The internal combustion engine remains the most efficient power unit in automobiles today. With this unit, you can cover any distance and enjoy your trip without spending a lot of time refilling the fuel tank.

However, to start the engine and ensure smooth acceleration, it must have a special part. This is a flywheel. Let's look at why it is needed in a motor, what types of flywheels there are, and also how to operate it correctly so that it does not fail prematurely.

What is a car engine flywheel?

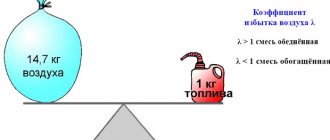

Simply put, an engine flywheel is a disk with a toothed ring. It is attached to one end of the crankshaft. This part connects the engine and transmission of the car. To ensure that torque is smoothly transmitted to the appropriate gearbox speed, a clutch basket is installed between the mechanisms. It presses the clutch disc against the flywheel elements, which allows torque to be transmitted from the motor to the gearbox drive shaft.

What is a flywheel and why is it needed?

When considering the specific functions of the flywheel, the following characteristics stand out:

- Reducing oscillatory movements when rotating the crankshaft. In this case, the flywheel can be considered as one of the engine parts.

- Transfer of torque from the engine to the gearbox. In addition, it is the primary clutch disc.

- Responsible for transmitting torque from the starter to the crankshaft.

In other words, the flywheel is necessary to perform three important functions: starting the engine from the starter, transmitting torque to the gearbox and ensuring smooth operation of the crankshaft.

The principle of operation itself is quite simple to explain: for clarity, imagine an ordinary toy top. If the top begins to spin by hand, then the flywheel begins to spin from the rotational movements of the crankshaft. The top will spin until the applied energy runs out. The drive disk is able to transfer the received energy back, thereby forcing the crankshaft to work. As a result, we have a closed system that ensures the operation of the flywheel.

Operating principle of the engine flywheel

The flywheel is fixed on the crankshaft in close proximity to the main bearing. Depending on the design of the disk, it compensates for vibrations during rotation of the crank mechanism. Many modern flywheels are equipped with a spring mechanism that acts as a damper when the engine jerks.

When the engine is at rest, the flywheel is used to turn the crankshaft. In this case, it works on the principle of a manual starter of old cars (a manual lever was inserted into a special hole in the engine, which allowed the driver to crank the crankshaft and start the internal combustion engine).

Possible faults

Below are the most common part malfunctions.

- Wear of the crown. Over time, the teeth on the ring can wear out, causing the starter to slip on them when starting the engine. Starting the car will be problematic - it will not work the first time.

- Misalignment. The flywheel must be installed coaxially with the cardan and clutch disc. Otherwise, when moving on a vehicle, the so-called “beating” will be heard.

- Disc wear. The part of the part that performs the functions of the clutch disc is subject to the most severe loads. As a result of this, it can wear out, and burrs and depressions may appear on its surface. The result of all this is a reduction in the size of the contact area of the transmission discs and, as a result, poor clutch. Another sign of a breakdown is noise when the car moves.

- Wear of crankshaft fasteners. The place where the crankshaft is attached also wears out over time. As a result, backlash appears. It causes noise while the vehicle is moving.

All of the above breakdowns occur in single-mass or lightweight devices. In dual-mass models, dampers may also malfunction. It is most often expressed in their wear. As a result, the part of the structure connected to the crankshaft does not transfer all the energy to the part that is the clutch disc. You can tell that problems have arisen by looking at the following “symptoms”:

- noise, knocking;

- the appearance of so-called floating revolutions;

- spontaneous “twitching” that occurs at idle;

- increased vibration level when driving;

- jerking when changing gears.

Flywheel design

Most flywheels do not have a complex design. In many cars, this is a solid, weighty disc with teeth on the end. It is attached to the crankshaft shank flange using bolts.

With an increase in the power of power units and an increase in their maximum speed, the need arose to create modernized parts that already have a complex design. They can safely be called a damper mechanism, and not an ordinary part.

Can the flywheel be repaired?

