In modern form, there is a wide variety of car tires. Types of tires and their correct selection are the key to a comfortable and safe ride. Depending on the height and width of the tread, tire composition and other technical characteristics, you can achieve the highest quality grip on the road surface.

There are specially manufactured tires for driving on difficult terrain, including mud, sand and off-road. For each car, you need to carefully organize the selection of the most suitable option. What types of tires are there for cars and how to choose them correctly, as well as what the structure of a car wheel is, we’ll look at it in this article.

Car tire design

The structure of car tires is not complicated and contains several main components: tread, cord, breaker, shoulder area, bead and sides. Let's look at each separately.

Cord

A novice motorist often asks himself the question: tire cord - what is it? For a standard tire, you will need several layers of cord, since the cord is a rubberized textile, the layers of which make up the carcass for the tire. The threads used in the cord can be metal, fabric or polymer. The cord tension occurs along the entire perimeter of the tire. There are two possible ways to tension the cord:

- radial;

- diagonal.

Tread

The outer part of the tire that has direct contact with the road is called the tread. It performs the function of adhesion of the tire to the road surface and ensures the safety of the entire wheel. It is good to monitor wheel wear on the tread, as the tread pattern will change with increasing mileage. Also, depending on the type of tread, you can adjust the degree of noise when driving.

The tread consists of grooves in the rubber layer, made in the form of one pattern or another. Depending on the size and relief of such grooves, the tread is divided into: tires for urban conditions, for off-road driving, winter and summer options, etc. These types of tires are designed to function in various conditions, so each driver selects them according to his own option.

Breaker

To strengthen all the layers in the tire, there is a breaker, which is located in the middle of the base and tread. It secures the bond of these components and prevents the tread from detaching due to environmental influences.

Shoulder area

The section of tread in the middle of the sides and the central track is called the “shoulder area”. With its help, the rigidity of the tire and the connection between the base and the tread increase. This area also takes on part of the load factors performed by the central tread track.

Sides

These are the parts of the car wheel that go to the left and right side of the tire. In other words, it is the area of tread that extends to the sides of the tire. Protects the base from mechanical irritants and humidity. Typically, this part of the tire is marked to make it easier to determine the type of tire you need.

Board

The side of the tire goes into the bead, which performs the fastening function of the structure on the wheel frame. The bead contains a wheel consisting of a rigid metal wire under a layer of rubber, which adds increased strength to the entire functionality.

Recommendations

It is desirable that all tires installed on a car are not only the same size and design, but also the same model and, if possible, the same manufacturer. Despite the external similarity of some tread patterns, each tire model has a set of properties unique to it. When installing tires with different, although very similar, patterns on different axles of a car (this is allowed by the Road Traffic Rules), the grip properties will inevitably differ, which can have a detrimental effect on handling in critical situations. In the case of forced installation of non-identical tires, the following combinations should be avoided if possible: low-profile “rubber” in front and high-profile tires in the rear; Studded tires are installed on the drive axle of a front-wheel drive car, and without studs on the rear; New tires are installed in front, completely worn tires in the rear, or vice versa, etc. The last two options are especially dangerous, since on wet or icy asphalt the grip of the rear tires on the road is significantly reduced, which can lead to skidding and an accident. All tires, even within the same type, vary in rubber chemical composition, internal structure and tread pattern. This is due to the fact that it is impossible to make an “ideal” tire that would ensure maximum performance of the car under all road conditions. Therefore, manufacturers produce tires: with a certain specialization, when one (or two) properties are most developed (usually to the slight detriment of others). For example, a tire for comfortable highway driving, while having low noise and good ride comfort, may not provide good stability and controllability at high speeds. Or the tire has an increased service life and provides reduced fuel consumption (compared to other models) due to low rolling resistance, but may not provide good comfort, stability and handling. As a rule, all major manufacturers (unfortunately, still mostly foreign) indicate in their advertising brochures what exactly the best properties a given tire model has. True, they are silent about what properties were “sacrificed”; with averaged, approximately identical in magnitude, properties to ensure acceptable implementation of vehicle characteristics in a wide range of road conditions. Therefore, before choosing tires, you need to determine what properties of tires, in addition to reliable grip, are most important to you - “sportiness”, comfort, efficiency, etc. conditions in which the vehicle will be operated for a longer period of time; maximum load capacity and speed, overall tire dimensions that must match the vehicle. When switching to another dimension, it is desirable that the outer diameter of the tire does not change, which can be calculated using the formula: D = 25.4d+2sh, where d is the wheel diameter (inches), s is the tire profile width (mm), h is the series tires (the ratio of the height of the tire profile to its width in %). Recommended replacement options are given in table. 5. It is necessary to take into account that operating tires at maximum speeds and loads significantly reduces their service life.

