In recent years, life in Russia has changed dramatically, and the arrival of various official dealers of world-famous foreign car brands, as well as the availability of car loans, have done their job - the volume of foreign cars sold began to exceed the number of domestically produced “iron horses” sold.

However, the fact that the famous flagship of the AvtoVAZ concern, 2107, was produced from 1982 to 2012, that is, for 30 years, suggests that Russians have not lost their love for Russian car brands.

Along with sales and service of “Zhiguli”, to this day you can find various accessories for “classics” on the shelves of car shops, including rims.

What wheels are suitable for the VAZ 2104?

Tire and wheel sizes for VAZ 2104

| Engine | Year | Tires |

| 1.3 | 2011 | Factory equipment - Replacement options 165/70 R13 175/70 R13 |

| 2012 | ||

| 1.5 | 1984 | Factory equipment - Replacement options 165/70 R13 175/70 R13 |

| 1985 |

THIS IS INTERESTING: How to remove the rear seats on a VAZ 21099?

Wheels for VAZ 2107

Despite the fact that the model was produced for many years, and it would seem that the restyled versions should have differed greatly from each other over time, the wheelbase, body shape and other exterior parameters remained unchanged.

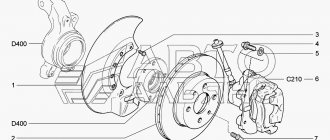

Wheel rims on the VAZ 2107 in the factory configuration have the following parameters:

VAZ 2107

- The standard drilling for VAZ products, or the diameter of the mounting hole on the axle shaft of the car, is 58.5 mm, as well as the bolt pattern - each hub is attached to 4 studs of 98 mm each. This is a fairly universal size, because many European manufacturers of wheels, which are installed on most economy-class cars, often use the 4×100 dimension, which is fully compatible with the products of the Russian plant.

- Over the past 30 years, the concern has installed “classic” car wheels on its cars in the simplest configuration with the dimension 5J × 13 ET29 in a stamped version and without hubcaps, on which 165/80/R13 and 175/70/R13 tires were easily installed.

- More expensive modifications were equipped with 5.5J × 12 ET32 wheels and 175/65/R14 or 185/60/R14 tires, slightly increasing the disc offset so that the visible part of the wheel did not protrude beyond the transverse dimensions of the body.

- Wheels 15 on 2107 are a special “highlight” of the models of the first years. All these years, the plant installed wheels with parameters 6J × 15 ET25 and, accordingly, tires 185/55/R15 or 195/50/R15 on the top-end configurations, and this was the maximum that Russian engineers were able to achieve.

Stamped wheels on a VAZ 2107 Almost all car enthusiasts, immediately after purchasing a car, additionally purchased and installed special decorative plastic linings on the wheels, produced in abundance by the same manufacturers that supplied “stamping” to the AvtoVAZ concern. However, some of the most demanding and wealthy clients often resorted to more expensive products and drove on cast and even forged wheels.

What wheels are suitable for the VAZ 2107 in a non-standard version?

Any manufacturer will always recommend for installation as an option exactly the same dimension that he sets himself, since when using it he can guarantee the operation of the car without any risk of mechanical failure. This means that when developing the model, all calculated loads were taken with these wheels, and other parameters can harm the car.

AvtoVAZ allows the following options for replacing disks for the VAZ 2107:

- If a driver wants to change all 4 standard wheels on a car, and their original radius was R13, he should consider “stamping” or “casting” with dimensions of 5.5J × 13 ET32 or 6.0J × 13 ET32, which will be especially convenient for installation of winter tires, which should be slightly wider than summer tires to increase the specific area of adhesion to the road surface. Tires suitable for this size are 175-195/70-80/R13.

- When a car enthusiast prefers a 14 radius, but for some reason he is not satisfied with the factory size, he has the opportunity to use the 6.0J × 14 ET32 size and tires with a width of up to 195 mm and a profile height of at least 60 mm on his Lada. These characteristics are so universal for VAZ that you can install all-season tires on them and not spend extra money on seasonal re-shoes.

- When a car owner sets the radius to R15, he should still adhere to the factory size, changing the rim width to a maximum of 6.5J or the overall tire size to 205/50/R15, since otherwise he will not be able to do without modifications to the suspension, or the deadline car service will be significantly reduced.

Alloy wheels for VAZ 2107

In some cases, some car enthusiasts prefer to install alloy wheels with dimensions R16 or R17 on their “Seven” cars, but this inevitably increases the overall width of the wheel and its offset (ET). This leads to the need to strengthen the suspension elements and the use of low-profile tires, which do not work well on country roads or in winter.

In order to choose the right stamped or cast wheels for a VAZ 2107, drivers should not go beyond the limits of wheel offset ET23-34 mm, width 5.0J-6.5J, and also should not set the radius above 16. In addition, you must carefully observe bolt pattern and drilling pattern upon purchase, as this is the main indicator of compatibility.