A single mass flywheel is difficult to repair, so when it wears out, it must be replaced with a new one. (The only thing that can be replaced is a dental crown if one of the teeth is worn out or broken).

Dual mass flywheels have begun to be redesigned in recent years.

What does flywheel repair mean? Generally speaking, scrapping separates the two flywheel discs and cleans them well. Then the bearings, springs and all other elements are replaced with new ones, and both disks are riveted together again. Finally, the adjustment is made and if everything is in order, the flywheel is installed in place in the car.

This method of restoring dual-mass flywheels, as already mentioned, is quite popular, but does not always give good results. Sometimes, when discs are opened for reuse, this is not possible.

In addition, although almost all repair shops provide a warranty after disposal, none can guarantee that all items were actually replaced with new ones.

The role and place of the flywheel in the engine

Depending on the design, in addition to the drive function for the transmission, the flywheel also plays other roles:

- Softening of vibrations during uneven rotation. Manufacturers strive to distribute the stroke time in the internal combustion engine cylinders so that the crankshaft rotates with minimal jerks. Despite this, torsional vibrations are still present (the fewer pistons in the engine, the clearer the vibration will be). A modern flywheel must dampen such vibrations as much as possible in order to prevent rapid wear of the gearbox. For this purpose, its design contains several springs of different stiffness. They provide a smooth increase in effort even during sudden operation of the unit.

- Transmission of torque from the motor to the drive shaft of the gearbox. This process is ensured thanks to the clutch basket. In it, the driven disk is tightly fixed to the friction surface of the flywheel using a clamping mechanism.

- Provides transmission of torque from the starter to the crankshaft when the engine starts. For this purpose, the flywheel crown is equipped with teeth that engage the starter gear.

- Damper modifications provide inertial force to decouple the crank mechanism. This allows the pistons to smoothly move out of their dead points (top or bottom).

Flywheels are often made to be quite heavy so that they are able to store a small amount of kinetic energy when the cylinder undergoes an expansion stroke. This element returns this energy back to the crankshaft, thereby facilitating the operation of the other three strokes (suction, compression and exhaust).

Operating principle

At the moment the internal combustion engine starts, rotation of the flywheel is ensured by the starter, the part receives an initial speed and gains inertia. Then the engine piston “hangs” at top dead center, and the shaft cannot rotate. However, due to the inertia of the flywheel, the crankshaft rotates slightly, which allows it to carry out the next compression cycle, ignite the fuel mixture, and obtain energy for the next rotation.

Rice. 12 The principle of operation of the flywheel with clutch

At the same time, the sensor monitors the position of the shaft and the pistons on it, respectively. The information transmitted by this device is analyzed by a computer, alternately supplying ignition to the corresponding combustion chambers.

With a dual-mass flywheel the situation is slightly different:

- at the moment of start, one half of this assembly receives a high angular velocity, the second remains motionless;

- at the same time, the first half of the flywheel begins to compress the spring, which ensures smooth rotation of the transmission disk rigidly connected to it;

- then the speeds of both halves are aligned relative to each other and operate in a single mode;

- at the moment the driver slows down the gas pedal, the second half begins to overtake the first;

- however, a hard impact on the motor parts does not occur again, since another spring begins to compress in the opposite direction;

- the speeds of the halves are equalized again, the cycle repeats again.

Rice. 13 Operating principle of a dual-mass flywheel

The DPKV sensor is still responsible for ignition, and the flywheel casing protects the unit from external influences. A similar damper is built into the clutch assembly, which becomes unnecessary when using a dual-mass flywheel.

Types of flywheels

As already mentioned, in old cars the flywheel was made of a cast-iron disk, onto the end of which a ring gear was pressed. With the development of the automotive industry and the increase in power characteristics of power units, new flywheels were developed that differ from each other in efficiency.

Of all the types, three are distinguished:

- Single mass;

- Dual mass;

- Lightweight.

