despite the increase in engine speed, the regulator must be replaced .

Checking the sensors

The complete verification of the presented error includes checking all kinds of sensors. First on the list is the mass air flow sensor, the so-called air meter. One of the testing methods is to simply turn off this sensor and evaluate the dynamic characteristics of the car without its participation. If improvements are evident, it is highly likely that it is malfunctioning.

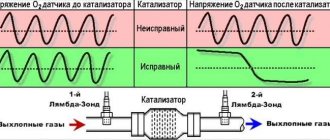

When this error appears, it is advisable to check the oxygen metering sensor, the so-called lambda probe. If an external inspection did not reveal obvious deposits on the surface of the sensor, a more thorough check should be started. To do this, we will use a tester in voltmeter mode.

So, 4 wires go to the sensor. One of them (black), the so-called “+ signal,” is connected to the + of the voltmeter, and the negative terminal to the mass end of the sensor.

If the sensor is working properly, the voltmeter reading on a cold engine should be about 0.2 V. On one warmed up to operating temperature - up to 0.3 - 0.9 V. In this case, it is important to measure the signal voltage of the sensor.

On the subject: What is a Thermostat: principle of operation, testing and troubleshooting

As soon as the engine starts, a working sensor will operate in open-loop mode, and the voltage will be stable around 0.1 - 0.2 V. As the engine warms up, the sensor will switch to closed-loop mode, with the voltage varying from 0. 2 to 1 V up to 10 times per second.

If no oscillations are observed, which indicates that the sensor does not go into closed-loop mode, we can assume that the lambda probe has given up its life.

Checking the fuel system

Checking the fuel system involves diagnosing all elements of the fuel equipment and fuel lines.

An inspection of the vehicle's power system in the event of this error involves checking the functionality of the following components:

- submersible fuel pump;

- fuel pressure regulator;

- nozzles;

- fuel lines.

It is important to remember that a condition for the efficient operation of the power system of any injection engine is the presence of a given operating fuel pressure. This factor should serve as a starting point in identifying all kinds of malfunctions in the vehicle’s fuel system.

How does a mechanic diagnose a P0171 code?

- First, the mechanic will check the engine for vacuum leaks using a vacuum gauge. If there is a leak, a hissing sound will be heard. It can usually be heard clearly when the engine is turned off.

- He will then check the fuel pressure sensor and mass air flow sensor using the fuel pressure gauge.

- To maintain the correct air-fuel mixture ratio, the vacuum pressure and fuel pressure in the engine must correspond to the values specified in the manufacturer's specifications.

- If no fault is found after performing the above checks, the problem is most likely a fault with one or more of the oxygen sensors.

- The mechanic will check the operation of the oxygen sensors following the procedure set forth by the vehicle manufacturer.

- If no problem is found, the mechanic will check the PCM (Powertrain control module).

How does a car behave on a lean mixture?

When operating on a lean mixture, the car engine idles unevenly, overheats due to the lower combustion rate of such a mixture, and popping noises are heard in the intake pipe. The car itself can slow down and slowly gain momentum under load.

When the mixture is lean, the temperature of the engine increases, which leads to overheating, burnout of the valves and piston.

During long-term operation with a lean mixture, excessive fuel consumption occurs due to a slow increase in speed, as a result of which you have to operate the car in low gears. A lean mixture appears as a result of an imbalance in the supply of air and fuel for mixing with a large amount of air.

Common mistakes when diagnosing code P0171

The most common mistake made when diagnosing a P0171 code is that mechanics do not consult the vehicle manufacturer's technical service bulletin for common troubleshooting tips before diagnosing the error.

Although recommendations may not be provided for all error codes, it is important to review the Technical Service Bulletin as in some cases this will save time and make it easier to diagnose and resolve the error.

Why does error P0171 occur?

What is the primary source of the presented error? It is not possible to answer this question unambiguously. The fact is that this error can be caused by a variety of malfunctions in the operation of various related devices.

This encoding allows us to conclude that the mixture entering the car engine cylinders is poor. The power system of a working passenger car provides the optimal proportion of the air-fuel mixture, where 1 part gasoline accounts for 14 parts air. In our case, there is a deviation from the specified parameters.

Causes of excess air

If, after carrying out this work, instability is also observed in the operation of the system, pay attention to possible places where excess air occurs, since it also affects the leanness of the mixture and the main reasons lie in the following:

- Presence of dirt or marks on the mass air flow sensor.

And in order to eliminate the above reasons, it is necessary to conduct a thorough diagnosis.

Troubleshooting

Mass air flow sensor - the air flow sensor can become clogged due to natural reasons, as well as from vapors that come from the throttle valve while the car is not running. And then, over time, accumulating in a thick layer on the thin thread of the sensor, forcing it to send inaccurate data to the ECU, which in turn negatively affects the parameters of air flow and flow into the system.

