Many VAZ 2110 car owners, especially those who have no accumulated experience in driving and repairing the “tens”, fall into a slight panic if “CHECK” suddenly lights up on a seemingly serviceable car, and the on-board computer begins to generate an error.

They are usually expressed using the letter P and a numeric four-digit code. Naturally, error codes for the VAZ 2110 are not difficult to find in special tables in order to understand in which system the cause should be looked for. However, the decoding is often very vague, and it is not clear what to do next?

OBD 2 error codes

VAZ error codes

Error codes for Mikas 10.3/11 controllers

Errors Lada 2110

Many VAZ 2110 car owners, especially those who have no accumulated experience in driving and repairing the “tens”, fall into a slight panic if “CHECK” suddenly lights up on a seemingly serviceable car, and the on-board computer begins to generate an error.

They are usually expressed using the letter P and a numeric four-digit code. Naturally, error codes for the VAZ 2110 are not difficult to find in special tables in order to understand in which system the cause should be looked for. However, the decoding is often very vague, and it is not clear what to do next?

OBD 2 error codes

VAZ error codes

Error codes for Mikas 10.3/11 controllers

- 1 Electronics

- 2 Crankshaft and camshaft

- 3 Electrical equipment

- 4 Idling

- 5 Throttle valve

- 6 Oxygen sensor

Diagnostics using a scanner

The method involves connecting an external computer with the program installed. This opens up more opportunities for car diagnostics. In this case, error codes for VAZ 2110 and VAZ 2112 consist of 5 characters.

- P – failure or malfunction of the power plant, transmission;

- B – body systems are damaged;

- C – a problem has been detected in the vehicle’s chassis;

- U – violation of pairing of different modules.

- 0 – general value;

- 1/2 – manufacturer code;

- 3 – reserve.

- 1-2 – violation in the air-fuel mixture supply devices;

- 3 – malfunction of the ignition units;

- 4 – atmospheric emissions control device;

- 5 – malfunction of the engine speed or engine speed meters;

- 6 – failures in electronics;

- 7-8 – malfunction of the gearbox module;

- 9-0 – reserve unit.

The last two digits give the serial number of the breakdown and its location.

Electronics

Let's look at some especially annoying error codes, which, as if they don’t affect the speed, but constantly remind you that something may be wrong with the VAZ 2110. These include:

- error 1621, warning the driver that the RAM is disabled, that is, code 1621 indicates that the controller is not working, which means that errors are not read, you remain in the dark about what is happening with the systems of your car. Most often, when drivers see the numbers 1621, they ignore them, reset the RAM error (remove the terminal from the battery for a couple of minutes, then put it back on) and drive on. But, after turning off the car and starting it again, they see the same ill-fated code 1621. You can try to carefully inspect the twist near the ECU (to ground), and perhaps additionally solder the factory crimp. However, often even contacting specialists does not help; code 1621 remains on until the RAM memory is changed;

- Sometimes it happens that the injector light comes on. This is especially observed in winter, and when the engine warms up well, the light goes out. Although this is not so scary, it is somewhat unnerving, and the light bulb breaks down if it burns for a long time. It’s better to contact a service center where they can update the firmware, then the light bulb will stop bothering you.

From english:

Decoding the error P1621 from Isuzu: Cylinder 5-Knock Control Limit Attained

Make:

Isuzu

Code:

P1621

Definition:

Cylinder 5-Knock Control Limit Attained

Description:

Engine started,battery voltage at least 11.5v,all electrical components off,ground connections between engine and chassis well connected,and the ECM detected the Knock Sensor signal was more than the calibrated value.

Cause:

- Knock sensor circuit is open

- Knock sensor circuit is shorted to ground,or shorted to power

- Knock sensor is damaged or it has failed

- Poor fuel quality

- Loosen knock sensors and tighten again to 20 Nm

- ECM has failed

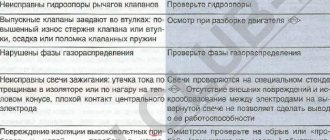

Crankshaft and camshaft

- code 0335 indicates a malfunction of the crankshaft position sensor. Therefore, when you see 0335 on the computer, you need to check whether the signal is coming from this sensor. If you find that the signal is weak, you can help by changing the air flow if it is excessive (above the maximum). After this, error 0335 should disappear;

- When you see error 0340, you know that the camshaft position sensor is most likely faulty. Although in fact, even if 0340 is displayed, the camshaft itself may be in good condition, the car is working as usual. But when the numbers 0340 do not disappear while the engine is running, this unit should be carefully inspected.

Crankshaft position sensor

Electrical equipment

Malfunctions of the electrical equipment of the VAZ 2110 should be responded to as quickly as possible. By the way, this can be signaled by code 1602, although its decoding sounds like a loss of on-board power supply voltage in the RAM.