Single mass flywheels

Most internal combustion engines are equipped with just this modification of flywheels. Basically, such parts are made of cast iron or steel. There is a large hole where it is attached to the crankshaft shank, and the housing around it has mounting holes for mounting bolts. With their help, the part is firmly fixed to the flange near the main bearing.

On the outside there is a contact area for the clutch drive disc (friction surface). The crown at the end of the part is used only when the engine starts.

During the manufacturing process at the factory, such disks are balanced to eliminate additional vibrations during operation of the mechanism. Balance is achieved by removing some of the metal from the surface of the part (most often, a corresponding hole is drilled in it).

Dual mass flywheels

The dual-mass or damper flywheel is more complex. Each manufacturer tries to improve the efficiency of such modifications, which is why the design of different models may differ. The main elements in such mechanisms are:

- Driven disk. A gear ring is attached to it.

- Master disk. It is fixed to the crankshaft flange.

- Torsional vibration dampers. They are located between two disks and are made in the form of steel springs of different stiffness.

- Gears. These elements are installed in more complex flywheels. They perform the function of planetary gears.

Such modifications are much more expensive than classic solid flywheels. However, they facilitate the operation of the transmission (provide maximum smoothness) and prevent its wear due to shocks and vibrations while the car is moving.

Lightweight flywheels

A lightweight flywheel is a type of single-mass flywheel. The only difference between these parts is their shape. To reduce weight, some metal is removed from the main surface of the disk at the factory.

Such flywheels are used for tuning cars. Thanks to the lighter disc weight, it is easier for the motor to reach maximum speed. However, such modernization is always carried out together with other manipulations with the engine and transmission.

Under normal conditions, such elements are not installed, as they slightly destabilize the operation of the motor. At high speeds this is not so noticeable, but at low speeds serious problems and inconveniences can arise.

Features of the dual-mass flywheel design

The design features of the part consist in the presence of two housings, one of which is installed on the crankshaft with subsequent connection to the crankshaft, and the second is in contact with the working surface of the clutch disc. The connection between the housings is ensured by two bearings (axial and radial), which can slide freely regardless of each other’s operation. Also in the middle of the part there is a damping system consisting of springs. All mechanisms are treated with a special grease, which ensures reliable operation of the springs and separators between them.

Damper flywheel

The dual-mass flywheel contains two sets of springs. A soft spring package ensures soft starting and stopping, while a hard spring package provides damping of vibrations in the operating speed ranges of the engine.

Principle of operation

The operating principle is effective and simple at the same time. Due to an increase in the inertial moment of mass on the input shaft of the gearbox, the resonant number of revolutions becomes less than the speed range of the internal combustion engine. This ensures damping of oscillatory movements generated by the power unit. Vibration damping is achieved through a damper-spring system, which prevents collisions between gearbox parts. The result is a reduction in the load on the working elements.

What are the advantages and disadvantages?

In practice, the driver cares not so much about the technical performance and design features of the mechanism, but about the convenience and comfort of driving. Installing a dual-mass flywheel in a car gives the following advantages in practice:

- Gear shifting becomes more comfortable and smooth.

- The inertial moment during switching decreases.

- The resource of the internal combustion engine and gearbox increases.

- Space savings are achieved in the clutch housing, which is an important advantage for compact vehicles.

Despite its many advantages, it also has disadvantages. Firstly, the cost is quite high. Secondly, the service life is significantly lower than that of other types of clutch discs. This disadvantage is due to the design and internal lubrication, which is destroyed during operation. These are the only significant disadvantages that dual-mass flywheels have.

Despite the fact that the service life of the part is not unlimited, with proper driving the service life is estimated at 350-400 thousand kilometers.

To do this, you should adhere to the following operating recommendations:

- do not overload the car;

- do not hold the clutch pedal depressed, for example, when stopping at a traffic light;

- Do not release the clutch pedal when starting to move and changing gears;

- do not start in high gear;

- Do not drive for long periods of time at low speeds, especially in diesel vehicles. In this mode, the torsional vibrations of the crankshaft are very high, and there is increased wear on the springs of the damper system.