When diagnosing its malfunction, it is best not to rush into purchasing, since it costs a lot of money, but it is best to check its performance on a known working device. And when it is established that the reason lies in it, then you can try to clean it, or then replace it with a new one.

Vacuum leak

Vacuum leak - these words mean any form of air leaks, i.e. suction into the system, primarily through the manifold gasket or hoses.

The vacuum pump and return hose may cause

Pay attention to the condition of the pipe leading from the air filter to the throttle valve, and the hoses that go to the crankcase ventilation. There should be no visible damage to them, as well as large cracks through which excess air could enter.

In addition to all of the above, you can check the engine oil dipstick and the oil filler cap on the neck, because if these connections are not completely closed, they can cause the appearance of that same excess air.

Let's sum it up

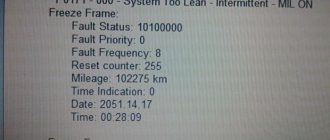

Taking into account the above information, it becomes clear that error P0171 can occur either separately or in combination with other errors recorded in the ECU memory. In any case, you first need computer diagnostics of the engine and decoding of all errors.

If no causes are found or the P0171 error is the only one on the list of problems after diagnosis, then it is necessary to check the systems and elements discussed in this article.

We also recommend reading the article on how to clean injection nozzles. In this article, you will learn about the available methods for cleaning injectors, as well as what you need to consider when choosing a cleaning method.

As a summary, we note that a lean mixture is dangerous for a car engine, that is, the problem cannot be ignored. Otherwise, further operation of the vehicle will lead to the fact that the power unit itself, as well as other elements and systems, may require repair.

To avoid possible consequences, it is necessary to regularly clean and check the EGR system (if equipped), as well as read and decipher errors in the ECU memory at certain intervals (even if the “check” is not lit). This approach will make it possible to timely identify failures and malfunctions at the initial stage, which eliminates prolonged operation of the internal combustion engine on a lean mixture.

How to diagnose the fuel system?

The most common cause of breakdown is the presence of air leaks. First, check the tightness of the system. If the seal is broken, the damaged part is replaced. Next, make sure the fuel system is working properly. You need to check the pressure in the fuel supply system and check whether the injectors are clogged. If the pressure is insufficient, you need to disassemble and check the fuel pump.

When idling, the pressure in the fuel rail should be from 2.8 to 3.2 kgf/cm²,

Having found out the reasons for the lean mixture on the VAZ 2114, you need to move on to eliminating them.

Symptoms of malfunction

The main driver symptom of P0171 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

The severity of the P0171 code is higher than average, so it is recommended to fix the problem as soon as possible. Most likely, with this problem, you will be able to continue your trip, but fuel consumption will increase. And due to poor fuel combustion, problems with the catalyst are possible in the future.

Search for air leaks from a smoke generator

For a smoke generator from a cigarette we will need:

- empty 1.5-2 liter bottle

- bottom from the same bottle

- knife

- drill with 5-6mm drill bit

- a couple of cigarettes

- old bicycle camera

- hose from the brake booster (or similar).

- pump or compressor

I explain in detail how to assemble all this into a finished structure in the video below. We connect a ready-made smoke generator instead of a vacuum amplifier and begin to pump smoke into the intake manifold, simultaneously checking all the connections and hoses to see if smoke is coming out of them. The appearance of smoke indicates a leaky connection and, accordingly, a possible air leak.

Also, separately from the intake manifold, you should check the vacuum brake booster and the adsorber valve. It is quite easy to check the vacuum seal - just disconnect it from the intake manifold, install a plug and see if there are any changes in the operation of the engine. If it starts to work smoothly and well, then the problem is in the vacuum seal - you need to check the hose itself; if it is intact, we buy a new vacuum seal.

The adsorber valve can be checked just as easily - we disconnect the hose from the throttle assembly and blow into it - it should not blow, i.e. the valve should be closed. If it blows, the valve must be replaced.

Diagnosis and problem solving

A dirty MAF sensor can skew air intake measurements and therefore skew fuel injection calculations. Next, check the fuel pressure to make sure it is in the correct range. Excessive pressure, due to a faulty pressure regulator or a compressed line tube, will cause more fuel to be injected than the ECU expected.

Check that the ECT and IAT (inlet air temperature) readings are correct. The ECU can pick up blocked sensors, so it's good to check that the ECT and IAT readings are within the normal range.

For example, if the engine is running for half an hour on a hot day, the ECT should show a temperature of about 80°C. If it still reads 0°C, the ECU will richen the air/fuel mixture to compensate, resulting in a rich condition.

