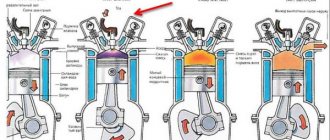

In the combustion chamber of the engine, the energy of the rapidly expanding gases is transferred to the piston, after which the crankshaft is driven through the connecting rods. This element of the CPG is constantly exposed to mechanical, temperature and other loads. The piston experiences the force of gas pressure, heats up significantly from contact with fuel combustion products, and experiences heating as a result of friction against the cylinder walls.

We also recommend reading the article about what a piston in an internal combustion engine is and how it works. From this article you will learn about the design features of the piston.

Being one of the most loaded engine elements, and also taking into account operating conditions, the pistons gradually become covered with soot during the operation of the internal combustion engine. Accelerated carbon formation can also occur if there is any engine malfunction that leads to disturbances in the combustion process of the fuel-air mixture in the cylinders. Next we will talk about what could be the cause of carbon deposits on the pistons, as well as how to remove carbon deposits from the pistons and how to do it.

Principle of operation

In order to perform a procedure such as cleaning a part, you need to understand how it works. In the internal combustion chamber, the gases expand and energy is transferred to the piston. The connecting rods then drive the crankshaft. This block is continuously exposed to temperature, mechanical and other extraneous loads. Experiencing the force of gas pressure, the piston becomes very hot due to contact with substances that are formed from the combustion of fuel.

Due to the increased load on the piston during operation, black carbon deposits gradually form on it. This also happens due to some kind of motor failure. Often such malfunctions can become a factor affecting the disruption of the combustion process of the fuel mixture inside the cylinders.

Engine coking: possible consequences

It is quite obvious that carbon deposits reduce efficiency and deteriorate the overall performance of the engine.

In parallel with this, there is a risk of serious damage to the internal combustion engine. For example, critical situations can be considered those when valves, rings become heavily coked, or a short circuit (glow ignition) effect occurs. In the first case, the valve cannot close completely due to a thick layer of carbon deposits, the rings become stuck and compression in the engine decreases, the engine begins to stall and starts poorly. Quite often the valves burn out, which leads to expensive repairs. As for short circuit, this phenomenon causes uncontrolled ignition of the mixture in the engine cylinders from smoldering carbon deposits. In other words, the charge will ignite not from an ignition spark in a gasoline engine or from contact with air heated from compression in a diesel engine, but spontaneously. As a result, the engine overheats, causing significant damage to the CPG, etc.

To prevent negative consequences, it is recommended to carry out periodic cleaning for preventive purposes, that is, to prevent heavy accumulation of deposits. Also, after the first symptoms appear, you can clean an already coked engine from carbon deposits, that is, carry out the procedure for decoking the engine.

What is carbon deposits on pistons?

Looking inside the power plant, we will definitely see that many parts are covered with deposits of various types. Experienced drivers divide them into sludge, carbon deposits and varnish formations. One of the reasons for the formation of deposits is the breakdown of engine oil in the engine. It oxidizes and decomposes over time, so breakdown products can settle on the elements, forming a deposit. Therefore, every driver should know how to clean the piston from carbon deposits.

No washing, no hydrogenation...

– Today there are already car owners who are interested in high-quality engine flushing. But quite recently this service was not in demand. Although, it is worth admitting, in the good old days, many people flushed the engines of their old cars with every oil change. But when modern vehicles appeared, washing was widely forgotten. However, car owners are gradually learning more and more that flushing or comprehensive cleaning of the engine from carbon deposits is extremely necessary. This is largely facilitated by car mechanics working in dealerships, telling drivers about the consequences of carbon deposits in the engine, says Vladimir Drozdovsky.

Causes of soot

The most common cause of soot is incomplete combustion of fuel or a high percentage of various impurities and additives in the fuel. Once fuel comes into contact with a heated piston, valves or cylinder walls, harmful additives begin to accumulate, and over time a whole layer of deposits forms.

One common reason is infrequent oil changes. When the driver does not take care of regular inspection of this system, the engine gradually begins to coke. Therefore, experienced car mechanics recommend changing the oil after driving 15-20 thousand km. Other factors that affect piston fouling include:

- failed injectors;

- old spark plugs;

- faulty seals;

- wear of piston rings.

Sludge most often forms on the side surfaces of pistons and cylinder walls. Experts believe that carbon deposits appearing at the top of the piston will contribute to increased wear on the cylinder walls. Deposits can become lodged in the gap between the groove and the ring on the piston. This leads to significant engine wear. Therefore, it is better to fix the problem as quickly as possible.