Clutch malfunctions

Based on the results, the following conclusions can be drawn: the drive disc is an integral part of the vehicle control system. Nowadays, the most promising is the dual-mass flywheel system, which has significant advantages over other types. And if you use your car correctly, you won’t be afraid of breakdowns for quite a long time.

Flywheel operation and possible malfunctions

By and large, the flywheel is one of the most reliable engine elements. Most often, its working resource is identical to the resource of the power unit. Depending on the material and manufacturer, these parts last 350 thousand kilometers or more.

The most problematic part of the flywheel is the teeth on the crown. The resource of this element directly depends on the serviceability of the starter. The tooth may break or simply wear out from frequent use of the starter. If such a breakdown occurs, you can buy a new crown and install it in place of the old one. In this case, the entire disk must be removed from the engine, and after repair it is installed back, only using new bolts.

Another common flywheel failure is overheating of the friction surface. This usually occurs during improper operation of the car, associated with violation of the rules for shifting gears (for example, the clutch pedal is not fully depressed).

Due to overheating, the disc may become deformed or cracks may appear on it. One of the symptoms of such a malfunction is constant clutch beating in a certain speed range. This is also accompanied by strong vibration. If the driver burns out the clutch and it is immediately replaced with a new one, there is no need to change the flywheel.

Dual-mass models fail a little more often, since they have more additional parts in their design. A spring may burst, a lubricant leak may occur, or a bearing may fail (this happens extremely rarely, but does occur in this list).

Another reason for flywheel wear is untimely replacement of the clutch friction disc. In this case, the rivets will scratch the surface of the part, the consequences of which cannot be eliminated except by replacing the part.

Driving style can also affect the life of the flywheel. For example, if a driver drives a car at low speed over a long distance, the vibration from the unit increases, which can damage the flywheel mounting elements. Some motorists start and stop the engine without pressing the clutch pedal.

The flywheel is not serviced separately. This procedure is mainly performed when replacing the clutch. In this case, a visual inspection of the part is carried out. If there are no defects, nothing is done. If you hear a grinding sound, you must have the car towed to a service station so that the worn friction disc does not scratch the surface of the flywheel.

Malfunctions and their symptoms

Due to considerable loads, over time the flywheel becomes deformed and destroyed.

In a single-mass flywheel, the problem area can be the ring gear, which can break down over time. It is dismantled mechanically. When installing a new one, you have to resort to heating and replace the bolts. It is also possible for the disc to crack and break. The only solution is to replace the entire part.

Damage to gear teeth

Replacing the ring gear on a single-mass flywheel

To promptly identify malfunctions of the single-mass flywheel, pay attention to:

- increased level of vibrations and noise;

- deterioration of clutch performance;

- problems when starting the engine.

As for the dual-mass flywheel, its more complex design implies the occurrence of malfunctions that are more difficult to eliminate. It can:

- arc springs break, completely collapse;

- bearings and parts subject to friction wear out.

Broken springs in the dual-mass flywheel

Signs of problems with the dual mass flywheel are:

- A feeling of vibration when starting the engine, possibly with jolts that can be felt even in the gearshift lever.

- A soft knocking sound when the engine is idling.

- Vibration during acceleration.

- Shocks when changing gears.

- Vibration that occurs even after the engine is turned off.

In theory, the dual-mass flywheel can be rebuilt, but in practice it is only replaced.

Is it possible to repair and restore the flywheel?

This question most often concerns dual-mass flywheels. If a solid modification fails, it is only replaced with a new one. A standard part is not too expensive to ask such a question.

However, expensive damper modifications often lead to similar considerations. Some specialists grind the friction surface to remove scratches caused by a worn clutch disc. In most cases, such repairs do not bring the desired result. The thin friction surface can burst under high loads, which will entail not only replacing the flywheel, but also repairing the clutch.

Some cooperative service stations offer to repair an expensive flywheel for a reasonable fee. However, this is also a dubious procedure. The fact is that except for the crown, not a single part of the flywheel is sold separately. For this reason, such “restoration” work is dubious.