Tire classification

Types of car tires can be divided depending on seasonality, the make of the car and the type of tracks used. Each tire has its own parameters and its own maximum speed value. The purpose of car tires is determined by the corresponding markings that are applied to the product. How to understand the tire tread pattern, decipher the markings on the rubber, and find out the date when the tire was produced - read in our article.

Differences in tire design

Cord tension occurs in two standard ways: radial and diagonal. Let's look at each type in more detail and evaluate the structure of a car tire separately for each type.

Radial tires

It is the radial tire design that has gained wide popularity on the market, since it has a more elastic base, which increases performance characteristics due to reduced heat generation and resistance parameters. Mostly in the automotive market there are radial tires, which are in greater demand than bias-ply tires. But their cost is higher due to their endurance and durability.

Diagonal tires

In diagonal samples, the cord layers are made in a cross pattern. And although such tires have stronger sidewalls, the technical characteristics are inferior to those of a radial tire. The load capacity of a diagonal sample is reduced compared to a radial one. Also, the degree of thermal conductivity is lower than in the radial product version. Therefore, the cost of bias tires is much lower.

When choosing a wheel...

And to conclude the topic, the structure of a car wheel, a few words about the marking of tires and wheels. You've probably noticed that there are many different symbols on the sidewalls of tires - all of them are needed in order to choose the right tires for your car.

The main parameters are the width and height of the profile, type of tire and bore diameter. For a disk, important values are its diameter, rim width, as well as the distance between the transverse axis and the plane of attachment to the hub - the so-called offset.

Explanation of load and speed indices:

As you can see, friends, a lot of useful things can be said about a car wheel, although at first glance it does not look like such a complex structure.

I hope you found it interesting! See you again on the blog and don’t forget to subscribe!

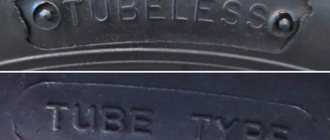

Sealing

Based on the sealing method, tires are divided into tubed and tubeless. It is very easy to determine which tire you have in front of your eyes - just look at the markings that the manufacturer has installed on the product: TT - tube version and TL - tubeless. Let's start with the type of tires that appeared earlier than others - consider the option of tires with a tube.

Tube tires

This type of tire appeared quite early in the history of the automotive industry. This option replaced a very inconvenient type of balloon tire, which was based on a tube with a thick rubber edging. A tube tire consists of a tube, a tire and a valve for inflation.

At the moment, tube tires are in less demand, since if this type of rubber is punctured on the road, the car will not be able to continue moving. The characteristic of the tire is such that the air will quickly escape from such a chamber, and this will lead to a complete deflation of the wheel.

Tubeless tires

The design of a tubeless tire allows for additional strength of the product. The characteristics of rubber include a durable sealing layer reaching a thickness of 2 mm. Tubeless tires are filled with air mass through a valve not inside it (as in the tube version), but in the passage of the wheel frame.

This tire option guarantees that you can travel several kilometers to the service station in case of a puncture. These tires provide maximum safety while driving. But the tubeless version is significantly more expensive than samples with a camera.

Wheel rim: the work of engineers and designers

The rim and the disc are, in fact, a single whole, so the division between these elements is very conditional. Often, when they talk about a disk, they mean both of these parts together - we will do the same. There are the following types of disks:

- steel (rim and disc are connected by welding). These are classics - cheap and cheerful, which is why they have become widespread. Disadvantages - weight and inability to create an original design;

- light alloy (completely monolithic). There are cast and forged wheels. The first ones, although they allow you to play with the design, are quite fragile. The second ones are much stronger and generally practically devoid of any drawbacks with the exception of one - price, due to the complexity of manufacturing. In general, light alloy products are in many ways superior to their steel counterparts - in addition to weight and aesthetics, they also cool the brakes more effectively, and also do not require such painstaking balancing.

Types of car tire profiles

The tire characteristics show the driver in what conditions and in what weather conditions the tires can be used. Even novice drivers usually know what types of tires there are. Typically, when dividing tires based on weather conditions, there are the following types of transport tires: summer, winter and all-season.