Parameters of forged wheels on VAZ 2107

The most practical and wealthy Lada owners install forged wheels on their cars, which have undoubted advantages over casting and stamping.

Forged products, having high strength, weigh much less than analogues made from other materials, and their special structure and hardening method during manufacturing prevent microcracks from forming in the material when hitting a serious obstacle.

Compact wheels - radius R13 and R14 - should be purchased only in the ranges described above: 5.0J-6.0J × 13 ET29-32 or 5.5J-6.0J × 14 ET32, which is suitable primarily for installing winter tires on change to larger rims for high-speed driving around the city on larger wheels.

Most cars produced before 1992 had tube tires, and it will not be possible to save old tires, even if they were just lying in the garage without use, because all the “forging” is oriented exclusively for tubeless tires.

Medium-sized forged wheels are an ideal combination with high-quality 15-radius tires, since the all-season version will allow you to operate the car for many years without worrying about the wheels at all.

The permissible size of disks can reach 5.5J-6.0J × 14 ET29-32.

Those drivers who dream of wide rims can set the size to 6.5J with a 23 mm offset, but they need to be prepared that the front wheels will definitely catch on the fender liner when cornering.

Forged wheels for "seven"

Forged wheels with parameters R16 and R17 are considered exclusive to the VAZ 2107, which are most often installed on later Lada models, such as Priora, Kalina, Largus and others.

This means that, of course, this drilling and bolt pattern is available on the market, but the small wheel arches of the “seven” can only be used for wheel sizes 6.0J-7.0J × 16-17 ET23-34, and this is the maximum range of parameters.

It is quite difficult to select such wheels, since they most often have an offset that is not compatible with the “classics”.

With a maximum tire width of 215 mm, the wheels, of course, will look very advantageous on the road, but at the same time they will most likely touch the calipers, which will require their processing, or, conversely, they will protrude beyond the body. In such situations, the driver will have to install additional plastic protection around the perimeter of the wheel arches on the body to prevent it from quickly becoming dirty on a rainy day.

Those who like to highlight their “seven” in the general traffic flow should be reminded that when installing forged wheels on 17, the maximum profile height is only 40 mm, which is popularly called “insulating tape”.

This means that the lack of an air buffer between the rubber and steel on the suspension part of the car often leads to the transfer of vibrations from the road to the hub, suspension, frame and interior of the car, which not only causes driver discomfort, but also reduces the period of maintenance and routine maintenance. repair work.

Technical specifications

The choice of disks is based on technical parameters that are important to consider for safe use in subsequent operation. Experts have formed basic technical standards that are important to adhere to when choosing disks in order to avoid operational inconveniences:

- The number of mounting holes and their circumference diameter is 4*98.

- Hub diameter is 58 mm.

- The most suitable disk size is 13-15, but the 16 radius refers to non-standard variants of a special design.

- Reach – 15-30 mm.

- The most suitable disc width is 5-6 mm.

- M12*1.25 bolts are suitable for fastening the wheels.

These are technical recommendations, but depending on the specifics of the tires and the individual needs of the buyer, wheels are also selected.

Parameters of standard nuts

In the factory assembly, M12x1.25 bolts were used to fasten the disks. Standard bolts from VAZ-2106 wheels can only be used to fasten stamped steel wheels. When replacing with alloy wheels, the bolts must also be replaced. The diameter and thread pitch will remain the same. The overall length and shape of the cone under the head will change.

The thickness of cast discs is greater than that of stamped ones. Therefore, the fasteners must be longer. The conical thickening under the head is the clamping surface of the bolt. If the bolts are replaced with studs, the standard nuts should have a similar surface.

The pressing surface can be not only conical, but also flat or spherical in configuration. The choice of bolts or nuts according to the profile of the clamping surface depends on the shape of the recesses in the holes of the disks, since their contours must completely coincide. This will ensure reliable clamping density. The most common conical version of the clamping circuit. For cast wheels, the cone is more pronounced than for stamps, and its angle is 60°.

Important! After installing new alloy wheels, the first time you need to regularly check the tightness of the bolts or nuts until the soft metal is finally compacted under the influence of loads. If this is not done, spontaneous loosening of the bolt may occur.

What wheels were installed on different bodies and configurations?

Initially, the VAZ-2106 car was conceived as a modernization of the VAZ-2103, which included getting rid of various “excesses” and bringing some parameters to European standards of that time. In total, since 1976, 7 modifications of the domestic “six” have been produced.

But none of these transformations affected the assembly line equipment with car wheels. The VAZ-2106 was always factory-installed with the most budget-friendly 13-inch stamped steel wheels with the following parameters:

- 4.5JX13ET37;

- 5JX13ET

4.5J and 5J are the width (inches);

13 – diameter (inches);

ET – disc offset size in mm.

Options with wider 13- and 14-inch wheels were considered as an acceptable replacement. Equipping the wheels with only the smallest diameter and most inexpensive steel stampings was caused not by the design features of the car, but by the desire to reduce the financial costs of production.