Availability of BG products

- For individuals, BG offers decoking and flushing additives for adding to fuel and oil. These products can be used as a preventative measure every 5-10 thousand kilometers (every oil change).

- Hardware washing products and induction service are intended only for professional use in car services and service stations. Induction service is carried out as a preventative measure every 30-40 thousand km. Hardware hard cleaning is an effective preventative measure that must be carried out after 100 thousand kilometers.

Cleaning pistons without disassembling the engine

According to experienced specialists with many years of practice, it is imperative to use manual mechanical cleaning in order to efficiently and quickly remove carbon deposits from pistons and other internal combustion engine parts. It turns out that first you need to almost completely disassemble the power plant. This method is the most labor-intensive and costly, so many car owners try to make do with cleaning the pistons from carbon deposits without disassembling them.

In this case, decoking of the engine and piston rings is done. In this method of cleaning pistons from carbon deposits, the parts are not removed from the machine. Products intended for this purpose are active solvents. They are poured into the engine through spark plug holes or through the lubrication system. Thanks to this, the pistons are cleaned without additional time and financial costs for disassembly.

A similar product can be purchased at any store that sells auto chemicals. These products are produced by well-known brands - Liqui Moly, Xado, Gzox. For decarbonization, it is best to use products from these companies. Automotive chemicals have their own advantages and disadvantages. The advantages include the speed of the procedure and a gentle effect on the engine. The disadvantages of this method are that during these manipulations it will not be possible to remove carbon deposits from the combustion chamber of the valves and the piston surface. In addition, according to many motorists, Gzox for decarbonization can only wash oil scraper piston rings.

Therefore, this decision is classified as preventive. If the engine is very dirty, then these procedures will not help get rid of problems such as carbon deposits.

Results of regular use of BG technology

BG's decarbonization technology is ideal compared to the so-called "old-fashioned" methods of engine cylinder decarbonization.

BG technology brings real results:

- Restoring compression, returning the calculated dynamics of the vehicle, normalizing fuel and oil consumption.

- Preserving the life of the motor and reducing the likelihood of sudden breakdowns.

- After decoking, the engine returns to its previous environmental performance (including after EGR service).

The most important result of regular use of BG technology is the preservation of engine life, the prevention of breakdowns and wear of parts, the repair and replacement of which will require serious financial costs.

Regular use of BG products extends the life of the engine with each service completed!

Removing deposits from the combustion chamber and piston

This method is designed for the solvent cleaner to be poured directly into the combustion chamber. Thanks to this, the soot loosens. And after the engine resumes operation, all deposits simply burn off. It should be borne in mind that this type of decarbonization will require more aggressive means. The most effective of them is considered to be the Lavr cleaner or its analogues.

In order to quickly decarbonize without removing the power unit and not spend too much time, you must follow the sequence of work:

- Warm up the engine to operating temperature, without allowing it to cool, and remove the spark plugs.

- Set the pistons to the middle position by lifting the car with a jack (for rear-wheel drive cars, you need to jack up the wheel at the back, and with front-wheel drive, at the front).

- Engage fourth or fifth gear and crank the engine using a raised wheel.

- After this, the location of the pistons is determined using a screwdriver inserted through the spark plug hole into the combustion chamber. After this, you can pour decoking agent into each cylinder and leave the car for 30-40 minutes.

- After time has passed, go to the understood wheel and spin it up or down. This must be done so that the cleaner flows to the rings. Such actions should be performed for at least 5-10 minutes.

- Now you should crank the engine using the starter with the spark plugs removed. It will only take 15-20 seconds. During this procedure, residual fluids are removed from the cylinders through spark plug wells.

The last operation must be done, since accumulated liquid can lead to water hammer if you start the engine with the spark plugs screwed in. Finally, the spark plugs are screwed into place and the power plant starts. You should not worry if the engine does not start immediately, since the oil film from the cylinder walls is washed off during such a procedure. Sometimes thick smoke with a pungent odor appears from the exhaust system. In this case, you need to leave the engine idling for at least 15 minutes.

Tip 2: How to clean the engine

Fuels and lubricants are volatile chemical compounds containing sulfur and resins, which under the influence of temperatures turn into coke. And if the contaminants that have arisen on the outer surface of the engine can be cleaned without any problems using chemical solvents, then decoking the engine from the inside is quite a difficult undertaking.