In conclusion, it is worth noting that if you use the clutch carefully and have a measured driving style, there will be no problems with the flywheel. If the machine is rarely used, then you can think about installing a damper flywheel. In other cases, solid analogues will be more reliable.

Flywheel repair

Repairing the flywheel ring During rotation, the Bendix gear meshes with the teeth of the flywheel ring. Therefore, the entire load during operation is placed on the gears. Over time they wear off. As a result, the car breaks down, which is manifested by the following symptoms: the car does not start well, the starter clicks, but does not spin. These symptoms are not constant. The car starts up, then the starter clicks or crackles again. This indicates poor engagement of the Bendix gears and the flywheel. If the flywheel teeth are worn out in a certain place, the starter spins and does not start the engine until the flywheel rotates the defective place.

After some time, the gears engage and the engine starts. It is necessary to inspect the flywheel ring and bendix gear, and if worn, replace them. You can do the repair yourself. To do this, you need to remove the flywheel from the car and use a hammer and chisel to knock out the crown. If the new crown is not put on, it must be heated with a torch or, even better, an electric stove and, tapping with a hammer, pressed evenly onto the disc. Note! The crown must be heated over the entire surface and not very much. If you heat it up until red hot, this will contribute to rapid wear of the teeth in the heating areas. Sometimes, if the teeth are not very worn, the crown is removed from the flywheel and put on the other side. To do this, you need to mark the disk and the crown with several marks so that you can turn it over and put it in the same place. This will keep the flywheel as balanced as possible.

Types of flywheels

Scheme of a car clutch flywheel

Solid is made as a cast iron disk with steel teeth on the outer surface. It is most often installed in cars.

Tuning cars and models with automatic transmissions are equipped with lightweight flywheels. Its main advantage is reduced weight. The mass of the flywheel is redistributed over the disk, so it is lighter by about 1.5 kg. Inertia decreases, engine output increases up to 5%. This type of device is structurally simplified. Its purpose is to be a gear that the starter bendix rotates when starting.

The dual-mass (damper) flywheel is widely used. It dampens vibrations, combats torsional vibrations of the crankshaft, reduces noise, reduces wear on synchronizers, protects the transmission from overload, and also simplifies gear shifting. This type of device is not as lightweight as simple flywheels. Therefore, some manufacturers do not install them on their models.

Classification of flywheels

Designers determine the following classification of flywheels:

- Two- and single-mass.

- Lightweight.

- Solid.

Single-mass is a solid cast part with the simplest design. Thanks to this, it has good reliability and is inexpensive. It is a disk with a diameter of 30–40 centimeters with a mounting mounting hole made according to the hub principle. On the outer part there is a ring contact pad and a place for attaching the clutch.

For cars with high-power engines, dual-mass flywheels are used. They are a pair of disks housed in a single housing. The adhesion between them is ensured by a spring damping system. Among the advantages of this design are:

- Possibility of smooth gear shifting.

- Reduced transmission wear, increased service life of synchronizers.

- Prevents shocks and unnecessary vibrations.

Engines with flywheels of this type are considered more economical.

If you want to make the car more dynamic, increase sensitivity to pressing the gas pedal, lightweight flywheels are installed during tuning. Thanks to weight reduction, it is possible to reduce the inertial moment and increase the performance of the internal combustion engine. It is worth noting that the installation of such parts is not possible on all power units.

The advantage of a design of this class is the ability to reduce the size of the engine without loss of power. Due to this, it is possible to ensure stable operation of the internal combustion engine even at minimum speeds.

How to change the flywheel?

Replacing this component is quite a difficult task, and unless you have good technical knowledge and specialized tools, you will find it difficult to do it yourself. Why?

To replace the flywheel, you must first remove the transmission and clutch. Not only is this time-consuming, but it also requires specialized tools to be done correctly.

If you still decide to do it yourself, we advise you to purchase a clutch kit with a flywheel included. This way, you can be sure that you have taken care of not only the flywheel, but also the entire clutch, and those that are so important for the efficient operation of the car will serve you for a long time.