Summer tires

To produce this type of tire, rough categories of rubber compounds are used. Thanks to this, the tires hold dry roads well at high speeds and provide good grip on the surface. The purpose of tires in this case is limited to positive temperatures, since even at temperatures of minus 7 degrees and below, a summer tire will become stiff and not function fully, providing proper grip on the road.

These tires have a smooth structure and are not equipped with a special sign in the marking number. For winter weather, the summer option is not suitable, since the braking distance will be significantly increased and the level of driver safety will decrease.

Winter tires

For winter tires, softened types of rubber base are used. The marking in this case shows a snowflake or the letter W (winter) at the end of the element. The wheels can be additionally equipped with metal spikes for good handling of snow and ice surfaces. But spikes can harm the integrity of the road surface, so the best use for them would be driving on ice.

Winter tires can be divided into the following types: European and Scandinavian. The first type is suitable for milder winter periods with a wet snow surface, and the Scandinavian type of tires is intended for harsh winters with lush and harder snow.

All-season tires

This type of tire is a compromise for drivers, but this does not mean that the tires will fit perfectly in any weather conditions. All-season tires feel best at temperatures close to zero. At very low temperatures, the tires will harden, and at high temperatures there is a possibility of reducing good grip on the road.

Low profile tires

An additional type of car tires is the profile type. Low profile tires have a narrower rubber rim and, to some drivers, look more prestigious than the traditional tire format. The main importance here is the visual component, and the closest possible connection with the road determines high dynamics of movement. But it is worth considering that such tires are not suitable for bad roads, as the car’s depreciation and ground clearance are reduced.

Wide profile tires

This is a more common type of rubber. This type of tire gives the driver a feeling of comfort on different tracks, including wet surfaces. Also, in wide-profile tires, depreciation will be better, the ride will be smoother, and when impacted on potholes, the disc will be reliably protected. Rubber wear can be determined by the TWI marking, which is printed in several places for convenience.

Tires with pressure adjustment

The pressure inside these tires can be adjusted depending on the situation in which they are used. They feature a wider profile than standard tires. The elasticity of such rubber is higher than standard samples, as well as the characteristics of the tread provide high-quality grip on the road. The tires are well suited for overcoming difficult road sections such as dust, mud, swamps, snowdrifts, etc. On these roads the pressure is reduced, and then on smooth roads the pressure is increased.

SUV tires

There are special tires for crossovers and SUVs. This direction of rubber can be read on the corresponding marking. The letter T indicates that this tire is suitable for trucks, and the letter P indicates that this type of tire is intended for passenger cars. Rubber for SUVs is characterized by the AT symbol. When choosing tires, pay attention to the maximum speed at which the product can be operated.

Car tire composition

When buying new tires, you should look at the specified structure of the car's wheel, i.e. tire composition. Ride quality and cross-country ability, comfort and safety are directly dependent on the rubber composition. Some tire manufacturers keep the full composition secret, but the main components are still known.

The standard components of automobile rubber are:

- Natural rubber. This ingredient is extracted from unique trees - Hevea brasiliensis. They are grown specifically to extract this valuable juice, from which many rubber products are made.

- Artificial rubber. It is also one of the main components for tire production and has a direct impact on driving performance.

- Technical soot (carbon). Adds strength and stability to the wheels on the road, increases tire wear time.

- Silicon dioxide. Used for the production of winter tires. Adds softness, elastic characteristics and good road grip to tires.

- Sulfur. Thanks to this substance, the higher elements are bonded, which adds integrity to the tire.

- Oils or resins of natural origin. They are used on winter tires and provide softening characteristics.

General information

Tires can be tubed or tubeless in design, and radial and diagonal in design. Depending on the purpose and operating conditions, tires are divided into: road

(commonly called summer) are intended for use at positive temperatures on highways.

Tires of this type provide the best grip on dry and wet roads, have maximum wear resistance and are best suited for high-speed driving. They are of little use for driving on dirt roads (especially wet ones) and in winter. winter,

used on icy and snowy roads, the adhesion qualities of which can vary depending on the situation, from minimal (smooth ice or a mess of snow and water) to small (rolled snow in the cold).

They have good road properties, somewhat inferior to summer tires. Many winter tires allow or have anti-skid studs. All-season tires are

They allow you to operate your car year-round on one set of tires.

universal ones have

It is advisable to use them for all-terrain vehicles that make approximately equal mileage on highways and roads.

It can be quite difficult to draw a clear line between them and all-season tires. all-terrain vehicles are designed

It is advisable to use such tires only when driving rarely on the highway. Otherwise, they will wear out faster and create high noise levels.