Stamped steel wheels are durable, repairable and low cost. But this is where the list of their advantages ends. If we compare dies with cast or forged lightweight specimens, then we can only talk about some shortcomings.

The result of replacing with lightweight versions of products is improved handling and reduced fuel consumption. But you shouldn’t make a replacement just for the sake of replacing it. Improper implementation can later turn into a real problem.

Suitable wheels for VAZ 2106

The size of the discs plays an important role in the process, so attention to detail is required to avoid further operational inconveniences. In this regard, experts have compiled a brief description of each diameter for a comfortable choice by the motorist.

| Radius | Description |

| R13 | This is a factory option, which is characterized by its characteristic convenience and practicality of technological plan. For lovers of the classics, this disc radius will be the most optimal. |

| R14 | The option can be compared with the factory one, but the model is more suitable for country driving due to the softness and comfort of the ride in conditions that are far from the best road surface. |

| R15 | This option is suitable for lovers of city driving in order not only to create convenience, but also to emphasize the solidity of their car. In poor road conditions, the discs may not be able to cope with the load, which is why there is a high probability of damage. |

| R16 | This is a non-standard option, so it will not suit everyone. To a greater extent, this is a decorative element, and as for the technical part, such disks are not suitable for poor road surfaces, since there is a possibility of damage to the disk and, accordingly, the wheel. |

You need to choose disk sizes depending on individual requirements, since otherwise beauty may result in a violation of the technical convenience of the car and damage to the element.

What drives can be installed

With the installation of standard disks everything is very clear. Stamped steel wheels perfectly match the parameters of the hub, and together with the tires, they completely fit into the wheel arch of the car. However, their heavy weight reduces dynamic performance and increases fuel consumption.

To improve these indicators, you can install light alloy wheel options. In addition to optimizing technical characteristics, the appearance of the car is also significantly improved. Today's aftermarket offers aluminum, magnesium and titanium rims. They are much more expensive than stamped ones, but lower fuel costs partially offset such costs.

When choosing replacement options, when purchasing a new rim you need to pay attention to the following aspects:

- Manufacturer reliability. You should not buy products from unknown manufacturers. After all, everyone claims the high quality of their goods, but no one knows how things really are.

- Technical specifications. When choosing a disk, at a minimum, you need to take into account the dimensions and technical parameters of the car's hub and wheel arch. If the product exceeds the standard parameters, then you need to make sure that you can select the appropriate adapters or the right type of tires.

- Material of manufacture. The disc material must be certified and meet all safety requirements

- Place of purchase. It is better to buy new discs at official retail outlets, because not only the product itself, but also the technical passport and quality certificate can be counterfeited.

Minimum and maximum possible parameters of non-standard disks

Selecting non-standard disks is associated with certain difficulties. This applies to the boundaries of the wheel arch, hub parameters, overhang and permissible rim width.

Despite the fact that at the factory only 13-inch wheels were installed on the VAZ-2106, and only 14-inch wheels were considered as replacement options, 15 and even 16-inch wheels are also applicable for installation in this car model.

- The R 15-inch version is more suitable for driving in urban environments. Bad roads can cause them to wear out quickly.

- R To a large extent, this size is set only to improve the appearance of the car. Use on bad roads can lead to damage to the rims and wheel arch.

In the latest VAZ models, manufacturers abandoned their usual 4x98 mm bolt pattern in favor of the more universal 4x100 mm. With the use of eccentrics, a difference of 2 mm can be solved. Other bolt patterns require the installation of additional adapter spacers.

The maximum rim width provided by the manufacturer is 6 inches with an offset of 29 mm. When installing a wider version, you will have to adjust the offset using spacers. But you need to understand that wide rims can worsen the car’s handling. In addition, they are more susceptible to drifts in bad weather or during the winter season.

To increase the level of driving comfort, using new alloy wheels is not only possible, but also necessary. But, based on safety and common sense considerations, it is worth sticking to the standard factory parameters.

Main types of disks

Different technologies can be used to manufacture disks in order to obtain strength, quality and reliability of the products. Manufacturers are actively expanding their offerings so that even the most demanding customers do not encounter difficulties in use.

| Type | Description |

| Regular | This is a standard option that is provided as standard. Average strength is combined with long-term operation and reasonable cost. In addition, the products are suitable for repair, because if necessary, the discs can be straightened to restore structural and technical parameters. |

| Cast | Light alloy metal is used for production, which ensures strength combined with technical qualities. The one-piece structure ensures reliable use over a long period of time. |

| Forged | This is an ideal ratio of cost and quality, and this model is suitable for connoisseurs of an attractive appearance, as it perfectly complements the exterior of the car. The basis is stamped manufacturing technology, so the consumer receives strength, quality and important technical features. |

You can select any type of disk for the VAZ 2106, since by observing technological features, manufacturers guarantee quality and reliability. But it is still best to make a purchase in specialized stores, where the final quality, reliability and practicality are guaranteed.