Sometimes it is enough to reset error 1602, and it will not appear again. Some people call these numbers “good”; 1602 may appear after the battery is disconnected, due to a voltage surge when starting the engine (for example, in cold weather). However, if 1602 “pops up” constantly, you need to look for a network break.

First, try to clean the battery terminals and secure them well. Did not help? Check the circuit, starting from the “+” of the battery, be sure to check the fuse, fuse link.

And also inspect the mass of the ECU, TPS. There are cases when code 1602 appears due to the fact that the security alarm blocks the controller circuit, and it issues this as an error every time. You should contact the installer of your alarm system.

Idling

Code 0505 indicates a malfunction of the idle air control. Moreover, 0505 is most often “issued” when the engine is started with the gas pedal pressed. This often affects drivers who switched from a carburetor VAZ 2110 to an injection one.

However, 0505 also occurs if the ignition module, spark plugs are faulty, there are broken wires, or the engine speed is not the one set by the XX regulator.

If you notice popping noises in the muffler, this may also indicate displacement of the crankshaft ring gear. Code 0505 can be displayed either alone or with 0300 (missing cylinders).

Throttle valve

The on-board computer issues two unpleasant errors - 0122 and 0123 when there is a problem with the throttle sensor. Moreover, 0122 will be displayed if the signal level of this sensor is low, and 0123 will be displayed if the signal level is high.

Both one and the other, naturally, are not good. Especially if the on-board computer readings are accompanied by increased idle speeds, jerks at low speeds and dips. In this case, replacing the sensor does not always help.

If codes 0122, 0123 are issued, be sure to check the signal and power wires for breaks, and also pay attention to whether there is any leakage through the injector rings. Remember: the main enemies of DPZD are engine washing and also the manufacturing plant, since there are a lot of defects here.

Oxygen sensor

For some reason, it is quite difficult to find code 0525 in the decoding tables, but this is simply an error in the oxygen sensor, otherwise called a lambda probe. And if you see 0525 on the display again, it means that not everything is in order with the oxygen content in the exhaust.

This sensor is not installed on all VAZ models; it sends a signal to the engine regarding how much oxygen should be in the fuel system. That this sensor does not cope with its duties is evidenced by:

- increased fuel consumption;

- unstable work at XX;

- loss of power, lack of "response".

In principle, the lambda probe should be changed after about 60 thousand mileage, but this can happen earlier, especially considering the quality of our gasoline. Therefore, it may display 0525, warning that it is time to replace the oxygen sensor.

- Author: Veniamin

Error P0123 - what it means, symptoms, causes, diagnosis, solution

Trouble code P0123 indicates a problem with the throttle/pedal position sensor. When the engine control module (ECM) detects that the rated output voltage of the throttle position sensor exceeds the manufacturer's specification, it generates trouble code P0123.

The throttle position sensor (TPS) is another name for a potentiometer. It is located on the throttle body while the pedal position sensor is connected to the accelerator pedal.

The throttle position sensor monitors the movement of the accelerator pedal and determines how much power the engine requires. Code P0123 is triggered when the TPS voltage value is outside the specified range.

On which cars is this problem most common?

The problem with code P0505 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- BMW (BMW 330i)

- Chrysler

- Daewoo (Daewoo Lanos, Matiz, Nexia)

- Dodge (Dodge Durango, Ram, Stratus)

- Fiat (Fiat Punto)

- Ford

- Honda (Honda Accord, SRV)

- Jeep (Jeep Wrangler, Grand Cherokee)

- Lexus

- Mazda (Mazda 6)

- Mitsubishi (Mitsubishi Karizma, Lancer, Montero, Pajero)

- Nissan (Nissan Almera, Maxima, Pathfinder, Primera)

- Opel (Opel Astra, Vectra, Zafira, Corsa)

- Renault (Renault Duster, Logan, Sandero)

- Scion xB

- Suzuki

- Toyota (Toyota Vitz, East, Camry, Corolla, Prius, Probox, Rav4, Harrier, Echo)

- VAZ 2107, 2109, 2110, 2112, 2114

- Zaz Sens, Chance

- Lada Granta, Kalina, Largus, Niva

With fault code P0505, you can sometimes encounter other errors. The most common ones are: P0036, P0056, P0102, P0302, P0304, P0444, P0500, P0506, P0507, P0600, P1145, P1519, U1602.

How to diagnose error code P0123?

Connect your car charger

Before searching for the cause of the P0123 code, be sure to connect the car charger.

During diagnostics, the ignition will be turned on and this can lead to rapid depletion of the battery charge. To avoid this situation, it is recommended to install a car charger before testing.