You will need

- - medical syringe,

- - a bottle with a chemical composition for engine decarbonization,

- - fuel additive.

Instructions

1

The appearance of smoke in the exhaust gases when the engine is running, as well as soot deposits on the inner surface of the exhaust pipe, are the first signs of the appearance of unwanted deposits in the engine cylinders, which leads to increased engine oil consumption and also reduces the dynamics of the vehicle.

2

Most technicians at car service stations charge an unreasonably high price for cleaning the insides of the engine from coke and soot. Therefore, it is better to restore the “sterility” of the engine yourself, which will significantly save the family budget.

3

The simplest way to clean the engine is to add an appropriate additive to the fuel, which is simply poured into the tank before refueling with gasoline or diesel fuel. But this method is, to put it mildly, ineffective, so it is used very rarely.

4

A more thorough cleaning of the insides of the engine is carried out by pouring a chemical composition designed to dissolve soot and coke deposited inside the cylinders through the holes, after first unscrewing the spark plugs. In this case, the engine must be warmed up to operating temperature.

Removing the piston group

This procedure must be performed carefully so as not to damage foreign parts. A car owner who wants to do everything at home must take care of a set of tools in advance and prepare a place for disassembly in the garage.

The oil from the power unit is first drained. You can then remove any bits stuck to the part from the head gasket. Care must be taken to ensure that they do not fall into the mounting hole. Then, using a special triangular file, carbon deposits are removed from the top of the cylinder block. If you do not do this, you will not be able to pull out the piston itself. After the necessary measurements of cylinder wear have been made, the piston group can be removed. If you also need to remove the connecting rods, you will have to remove the engine sump.

Decarbonization methods

In order to perform decarbonization yourself, you can use one of two methods.

The first of them involves pouring pre-purchased products into the engine cylinders through the spark plug holes, which loosen and remove coke deposits. This option is considered more effective, and it should be carried out on a warm engine.

In the second case, you should add the chemical to gasoline or oil. This method is less troublesome, but also less effective. If you still choose this method, then carefully read the instructions on the liquid packaging, noting how much of the substance, in what order and where to pour it.

Now let's look at the first decarbonization method in more detail.

Prepare a screwdriver and purchased smoke remover.

1. Remove all spark plugs.

2. Set the cylinder pistons to the middle position by lifting the front or rear wheel using a jack, depending on whether your car is rear-wheel drive or front-wheel drive.

3. Depending on the gearbox, engage fifth or fourth gear, spin the wheel, and, taking a screwdriver, change the position of the pistons through the spark plug holes.

4. Carefully pour “chemistry” through them into the cylinders for decarbonization. Try to fill no more than 25 mm into each cylinder. To do this, it is most convenient to take an ordinary syringe.

5. In order for the product to quickly reach the piston rings and quickly soak the carbon deposits, gradually turn the wheel on the jack and rock it slightly, moving the pistons at the same time. After three movements of the wheel, do nothing for a couple of minutes. Then repeat. Depending on the severity of the contamination and the product purchased, decarbonization can take from 10 minutes to 1 hour. During this time, carbon deposits turn into jelly and fly out of the combustion chamber when the engine is running.

6. Turn off the gear and be sure to crank the engine with the starter for at least 15 seconds to remove any fluid remaining in the cylinders. If you forget about this, the engine may be damaged due to water hammer. Before cranking the motor, secure the central high-voltage drive by creating a gap of a couple of centimeters between the ground and the tip of the wire. This will avoid breakdown of the ignition coil.

7. Tighten the spark plugs, return the drive to its place and start the car. Do not be alarmed by any difficulties starting the engine or the appearance of an unpleasant odor after this procedure. Smoke may appear during the first 10 km of vehicle movement. You can drive when the car has been idling for about twenty minutes.

Home →

With your own hands →

Methods for external piston cleaning

The removed parts are ready for further action. Now you can not only inspect them from all sides, but also clean the pistons from carbon deposits by disassembling them using any of the known methods. Folk auto repairmen who repair cars at home suggest using alternative methods instead of traditional means.

In their opinion, the most effective cleaning products are:

- ovens from fat;

- salon;

- carburetor

They even suggest using the well-known Coca-Cola, claiming that it copes well with even the most severe carbon deposits. However, despite the fact that the drink is famous for its cleansing properties, the effect is minimal.

Therefore, experienced specialists do not advise experimenting with food products. The pharmaceutical drug "Dimexide" has proven itself to be good for decoking rings, but it should be used as a last resort, when the main sludge has been removed.