Reduced fuel pressure

With the engine running, record the fuel pressure, and then stop the engine. Fuel pressure may drop slightly but should remain stable for at least 10 or 15 minutes.

If fuel pressure continues to drop, you may have a leaking fuel injector, which will result in a rich and possibly non-ignitable condition.

Valve blocking

A faulty valve in the cylinder head dumps unburned fuel into the exhaust gas stream. Check and correct this problem before attempting to correct a rich air/fuel mixture error.

Pay attention to other trouble codes that may be present at the same time as P0171. For example, for VVT (variable valve timing) or ignition system.

Traffic fumes

Check the exhaust system for leaks, especially in front of the first O₂ sensor. Damage can be mechanical, in the form of cracks, or caused by corrosion.

The entry of atmospheric air before this sensor can distort the oxygen content measurements. At the same time, the ECU will try to compensate the mixture and add fuel.

Rich fuel assembly: concepts

Thus, the composition of the fuel mixture is determined by the ratio of air to fuel. This ratio depends on the volume of liquid fuel supplied to the cylinders. When acceleration occurs, the liquid fuel is intensively saturated with air mass. When this ratio is disrupted, the air/fuel mixture is either rich or lean.

Preparing the fuel-air mixture is a process for which the car's injector is responsible. The injection system prepares mixtures with different oxygen contents, and this is what provides a variety of operating modes for the internal combustion engine. It is the composition of the fuel mixture that allows the car to sharply increase speed while overtaking or overcome an incline.

A rich mixture is a mixture that contains less air than required and more gasoline than required. The burning rate of the rich mixture is reduced, and therefore it burns out already in the muffler. Sometimes such a mixture is symbolically called high-calorie.

There is a mathematical formula that determines at what ratio of atmospheric air to fuel the fuel mixture will be normal, rich or lean. It is believed that the normal ratio is a mixture of 14.7 kg of air and 1 kg of liquid fuel. If the ratio of 14:1 is increased in favor of the air mixture, the fuel mixture will be lean. And, on the contrary, when the ratio is 14:1 in favor of liquid fuel, the mixture will be rich.

Artificial boosting of engine power is ensured by adjusting the fuel supply when the amount of supplied oxygen increases. The car owner’s desire to save on fuel consumption is achieved by supplying more atmospheric air.

Signs and causes of lean mixture formation

However, it is very easy to diagnose:

- The simplest and most obvious is that the car stalls when moving. And not only when driving uphill, when this can be attributed to an incorrectly selected gear, but when driving on straight, level roads. However, this is only when the mixture is really lean.

- Another situation is when the car jerks while driving. Especially if you are driving not a fully loaded car, but an empty one, on a flat road. Although in this situation it cannot be said unequivocally that a poor air-fuel mixture is an indispensable reason. You may need to check other vehicle systems, such as the exhaust system.

- Another sign is that the car “shoots” when driving. Although more and more often in new cars this is not due to a lean mixture, but to problems in the exhaust system, this symptom is obvious. Especially when unstable exhaust appears not just once in a while, but constantly, since with single pops the situation is the opposite: the mixture is too rich, and the remaining gasoline that is not burned in the engine burns out in the muffler, ignited by a hot pipe.

- The color of the carbon deposits on the spark plugs can also tell a lot about the composition of the mixture. If it is: brown, then everything is fine, there is an optimal amount of air-gasoline in the mixture;

- white, or alternatively light, then there is a lot of air in the mixture and it is poor;

- black candles - excess gasoline that does not burn completely;

If signs of a lean mixture are detected, this diagnosis can be confirmed in several ways:

- If the car is equipped with an on-board computer, the “Check Engine” indicator will light up on the dashboard, and P0171 will appear in the error list.

- By contacting a specialized service station, you can test the operation of the engine using a gas analyzer sensor, which is installed in the exhaust pipe.

- Finally, you can use a simple wired or Bluetooth OBD scanner, which costs only a few dollars on Aliexpress, a smartphone and the appropriate software.

You need to look for the cause of the formation of a lean mixture based on the diagnostic results and errors that appear along with P0171. The standard reasons are:

- Problems with sensors (mass air flow sensor, air pressure sensor, diaphragm pressure sensor, oxygen sensor). Incorrect sensor information usually results in an incorrect fuel/air mixture.

- Problems with the EGR valve. The valve may allow more exhaust gases into the engine than necessary.

- Timing problems. Incorrectly aligned marks or problems with tensioners can also lead to this problem.

- Problems with the fuel supply (faulty fuel pump, clogged fuel filter or injectors).

- Excess air supply through a crack in the hose or a loose connection in the air supply system.