Use an OBD2 scanner

OBD2 scanner is a must-have tool for scanning trouble codes. An on-board diagnostic system is included in every vehicle manufactured after 1996.

The OBD2 scanner has the ability to read and clear error codes, as well as receive real-time data and record this information.

Alternatively, you can use a digital multimeter, which is cheaper but lacks the functionality that an OBD2 scanner has.

Check the TPS wiring

Before replacing the sensor or performing any other procedure, it is recommended that you check the wiring harness that leads to the throttle position sensor. Inspect the wiring and note any signs of damage or corrosion.

Inspect the throttle body

Visually inspect the throttle body and see if it is dirty. If it's really dirty, use throttle body (carburetor) cleaner, which can be easily found at any auto store. After cleaning the throttle body, reset the error and see if it occurs again.

Check the ground

Using a multimeter, check the voltage at ground. Connect the red lead of the multimeter to the positive terminal of the battery and the black lead to ground. If the reading is close to the battery voltage, then the grounding is good. If not, it could be a power issue.

Sensor check

If you didn’t find anything during a visual inspection of the TPS, it’s time to check the voltage on it. Set your multimeter to test voltage and look at the wiring diagram to see what each wire means.

Insert the black probe into the signal wire pin of the connector and the other pin into ground. Slowly open the throttle valve and watch the reading. The voltage should increase when the throttle is opened.

At wide open throttle, the ideal reading is 4.5 volts. In the closed position, the reading should be 0.45 Volts.

Cleaning the sensor and connector

Before you think about replacing the sensor, it is recommended that you clean and repair it first, as a dirty sensor will send incorrect data to the ECU. To do this, you should have the following tools ready:

- Carburetor cleaner.

- Clean cloth.

- Screwdriver.

- Gloves.

Step 1: Let the engine run for a while

Start the car and let the engine idle for a few minutes. This will heat up the engine and some of the dirt will loosen on its own.

Step 2: Open the hood and locate the sensor

Once the engine is warm, open the hood of the car and locate the throttle position sensor. You may have to remove the engine cover to do this.

Step 3: Disconnect the connector

Disconnect all wiring and connections leading to the TPS. Next, unscrew the nuts and bolts securing the sensor and carefully remove it.

Step 4: Clean the sensor and connector

Clean the sensor with cleaner. Clean around the sensor thoroughly until all dirt is removed.

Step 5: Drying the Sensor

After cleaning the sensor, use a dry cloth and rub gently to remove any remaining liquid. Then plug the sensor into place, close the hood, and you're done.

Diagnosis and problem solving

Connect the scanner, read and write down all available codes. This information may be useful if an intermittent fault is later diagnosed.

If other codes are present along with the P0505 code, diagnose and resolve them in the order in which they were stored. The most likely additional codes are usually related to the vacuum system.

Therefore, check the vacuum system for leaks caused by damaged vacuum lines. If necessary, repair and clear all codes before operating the vehicle. Then, retest the system to see if any codes are returned.

Throttle valve

If the code persists, remove the throttle body from the intake tract and inspect it for excessive carbon deposit buildup. In some cases, it may be possible to remove light carbon deposits from the throttle body and auxiliary air passages using approved cleaners.

However, heavy deposits usually cannot be removed without damaging the throttle body or idle air control valve. In these cases, the best option is to replace the throttle body or idle air control valve with original parts.

When installing cleaned or replaced parts, ensure that all seals and gaskets are also replaced to prevent vacuum leaks. Double check all vacuum line connections before starting the engine or operating the vehicle.

Checking wires and connections

If the P0505 code persists, perform a thorough visual inspection of all associated wiring. Look for damaged, burnt, shorted or corroded wires and connectors.

Once no visible damage is found, check resistance, ground, and reference voltage. Compare all readings obtained with the data specified in the manual. Replace wiring as necessary to ensure all readings are within manufacturer specifications.

Stepper motor and idle control valve

Check the actual signal voltage that reaches the stepper motor at the connector. Using a scanner, command the idle air control valve to open. Compare the obtained value with the values specified in the manual.

Special diagnostic programs usually produce a voltage range that corresponds to the degree of opening of the idle air valve. And sometimes the degrees of rotation of the stepper motor.

These readings must correspond exactly to the stated values, otherwise the harness must be replaced. If all readings obtained are consistent with the stated values, the stepper motor is faulty and must be replaced.

These steps should resolve the P0505 code. But if it still appears again, then perhaps the problem is periodic. In such a case, diagnosis can be challenging. And sometimes it is necessary to give the malfunction a chance to worsen in order to understand exactly where the problem is.