What's the result?

Based on the sum of all the results, the foam cleaner “Valera” and con performed better and safer than the others. However, the foam composition, due to its consistency, in practice turns out to be more effective, convenient and economical than liquid.

The popular “Shumanit” turned out to be very effective, but extremely unsafe for engine parts, but a solution of dimethyl sulfoxide would have shown itself to be a real alternative to professional products if it had not dissolved the paint of the engine pan. The expensive and specialized cleaners Greenol Reanimator and VeryLube Anticox performed averagely.

Oven cleaner

These household chemicals are also designed to combat pollution, albeit of a different kind. This product for cleaning pistons from carbon deposits is intended for removing grease from ovens, frying pans, and barbecues. According to reviews from many drivers, the gel is very effective in combating carbon deposits on pistons. The Queen Cleaner gel from Amway performed especially well.

The product must be used carefully, because it is aggressive on any aluminum surface. Therefore, it is necessary to apply the composition only to the surface of the soot. Just wait 15-25 minutes and then wash off with a damp cloth. Most of the dark plaque will disappear.

Use of nut shells

Frequent problems with the formation of carbon deposits in the combustion chamber of carburetor engines, especially direct fuel injection systems, have forced automotive specialists to develop technology for removing these deposits in an ergonomic and safe way. The latest developments by scientists in the field of chemistry make it possible to clean carbon deposits without dismantling parts. European automotive service companies are introducing cleaning technology based on the use of special granules that safely remove deposits from intake ports and valves. A process has also been developed to neutralize the granules, which does not leave residues.

To effectively clean the intake channels and valves until they are completely free of deposits using the new technology, you do not need to open the engine head; it is enough to dismantle only the intake manifold. The high efficiency and short time required to complete this procedure is an excellent alternative to traditional methods of removing carbon deposits and disassembling the engine.

The technological process of cleaning with granules does not cause abrasion of the material, so the surface of the cylinder mirror is maintained in good condition. Benefits of carbon blasting:

- Effective removal of contaminants with a flow of granules.

- A special abrasive ensures stable cleaning quality.

- The specific, non-sharp geometry of the granules, as well as their internal structure, makes it possible to remove contaminants with high quality, while maintaining the surface of the parts.

- The neutralizer allows you to effectively remove slag residues after cleaning.

- The nozzles in the set are selected for various channel shapes.

Interior cleaner

The most effective way to perform such a procedure as cleaning the piston from carbon deposits is considered to be a universal concentrate intended for washing heavily soiled surfaces of the car interior. Of the products offered on the market, the most effective is the Italian product Atas Vinet. To carry out the procedure, you need to dilute it in a ratio of 1/10 with water. However, even this decarbonizing liquid has difficulty coping with hard carbon deposits. After this, a special product is used to completely remove small residues of carbon deposits. It is "Dimexide". This drug is used quite often to decarbonize rings. True, this solution is even more often used for medical purposes.

Experts recommend finding out in advance how to clean the piston from carbon deposits, and performing these actions for preventive purposes, without waiting for the engine to break down.

Valve cleaner ratings

The list of the most popular and effective valve cleaners at the moment consists of 5 products, created on the basis of reviews and reviews found on the Internet. Most of them are used not only to remove carbon deposits on valves, but also to clean piston rings and the power system because deposits settle on all parts of the combustion chamber.

Liqui Moly Ventil Sauber

The Liqui Moly Ventil Sauber valve cleaning additive is one of the most popular such products. This is due to its extreme efficiency. It is a liquid that is added to fuel. It not only removes carbon deposits on valves, but also removes deposits in the power system, injectors, carburetor and intake tract elements. In addition, it prevents the formation of corrosion on metal surfaces, both liquid and electrolytic. Liquid Moly valve cleaner can be used on any type of engine, including those equipped with catalysts and turbocharging.

Reviews of the Liqui Moly Ventil Sauber 1989 valve cleaner are mostly positive. Most car enthusiasts who have used Liquid Moly to clean valves note its high effectiveness. In particular, many write that even quite deep deposits are removed from the surface of the valves, including those formed when using low-quality fuel. Accordingly, engine power increases, and the clicking sounds made by the valves go away. Thus, the cleaner definitely deserves a leading position in the ranking.

The only drawback is the price is a little high compared to its competitors. You can buy the additive in a 250 ml can, which is enough to dissolve in 75 liters of fuel. If the volume of the car tank is smaller, then the product must be poured in proportion. The price of one package as of summer 2020 is about 500 rubles.

HI-GEAR FUEL SYSTEM & VALVES CLEANER

HI-GEAR FUEL SYSTEM & VALVES CLEANER valve cleaner is designed for use with any type of gasoline engine up to 2.5 liters. Including engines equipped with catalysts and turbines. The manufacturer directly states that this product is recommended for preventive use every three thousand kilometers. The additive is poured into the fuel tank, so it also has a positive effect on the power system. The original detergent element included in the product is TFS23. Stops rusting and also reduces fuel consumption by 5...7%.

The HI-GEAR valve cleaner is highly effective. It efficiently and quickly removes not only carbon deposits from valves, but also cleans pistons, as well as elements of the fuel system. Accordingly, there are mostly positive things about him. In rare cases, when the soot is already significant, it may not cope, but since the product is positioned as a preventative, there can be no corresponding claims against it. One of the disadvantages is the high consumption of the additive for a small volume of gasoline.

The High Gear valve cleaner is sold in metal bottles of two different volumes - 295 ml and 325 ml (items HG3235 and HG3236). The volume of the larger jar is enough to dissolve it in 40 liters of gasoline. The price of the smaller can as of the above period is about 550 rubles, and the larger one is about 600 rubles.

Valve cleaner Lavr

Valve and combustion chamber cleaner “Lavr” Ln2134 is the third most popular liquid cleaner among car enthusiasts. Reviews from car owners indicate that it very quickly and efficiently washes not only carbon deposits on valves, but also dirt on other elements, in particular on rings.

Can be used on any gasoline engines, including those with catalysts and turbines. Its use is standard, that is, it must be poured into the fuel tank immediately before refueling, where you then add gasoline and drive until it is empty. The composition contains: a base aliphatic solvent, a package of proprietary detergent additives, aliphatic alcohol and functional active substances.

Valve cleaner “Lavr” increases the power characteristics of the engine, reduces fuel consumption, and reduces the toxicity of exhaust gases. Reviews about the product are mostly positive. There are positive changes in the cleanliness of pistons and valves. So, there is a 310 ml jar on sale, the price of which is about 250 rubles. One jar is enough for 40...60 liters of gasoline.

Foam decarbonizer “Valera”

A domestic product, the Valera foam decarbonizer from VMPAvto 8507, is also very popular for cleaning valves. The product is positioned by the manufacturer as a universal product designed for cleaning engine parts during disassembly, including valves and rings. It effectively removes deposits and dirt.

Foam must be applied to the surface to be treated. After this, leave the foam for 5.7 minutes to perform a chemical reaction so that the carbon deposits dissolve. It is recommended to perform this cycle up to 3.5 times depending on the complexity. The foam must be removed using a syringe, then blow off the surface with compressed air. Therefore, the product will have to be used when partially dismantling some elements or when disassembling the engine.

The “Valera” decarbonizer is popular among both car service professionals and ordinary car enthusiasts, which confirms its effectiveness. To clean carbon deposits from valves or rings, up to 5 cycles are usually carried out. This is enough to remove even the most stubborn carbon deposits. It can be used to clean intake and exhaust manifolds, rings and other parts removed from the engine. Among the disadvantages, one can note only a fairly high price with a large consumption of funds.

Decoking “Valera” is sold in packages of two sizes. The first is 400 ml in volume (enough for processing parts of a 12-cylinder engine), its price is about 750 rubles. The second package volume is 210 ml, costing 580 rubles.

Wurth Foam Valve Cleaner

Valve cleaner "Vert" 0893033 is a foam cleaner, that is, it must be applied inside the intake manifold. According to the instructions, it is fed into the intake manifold on a warm engine running at 2 thousand rpm, in two passes with an interval of 30 minutes.

DESIGN

The use of aluminum in the piston material reduces the reciprocating masses, which makes it possible to achieve high rotation speeds of the crankshafts of modern highly accelerated engines with high specific power.

The use of aluminum (fast thermal expansion) in a piston operating inside a steel (slower thermal expansion) snowmobile cylinder liner dictates a slightly barrel-shaped piston skirt and an oval piston cross-section (when looking at the piston from above from the dome side). Such forms make it possible to achieve minimal clearances between the piston and the working surface of the cylinder when the engine reaches operating temperatures.

Aluminum's high thermal conductivity helps the piston dome withstand the high combustion temperatures of the mixture, transferring this heat to the cylinder walls through the skirt and piston rings, while maintaining its temperature below the maximum permissible temperature.