Error P1602 on VAZ 2110 engines: reasons, how to fix

Errors in the engine control system on VAZ cars equipped with injection engines of the tenth family (and this is almost the entire model range, starting with the VAZ 2110, Kalina, Priora...) are not as rare as we would like. Among them there are error codes that require immediate elimination and identification of causes, and there are those that appear from time to time. Among them, one of the leaders was error P1602. What the error code means, what it means and how to fix it, we’ll figure it out together.

More category errors

P1625P1626P1627P1630P1631P1632P1633P1634P1635P1637P1639P1640P1644P1650P1668P1681P1682P1683P1689P1762P1790P1792P1810P1815P181 6P1818P1850P1860P1870P2101P2119P2120P2122P2123P2125P2127P2128P2135P2138P2176P2270P2271P2272P2273P2430P2431P2432P2433P2440P244 4P2534P2544P2610P2761P2763P2764P2769P2770P2771P2A00P2A01P2A03P2A04P3400P3401P3425P3441P3449U0001U0073U0100U0101U0140U0151U015 5U0184U0299U1000U1001U1016U1017U1024U1026U1040U1041U1064U1088U1096U1097U1098U1099U1111U1128U1129U1133U1137U1144U1147U1151U115 2See all errors →

Error P1602: what does it mean, decoding

The appearance of error code p1602 when scanning with a diagnostic device or during self-diagnosis using an on-board computer is a fairly common problem. Despite the fact that in the absence of other symptoms of malfunctions, you can use the car without problems, the message itself with error code P1602 begins to irritate. Especially when this has not been happening for the first month. Theoretically, error code 1602 stands for a message from the ECU about an interruption in the on-board network voltage. In practice, this means that in some place there is no contact on the terminals, plugs, connectors.

The message may also mean that one or more electrical devices on the on-board network may not have contact with ground, temporarily or permanently. Naturally, if the battery is not in full contact with the vehicle’s ground , we will not see any message, since the electrical equipment will simply die without signs of life. True, this happens extremely rarely, but it doesn’t hurt to remember it. As well as temporary problems with charging the battery , which can be associated both with the battery itself and with the charging relay, generator or their contacts.

What to do if after replacing the sensor the error does not disappear

There may be several reasons why the error persists:

- it was recorded in the memory of the VAZ-2114 computer;

- you have installed a faulty element (in this case, it must be returned to the store along with the receipt and replaced with a new one);

- The fault was not related to the coolant sensor.

To solve the problem, you need to remove the negative terminal from the battery for a few seconds, then perform self-diagnosis again. If error 14 persists, then you need to contact a service station to establish which sum of codes led to the appearance of this entry.

What to do when error P1602 appears: DIY diagnostics

It is clear that with such an error code it is necessary to look for poor contact in the engine control system circuits. True, the direction of the search is not entirely clear and it depends on the symptoms. Therefore, we can only assume what can happen to the electrical system of a VAZ injection engine with error P1602, based on reviews from owners and personal experience:

- No contact at the negative terminal battery It's easy to check. We remove the terminal, assess its condition, if necessary, clean the terminal and terminal, and lubricate it with a special conductive lubricant with an anti-oxidative effect.

- Lack of contact at the negative wire of the battery at the point of connection to the body . We unscrew the wire from the body, carefully clean the terminal and the attachment point, install the terminal in place, carefully screwing it into place with clean fasteners.

- No contact on electronic control unit board . Here the situation is more complicated, since for diagnostics you need to have at least basic knowledge in the field of electronic systems and circuitry.

First, we inspect the ECU contacts, if necessary, clean them, as well as the terminals on the block. After this, you can open the block and visually inspect the board. If there is a loose solder on the board, solder it with a low-power soldering iron, being careful not to overheat the elements. In some cases, warming up the board with a hairdryer helps, but this is a temporary measure. - No contact on the generator . The contact may be damaged either on the power wire or on the signal wire. In both cases, the generator may not charge the battery.

Alternatively, you can remove the generator and check (clean) the contact of its housing with the cylinder block. In some cases this works. - In some cases, periodically power supply to the electronic control unit is lost engine. In these cases, either the fuse may be to blame (depending on the VAZ model, it may have different designations). We check the fuse, as well as the contacts of the mounting block.

Practice shows that these main reasons are the reason for the occurrence of error code P1602 on VAZ cars with an injection engine.

Prevention of breakdowns of electrical appliances

To prevent breakdowns of electrical circuits, you must follow a number of simple rules.

- Periodically check the contact connectors for oxidation or overheating. Rust disrupts the passage of impulses, which can be read by instruments as damage to the unit.

- Once a year, treat contacts with special oils. Lubricants prevent moisture from entering metals, which prolongs their service life.

- Replace dry wires in a timely manner. Cracked insulation can cause a short circuit.